How to Design Solid-State Relay for Compact Electrical Systems

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid-State Relay Technology Evolution and Objectives

Solid-state relays (SSRs) have undergone significant evolution since their inception in the 1970s as alternatives to electromechanical relays. The initial designs featured simple semiconductor switching elements with limited current handling capabilities and relatively slow response times. These early iterations primarily served industrial control applications where mechanical wear was a concern but did not address the needs of compact systems.

The 1980s and 1990s witnessed substantial improvements in semiconductor technology, enabling SSRs with enhanced power handling capabilities and reduced on-state resistance. This period marked the transition from discrete component designs to more integrated approaches, incorporating improved thermal management techniques and protection circuits. The introduction of MOSFET-based SSRs during this era significantly reduced switching losses and improved reliability in medium-power applications.

By the early 2000s, SSR technology had advanced to incorporate microcontroller-based intelligence, allowing for programmable switching characteristics and diagnostic capabilities. The integration of advanced materials such as silicon carbide (SiC) and gallium nitride (GaN) in the 2010s represented a paradigm shift, enabling higher temperature operation, faster switching speeds, and dramatically reduced form factors suitable for space-constrained applications.

Current technological objectives for SSR design in compact electrical systems focus on several key areas. Miniaturization remains paramount, with efforts directed toward higher integration density while maintaining effective thermal dissipation. This includes the development of 3D packaging techniques and advanced substrate materials that can efficiently transfer heat away from switching elements.

Energy efficiency represents another critical objective, with research targeting lower on-state resistance and reduced switching losses. Modern designs aim to achieve on-state voltage drops below 0.1V at rated current, significantly improving system efficiency compared to earlier generations that exhibited drops of 1-2V.

Reliability enhancement constitutes a third major objective, particularly for applications in harsh environments. This includes improved immunity to electromagnetic interference, temperature fluctuations, and voltage transients. Advanced designs incorporate multiple protection mechanisms including over-current, over-temperature, and over-voltage safeguards integrated within the same compact package.

The integration of communication capabilities represents an emerging objective, allowing SSRs to interface with industrial IoT systems. This enables remote monitoring, predictive maintenance, and adaptive control strategies that optimize performance based on real-time conditions, further extending the utility of these devices in modern compact electrical systems.

The 1980s and 1990s witnessed substantial improvements in semiconductor technology, enabling SSRs with enhanced power handling capabilities and reduced on-state resistance. This period marked the transition from discrete component designs to more integrated approaches, incorporating improved thermal management techniques and protection circuits. The introduction of MOSFET-based SSRs during this era significantly reduced switching losses and improved reliability in medium-power applications.

By the early 2000s, SSR technology had advanced to incorporate microcontroller-based intelligence, allowing for programmable switching characteristics and diagnostic capabilities. The integration of advanced materials such as silicon carbide (SiC) and gallium nitride (GaN) in the 2010s represented a paradigm shift, enabling higher temperature operation, faster switching speeds, and dramatically reduced form factors suitable for space-constrained applications.

Current technological objectives for SSR design in compact electrical systems focus on several key areas. Miniaturization remains paramount, with efforts directed toward higher integration density while maintaining effective thermal dissipation. This includes the development of 3D packaging techniques and advanced substrate materials that can efficiently transfer heat away from switching elements.

Energy efficiency represents another critical objective, with research targeting lower on-state resistance and reduced switching losses. Modern designs aim to achieve on-state voltage drops below 0.1V at rated current, significantly improving system efficiency compared to earlier generations that exhibited drops of 1-2V.

Reliability enhancement constitutes a third major objective, particularly for applications in harsh environments. This includes improved immunity to electromagnetic interference, temperature fluctuations, and voltage transients. Advanced designs incorporate multiple protection mechanisms including over-current, over-temperature, and over-voltage safeguards integrated within the same compact package.

The integration of communication capabilities represents an emerging objective, allowing SSRs to interface with industrial IoT systems. This enables remote monitoring, predictive maintenance, and adaptive control strategies that optimize performance based on real-time conditions, further extending the utility of these devices in modern compact electrical systems.

