How to Calibrate Solid-State Relay Response under Variability

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid-State Relay Calibration Background and Objectives

Solid-state relays (SSRs) have evolved significantly since their introduction in the 1970s as alternatives to electromechanical relays. These semiconductor-based switching devices offer numerous advantages including faster switching speeds, absence of moving parts, silent operation, and enhanced reliability. The evolution of SSR technology has been closely tied to advancements in semiconductor manufacturing, with each generation bringing improvements in performance characteristics and application versatility.

The current technological landscape presents SSRs with increasingly complex operating environments characterized by variable conditions including temperature fluctuations, input voltage variations, load impedance changes, and electromagnetic interference. These variability factors directly impact the switching behavior and reliability of solid-state relays, creating challenges for consistent performance across applications ranging from industrial automation to critical infrastructure systems.

Calibration of solid-state relays has traditionally followed deterministic approaches that establish fixed parameters during manufacturing or installation. However, these conventional methods prove inadequate when confronting the dynamic variability encountered in modern applications. The technological goal is to develop adaptive calibration methodologies that can continuously optimize relay response characteristics despite environmental and operational fluctuations.

Recent technological trends indicate a shift toward intelligent calibration systems incorporating real-time monitoring and adjustment capabilities. These systems leverage advances in microcontroller technology, sensor integration, and machine learning algorithms to create responsive calibration frameworks. The integration of digital twins and predictive modeling further enhances the potential for preemptive calibration adjustments based on anticipated variability patterns.

The primary technical objectives for solid-state relay calibration under variability conditions include: establishing standardized characterization protocols for relay response under variable conditions; developing adaptive calibration algorithms capable of real-time parameter adjustment; creating robust feedback mechanisms to monitor performance drift; implementing predictive calibration models that anticipate environmental and load changes; and designing calibration systems with minimal impact on relay switching performance.

Additionally, there is growing emphasis on calibration approaches that address emerging challenges such as aging-related parameter drift, harmonic distortion in switching waveforms, and thermal management concerns. The technical goal extends beyond mere functionality to encompass optimization of energy efficiency, reduction of electromagnetic emissions, and extension of operational lifespan through precise calibration methodologies.

The convergence of power electronics, embedded systems, and data analytics creates new opportunities for revolutionary approaches to SSR calibration that can transform these devices from simple switches to intelligent nodes within sophisticated control systems.

The current technological landscape presents SSRs with increasingly complex operating environments characterized by variable conditions including temperature fluctuations, input voltage variations, load impedance changes, and electromagnetic interference. These variability factors directly impact the switching behavior and reliability of solid-state relays, creating challenges for consistent performance across applications ranging from industrial automation to critical infrastructure systems.

Calibration of solid-state relays has traditionally followed deterministic approaches that establish fixed parameters during manufacturing or installation. However, these conventional methods prove inadequate when confronting the dynamic variability encountered in modern applications. The technological goal is to develop adaptive calibration methodologies that can continuously optimize relay response characteristics despite environmental and operational fluctuations.

Recent technological trends indicate a shift toward intelligent calibration systems incorporating real-time monitoring and adjustment capabilities. These systems leverage advances in microcontroller technology, sensor integration, and machine learning algorithms to create responsive calibration frameworks. The integration of digital twins and predictive modeling further enhances the potential for preemptive calibration adjustments based on anticipated variability patterns.

The primary technical objectives for solid-state relay calibration under variability conditions include: establishing standardized characterization protocols for relay response under variable conditions; developing adaptive calibration algorithms capable of real-time parameter adjustment; creating robust feedback mechanisms to monitor performance drift; implementing predictive calibration models that anticipate environmental and load changes; and designing calibration systems with minimal impact on relay switching performance.

Additionally, there is growing emphasis on calibration approaches that address emerging challenges such as aging-related parameter drift, harmonic distortion in switching waveforms, and thermal management concerns. The technical goal extends beyond mere functionality to encompass optimization of energy efficiency, reduction of electromagnetic emissions, and extension of operational lifespan through precise calibration methodologies.

The convergence of power electronics, embedded systems, and data analytics creates new opportunities for revolutionary approaches to SSR calibration that can transform these devices from simple switches to intelligent nodes within sophisticated control systems.

