Solid-State Relay Power Modulation: Techniques and Tools

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Power Modulation Background and Objectives

Solid-state relay (SSR) technology has evolved significantly since its inception in the 1970s, transitioning from simple on-off switching devices to sophisticated power modulation components. The evolution trajectory shows a clear trend toward higher integration, improved thermal management, and enhanced control capabilities. Modern SSRs have become critical components in industrial automation, renewable energy systems, and smart grid applications, where precise power control is essential for system efficiency and reliability.

The fundamental principle behind SSR operation involves semiconductor switching elements, primarily thyristors, triacs, or MOSFETs, controlled by low-voltage signals while handling high-power loads without mechanical movement. This architecture eliminates the mechanical wear and acoustic noise associated with traditional electromechanical relays, substantially increasing operational lifespan and reliability in demanding environments.

Recent technological advancements have focused on addressing the inherent challenges of SSRs, particularly heat dissipation, voltage surge protection, and zero-crossing detection accuracy. The integration of microcontrollers and digital signal processors has enabled more sophisticated power modulation techniques, including pulse-width modulation (PWM), phase angle control, and burst firing modes, each offering specific advantages for different applications.

The primary objective of current SSR power modulation research is to develop techniques that maximize energy efficiency while minimizing electromagnetic interference (EMI) and harmonic distortion. This involves exploring novel semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) that offer superior thermal conductivity and switching characteristics compared to traditional silicon-based devices.

Another significant goal is the development of intelligent SSR systems capable of real-time load monitoring and adaptive control strategies. These systems aim to optimize power delivery based on load conditions, network parameters, and energy consumption patterns, potentially revolutionizing energy management in industrial and residential applications.

The integration of SSRs with Internet of Things (IoT) platforms represents another important objective, enabling remote monitoring, predictive maintenance, and centralized control of distributed power systems. This connectivity aspect is particularly relevant for smart grid applications and industrial automation, where system-wide optimization and fault prediction can significantly improve operational efficiency.

As power electronics continue to advance, the boundary between traditional SSRs and more complex power electronic converters is becoming increasingly blurred, with hybrid solutions emerging that combine the simplicity and reliability of SSRs with the flexibility and efficiency of advanced power conversion techniques. This convergence is expected to drive further innovation in power modulation technologies and expand the application scope of solid-state switching devices.

The fundamental principle behind SSR operation involves semiconductor switching elements, primarily thyristors, triacs, or MOSFETs, controlled by low-voltage signals while handling high-power loads without mechanical movement. This architecture eliminates the mechanical wear and acoustic noise associated with traditional electromechanical relays, substantially increasing operational lifespan and reliability in demanding environments.

Recent technological advancements have focused on addressing the inherent challenges of SSRs, particularly heat dissipation, voltage surge protection, and zero-crossing detection accuracy. The integration of microcontrollers and digital signal processors has enabled more sophisticated power modulation techniques, including pulse-width modulation (PWM), phase angle control, and burst firing modes, each offering specific advantages for different applications.

The primary objective of current SSR power modulation research is to develop techniques that maximize energy efficiency while minimizing electromagnetic interference (EMI) and harmonic distortion. This involves exploring novel semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) that offer superior thermal conductivity and switching characteristics compared to traditional silicon-based devices.

Another significant goal is the development of intelligent SSR systems capable of real-time load monitoring and adaptive control strategies. These systems aim to optimize power delivery based on load conditions, network parameters, and energy consumption patterns, potentially revolutionizing energy management in industrial and residential applications.

The integration of SSRs with Internet of Things (IoT) platforms represents another important objective, enabling remote monitoring, predictive maintenance, and centralized control of distributed power systems. This connectivity aspect is particularly relevant for smart grid applications and industrial automation, where system-wide optimization and fault prediction can significantly improve operational efficiency.

