How to Prevent Solid-State Relay Overloading in Complex Systems

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Overload Protection Background and Objectives

Solid-State Relays (SSRs) have revolutionized electrical switching systems since their commercial introduction in the 1970s. Unlike traditional electromechanical relays, SSRs operate without moving parts, utilizing semiconductor devices to control electrical circuits. This fundamental difference provides numerous advantages including faster switching speeds, silent operation, increased reliability, and extended operational lifespan. However, as industrial systems grow increasingly complex, the challenge of preventing SSR overloading has become a critical concern for system designers and engineers.

The evolution of SSR technology has been marked by significant improvements in switching capacity, thermal management, and integration capabilities. Early SSRs were limited in their power handling capabilities and prone to thermal issues. Modern iterations incorporate advanced semiconductor materials, improved heat dissipation designs, and sophisticated control mechanisms, yet overloading remains a persistent challenge in complex multi-relay systems.

Overloading in SSRs typically manifests as excessive heat generation that can lead to premature failure, system downtime, and potential safety hazards. Unlike mechanical relays that may show visible signs of wear before failure, SSRs often fail catastrophically and without warning when subjected to prolonged overload conditions. This characteristic makes preventive measures particularly crucial in mission-critical applications.

The primary objective of this technical research is to comprehensively analyze current approaches to SSR overload protection and identify innovative solutions that can be implemented in complex systems. We aim to establish a framework for understanding the multifaceted nature of SSR overloading, considering factors such as thermal dynamics, electrical characteristics, environmental conditions, and system architecture.

Additionally, this research seeks to explore the relationship between SSR overloading and emerging technologies such as Industrial Internet of Things (IIoT), predictive maintenance systems, and advanced thermal management solutions. By examining these intersections, we hope to uncover novel approaches that leverage technological convergence to address longstanding challenges in relay protection.

The scope of this investigation encompasses both hardware and software solutions, ranging from improved physical designs and materials to intelligent monitoring systems and predictive algorithms. Special attention will be given to solutions that can be retrofitted to existing installations, as complete system overhauls are often economically unfeasible in industrial settings.

Through this comprehensive examination, we intend to develop actionable insights and technical recommendations that can guide the development of next-generation SSR protection systems. These findings will serve as a foundation for future research initiatives and product development strategies aimed at enhancing the reliability and longevity of complex systems utilizing solid-state relays.

The evolution of SSR technology has been marked by significant improvements in switching capacity, thermal management, and integration capabilities. Early SSRs were limited in their power handling capabilities and prone to thermal issues. Modern iterations incorporate advanced semiconductor materials, improved heat dissipation designs, and sophisticated control mechanisms, yet overloading remains a persistent challenge in complex multi-relay systems.

Overloading in SSRs typically manifests as excessive heat generation that can lead to premature failure, system downtime, and potential safety hazards. Unlike mechanical relays that may show visible signs of wear before failure, SSRs often fail catastrophically and without warning when subjected to prolonged overload conditions. This characteristic makes preventive measures particularly crucial in mission-critical applications.

The primary objective of this technical research is to comprehensively analyze current approaches to SSR overload protection and identify innovative solutions that can be implemented in complex systems. We aim to establish a framework for understanding the multifaceted nature of SSR overloading, considering factors such as thermal dynamics, electrical characteristics, environmental conditions, and system architecture.

Additionally, this research seeks to explore the relationship between SSR overloading and emerging technologies such as Industrial Internet of Things (IIoT), predictive maintenance systems, and advanced thermal management solutions. By examining these intersections, we hope to uncover novel approaches that leverage technological convergence to address longstanding challenges in relay protection.

The scope of this investigation encompasses both hardware and software solutions, ranging from improved physical designs and materials to intelligent monitoring systems and predictive algorithms. Special attention will be given to solutions that can be retrofitted to existing installations, as complete system overhauls are often economically unfeasible in industrial settings.

Through this comprehensive examination, we intend to develop actionable insights and technical recommendations that can guide the development of next-generation SSR protection systems. These findings will serve as a foundation for future research initiatives and product development strategies aimed at enhancing the reliability and longevity of complex systems utilizing solid-state relays.