Market Analysis for Precision SSR Applications

The precision Solid-State Relay (SSR) market is experiencing significant growth driven by increasing demand for reliable switching solutions in critical applications. The global SSR market was valued at approximately $1.2 billion in 2022 and is projected to reach $1.8 billion by 2027, with precision applications representing about 35% of this market. Industries requiring high-precision SSR calibration include medical equipment, semiconductor manufacturing, aerospace, and industrial automation.

Medical equipment represents a particularly strong growth segment, with precision SSRs being essential components in diagnostic imaging systems, patient monitoring devices, and therapeutic equipment. The medical SSR market segment is growing at nearly 7% annually, outpacing the overall SSR market growth rate of 5.5%.

Semiconductor manufacturing presents another substantial market opportunity, where precisely calibrated SSRs are crucial for maintaining exact process parameters. As chip manufacturing tolerances continue to tighten, the demand for SSRs with predictable and consistent response characteristics under variable conditions has intensified. This segment values SSRs with response time variability below 50 microseconds.

The industrial automation sector remains the largest consumer of precision SSRs by volume, particularly in applications requiring high-frequency switching operations. Manufacturing facilities implementing Industry 4.0 technologies are increasingly replacing mechanical relays with solid-state alternatives that offer better reliability and more precise control capabilities.

Regional analysis shows North America and Europe leading in adoption of precision-calibrated SSRs, primarily due to their established high-tech manufacturing bases. However, the Asia-Pacific region, particularly China, South Korea, and Taiwan, is showing the fastest growth rate at approximately 9% annually, driven by expanding semiconductor and electronics manufacturing facilities.

Customer requirements analysis reveals that end-users are increasingly prioritizing SSRs with self-calibration capabilities and built-in diagnostics to address variability concerns. There is growing demand for SSRs that can maintain consistent performance across temperature fluctuations (-40°C to +125°C), input voltage variations (±10%), and over extended operational lifespans (10+ years).

Price sensitivity varies significantly by application, with medical and aerospace customers willing to pay premium prices for SSRs with guaranteed precision and comprehensive calibration documentation. Industrial customers typically seek a balance between performance and cost, creating opportunities for tiered product offerings with varying levels of precision calibration.

Medical equipment represents a particularly strong growth segment, with precision SSRs being essential components in diagnostic imaging systems, patient monitoring devices, and therapeutic equipment. The medical SSR market segment is growing at nearly 7% annually, outpacing the overall SSR market growth rate of 5.5%.

Semiconductor manufacturing presents another substantial market opportunity, where precisely calibrated SSRs are crucial for maintaining exact process parameters. As chip manufacturing tolerances continue to tighten, the demand for SSRs with predictable and consistent response characteristics under variable conditions has intensified. This segment values SSRs with response time variability below 50 microseconds.

The industrial automation sector remains the largest consumer of precision SSRs by volume, particularly in applications requiring high-frequency switching operations. Manufacturing facilities implementing Industry 4.0 technologies are increasingly replacing mechanical relays with solid-state alternatives that offer better reliability and more precise control capabilities.

Regional analysis shows North America and Europe leading in adoption of precision-calibrated SSRs, primarily due to their established high-tech manufacturing bases. However, the Asia-Pacific region, particularly China, South Korea, and Taiwan, is showing the fastest growth rate at approximately 9% annually, driven by expanding semiconductor and electronics manufacturing facilities.

Customer requirements analysis reveals that end-users are increasingly prioritizing SSRs with self-calibration capabilities and built-in diagnostics to address variability concerns. There is growing demand for SSRs that can maintain consistent performance across temperature fluctuations (-40°C to +125°C), input voltage variations (±10%), and over extended operational lifespans (10+ years).

Price sensitivity varies significantly by application, with medical and aerospace customers willing to pay premium prices for SSRs with guaranteed precision and comprehensive calibration documentation. Industrial customers typically seek a balance between performance and cost, creating opportunities for tiered product offerings with varying levels of precision calibration.

Technical Challenges in SSR Response Variability

Solid-state relays (SSRs) face significant response variability challenges that complicate their calibration and reliable operation. These challenges stem from multiple sources, creating a complex technical landscape that engineers must navigate. Understanding these challenges is crucial for developing effective calibration methodologies.