As power electronics continue to advance, the boundary between traditional SSRs and more complex power electronic converters is becoming increasingly blurred, with hybrid solutions emerging that combine the simplicity and reliability of SSRs with the flexibility and efficiency of advanced power conversion techniques. This convergence is expected to drive further innovation in power modulation technologies and expand the application scope of solid-state switching devices.

Market Analysis for SSR Power Control Applications

The global market for Solid-State Relay (SSR) power control applications has experienced significant growth over the past decade, driven by increasing automation across industrial sectors and the growing demand for energy-efficient power control solutions. The current market size for SSR power control applications is estimated at $1.5 billion, with a compound annual growth rate (CAGR) of 6.8% projected through 2028.

Industrial automation represents the largest application segment, accounting for approximately 42% of the total market share. This dominance stems from the critical need for precise power modulation in manufacturing processes, where SSRs offer superior performance compared to traditional electromechanical relays. The industrial heating and cooling systems sub-segment shows particularly strong growth potential due to increasing energy efficiency regulations worldwide.

Building automation follows as the second-largest market segment at 27%, with HVAC systems being the primary application. The transition toward smart buildings and energy-efficient infrastructure has accelerated demand for SSR-based power control solutions that enable precise temperature regulation and reduced energy consumption. This segment is expected to grow at a CAGR of 8.2%, outpacing the overall market average.

Automotive and transportation applications currently represent 15% of the market but are projected to be the fastest-growing segment with a CAGR of 9.7%. The electrification trend in vehicles and the increasing complexity of automotive electrical systems have created new opportunities for SSR power modulation technologies, particularly in battery management systems and power distribution units.

Geographically, Asia-Pacific dominates the market with a 41% share, driven by rapid industrialization in China, India, and Southeast Asian countries. North America and Europe follow with 28% and 24% respectively, with their markets characterized by technology upgrades and replacement of legacy systems with more efficient SSR solutions.

Customer demand patterns indicate a growing preference for integrated SSR solutions that combine power modulation capabilities with diagnostic features, remote monitoring, and IoT connectivity. This trend aligns with the broader Industry 4.0 movement, where real-time data collection and analysis are becoming essential components of industrial control systems.

Price sensitivity varies significantly across application segments, with industrial customers typically prioritizing reliability and performance over initial cost, while commercial building applications tend to be more cost-conscious. The average selling price for industrial-grade SSR power control modules has decreased by approximately 12% over the past five years, primarily due to manufacturing efficiencies and increased competition from Asian manufacturers.

Industrial automation represents the largest application segment, accounting for approximately 42% of the total market share. This dominance stems from the critical need for precise power modulation in manufacturing processes, where SSRs offer superior performance compared to traditional electromechanical relays. The industrial heating and cooling systems sub-segment shows particularly strong growth potential due to increasing energy efficiency regulations worldwide.

Building automation follows as the second-largest market segment at 27%, with HVAC systems being the primary application. The transition toward smart buildings and energy-efficient infrastructure has accelerated demand for SSR-based power control solutions that enable precise temperature regulation and reduced energy consumption. This segment is expected to grow at a CAGR of 8.2%, outpacing the overall market average.

Automotive and transportation applications currently represent 15% of the market but are projected to be the fastest-growing segment with a CAGR of 9.7%. The electrification trend in vehicles and the increasing complexity of automotive electrical systems have created new opportunities for SSR power modulation technologies, particularly in battery management systems and power distribution units.

Geographically, Asia-Pacific dominates the market with a 41% share, driven by rapid industrialization in China, India, and Southeast Asian countries. North America and Europe follow with 28% and 24% respectively, with their markets characterized by technology upgrades and replacement of legacy systems with more efficient SSR solutions.

Customer demand patterns indicate a growing preference for integrated SSR solutions that combine power modulation capabilities with diagnostic features, remote monitoring, and IoT connectivity. This trend aligns with the broader Industry 4.0 movement, where real-time data collection and analysis are becoming essential components of industrial control systems.