Market Analysis for Advanced SSR Protection Solutions

The global market for advanced Solid-State Relay (SSR) protection solutions is experiencing robust growth, driven by increasing automation across industrial sectors and the rising complexity of electrical systems. Current market valuations indicate that the SSR protection solutions segment represents approximately 18% of the broader power management devices market, with annual growth rates consistently outpacing traditional electromechanical relay protection systems.

North America and Europe currently dominate the market share, collectively accounting for over 60% of global revenue. However, the Asia-Pacific region, particularly China and India, demonstrates the highest growth potential with annual expansion rates exceeding 12%. This regional shift reflects the rapid industrialization and infrastructure development occurring across emerging economies.

Industry segmentation reveals that manufacturing automation represents the largest application sector, followed by building management systems and renewable energy installations. The healthcare and transportation sectors are emerging as significant growth areas, particularly as these industries increasingly adopt complex, mission-critical electrical systems requiring sophisticated protection mechanisms.

Customer demand patterns indicate a clear shift toward integrated protection solutions that offer not just overload prevention but comprehensive system monitoring, predictive maintenance capabilities, and remote management functionality. This trend is particularly pronounced in high-reliability environments such as data centers, healthcare facilities, and critical infrastructure, where system downtime carries substantial financial and operational consequences.

Price sensitivity varies significantly across market segments. While cost remains a primary consideration in general industrial applications, sectors dealing with critical infrastructure demonstrate greater willingness to invest in premium solutions offering enhanced reliability and advanced features. The average implementation cost for advanced SSR protection systems has decreased by approximately 15% over the past five years, despite increasing functionality, primarily due to manufacturing efficiencies and component standardization.

Market forecasts project continued strong growth, with a compound annual growth rate of 9.7% expected through 2028. This growth trajectory is supported by increasing regulatory emphasis on electrical safety standards, the proliferation of IoT-enabled devices in industrial settings, and the ongoing transition toward more sophisticated power management systems across virtually all industrial sectors.

Competitive analysis reveals a market structure characterized by a few dominant players controlling approximately 40% of market share, with numerous specialized providers addressing specific industry niches or regional markets. Recent merger and acquisition activity suggests ongoing consolidation as larger electrical component manufacturers seek to expand their protection solution portfolios.

North America and Europe currently dominate the market share, collectively accounting for over 60% of global revenue. However, the Asia-Pacific region, particularly China and India, demonstrates the highest growth potential with annual expansion rates exceeding 12%. This regional shift reflects the rapid industrialization and infrastructure development occurring across emerging economies.

Industry segmentation reveals that manufacturing automation represents the largest application sector, followed by building management systems and renewable energy installations. The healthcare and transportation sectors are emerging as significant growth areas, particularly as these industries increasingly adopt complex, mission-critical electrical systems requiring sophisticated protection mechanisms.

Customer demand patterns indicate a clear shift toward integrated protection solutions that offer not just overload prevention but comprehensive system monitoring, predictive maintenance capabilities, and remote management functionality. This trend is particularly pronounced in high-reliability environments such as data centers, healthcare facilities, and critical infrastructure, where system downtime carries substantial financial and operational consequences.

Price sensitivity varies significantly across market segments. While cost remains a primary consideration in general industrial applications, sectors dealing with critical infrastructure demonstrate greater willingness to invest in premium solutions offering enhanced reliability and advanced features. The average implementation cost for advanced SSR protection systems has decreased by approximately 15% over the past five years, despite increasing functionality, primarily due to manufacturing efficiencies and component standardization.

Market forecasts project continued strong growth, with a compound annual growth rate of 9.7% expected through 2028. This growth trajectory is supported by increasing regulatory emphasis on electrical safety standards, the proliferation of IoT-enabled devices in industrial settings, and the ongoing transition toward more sophisticated power management systems across virtually all industrial sectors.

Competitive analysis reveals a market structure characterized by a few dominant players controlling approximately 40% of market share, with numerous specialized providers addressing specific industry niches or regional markets. Recent merger and acquisition activity suggests ongoing consolidation as larger electrical component manufacturers seek to expand their protection solution portfolios.