Temperature fluctuations represent one of the most prominent challenges affecting SSR response. As semiconductor-based devices, SSRs exhibit temperature-dependent characteristics where switching thresholds, turn-on/turn-off times, and leakage currents can vary substantially across operating temperature ranges. This variability is particularly problematic in industrial environments where temperature conditions may change dramatically.

Manufacturing process variations introduce another layer of complexity. Even SSRs from the same production batch can display different electrical characteristics due to semiconductor doping inconsistencies, material impurities, and structural variations at the microscopic level. These manufacturing tolerances create a baseline variability that must be accounted for in calibration procedures.

Aging effects and degradation mechanisms pose long-term challenges to SSR calibration. Over time, semiconductor materials experience electron migration, interface state changes, and thermal cycling stress that gradually alter device characteristics. This time-dependent drift necessitates recalibration strategies that can adapt to the evolving nature of the device parameters.

Load-dependent variability further complicates SSR response calibration. The nature of the connected load—whether resistive, capacitive, or inductive—significantly impacts switching behavior and timing characteristics. Inductive loads, in particular, create back-EMF effects that can stress SSR components and alter their response profiles over repeated operations.

Environmental factors beyond temperature also contribute to variability challenges. Humidity, electromagnetic interference (EMI), vibration, and power supply fluctuations can all influence SSR performance in unpredictable ways. These environmental variables often interact with each other, creating complex multi-factor effects that are difficult to isolate and compensate for during calibration.

Measurement and instrumentation limitations present meta-challenges in addressing SSR variability. The very tools used to measure and calibrate SSRs have their own accuracy limitations, resolution constraints, and potential for introducing measurement artifacts. This creates fundamental uncertainty boundaries that limit the precision of any calibration methodology.

The dynamic nature of modern industrial systems adds another dimension to the challenge. Many applications require SSRs to operate under varying conditions rather than steady-state scenarios, making static calibration approaches insufficient. Developing adaptive calibration techniques that can respond to changing operational contexts remains an ongoing technical hurdle.

Temperature fluctuations represent one of the most prominent challenges affecting SSR response. As semiconductor-based devices, SSRs exhibit temperature-dependent characteristics where switching thresholds, turn-on/turn-off times, and leakage currents can vary substantially across operating temperature ranges. This variability is particularly problematic in industrial environments where temperature conditions may change dramatically.

Manufacturing process variations introduce another layer of complexity. Even SSRs from the same production batch can display different electrical characteristics due to semiconductor doping inconsistencies, material impurities, and structural variations at the microscopic level. These manufacturing tolerances create a baseline variability that must be accounted for in calibration procedures.

Aging effects and degradation mechanisms pose long-term challenges to SSR calibration. Over time, semiconductor materials experience electron migration, interface state changes, and thermal cycling stress that gradually alter device characteristics. This time-dependent drift necessitates recalibration strategies that can adapt to the evolving nature of the device parameters.

Load-dependent variability further complicates SSR response calibration. The nature of the connected load—whether resistive, capacitive, or inductive—significantly impacts switching behavior and timing characteristics. Inductive loads, in particular, create back-EMF effects that can stress SSR components and alter their response profiles over repeated operations.

Environmental factors beyond temperature also contribute to variability challenges. Humidity, electromagnetic interference (EMI), vibration, and power supply fluctuations can all influence SSR performance in unpredictable ways. These environmental variables often interact with each other, creating complex multi-factor effects that are difficult to isolate and compensate for during calibration.

Measurement and instrumentation limitations present meta-challenges in addressing SSR variability. The very tools used to measure and calibrate SSRs have their own accuracy limitations, resolution constraints, and potential for introducing measurement artifacts. This creates fundamental uncertainty boundaries that limit the precision of any calibration methodology.

The dynamic nature of modern industrial systems adds another dimension to the challenge. Many applications require SSRs to operate under varying conditions rather than steady-state scenarios, making static calibration approaches insufficient. Developing adaptive calibration techniques that can respond to changing operational contexts remains an ongoing technical hurdle.