Price sensitivity varies significantly across application segments, with industrial customers typically prioritizing reliability and performance over initial cost, while commercial building applications tend to be more cost-conscious. The average selling price for industrial-grade SSR power control modules has decreased by approximately 12% over the past five years, primarily due to manufacturing efficiencies and increased competition from Asian manufacturers.

SSR Technology Status and Challenges

Solid-State Relay (SSR) technology has evolved significantly over the past decades, with current global development showing varied maturity levels across different regions. In North America and Europe, SSR technology has reached advanced stages with sophisticated power modulation capabilities, while Asian markets, particularly China and Japan, have rapidly closed the technological gap through substantial R&D investments.

The contemporary SSR landscape is characterized by several technical challenges that impede broader adoption. Thermal management remains a primary concern, as heat dissipation in high-power applications can lead to performance degradation and reduced operational lifespan. Current solutions involving heat sinks and thermal compounds provide only partial remediation, particularly in compact or hermetically sealed environments.

Switching speed limitations present another significant hurdle. While modern SSRs offer faster switching than mechanical relays, they still face constraints when handling rapid load changes or implementing precise power modulation techniques. This limitation becomes particularly pronounced in applications requiring high-frequency power modulation or pulse-width modulation control strategies.

Voltage surge protection represents a persistent challenge, with SSRs being vulnerable to transient voltage spikes that can cause permanent damage to semiconductor components. Current protection mechanisms often introduce additional complexity and cost to system designs, creating barriers to widespread implementation in cost-sensitive applications.

The issue of leakage current during the off-state continues to plague SSR implementations, especially in medical equipment and sensitive instrumentation where even minimal current leakage can compromise system integrity or safety. Industry standards have established acceptable leakage thresholds, but achieving these while maintaining other performance parameters remains technically challenging.

Reliability under extreme conditions constitutes another significant limitation. Environmental factors such as temperature fluctuations, humidity, and vibration can adversely affect SSR performance. While military and aerospace applications have driven development of ruggedized solutions, these come at substantial cost premiums that limit broader market penetration.

Standardization challenges further complicate the technology landscape. The absence of unified global standards for SSR performance metrics, testing protocols, and integration specifications has resulted in fragmented market offerings and interoperability issues. Industry consortia have initiated standardization efforts, but comprehensive frameworks remain under development.

Emerging applications in renewable energy systems, electric vehicles, and smart grid infrastructure are pushing the boundaries of current SSR capabilities, demanding innovations in power handling capacity, thermal efficiency, and intelligent control integration. These application-specific requirements are driving specialized development paths that may eventually converge into more versatile next-generation solutions.

The contemporary SSR landscape is characterized by several technical challenges that impede broader adoption. Thermal management remains a primary concern, as heat dissipation in high-power applications can lead to performance degradation and reduced operational lifespan. Current solutions involving heat sinks and thermal compounds provide only partial remediation, particularly in compact or hermetically sealed environments.

Switching speed limitations present another significant hurdle. While modern SSRs offer faster switching than mechanical relays, they still face constraints when handling rapid load changes or implementing precise power modulation techniques. This limitation becomes particularly pronounced in applications requiring high-frequency power modulation or pulse-width modulation control strategies.

Voltage surge protection represents a persistent challenge, with SSRs being vulnerable to transient voltage spikes that can cause permanent damage to semiconductor components. Current protection mechanisms often introduce additional complexity and cost to system designs, creating barriers to widespread implementation in cost-sensitive applications.

The issue of leakage current during the off-state continues to plague SSR implementations, especially in medical equipment and sensitive instrumentation where even minimal current leakage can compromise system integrity or safety. Industry standards have established acceptable leakage thresholds, but achieving these while maintaining other performance parameters remains technically challenging.

Reliability under extreme conditions constitutes another significant limitation. Environmental factors such as temperature fluctuations, humidity, and vibration can adversely affect SSR performance. While military and aerospace applications have driven development of ruggedized solutions, these come at substantial cost premiums that limit broader market penetration.