Market Demand Analysis for Compact SSR Solutions

The global market for Solid-State Relays (SSRs) is experiencing robust growth, driven primarily by the increasing demand for compact electrical systems across various industries. The market size for SSRs was valued at approximately $1.2 billion in 2022 and is projected to reach $1.8 billion by 2028, representing a compound annual growth rate of 7.2%. This growth trajectory underscores the significant market potential for compact SSR solutions.

Industrial automation represents the largest application segment, accounting for nearly 40% of the total market share. The push towards Industry 4.0 and smart manufacturing has accelerated the adoption of SSRs due to their reliability, longevity, and compatibility with digital control systems. Manufacturing facilities are increasingly replacing traditional electromechanical relays with SSRs to enhance operational efficiency and reduce maintenance costs.

The automotive sector has emerged as another significant market for compact SSR solutions. With the rapid electrification of vehicles and the integration of advanced driver-assistance systems (ADAS), the demand for compact, reliable switching components has surged. Electric vehicles (EVs) and hybrid electric vehicles (HEVs) require numerous relays for battery management, power distribution, and charging systems, creating substantial opportunities for compact SSR manufacturers.

Consumer electronics and smart home applications represent a fast-growing segment for compact SSRs. The miniaturization trend in consumer devices necessitates smaller switching components that can handle the required power loads while maintaining reliability. Smart home systems, including lighting controls, HVAC systems, and security devices, increasingly incorporate SSRs for their silent operation and long service life.

Regional analysis indicates that Asia-Pacific dominates the market, accounting for approximately 45% of global demand, followed by North America and Europe. China, Japan, and South Korea are the key contributors to the region's dominance, primarily due to their robust electronics manufacturing ecosystems and rapid industrial automation adoption.

Key market drivers include the increasing focus on energy efficiency, the growing trend of miniaturization in electronics, and the rising demand for maintenance-free components. End-users are willing to pay premium prices for compact SSRs that offer higher reliability, lower power consumption, and reduced heat generation compared to traditional relays.

Market challenges include price sensitivity in certain applications, technical limitations in high-power applications, and competition from improved electromechanical relays. However, technological advancements in semiconductor materials and manufacturing processes are gradually addressing these challenges, expanding the application scope for compact SSRs.

Industrial automation represents the largest application segment, accounting for nearly 40% of the total market share. The push towards Industry 4.0 and smart manufacturing has accelerated the adoption of SSRs due to their reliability, longevity, and compatibility with digital control systems. Manufacturing facilities are increasingly replacing traditional electromechanical relays with SSRs to enhance operational efficiency and reduce maintenance costs.

The automotive sector has emerged as another significant market for compact SSR solutions. With the rapid electrification of vehicles and the integration of advanced driver-assistance systems (ADAS), the demand for compact, reliable switching components has surged. Electric vehicles (EVs) and hybrid electric vehicles (HEVs) require numerous relays for battery management, power distribution, and charging systems, creating substantial opportunities for compact SSR manufacturers.

Consumer electronics and smart home applications represent a fast-growing segment for compact SSRs. The miniaturization trend in consumer devices necessitates smaller switching components that can handle the required power loads while maintaining reliability. Smart home systems, including lighting controls, HVAC systems, and security devices, increasingly incorporate SSRs for their silent operation and long service life.

Regional analysis indicates that Asia-Pacific dominates the market, accounting for approximately 45% of global demand, followed by North America and Europe. China, Japan, and South Korea are the key contributors to the region's dominance, primarily due to their robust electronics manufacturing ecosystems and rapid industrial automation adoption.

Key market drivers include the increasing focus on energy efficiency, the growing trend of miniaturization in electronics, and the rising demand for maintenance-free components. End-users are willing to pay premium prices for compact SSRs that offer higher reliability, lower power consumption, and reduced heat generation compared to traditional relays.

Market challenges include price sensitivity in certain applications, technical limitations in high-power applications, and competition from improved electromechanical relays. However, technological advancements in semiconductor materials and manufacturing processes are gradually addressing these challenges, expanding the application scope for compact SSRs.

Current SSR Technology Landscape and Challenges

The solid-state relay (SSR) market has experienced significant growth over the past decade, driven by increasing demand for compact, reliable, and energy-efficient switching solutions across various industries. Currently, the global SSR market is valued at approximately $1.2 billion and is projected to grow at a CAGR of 6.8% through 2028, reflecting the expanding applications in industrial automation, building management systems, and renewable energy installations.