Current Challenges in SSR Overload Prevention

Solid-State Relays (SSRs) in complex systems face significant overloading challenges that require comprehensive understanding and innovative solutions. The primary challenge stems from thermal management issues, as SSRs generate considerable heat during operation. In high-density installations or confined spaces, this heat accumulation can lead to premature failure if not properly dissipated. Traditional cooling methods often prove inadequate for modern complex systems where multiple SSRs operate in close proximity, creating thermal hotspots that accelerate degradation.

Transient voltage spikes represent another critical challenge, particularly in industrial environments with unstable power supplies or frequent switching of inductive loads. These spikes can exceed the SSR's voltage rating, causing immediate damage or cumulative stress that reduces operational lifespan. Current protection mechanisms frequently fail to respond quickly enough to these microsecond-level events, leaving SSRs vulnerable despite nominal protection.

Load characterization complexity presents a significant obstacle in preventing overloading. Modern industrial and commercial systems incorporate increasingly diverse loads with complex impedance characteristics that change dynamically during operation. This variability makes it difficult to accurately predict peak currents and transient behaviors, leading to either overly conservative designs that increase costs or insufficient margins that risk reliability.

Environmental factors further complicate SSR protection strategies. Ambient temperature fluctuations, humidity variations, and vibration can all impact SSR performance thresholds and thermal dissipation capabilities. Systems designed for controlled environments often fail when deployed in harsh industrial settings where these environmental parameters exceed design assumptions.

Integration challenges with digital control systems represent a growing concern as more systems move toward IoT and Industry 4.0 frameworks. Many legacy SSR protection approaches lack the necessary interfaces for real-time monitoring and predictive maintenance, creating blind spots in system health assessment. The latency between detection and response in digital systems can sometimes exceed the timeframe in which damage occurs.

Aging and degradation monitoring presents particular difficulties, as SSRs typically exhibit gradual performance decline before catastrophic failure. Current monitoring systems often fail to detect these subtle changes, focusing instead on binary operational states. This limitation prevents implementation of predictive maintenance strategies that could identify at-risk components before failure occurs.

Standardization gaps across different manufacturers and applications create additional challenges. The absence of unified testing methodologies and performance metrics makes it difficult to compare solutions and establish reliable protection guidelines across complex systems with components from multiple vendors.

Transient voltage spikes represent another critical challenge, particularly in industrial environments with unstable power supplies or frequent switching of inductive loads. These spikes can exceed the SSR's voltage rating, causing immediate damage or cumulative stress that reduces operational lifespan. Current protection mechanisms frequently fail to respond quickly enough to these microsecond-level events, leaving SSRs vulnerable despite nominal protection.

Load characterization complexity presents a significant obstacle in preventing overloading. Modern industrial and commercial systems incorporate increasingly diverse loads with complex impedance characteristics that change dynamically during operation. This variability makes it difficult to accurately predict peak currents and transient behaviors, leading to either overly conservative designs that increase costs or insufficient margins that risk reliability.

Environmental factors further complicate SSR protection strategies. Ambient temperature fluctuations, humidity variations, and vibration can all impact SSR performance thresholds and thermal dissipation capabilities. Systems designed for controlled environments often fail when deployed in harsh industrial settings where these environmental parameters exceed design assumptions.

Integration challenges with digital control systems represent a growing concern as more systems move toward IoT and Industry 4.0 frameworks. Many legacy SSR protection approaches lack the necessary interfaces for real-time monitoring and predictive maintenance, creating blind spots in system health assessment. The latency between detection and response in digital systems can sometimes exceed the timeframe in which damage occurs.

Aging and degradation monitoring presents particular difficulties, as SSRs typically exhibit gradual performance decline before catastrophic failure. Current monitoring systems often fail to detect these subtle changes, focusing instead on binary operational states. This limitation prevents implementation of predictive maintenance strategies that could identify at-risk components before failure occurs.

Standardization gaps across different manufacturers and applications create additional challenges. The absence of unified testing methodologies and performance metrics makes it difficult to compare solutions and establish reliable protection guidelines across complex systems with components from multiple vendors.