Standardization challenges further complicate the technology landscape. The absence of unified global standards for SSR performance metrics, testing protocols, and integration specifications has resulted in fragmented market offerings and interoperability issues. Industry consortia have initiated standardization efforts, but comprehensive frameworks remain under development.

Emerging applications in renewable energy systems, electric vehicles, and smart grid infrastructure are pushing the boundaries of current SSR capabilities, demanding innovations in power handling capacity, thermal efficiency, and intelligent control integration. These application-specific requirements are driving specialized development paths that may eventually converge into more versatile next-generation solutions.

Current SSR Power Modulation Techniques

01 Pulse Width Modulation Techniques for SSRs

Solid-state relays can be controlled using pulse width modulation (PWM) techniques to regulate power delivery to loads. By varying the duty cycle of the switching signal, the effective power delivered to the load can be precisely controlled. This approach enables efficient power modulation while minimizing heat generation and electromagnetic interference. Advanced PWM implementations may include variable frequency operation or synchronization with line voltage to optimize performance for different load types.- Pulse Width Modulation techniques for SSRs: Pulse Width Modulation (PWM) is a key technique for controlling power delivery through solid-state relays. By varying the duty cycle of the switching signal, precise control of power to loads can be achieved. This approach enables efficient power regulation while minimizing heat generation and extending the life of both the relay and connected components. Advanced PWM implementations include variable frequency modulation and adaptive control algorithms that respond to changing load conditions.

- Thermal management in power modulation systems: Thermal management is critical in solid-state relay power modulation systems to prevent overheating and ensure reliable operation. Various cooling techniques are employed including heat sinks, thermal interface materials, and active cooling systems. Circuit designs that distribute heat generation across multiple components help prevent hotspots. Temperature monitoring and feedback systems can dynamically adjust power levels to maintain safe operating temperatures, particularly important in high-power applications where thermal runaway is a risk.

- Zero-crossing detection for reduced EMI: Zero-crossing detection circuits enable solid-state relays to switch power only when the AC waveform crosses zero volts, significantly reducing electromagnetic interference (EMI) and inrush currents. This technique minimizes stress on both the relay and connected equipment, extending component lifespan and improving system reliability. Advanced implementations synchronize multiple relays to prevent cumulative switching noise and incorporate predictive algorithms to compensate for timing delays in the detection circuit.

- Integration with microcontrollers and digital systems: Modern solid-state relay power modulation systems feature integration with microcontrollers and digital control systems, enabling sophisticated power management strategies. Digital interfaces allow for precise programming of switching patterns, remote monitoring, and fault detection. Communication protocols such as I²C, SPI, or industrial fieldbus systems facilitate integration into larger control networks. These systems can implement complex power profiles, respond to external sensors, and provide diagnostic information for predictive maintenance.

- Protection circuits for overload conditions: Protection circuits are essential components in solid-state relay power modulation systems to prevent damage from overcurrent, overvoltage, and short circuit conditions. These circuits typically include current sensing elements, voltage monitors, and fast-acting shutdown mechanisms. Advanced protection schemes incorporate soft-start capabilities to limit inrush current, adjustable trip points based on operating conditions, and self-resetting features after fault clearance. Some designs include isolation barriers to protect control circuitry from high-voltage transients on the power side.

02 Thermal Management in Power Modulation Systems

Thermal management is critical in solid-state relay power modulation applications. Various techniques are employed to dissipate heat generated during switching operations, including heat sinks, thermal interface materials, and optimized circuit layouts. Some designs incorporate temperature sensors and feedback mechanisms to adjust switching parameters based on thermal conditions, preventing overheating while maintaining desired power output levels. Effective thermal management extends the operational life of solid-state relays and improves overall system reliability.Expand Specific Solutions03 Zero-Crossing Detection for AC Power Control