The contemporary SSR technology landscape is dominated by four primary switching technologies: MOSFET-based, IGBT-based, thyristor-based, and triac-based designs. MOSFET-based SSRs have gained prominence in low to medium power applications due to their fast switching speeds and low on-state resistance, while IGBT-based solutions are preferred for higher power applications requiring robust performance characteristics. Thyristor and triac-based SSRs continue to maintain significant market share in AC applications due to their cost-effectiveness and established reliability.

Despite the maturity of SSR technology, several persistent challenges impede further miniaturization and performance optimization for compact electrical systems. Heat dissipation remains the foremost technical obstacle, as the semiconductor junction temperature must be maintained below critical thresholds to ensure reliable operation and longevity. This thermal management challenge becomes increasingly complex as form factors shrink, creating a fundamental tension between miniaturization goals and thermal performance.

Another significant challenge is the trade-off between on-state resistance and voltage rating in semiconductor switches. Lower on-state resistance typically requires larger die sizes, directly conflicting with miniaturization objectives. Additionally, parasitic capacitances in compact designs can lead to increased electromagnetic interference (EMI) and switching losses, necessitating careful circuit design and component selection.

The integration of protection features within compact SSRs presents another technical hurdle. Incorporating over-current, over-voltage, and thermal protection mechanisms while maintaining a small footprint requires sophisticated design approaches and often custom semiconductor solutions. This challenge is particularly acute in applications demanding high reliability under variable load conditions.

From a manufacturing perspective, the industry faces challenges in cost-effective production of miniaturized SSRs with consistent performance characteristics. Advanced packaging technologies such as chip-scale packaging (CSP) and system-in-package (SiP) approaches show promise but introduce complexity in thermal management and reliability testing.

Geographically, SSR technology development is concentrated in East Asia (particularly Japan, South Korea, and Taiwan), North America, and Europe, with emerging contributions from China and India. This distribution reflects both historical expertise in semiconductor manufacturing and regional investment in advanced electronics research and development.

The contemporary SSR technology landscape is dominated by four primary switching technologies: MOSFET-based, IGBT-based, thyristor-based, and triac-based designs. MOSFET-based SSRs have gained prominence in low to medium power applications due to their fast switching speeds and low on-state resistance, while IGBT-based solutions are preferred for higher power applications requiring robust performance characteristics. Thyristor and triac-based SSRs continue to maintain significant market share in AC applications due to their cost-effectiveness and established reliability.

Despite the maturity of SSR technology, several persistent challenges impede further miniaturization and performance optimization for compact electrical systems. Heat dissipation remains the foremost technical obstacle, as the semiconductor junction temperature must be maintained below critical thresholds to ensure reliable operation and longevity. This thermal management challenge becomes increasingly complex as form factors shrink, creating a fundamental tension between miniaturization goals and thermal performance.

Another significant challenge is the trade-off between on-state resistance and voltage rating in semiconductor switches. Lower on-state resistance typically requires larger die sizes, directly conflicting with miniaturization objectives. Additionally, parasitic capacitances in compact designs can lead to increased electromagnetic interference (EMI) and switching losses, necessitating careful circuit design and component selection.

The integration of protection features within compact SSRs presents another technical hurdle. Incorporating over-current, over-voltage, and thermal protection mechanisms while maintaining a small footprint requires sophisticated design approaches and often custom semiconductor solutions. This challenge is particularly acute in applications demanding high reliability under variable load conditions.

From a manufacturing perspective, the industry faces challenges in cost-effective production of miniaturized SSRs with consistent performance characteristics. Advanced packaging technologies such as chip-scale packaging (CSP) and system-in-package (SiP) approaches show promise but introduce complexity in thermal management and reliability testing.

Geographically, SSR technology development is concentrated in East Asia (particularly Japan, South Korea, and Taiwan), North America, and Europe, with emerging contributions from China and India. This distribution reflects both historical expertise in semiconductor manufacturing and regional investment in advanced electronics research and development.