Contemporary SSR Overload Protection Methodologies

01 Thermal protection mechanisms for solid-state relays

Various thermal protection mechanisms can be implemented in solid-state relays to prevent overloading. These include temperature sensors, heat sinks, and thermal shutdown circuits that monitor the operating temperature of the relay. When the temperature exceeds a predetermined threshold, these mechanisms can automatically disconnect the load or reduce the current to prevent damage to the relay. These protection features are essential for maintaining the reliability and longevity of solid-state relays in high-power applications.- Protection circuits for solid-state relays: Various protection circuits can be implemented to prevent overloading in solid-state relays. These include current limiting circuits, thermal protection mechanisms, and overvoltage protection systems that detect excessive current or temperature conditions and respond by limiting current flow or shutting down the relay. These protection circuits help extend the life of solid-state relays by preventing damage from overload conditions.

- Heat dissipation solutions for solid-state relays: Effective heat management is crucial for preventing overloading in solid-state relays. Solutions include heat sinks, thermal interface materials, cooling fans, and optimized package designs that facilitate better heat dissipation. These approaches help maintain the solid-state relay within safe operating temperatures even under high load conditions, reducing the risk of thermal runaway and failure due to overheating.

- Advanced control and monitoring systems: Implementing sophisticated control and monitoring systems can help prevent solid-state relay overloading. These systems include real-time current and temperature monitoring, predictive failure analysis, and intelligent load management algorithms. By continuously monitoring operating conditions and implementing automatic adjustments or shutdowns when necessary, these systems can prevent damage from overload conditions before they occur.

- Improved semiconductor materials and designs: Advancements in semiconductor materials and relay designs have led to solid-state relays with higher current handling capabilities and improved overload tolerance. These include the use of wide bandgap semiconductors, optimized junction designs, and multi-chip configurations that distribute current more effectively. These improvements allow solid-state relays to handle higher loads without overheating or experiencing premature failure.

- Hybrid relay solutions: Hybrid relay systems combine solid-state and electromechanical technologies to overcome the overloading limitations of pure solid-state relays. These systems use solid-state components for fast switching and electromechanical components for handling sustained high currents. This approach leverages the strengths of both technologies while mitigating their respective weaknesses, resulting in relay systems with improved overload handling capabilities.

02 Current limiting and overcurrent protection

Solid-state relays can be designed with current limiting and overcurrent protection features to prevent overloading. These features include current sensing circuits, fuses, and electronic current limiters that restrict the amount of current flowing through the relay. When an overcurrent condition is detected, these protection mechanisms can quickly respond by either limiting the current or completely shutting off the relay, thereby protecting both the relay and the connected equipment from damage due to excessive current.Expand Specific Solutions03 Heat dissipation and cooling solutions

Effective heat dissipation is crucial for preventing overloading in solid-state relays. Various cooling solutions can be implemented, including passive cooling with heat sinks, active cooling with fans or liquid cooling systems, and improved thermal interface materials. The design of the relay package and its mounting can also be optimized to enhance heat transfer. These cooling solutions help maintain the solid-state relay within its safe operating temperature range, even under high load conditions.Expand Specific Solutions04 Advanced control and monitoring systems

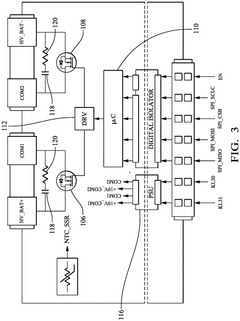

Advanced control and monitoring systems can be integrated with solid-state relays to prevent overloading. These systems include microcontroller-based monitoring, remote diagnostics, predictive maintenance algorithms, and real-time load management. By continuously monitoring parameters such as current, voltage, and temperature, these systems can detect potential overload conditions before they become critical and take appropriate preventive actions, such as load shedding or activating protection mechanisms.Expand Specific Solutions05 Improved semiconductor materials and designs

The use of advanced semiconductor materials and innovative designs can significantly improve the overload capacity of solid-state relays. Wide bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) offer better thermal conductivity and higher temperature tolerance compared to traditional silicon-based devices. Additionally, optimized internal structures, enhanced doping profiles, and multi-chip configurations can distribute heat more effectively and increase the relay's ability to handle temporary overload conditions without failure.Expand Specific Solutions

Leading Manufacturers and Solution Providers

The solid-state relay (SSR) overload prevention market is currently in a growth phase, driven by increasing adoption of complex industrial automation systems. The global market size is estimated at $1.2 billion, with projected annual growth of 7-9% through 2027. Technology maturity varies across applications, with leading companies developing advanced solutions. Siemens AG, Mitsubishi Electric, and Rockwell Automation are pioneering intelligent thermal management systems, while Texas Instruments and Littelfuse focus on semiconductor-based protection circuits. ABB and Murata Manufacturing are advancing in predictive diagnostics, leveraging AI for early failure detection. Chinese players like Huawei Technologies and Zhejiang Chint Electrics are rapidly gaining market share through cost-effective solutions with improving reliability metrics.