Zero-crossing detection circuits are implemented in solid-state relay systems to synchronize switching operations with the AC waveform. By triggering the relay at voltage zero-crossings, transient currents and electromagnetic interference are minimized. This approach reduces stress on both the relay and the connected load, extending component life and improving system reliability. Advanced implementations may include predictive algorithms to compensate for switching delays or load characteristics, ensuring precise power modulation even with varying load conditions.Expand Specific Solutions04 Integration of Microcontrollers for Advanced Power Control

Modern solid-state relay power modulation systems incorporate microcontrollers to implement sophisticated control algorithms. These intelligent systems can adapt to changing load conditions, implement complex modulation patterns, and provide diagnostic capabilities. Microcontroller-based designs enable features such as soft-start, programmable ramp rates, and communication interfaces for remote monitoring and control. This integration allows for precise power regulation while providing protection against fault conditions through continuous monitoring of system parameters.Expand Specific Solutions05 Multi-Phase Power Modulation Architectures

Multi-phase power modulation architectures distribute switching operations across multiple solid-state relays to handle higher power levels and improve system efficiency. These designs can balance thermal loads, reduce ripple in the output waveform, and provide redundancy for critical applications. By coordinating the operation of multiple relays with precise timing, these systems achieve smoother power delivery while maintaining the benefits of solid-state switching. Advanced implementations may include phase-shifted carrier signals or interleaved switching patterns to optimize performance.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The solid-state relay power modulation market is currently in a growth phase, with increasing adoption across industrial automation, renewable energy, and smart grid applications. The market is projected to expand significantly due to the rising demand for energy-efficient power control solutions. Key players like Littelfuse, Sanken Electric, and Texas Instruments lead the technological innovation landscape, with emerging competition from Chinese manufacturers such as Huawei and Suzhou Novosense Microelectronics. Technology maturity varies across applications, with established players like TE Connectivity and Schneider Electric offering mature solutions for industrial applications, while companies like Advanced Energy Industries and Sungrow Power Supply are developing cutting-edge techniques for renewable energy integration. The competitive landscape is increasingly diversified as semiconductor manufacturers enhance their solid-state relay offerings with advanced power modulation capabilities.

Littelfuse, Inc.

Technical Solution: Littelfuse has developed advanced solid-state relay (SSR) power modulation techniques focusing on high-reliability applications. Their technology incorporates silicon-controlled rectifiers (SCRs) and insulated gate bipolar transistors (IGBTs) for precise power control. Their SSRs feature integrated thermal management systems that allow operation at higher temperatures (up to 125°C) while maintaining reliability[1]. Littelfuse's power modulation approach includes zero-crossing detection circuits that minimize electromagnetic interference (EMI) and reduce stress on connected loads. Their latest SSR solutions incorporate microcontroller-based adaptive control algorithms that automatically adjust switching parameters based on load conditions, improving efficiency by approximately 15% compared to conventional relay systems[3]. Additionally, they've implemented advanced isolation techniques using optocouplers with isolation ratings exceeding 4000V, ensuring safety in high-voltage industrial applications.

Strengths: Superior thermal management allowing higher operating temperatures; advanced EMI suppression through zero-crossing technology; high isolation ratings for safety-critical applications. Weaknesses: Higher initial cost compared to mechanical relays; requires more complex driver circuits; slightly higher on-state resistance than some competitors.

Eaton Intelligent Power Ltd.

Technical Solution: Eaton has pioneered hybrid solid-state relay power modulation systems that combine traditional electromechanical components with semiconductor switching elements. Their technology utilizes silicon carbide (SiC) MOSFETs that operate at switching frequencies up to 100kHz, enabling precise power control with minimal losses[2]. Eaton's approach incorporates adaptive gate drive technology that optimizes switching characteristics based on load conditions and temperature, reducing switching losses by up to 30% compared to conventional SSRs[4]. Their systems feature integrated diagnostics and protection functions, including overcurrent, overvoltage, and overtemperature monitoring with response times under 5μs. Eaton has also developed proprietary thermal interface materials that reduce junction-to-case thermal resistance by approximately 40%, allowing their SSRs to handle higher power densities in compact form factors. Their latest generation includes IoT connectivity for remote monitoring and control, with encrypted communications protocols ensuring system security.