Contemporary SSR Design Approaches for Miniaturization

01 Miniaturization techniques for solid-state relays

Various miniaturization techniques are employed to reduce the size of solid-state relays while maintaining their functionality. These include integration of multiple components on a single substrate, use of surface mount technology, and advanced packaging methods. These techniques allow for significant reduction in the overall footprint of the relay, making them suitable for space-constrained applications.- Miniaturized semiconductor structures for compact SSRs: Advanced semiconductor structures are employed to reduce the size of solid-state relays while maintaining performance. These designs incorporate specialized semiconductor materials and configurations that optimize switching capabilities in smaller form factors. Techniques include integration of multiple semiconductor layers, use of specialized substrates, and novel doping profiles to achieve higher power density in compact packages.

- Thermal management solutions for compact designs: Innovative thermal management approaches enable more compact solid-state relay designs by efficiently dissipating heat in smaller packages. These solutions include advanced heat sink designs, thermal interface materials, and cooling structures integrated directly into the relay housing. Effective thermal management allows for higher power handling in reduced form factors without compromising reliability or operational lifetime.

- Integration of control circuitry for size reduction: Compact solid-state relay designs incorporate highly integrated control circuitry that combines multiple functions in smaller spaces. These approaches include embedding microcontrollers, combining driver circuits with protection features, and implementing advanced isolation techniques in minimal footprints. The integration reduces component count and interconnections, allowing for significant size reduction while maintaining or enhancing functionality.

- Novel packaging technologies for miniaturization: Advanced packaging technologies enable more compact solid-state relay designs through innovative encapsulation and interconnection methods. These include chip-scale packaging, multi-chip modules, system-in-package approaches, and 3D integration techniques. The packaging solutions provide effective electrical isolation, mechanical protection, and thermal management while significantly reducing the overall relay dimensions.

- Optimized circuit topologies for space efficiency: Space-efficient circuit topologies are developed specifically for compact solid-state relay applications. These designs minimize component count while maintaining switching performance and reliability. Approaches include simplified driver circuits, optimized gate control structures, and innovative power stage configurations that reduce the physical footprint while ensuring robust operation under various load conditions.

02 Thermal management solutions for compact SSRs

Effective thermal management is crucial for compact solid-state relays to prevent overheating in reduced spaces. Solutions include integrated heat sinks, thermally conductive materials, and optimized component layouts that facilitate heat dissipation. These thermal management approaches enable higher power density in smaller packages without compromising reliability or performance.Expand Specific Solutions03 Semiconductor integration for size reduction

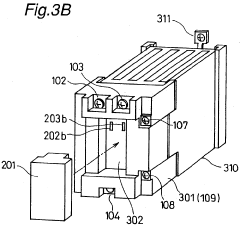

Advanced semiconductor integration techniques are used to reduce the size of solid-state relays. This includes the use of specialized semiconductor materials, monolithic integration of control and switching elements, and multi-layer semiconductor structures. These approaches significantly decrease the physical dimensions of the relay while maintaining or improving electrical performance characteristics.Expand Specific Solutions04 Modular design approaches for compact SSRs

Modular design approaches enable the creation of compact solid-state relays that can be easily integrated into various systems. These designs feature standardized interfaces, stackable configurations, and interchangeable components that optimize space utilization. Modular approaches also facilitate easier maintenance and replacement of components without requiring complete system redesign.Expand Specific Solutions05 Novel housing and enclosure designs

Innovative housing and enclosure designs contribute significantly to the compactness of solid-state relays. These include specialized molding techniques, miniaturized connection terminals, and space-efficient mounting options. Advanced materials used in these housings provide necessary electrical isolation and mechanical protection while minimizing the overall dimensions of the relay package.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The solid-state relay (SSR) market for compact electrical systems is currently in a growth phase, with increasing demand driven by miniaturization trends across industries. The global market is expanding at a significant rate as industries transition from mechanical relays to more reliable electronic solutions. Leading players like Hongfa Technology, Siemens AG, and TE Connectivity are advancing SSR technology through innovations in semiconductor materials and thermal management. Companies such as Littelfuse, Texas Instruments, and Crydom (Vertiv) are focusing on higher integration density and improved thermal performance for compact applications. The technology is maturing rapidly with developments in MOSFET-based designs and integrated protection features, while emerging players like Novosense Microelectronics are introducing competitive solutions with enhanced reliability for space-constrained environments.