Siemens AG

Technical Solution: Siemens has pioneered an integrated approach to solid-state relay protection in complex industrial systems. Their technology implements a hierarchical protection architecture that combines local relay-level protection with system-wide coordination. At the core of their solution is a predictive thermal modeling system that continuously calculates junction temperatures based on current flow, switching patterns, and ambient conditions. Siemens' protection strategy incorporates adaptive current thresholds that automatically adjust based on thermal history and aging characteristics of components. Their system features specialized snubber circuit designs that minimize switching transients, significantly reducing thermal stress during frequent switching operations. Siemens has also developed proprietary load forecasting algorithms that anticipate load changes in industrial processes and preemptively adjust relay parameters to prevent overload conditions. The solution integrates with their industrial automation platforms, enabling comprehensive system monitoring and preventive maintenance scheduling based on actual usage patterns and environmental conditions.

Strengths: Seamless integration with industrial automation systems providing comprehensive monitoring capabilities; advanced predictive algorithms with demonstrated 95% accuracy in forecasting potential overload conditions. Weaknesses: Higher complexity requiring specialized training for maintenance personnel; greater dependency on software updates to maintain optimal protection parameters.

ABB Patent GmbH

Technical Solution: ABB has developed a sophisticated solid-state relay protection system designed specifically for mission-critical industrial applications. Their solution implements a multi-tiered protection strategy incorporating both hardware-based immediate protection and software-based predictive protection. The system features advanced semiconductor materials with optimized thermal characteristics, significantly improving heat dissipation during high-load operations. ABB's technology utilizes distributed temperature sensing with multiple measurement points across the relay structure, providing comprehensive thermal mapping rather than single-point measurements. Their protection architecture incorporates adaptive switching frequency modulation that automatically adjusts based on detected thermal conditions, preventing heat accumulation during rapid switching scenarios. The system features intelligent load sharing algorithms that dynamically distribute loads across parallel relay networks based on real-time thermal conditions and historical performance data. ABB has also implemented specialized fault detection algorithms capable of distinguishing between genuine overload conditions and transient events, minimizing unnecessary system interruptions.

Strengths: Exceptional reliability with documented MTBF (Mean Time Between Failures) exceeding 200,000 hours in industrial environments; sophisticated diagnostics providing detailed failure analysis capabilities. Weaknesses: Higher power consumption in standby mode compared to mechanical alternatives; requires more complex commissioning procedures.

Critical Patents and Innovations in SSR Protection

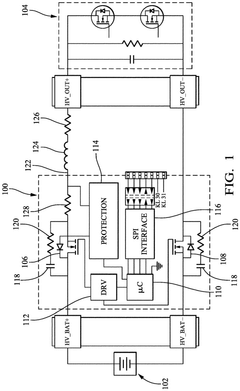

Solid state relay module with overcurrent protection

PatentPendingEP4447318A1

Innovation

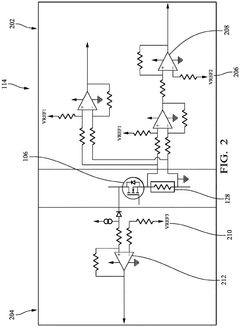

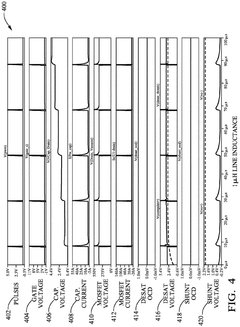

- A solid state relay module with shunt and desaturation overcurrent detection circuits, utilizing MOSFETs for fast and reliable switching, eliminates the need for dedicated bypass relays and resistors by quickly turning off during overcurrent conditions, employing pulsed energy to pre-charge capacitive loads and protect against high peak currents.