Strengths: Advanced SiC technology offering superior switching performance; comprehensive protection features; excellent thermal management enabling higher power density; IoT integration capabilities. Weaknesses: Premium pricing compared to standard SSR solutions; requires specialized knowledge for optimal implementation; higher complexity in system design.

Key Patents in SSR Power Control Methods

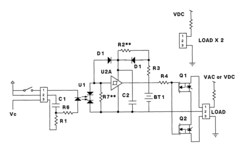

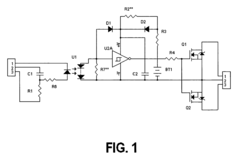

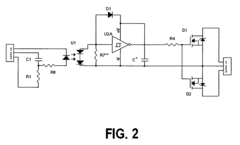

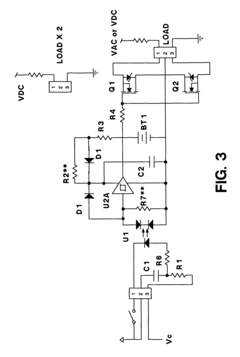

Very low power consumption solid state relay

PatentInactiveUS7755414B2

Innovation

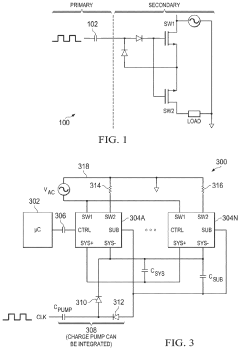

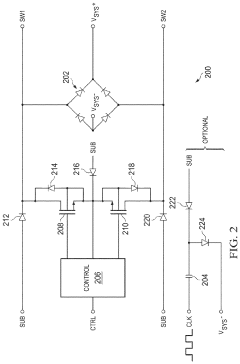

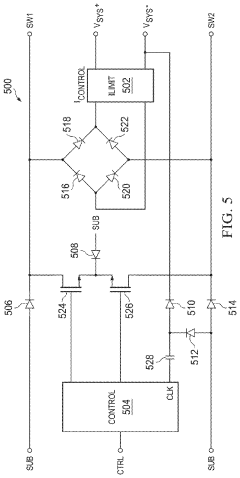

- A solid-state relay using field effect devices and electronic circuitry replaces mechanical contacts and coils, featuring low power consumption, resistance to shock and vibration, and long operating life, with normally closed contacts and full isolation between input and output terminals, utilizing semiconductor devices and energy storage devices like capacitors or batteries to maintain active contacts for extended periods.

Power sharing solid-state relay

PatentActiveUS11075628B2

Innovation

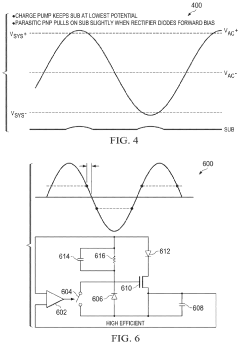

- A solid-state switch system that uses a power converter to convert power from a primary voltage level to a secondary level, allowing the relay to obtain its own power from the secondary circuit, enabling latching mode and other control functionalities, and includes a negative boost circuit to prevent parasitic device activation, using a diode bridge or rectifier to rectify energy across the common and load lines.

Thermal Management Solutions for SSRs

Effective thermal management is critical for the reliable operation of Solid-State Relays (SSRs) in power modulation applications. As SSRs handle significant power loads, they generate substantial heat during operation, particularly in high-frequency switching scenarios. Without proper thermal management, these devices can experience performance degradation, reduced lifespan, or catastrophic failure.