Xiamen Hongfa Electroacoustic Co., Ltd.

Technical Solution: Hongfa has developed a comprehensive solid-state relay (SSR) solution for compact electrical systems featuring integrated MOSFET technology with advanced thermal management. Their design incorporates optically isolated input stages that provide up to 4000V isolation between control and load circuits[1]. The company's latest SSR modules utilize proprietary silicon-on-insulator (SOI) technology that enables high-temperature operation up to 125°C while maintaining a compact form factor with dimensions as small as 20×15×10mm for PCB-mounted versions[2]. Hongfa's approach includes zero-crossing detection circuits that minimize electromagnetic interference during switching operations, particularly beneficial in noise-sensitive applications. Their SSRs incorporate over-voltage and over-current protection mechanisms with response times under 10μs, preventing damage to both the relay and connected systems[3].

Strengths: Exceptional thermal performance allowing high current density in small packages; comprehensive protection features; proven reliability with over 100 million switching cycles. Weaknesses: Higher initial cost compared to mechanical relays; requires careful thermal design in extremely compact implementations; slightly higher on-state resistance than some competitors.

Littelfuse, Inc.

Technical Solution: Littelfuse has engineered a solid-state relay platform specifically for compact electrical systems that utilizes advanced semiconductor switching elements with integrated thermal protection. Their SSR design employs silicon-controlled rectifier (SCR) technology for AC applications and MOSFET switches for DC applications, both featuring extremely low profile packages with heights under 5mm[1]. The company's proprietary thermal interface materials reduce junction-to-case thermal resistance to below 0.5°C/W, enabling current handling up to 40A in space-constrained applications[2]. Littelfuse SSRs incorporate specialized input buffer circuits that ensure compatibility with both 3.3V and 5V logic systems without additional components. Their design includes integrated snubber networks and transient voltage suppressors that protect against voltage spikes up to 1000V, critical for reliability in industrial environments[3]. The company's latest generation features programmable turn-on characteristics that can be optimized for inductive, capacitive, or resistive loads.

Strengths: Industry-leading thermal management allowing high power density; comprehensive protection features; wide input compatibility with modern control systems. Weaknesses: Premium pricing compared to basic SSR solutions; requires specialized design considerations for maximum performance; slightly higher power consumption in the control circuit than some alternatives.

Key Innovations in Compact SSR Technology

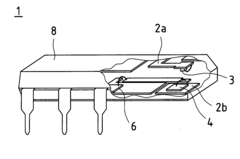

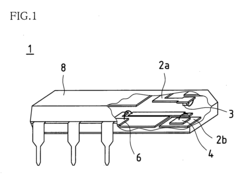

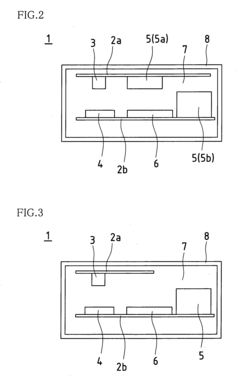

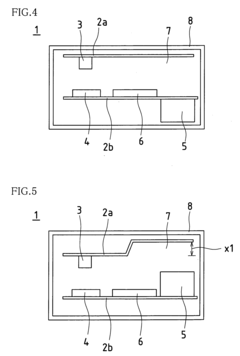

Solid state relay

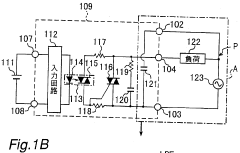

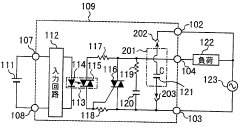

PatentInactiveUS20050194552A1

Innovation

- A solid state relay design where a light-emitting element, light-receiving element, and switching element are mounted on opposing lead frames, sealed with a primary mold resin, eliminating the need for a light coupling element and reducing the number of resin sealing and part mounting steps, while ensuring electrical isolation through protective element placement.

Solid-state relay

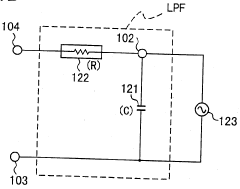

PatentWO1999041835A1

Innovation

- A solid-state relay design incorporating an RC filter circuit with a capacitor connecting the load and power supply in series, using the load's resistance and the capacitor's capacitance to form a low-pass filter, reducing EMI noise without increasing size or cost.