Current Calibration Methodologies and Approaches

01 Calibration methods for solid-state relay response time

Various methods are employed to calibrate the response time of solid-state relays to ensure accurate switching operations. These methods involve measuring the time between the control signal application and the actual switching of the relay. Calibration techniques may include digital signal processing, feedback loops, and reference timing circuits to compensate for variations in temperature, load conditions, and component aging. Proper calibration ensures consistent performance in critical applications where precise timing is essential.- Calibration methods for solid-state relay response time: Various methods are employed to calibrate the response time of solid-state relays to ensure accurate switching operations. These methods involve measuring the time between the control signal application and the actual switching action, and then adjusting parameters to achieve the desired response characteristics. Calibration techniques may include digital signal processing, feedback mechanisms, and reference timing circuits to compensate for variations in operating conditions and component tolerances.

- Temperature compensation in solid-state relay calibration: Temperature variations significantly affect solid-state relay performance, necessitating specialized calibration techniques. These approaches involve temperature sensing elements integrated with the relay circuitry to detect ambient or operational temperature changes. The calibration systems then apply compensation algorithms to adjust switching parameters, ensuring consistent relay response times across a wide temperature range. This compensation is critical for maintaining precise timing in industrial applications where environmental conditions fluctuate.

- Feedback-based calibration systems for solid-state relays: Feedback mechanisms are implemented to continuously monitor and calibrate solid-state relay response characteristics during operation. These systems compare actual switching behavior with expected performance parameters and make real-time adjustments to control signals. The feedback loops may incorporate current sensing, voltage monitoring, or optical detection to verify switching states. This approach enables dynamic calibration that adapts to changing load conditions and relay aging effects, maintaining optimal performance throughout the device lifecycle.

- Digital calibration techniques for solid-state relay timing: Advanced digital processing methods are employed to precisely calibrate solid-state relay response characteristics. These techniques utilize microcontrollers or dedicated digital signal processors to analyze switching behavior and implement sophisticated calibration algorithms. The digital systems can store calibration parameters in non-volatile memory, allowing for adaptive calibration based on historical performance data. This approach enables precise timing adjustments at the microsecond level, critical for applications requiring exact synchronization or phase control.

- Integrated test circuits for solid-state relay calibration: Specialized test and measurement circuits are integrated within solid-state relay modules to facilitate calibration procedures. These circuits generate reference signals and measure actual switching performance without disconnecting the relay from its application. The test systems may include precision timing generators, load simulators, and measurement components that verify response characteristics under various operating conditions. This integration allows for automated calibration sequences during manufacturing and periodic recalibration during maintenance, ensuring consistent performance throughout the relay's operational life.

02 Temperature compensation in solid-state relay calibration

Temperature fluctuations significantly affect solid-state relay response characteristics. Calibration systems incorporate temperature compensation mechanisms that adjust relay parameters based on ambient or operating temperature measurements. These systems may use thermistors, temperature sensors, or thermal modeling to dynamically adjust timing parameters, ensuring consistent relay performance across a wide temperature range. Advanced implementations may include adaptive algorithms that learn and predict temperature-related drift patterns to maintain calibration accuracy over time.Expand Specific Solutions03 Feedback-based calibration systems for solid-state relays

Feedback-based calibration systems continuously monitor solid-state relay performance and automatically adjust parameters to maintain optimal response characteristics. These systems measure actual switching events against expected behavior and implement corrective adjustments in real-time. Closed-loop control architectures may incorporate current sensing, voltage monitoring, or optical feedback to detect switching transitions accurately. This approach enables self-calibrating relays that maintain consistent performance despite component aging, environmental changes, or varying load conditions.Expand Specific Solutions04 Calibration circuits for solid-state relay timing precision

Specialized calibration circuits are designed to enhance the timing precision of solid-state relays. These circuits may include precision oscillators, delay lines, phase-locked loops, or digital counters to measure and adjust switching parameters with high accuracy. Some implementations use programmable delay elements that can be fine-tuned during calibration procedures. Advanced designs may incorporate field-programmable gate arrays or microcontrollers that execute sophisticated calibration algorithms to achieve nanosecond-level precision in relay response timing.Expand Specific Solutions05 Automated testing and calibration systems for solid-state relays

Automated systems streamline the testing and calibration process for solid-state relays in manufacturing and maintenance environments. These systems typically include programmable test equipment that applies controlled signals and measures relay responses under various conditions. Software algorithms analyze performance data to determine optimal calibration parameters and may generate calibration certificates or reports. Some systems support batch calibration of multiple relays simultaneously, with capabilities for statistical process control to ensure consistent quality across production runs.Expand Specific Solutions