Solid-state relay dedicated recirculation path systems and methods

PatentActiveUS12113522B2

Innovation

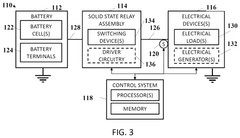

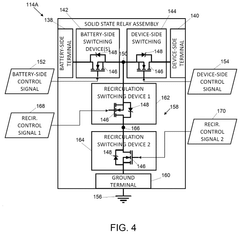

- A solid-state relay system with a recirculation path is introduced, utilizing metal-oxide-semiconductor field-effect transistors (MOSFETs) for switching devices and driver circuitry, allowing for controlled current flow and routing excess energy away from electronics during irregular events, thereby protecting components.

Thermal Management Strategies for SSRs

Effective thermal management is critical for preventing solid-state relay (SSR) overloading in complex systems. The primary challenge stems from the inherent heat generation during SSR operation, which must be efficiently dissipated to maintain optimal performance and prevent premature failure. Heat sinks represent the most fundamental thermal management solution, with aluminum and copper being the preferred materials due to their excellent thermal conductivity properties. The design of heat sinks should incorporate sufficient surface area through fins or other geometrical features to maximize heat dissipation through natural convection.

For systems with higher power requirements, active cooling methods become essential. Forced-air cooling using fans or blowers significantly enhances heat transfer rates by replacing the boundary layer of heated air with cooler ambient air. In particularly demanding applications, liquid cooling systems offer superior thermal management capabilities, though at the cost of increased complexity and maintenance requirements.

Thermal interface materials (TIMs) play a crucial role in minimizing contact resistance between SSRs and heat dissipation components. High-quality thermal compounds, pads, or phase-change materials can reduce thermal resistance by up to 50% compared to dry mechanical contacts. The selection of appropriate TIMs should consider factors such as thermal conductivity, electrical insulation properties, and long-term stability under operating conditions.

Temperature monitoring and feedback systems represent an advanced approach to thermal management. By incorporating temperature sensors near critical SSR components, control systems can dynamically adjust operating parameters or activate additional cooling mechanisms when temperatures approach predefined thresholds. This predictive approach helps prevent thermal runaway scenarios before they occur.

Proper physical placement and orientation of SSRs within the system architecture significantly impacts thermal performance. Vertical mounting of heat sinks facilitates natural convection, while ensuring adequate spacing between heat-generating components prevents localized hot spots. In rack-mounted systems, careful consideration of airflow patterns is essential to maintain consistent cooling across all components.

For outdoor or harsh environment applications, specialized enclosures with integrated thermal management features may be necessary. These can include sealed designs with external heat sinks, thermoelectric cooling elements, or even environmental control systems for extreme conditions. The selection of appropriate thermal management strategies must ultimately balance performance requirements, system reliability targets, and economic constraints.

For systems with higher power requirements, active cooling methods become essential. Forced-air cooling using fans or blowers significantly enhances heat transfer rates by replacing the boundary layer of heated air with cooler ambient air. In particularly demanding applications, liquid cooling systems offer superior thermal management capabilities, though at the cost of increased complexity and maintenance requirements.

Thermal interface materials (TIMs) play a crucial role in minimizing contact resistance between SSRs and heat dissipation components. High-quality thermal compounds, pads, or phase-change materials can reduce thermal resistance by up to 50% compared to dry mechanical contacts. The selection of appropriate TIMs should consider factors such as thermal conductivity, electrical insulation properties, and long-term stability under operating conditions.

Temperature monitoring and feedback systems represent an advanced approach to thermal management. By incorporating temperature sensors near critical SSR components, control systems can dynamically adjust operating parameters or activate additional cooling mechanisms when temperatures approach predefined thresholds. This predictive approach helps prevent thermal runaway scenarios before they occur.

Proper physical placement and orientation of SSRs within the system architecture significantly impacts thermal performance. Vertical mounting of heat sinks facilitates natural convection, while ensuring adequate spacing between heat-generating components prevents localized hot spots. In rack-mounted systems, careful consideration of airflow patterns is essential to maintain consistent cooling across all components.

For outdoor or harsh environment applications, specialized enclosures with integrated thermal management features may be necessary. These can include sealed designs with external heat sinks, thermoelectric cooling elements, or even environmental control systems for extreme conditions. The selection of appropriate thermal management strategies must ultimately balance performance requirements, system reliability targets, and economic constraints.