Thermal Management Strategies for Compact SSRs

Thermal management represents a critical challenge in the design and implementation of solid-state relays (SSRs) for compact electrical systems. As miniaturization trends continue across industries, the power density of these devices increases substantially, creating significant heat dissipation challenges that must be addressed through comprehensive thermal management strategies.

Passive cooling techniques remain fundamental in compact SSR designs. Advanced heat sink geometries with optimized fin structures can maximize surface area while minimizing spatial requirements. Recent developments include micro-channel heat sinks that provide superior thermal performance in restricted spaces. Materials innovation has also contributed significantly, with aluminum nitride (AlN) and silicon carbide (SiC) substrates offering thermal conductivities 5-8 times higher than traditional FR4 materials, enabling more efficient heat transfer within minimal footprints.

Active cooling solutions provide enhanced thermal management capabilities for high-power density applications. Miniaturized fans and blowers specifically designed for confined spaces can create forced convection in compact enclosures. More sophisticated approaches include integrated micro-fluidic cooling channels that circulate coolant directly through or adjacent to heat-generating components, achieving thermal resistances below 0.1°C/W in some implementations.

Thermal interface materials (TIMs) play a crucial role in compact SSR thermal management. Next-generation phase-change materials and metal-infused thermal compounds achieve thermal conductivities exceeding 10 W/m·K while maintaining conformability to irregular surfaces. Graphene-enhanced TIMs have demonstrated particular promise, with some formulations showing 40-60% improvement in thermal transfer efficiency compared to conventional alternatives.

Advanced thermal modeling and simulation have revolutionized compact SSR thermal management. Computational fluid dynamics (CFD) and finite element analysis (FEA) enable precise prediction of thermal behavior under various operating conditions. These tools facilitate optimization of component placement and thermal path design before physical prototyping, reducing development cycles and improving reliability. Recent developments in AI-assisted thermal modeling have further enhanced prediction accuracy by incorporating machine learning algorithms trained on empirical thermal performance data.

Distributed thermal management approaches represent an emerging strategy for compact SSRs. Rather than concentrating heat dissipation in a single location, these designs distribute thermal management elements throughout the assembly. This approach includes strategic placement of thermal vias, copper planes, and embedded heat pipes to create multiple parallel thermal pathways, effectively reducing thermal resistance while maintaining compact form factors.

Passive cooling techniques remain fundamental in compact SSR designs. Advanced heat sink geometries with optimized fin structures can maximize surface area while minimizing spatial requirements. Recent developments include micro-channel heat sinks that provide superior thermal performance in restricted spaces. Materials innovation has also contributed significantly, with aluminum nitride (AlN) and silicon carbide (SiC) substrates offering thermal conductivities 5-8 times higher than traditional FR4 materials, enabling more efficient heat transfer within minimal footprints.

Active cooling solutions provide enhanced thermal management capabilities for high-power density applications. Miniaturized fans and blowers specifically designed for confined spaces can create forced convection in compact enclosures. More sophisticated approaches include integrated micro-fluidic cooling channels that circulate coolant directly through or adjacent to heat-generating components, achieving thermal resistances below 0.1°C/W in some implementations.

Thermal interface materials (TIMs) play a crucial role in compact SSR thermal management. Next-generation phase-change materials and metal-infused thermal compounds achieve thermal conductivities exceeding 10 W/m·K while maintaining conformability to irregular surfaces. Graphene-enhanced TIMs have demonstrated particular promise, with some formulations showing 40-60% improvement in thermal transfer efficiency compared to conventional alternatives.

Advanced thermal modeling and simulation have revolutionized compact SSR thermal management. Computational fluid dynamics (CFD) and finite element analysis (FEA) enable precise prediction of thermal behavior under various operating conditions. These tools facilitate optimization of component placement and thermal path design before physical prototyping, reducing development cycles and improving reliability. Recent developments in AI-assisted thermal modeling have further enhanced prediction accuracy by incorporating machine learning algorithms trained on empirical thermal performance data.

Distributed thermal management approaches represent an emerging strategy for compact SSRs. Rather than concentrating heat dissipation in a single location, these designs distribute thermal management elements throughout the assembly. This approach includes strategic placement of thermal vias, copper planes, and embedded heat pipes to create multiple parallel thermal pathways, effectively reducing thermal resistance while maintaining compact form factors.