Leading Manufacturers and Research Institutions in SSR Technology

The solid-state relay calibration market is currently in a growth phase, characterized by increasing adoption across power grid applications. The market size is expanding due to rising demand for reliable power transmission systems, with an estimated value of $2-3 billion globally. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include State Grid Corporation of China and its research institutes (SGEPRI), which dominate the Asian market, while NARI Technology and Siemens AG offer advanced calibration solutions with proprietary algorithms. Academic institutions like Harbin Institute of Technology and Shanghai Jiao Tong University contribute significant research in addressing variability challenges. BYD and Goodwe are emerging as innovative players in integrating relay calibration with renewable energy systems, focusing on response time optimization under variable conditions.

State Grid Electric Power Research Institute

Technical Solution: State Grid Electric Power Research Institute has engineered a solid-state relay calibration system specifically designed to address variability challenges in ultra-high voltage transmission networks. Their approach combines hardware precision with advanced software algorithms to achieve consistent relay performance across diverse operating conditions. The institute's calibration technology employs reference-based comparative analysis, where each relay's performance is measured against a highly stable reference unit maintained under controlled conditions. This system features automated temperature cycling chambers that characterize relay behavior across the full operational temperature range, generating comprehensive response curves that serve as the foundation for calibration parameters. Their solution incorporates a unique drift compensation algorithm that continuously adjusts control signals based on real-time feedback from current and voltage sensors integrated into the relay circuit. The calibration process includes both initial factory calibration and periodic in-situ recalibration using portable field equipment that connects to standardized test points built into their relay designs. This methodology ensures that solid-state relays maintain precise switching characteristics despite component aging, temperature fluctuations, and load variations.

Strengths: Exceptional long-term stability of calibration parameters; comprehensive documentation of calibration history for each relay; seamless integration with existing power grid management systems. Weaknesses: Calibration equipment requires regular recertification to maintain accuracy standards; process is more time-consuming than simpler alternatives; requires specialized technical expertise for proper implementation.

China Electric Power Research Institute Ltd.

Technical Solution: China Electric Power Research Institute has developed a comprehensive solid-state relay calibration system specifically tailored for high-voltage power transmission applications. Their solution employs a three-tier calibration approach that addresses variability at the component, module, and system levels. At the core of their technology is a high-precision measurement system capable of detecting switching time variations as small as 10 microseconds across temperature ranges from -40°C to +85°C. The institute's calibration methodology incorporates environmental chambers that simulate real-world operating conditions while applying controlled test signals to characterize relay response under various stress factors. Their system utilizes machine learning algorithms trained on vast datasets of relay performance metrics to establish optimal calibration parameters for different operational scenarios. The calibration process includes both factory initialization and field recalibration capabilities, with the latter employing portable calibration units that can be deployed to remote substations. This approach ensures consistent relay performance even in geographically dispersed power networks experiencing diverse environmental conditions.

Strengths: Exceptional accuracy in timing calibration; comprehensive environmental testing capabilities; scalable from individual relay calibration to system-wide standardization. Weaknesses: Time-intensive calibration process that may impact maintenance schedules; requires specialized test equipment that represents significant capital investment; calibration parameters may need frequent updates in rapidly changing grid conditions.

Key Patents and Research in SSR Response Optimization

High-frequency solid-state relay

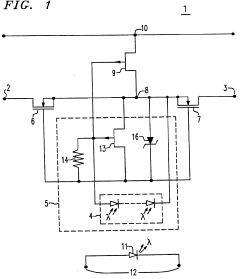

PatentInactiveUS5298817A

Innovation

- A solid-state relay design featuring a control circuit driving pass transistors and a shunt transistor, utilizing MOSFETs and JFETs with opposite bias conductivities, to minimize feed-through and maintain high isolation during signal switching, with an optical control signal converting electrical signals to control transistor conductivity.

Patent

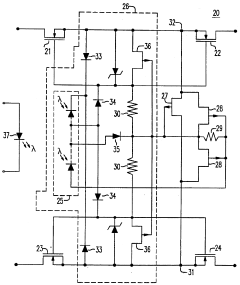

Innovation

- A calibration method for solid-state relays that compensates for manufacturing variability by measuring and storing individual relay response characteristics in memory for precise control.