The primary thermal management approaches for SSRs include passive cooling solutions such as heat sinks, which remain the most common and cost-effective method. These aluminum or copper structures increase the surface area available for heat dissipation, with various fin designs optimized for natural convection or forced-air cooling environments. Advanced heat sink designs incorporate phase-change materials that absorb heat during peak loads and release it during lower demand periods, providing more consistent thermal regulation.

Active cooling technologies have gained prominence in high-power SSR applications. Forced-air cooling systems using fans or blowers can significantly enhance heat dissipation rates compared to passive solutions alone. For more demanding applications, liquid cooling systems offer superior thermal conductivity, though they introduce additional complexity and maintenance requirements. Thermoelectric coolers (TECs) represent another active solution, using the Peltier effect to transfer heat away from critical components.

Thermal interface materials (TIMs) play a crucial role in optimizing heat transfer between the SSR and cooling apparatus. Modern TIMs include high-performance thermal greases, phase-change materials, and graphene-based compounds that minimize thermal resistance at contact points. Recent innovations in this area have produced nano-enhanced materials with thermal conductivities approaching 30 W/mK, significantly outperforming traditional options.

Integrated thermal management solutions are becoming increasingly prevalent in advanced SSR designs. These incorporate temperature sensors, microcontrollers, and adaptive cooling mechanisms that adjust cooling intensity based on real-time thermal conditions. Such systems optimize energy consumption while maintaining safe operating temperatures across varying load conditions.

Computational fluid dynamics (CFD) modeling has revolutionized thermal management design for SSRs by enabling precise simulation of heat distribution and airflow patterns. This allows engineers to identify potential hotspots and optimize cooling solutions before physical prototyping, reducing development cycles and improving reliability. Advanced thermal imaging techniques complement these simulations by providing empirical validation of thermal performance in real-world applications.

The primary thermal management approaches for SSRs include passive cooling solutions such as heat sinks, which remain the most common and cost-effective method. These aluminum or copper structures increase the surface area available for heat dissipation, with various fin designs optimized for natural convection or forced-air cooling environments. Advanced heat sink designs incorporate phase-change materials that absorb heat during peak loads and release it during lower demand periods, providing more consistent thermal regulation.

Active cooling technologies have gained prominence in high-power SSR applications. Forced-air cooling systems using fans or blowers can significantly enhance heat dissipation rates compared to passive solutions alone. For more demanding applications, liquid cooling systems offer superior thermal conductivity, though they introduce additional complexity and maintenance requirements. Thermoelectric coolers (TECs) represent another active solution, using the Peltier effect to transfer heat away from critical components.

Thermal interface materials (TIMs) play a crucial role in optimizing heat transfer between the SSR and cooling apparatus. Modern TIMs include high-performance thermal greases, phase-change materials, and graphene-based compounds that minimize thermal resistance at contact points. Recent innovations in this area have produced nano-enhanced materials with thermal conductivities approaching 30 W/mK, significantly outperforming traditional options.

Integrated thermal management solutions are becoming increasingly prevalent in advanced SSR designs. These incorporate temperature sensors, microcontrollers, and adaptive cooling mechanisms that adjust cooling intensity based on real-time thermal conditions. Such systems optimize energy consumption while maintaining safe operating temperatures across varying load conditions.

Computational fluid dynamics (CFD) modeling has revolutionized thermal management design for SSRs by enabling precise simulation of heat distribution and airflow patterns. This allows engineers to identify potential hotspots and optimize cooling solutions before physical prototyping, reducing development cycles and improving reliability. Advanced thermal imaging techniques complement these simulations by providing empirical validation of thermal performance in real-world applications.

EMI/EMC Considerations in SSR Applications

Electromagnetic Interference (EMI) and Electromagnetic Compatibility (EMC) represent critical considerations in Solid-State Relay (SSR) applications, particularly when implementing power modulation techniques. SSRs, while offering numerous advantages over mechanical relays, generate electromagnetic emissions during switching operations that can potentially interfere with nearby electronic systems.