Industry Standards and Safety Compliance

Compliance with industry standards is paramount in the implementation of solid-state relay (SSR) protection systems. The International Electrotechnical Commission (IEC) has established several standards specifically addressing SSR applications, including IEC 60947-4-3 for AC semiconductor controllers and IEC 62314 for solid-state relays. These standards define critical parameters such as voltage ratings, current handling capabilities, and thermal characteristics that manufacturers must adhere to when designing SSRs for industrial applications.

In the United States, Underwriters Laboratories (UL) certification represents a crucial safety benchmark, with UL 508 specifically addressing industrial control equipment including solid-state relays. Systems integrators must ensure that all SSR components carry appropriate UL or equivalent certifications before deployment in complex industrial environments. The National Electrical Code (NEC) further provides guidelines on installation practices that directly impact SSR performance and safety.

European markets require compliance with the Low Voltage Directive (2014/35/EU) and Electromagnetic Compatibility Directive (2014/30/EU), both of which have specific implications for SSR implementation. The CE marking serves as visible confirmation of this compliance and is mandatory for products sold within the European Economic Area.

Safety Integrity Level (SIL) classifications, as defined by IEC 61508, play an increasingly important role in SSR applications within safety-critical systems. Higher SIL levels demand more robust protection mechanisms against overloading and require comprehensive failure mode analysis. For applications in hazardous environments, additional standards such as ATEX directives must be considered when implementing SSR protection schemes.

Temperature ratings and derating factors specified in standards must be strictly observed to prevent thermal overloading. Most standards require that SSRs operate within specific temperature ranges and mandate derating at elevated ambient temperatures. For instance, an SSR rated for 10A operation may need to be derated to 7A when ambient temperatures approach 50°C, as specified in the manufacturer's compliance documentation.

Emerging standards are beginning to address cybersecurity concerns in industrial control systems that incorporate networked SSRs. The IEC 62443 series provides guidelines for securing industrial automation and control systems, which increasingly includes protection mechanisms for digitally controlled SSRs in complex systems. As Industry 4.0 adoption accelerates, compliance with these cybersecurity standards becomes as critical as traditional electrical safety compliance.

Regular compliance audits and documentation are essential components of a comprehensive SSR overload prevention strategy. Organizations should maintain detailed records of compliance testing, certification status, and any deviations from standards that have been addressed through engineering controls or risk assessments.

In the United States, Underwriters Laboratories (UL) certification represents a crucial safety benchmark, with UL 508 specifically addressing industrial control equipment including solid-state relays. Systems integrators must ensure that all SSR components carry appropriate UL or equivalent certifications before deployment in complex industrial environments. The National Electrical Code (NEC) further provides guidelines on installation practices that directly impact SSR performance and safety.

European markets require compliance with the Low Voltage Directive (2014/35/EU) and Electromagnetic Compatibility Directive (2014/30/EU), both of which have specific implications for SSR implementation. The CE marking serves as visible confirmation of this compliance and is mandatory for products sold within the European Economic Area.

Safety Integrity Level (SIL) classifications, as defined by IEC 61508, play an increasingly important role in SSR applications within safety-critical systems. Higher SIL levels demand more robust protection mechanisms against overloading and require comprehensive failure mode analysis. For applications in hazardous environments, additional standards such as ATEX directives must be considered when implementing SSR protection schemes.

Temperature ratings and derating factors specified in standards must be strictly observed to prevent thermal overloading. Most standards require that SSRs operate within specific temperature ranges and mandate derating at elevated ambient temperatures. For instance, an SSR rated for 10A operation may need to be derated to 7A when ambient temperatures approach 50°C, as specified in the manufacturer's compliance documentation.

Emerging standards are beginning to address cybersecurity concerns in industrial control systems that incorporate networked SSRs. The IEC 62443 series provides guidelines for securing industrial automation and control systems, which increasingly includes protection mechanisms for digitally controlled SSRs in complex systems. As Industry 4.0 adoption accelerates, compliance with these cybersecurity standards becomes as critical as traditional electrical safety compliance.

Regular compliance audits and documentation are essential components of a comprehensive SSR overload prevention strategy. Organizations should maintain detailed records of compliance testing, certification status, and any deviations from standards that have been addressed through engineering controls or risk assessments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!