- Integration of temperature compensation mechanisms that adjust relay control signals based on real-time temperature measurements to maintain consistent switching behavior across varying operating conditions.

- Implementation of a feedback loop system that continuously monitors relay performance and makes real-time adjustments to control signals, ensuring consistent operation despite component aging and environmental changes.

Environmental Factors Affecting SSR Performance

Solid-state relays (SSRs) operate under a wide range of environmental conditions that significantly impact their performance characteristics and calibration requirements. Temperature variations represent the most critical environmental factor affecting SSR operation. As ambient temperature increases, semiconductor junction resistance typically decreases, resulting in altered switching thresholds and potentially causing premature triggering or false activation. Conversely, extremely low temperatures can increase resistance, leading to delayed activation or complete failure to switch. These temperature-dependent behaviors necessitate comprehensive calibration protocols that account for the full operational temperature range.

Humidity presents another significant challenge for SSR performance stability. High moisture environments can lead to condensation on circuit boards and components, potentially creating leakage paths that compromise isolation integrity between input and output circuits. This is particularly problematic in industrial settings where SSRs may be exposed to wash-down procedures or outdoor installations. Advanced SSR designs incorporate conformal coatings and hermetic sealing techniques, but calibration procedures must still verify isolation performance across humidity variations.

Electromagnetic interference (EMI) constitutes a third major environmental factor affecting SSR reliability. Industrial environments often contain multiple sources of electromagnetic noise, including motors, welders, and power conversion equipment. This ambient EMI can induce spurious signals in SSR control circuits, leading to unpredictable switching behavior. Calibration protocols must therefore include EMI immunity testing to ensure consistent performance in electrically noisy environments.

Barometric pressure variations, while less commonly considered, become significant factors for SSRs deployed in aerospace applications or high-altitude installations. Reduced air pressure diminishes the dielectric strength of air gaps within the relay, potentially compromising isolation barriers. Calibration procedures for such applications must verify isolation performance across the expected pressure range.

Vibration and mechanical shock represent physical environmental factors that can affect SSR performance, particularly in automotive, aerospace, or heavy industrial applications. While SSRs lack moving mechanical contacts, their internal components and connections may still be susceptible to vibration-induced failures or parameter shifts. Calibration systems must incorporate vibration testing to identify potential failure modes and establish appropriate compensation mechanisms.

Dust, particulates, and corrosive atmospheres present additional environmental challenges that can degrade SSR performance over time. These contaminants may create conductive paths across isolation barriers or accelerate component degradation. Calibration intervals and procedures should be adjusted based on the severity of the deployment environment, with more frequent verification required in harsh conditions.

Humidity presents another significant challenge for SSR performance stability. High moisture environments can lead to condensation on circuit boards and components, potentially creating leakage paths that compromise isolation integrity between input and output circuits. This is particularly problematic in industrial settings where SSRs may be exposed to wash-down procedures or outdoor installations. Advanced SSR designs incorporate conformal coatings and hermetic sealing techniques, but calibration procedures must still verify isolation performance across humidity variations.

Electromagnetic interference (EMI) constitutes a third major environmental factor affecting SSR reliability. Industrial environments often contain multiple sources of electromagnetic noise, including motors, welders, and power conversion equipment. This ambient EMI can induce spurious signals in SSR control circuits, leading to unpredictable switching behavior. Calibration protocols must therefore include EMI immunity testing to ensure consistent performance in electrically noisy environments.

Barometric pressure variations, while less commonly considered, become significant factors for SSRs deployed in aerospace applications or high-altitude installations. Reduced air pressure diminishes the dielectric strength of air gaps within the relay, potentially compromising isolation barriers. Calibration procedures for such applications must verify isolation performance across the expected pressure range.

Vibration and mechanical shock represent physical environmental factors that can affect SSR performance, particularly in automotive, aerospace, or heavy industrial applications. While SSRs lack moving mechanical contacts, their internal components and connections may still be susceptible to vibration-induced failures or parameter shifts. Calibration systems must incorporate vibration testing to identify potential failure modes and establish appropriate compensation mechanisms.