The switching characteristics of SSRs create distinct EMI profiles that vary based on modulation technique. Zero-crossing switching SSRs produce minimal EMI due to their activation coinciding with the AC waveform's zero-voltage point, significantly reducing transient voltage spikes. In contrast, random-turn-on SSRs can generate substantial electromagnetic noise, especially at higher switching frequencies, necessitating additional mitigation measures.

Pulse Width Modulation (PWM) techniques in SSR applications present particular EMI challenges. The rapid on-off transitions inherent to PWM create high-frequency harmonics that can propagate through both conducted and radiated paths. These emissions typically manifest in the 150 kHz to 30 MHz range for conducted EMI and above 30 MHz for radiated emissions, potentially affecting sensitive equipment operating within these frequency bands.

Industry standards governing EMC for SSR implementations include IEC 61000-4-4 for electrical fast transient immunity, IEC 61000-4-5 for surge immunity, and CISPR 22/EN 55022 for emission limits. Compliance with these standards requires comprehensive testing during the development phase, including conducted and radiated emission measurements in specialized EMC chambers.

Effective EMI mitigation strategies for SSR power modulation applications include proper PCB layout techniques such as minimizing trace loops and implementing ground planes. Component-level solutions involve integrating snubber circuits (typically RC networks) to dampen voltage transients and optical isolation to prevent noise propagation through signal paths. At the system level, shielding enclosures, ferrite beads, and EMI filters at power entry points significantly reduce both incoming and outgoing electromagnetic interference.

The selection of appropriate SSR devices with integrated EMI suppression features represents another crucial consideration. Modern SSRs increasingly incorporate built-in zero-crossing detection, optimized semiconductor switching characteristics, and internal filtering components that collectively minimize EMI generation at the source.

Testing methodologies for EMI/EMC in SSR applications typically involve pre-compliance testing during development phases, followed by formal compliance verification. Specialized equipment including spectrum analyzers, EMI receivers, and near-field probes enable engineers to identify and address specific emission sources before product finalization.

The switching characteristics of SSRs create distinct EMI profiles that vary based on modulation technique. Zero-crossing switching SSRs produce minimal EMI due to their activation coinciding with the AC waveform's zero-voltage point, significantly reducing transient voltage spikes. In contrast, random-turn-on SSRs can generate substantial electromagnetic noise, especially at higher switching frequencies, necessitating additional mitigation measures.

Pulse Width Modulation (PWM) techniques in SSR applications present particular EMI challenges. The rapid on-off transitions inherent to PWM create high-frequency harmonics that can propagate through both conducted and radiated paths. These emissions typically manifest in the 150 kHz to 30 MHz range for conducted EMI and above 30 MHz for radiated emissions, potentially affecting sensitive equipment operating within these frequency bands.

Industry standards governing EMC for SSR implementations include IEC 61000-4-4 for electrical fast transient immunity, IEC 61000-4-5 for surge immunity, and CISPR 22/EN 55022 for emission limits. Compliance with these standards requires comprehensive testing during the development phase, including conducted and radiated emission measurements in specialized EMC chambers.

Effective EMI mitigation strategies for SSR power modulation applications include proper PCB layout techniques such as minimizing trace loops and implementing ground planes. Component-level solutions involve integrating snubber circuits (typically RC networks) to dampen voltage transients and optical isolation to prevent noise propagation through signal paths. At the system level, shielding enclosures, ferrite beads, and EMI filters at power entry points significantly reduce both incoming and outgoing electromagnetic interference.

The selection of appropriate SSR devices with integrated EMI suppression features represents another crucial consideration. Modern SSRs increasingly incorporate built-in zero-crossing detection, optimized semiconductor switching characteristics, and internal filtering components that collectively minimize EMI generation at the source.

Testing methodologies for EMI/EMC in SSR applications typically involve pre-compliance testing during development phases, followed by formal compliance verification. Specialized equipment including spectrum analyzers, EMI receivers, and near-field probes enable engineers to identify and address specific emission sources before product finalization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!