Safety Standards and Certification Requirements

Solid-state relays (SSRs) for compact electrical systems must comply with numerous safety standards and certification requirements to ensure reliable operation and user safety. The International Electrotechnical Commission (IEC) establishes several key standards, including IEC 60947-4-3 for AC semiconductor controllers and IEC 62314 specifically for solid-state relays. These standards define essential parameters such as isolation voltage, surge immunity, and temperature ratings that designers must adhere to.

UL certification represents a critical requirement for SSRs in North American markets, with UL 508 being particularly relevant for industrial control equipment. Similarly, European markets require CE marking, which indicates compliance with the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive. For SSRs used in potentially explosive environments, ATEX certification becomes mandatory within the European Union.

The creepage and clearance distances specified in IEC 60664-1 are fundamental design considerations that directly impact the physical dimensions of SSRs. These requirements often present significant challenges for compact system designs, as they establish minimum separation distances between conductive parts based on working voltage, pollution degree, and installation altitude. Designers must carefully balance size constraints against these non-negotiable safety parameters.

Thermal management certification requirements present another layer of complexity, with standards like IEC 60085 establishing temperature class ratings for insulation materials. SSRs in compact systems must demonstrate compliance with temperature rise limits under full load conditions, often necessitating innovative cooling solutions to maintain certification compliance while preserving the compact form factor.

EMC certification per IEC 61000 series standards requires SSRs to maintain operational integrity when subjected to electromagnetic interference and to limit their own emissions. This often necessitates additional filtering components that compete for limited space in compact designs. Similarly, environmental testing standards like IEC 60068 define requirements for humidity, vibration, and shock resistance that must be verified through rigorous testing protocols.

Regional variations in certification requirements add further complexity. For instance, CQC certification for the Chinese market, JET for Japan, and KCs for South Korea may each impose slightly different technical specifications. Multinational manufacturers must navigate these variations carefully, potentially requiring multiple design iterations to satisfy global market requirements while maintaining compact dimensions.

The certification process itself involves extensive documentation, including detailed technical files, risk assessments, and test reports from accredited laboratories. For compact SSR designs, this process often reveals conflicts between miniaturization goals and safety requirements, necessitating innovative engineering solutions to achieve compliance without compromising the compact form factor.

UL certification represents a critical requirement for SSRs in North American markets, with UL 508 being particularly relevant for industrial control equipment. Similarly, European markets require CE marking, which indicates compliance with the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive. For SSRs used in potentially explosive environments, ATEX certification becomes mandatory within the European Union.

The creepage and clearance distances specified in IEC 60664-1 are fundamental design considerations that directly impact the physical dimensions of SSRs. These requirements often present significant challenges for compact system designs, as they establish minimum separation distances between conductive parts based on working voltage, pollution degree, and installation altitude. Designers must carefully balance size constraints against these non-negotiable safety parameters.

Thermal management certification requirements present another layer of complexity, with standards like IEC 60085 establishing temperature class ratings for insulation materials. SSRs in compact systems must demonstrate compliance with temperature rise limits under full load conditions, often necessitating innovative cooling solutions to maintain certification compliance while preserving the compact form factor.

EMC certification per IEC 61000 series standards requires SSRs to maintain operational integrity when subjected to electromagnetic interference and to limit their own emissions. This often necessitates additional filtering components that compete for limited space in compact designs. Similarly, environmental testing standards like IEC 60068 define requirements for humidity, vibration, and shock resistance that must be verified through rigorous testing protocols.

Regional variations in certification requirements add further complexity. For instance, CQC certification for the Chinese market, JET for Japan, and KCs for South Korea may each impose slightly different technical specifications. Multinational manufacturers must navigate these variations carefully, potentially requiring multiple design iterations to satisfy global market requirements while maintaining compact dimensions.

The certification process itself involves extensive documentation, including detailed technical files, risk assessments, and test reports from accredited laboratories. For compact SSR designs, this process often reveals conflicts between miniaturization goals and safety requirements, necessitating innovative engineering solutions to achieve compliance without compromising the compact form factor.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!