Dust, particulates, and corrosive atmospheres present additional environmental challenges that can degrade SSR performance over time. These contaminants may create conductive paths across isolation barriers or accelerate component degradation. Calibration intervals and procedures should be adjusted based on the severity of the deployment environment, with more frequent verification required in harsh conditions.

Reliability Testing Standards for Calibrated SSRs

Reliability testing standards for calibrated Solid-State Relays (SSRs) have evolved significantly over the past decade to address the increasing demands for precision and consistency in industrial applications. These standards primarily focus on ensuring that calibrated SSRs maintain their specified performance parameters under various environmental and operational conditions. The International Electrotechnical Commission (IEC) has established IEC 62314 as the foundational standard for SSR reliability testing, which includes specific protocols for verifying calibration accuracy over time.

Key reliability testing parameters include load cycling endurance, temperature coefficient stability, and long-term drift measurements. According to industry benchmarks, properly calibrated SSRs should maintain switching time accuracy within ±5% of their calibrated values after 100,000 operational cycles. The JEDEC JESD22-A108 standard provides supplementary guidelines for environmental stress testing that specifically address how calibration parameters may shift under temperature extremes and humidity variations.

For applications requiring high precision, the more stringent IEC 61000-4-17 standard applies, which evaluates immunity to conducted disturbances that might affect calibration stability. This standard is particularly relevant for SSRs deployed in medical equipment and precision manufacturing environments where response variability must be minimized. Testing under this standard typically involves subjecting calibrated SSRs to ripple currents at various frequencies while monitoring for deviations in switching thresholds.

Military and aerospace applications follow the MIL-STD-883 method 1015 for burn-in testing of calibrated SSRs, requiring 168 hours of operation at elevated temperatures to identify early failures and stabilize performance parameters. This approach has been shown to reduce in-field calibration drift by approximately 40% compared to units that have not undergone such rigorous testing.

Recent developments in reliability standards now incorporate accelerated life testing methodologies that can predict long-term calibration stability. The Highly Accelerated Life Testing (HALT) and Highly Accelerated Stress Screening (HASS) protocols expose SSRs to progressively increasing stress levels to identify failure modes that might affect calibration accuracy over the product's lifetime. These methods have become industry standard practices for manufacturers seeking to validate calibration stability claims beyond the traditional 1000-hour testing window.

Compliance with these standards typically requires documentation of statistical process control data showing that calibrated parameters remain within specified tolerances across production batches. For critical applications, lot sampling and periodic verification testing are mandated to ensure ongoing reliability of calibrated SSRs throughout their operational lifecycle.

Key reliability testing parameters include load cycling endurance, temperature coefficient stability, and long-term drift measurements. According to industry benchmarks, properly calibrated SSRs should maintain switching time accuracy within ±5% of their calibrated values after 100,000 operational cycles. The JEDEC JESD22-A108 standard provides supplementary guidelines for environmental stress testing that specifically address how calibration parameters may shift under temperature extremes and humidity variations.

For applications requiring high precision, the more stringent IEC 61000-4-17 standard applies, which evaluates immunity to conducted disturbances that might affect calibration stability. This standard is particularly relevant for SSRs deployed in medical equipment and precision manufacturing environments where response variability must be minimized. Testing under this standard typically involves subjecting calibrated SSRs to ripple currents at various frequencies while monitoring for deviations in switching thresholds.

Military and aerospace applications follow the MIL-STD-883 method 1015 for burn-in testing of calibrated SSRs, requiring 168 hours of operation at elevated temperatures to identify early failures and stabilize performance parameters. This approach has been shown to reduce in-field calibration drift by approximately 40% compared to units that have not undergone such rigorous testing.

Recent developments in reliability standards now incorporate accelerated life testing methodologies that can predict long-term calibration stability. The Highly Accelerated Life Testing (HALT) and Highly Accelerated Stress Screening (HASS) protocols expose SSRs to progressively increasing stress levels to identify failure modes that might affect calibration accuracy over the product's lifetime. These methods have become industry standard practices for manufacturers seeking to validate calibration stability claims beyond the traditional 1000-hour testing window.

Compliance with these standards typically requires documentation of statistical process control data showing that calibrated parameters remain within specified tolerances across production batches. For critical applications, lot sampling and periodic verification testing are mandated to ensure ongoing reliability of calibrated SSRs throughout their operational lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!