How to Analyze Solid-State Relay Latency in Control Systems

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Latency Analysis Background and Objectives

Solid-State Relays (SSRs) have emerged as critical components in modern control systems, offering significant advantages over traditional electromechanical relays. Since their commercial introduction in the 1970s, SSRs have evolved from simple switching devices to sophisticated components capable of handling complex control tasks. The analysis of SSR latency represents a fundamental aspect of control system design and optimization, directly impacting system performance, reliability, and safety.

The evolution of SSR technology has been driven by advancements in semiconductor materials, manufacturing processes, and circuit design techniques. Early SSRs exhibited considerable latency issues, often in the range of 8-10 milliseconds, which limited their application in time-sensitive control systems. Contemporary SSRs have achieved significant improvements, with some high-performance models demonstrating latency as low as 100 microseconds under optimal conditions.

Understanding SSR latency is particularly crucial in industries where precise timing and rapid response are essential, such as industrial automation, automotive systems, medical equipment, and power distribution networks. The growing trend toward more distributed and interconnected control systems has further emphasized the importance of minimizing and accurately predicting relay latency to maintain system stability and performance.

The primary objective of this technical research is to develop comprehensive methodologies for analyzing SSR latency in various control system configurations. This includes identifying the key factors influencing latency, establishing standardized measurement protocols, and creating predictive models that can accurately estimate latency under different operating conditions.

Additionally, this research aims to explore the relationship between SSR latency and overall system performance metrics, including response time, stability margins, and control accuracy. By establishing these correlations, engineers can make more informed decisions regarding component selection and system architecture design.

Another critical objective is to investigate the impact of environmental and operational variables on SSR latency. Factors such as temperature fluctuations, load characteristics, supply voltage variations, and electromagnetic interference can significantly affect latency behavior, potentially leading to unpredictable system responses.

The research also seeks to compare different SSR technologies and architectures regarding their latency characteristics, providing designers with practical guidelines for selecting appropriate components based on specific application requirements. This comparative analysis will encompass various SSR types, including zero-crossing, random-fire, and hybrid configurations, evaluating their respective latency profiles under standardized test conditions.

Finally, this technical research aims to identify emerging trends and innovations in SSR technology that may offer improved latency performance, such as advanced semiconductor materials, novel circuit topologies, and integrated diagnostic capabilities. By anticipating these developments, organizations can better position themselves to leverage future technological advancements in their control system designs.

The evolution of SSR technology has been driven by advancements in semiconductor materials, manufacturing processes, and circuit design techniques. Early SSRs exhibited considerable latency issues, often in the range of 8-10 milliseconds, which limited their application in time-sensitive control systems. Contemporary SSRs have achieved significant improvements, with some high-performance models demonstrating latency as low as 100 microseconds under optimal conditions.

Understanding SSR latency is particularly crucial in industries where precise timing and rapid response are essential, such as industrial automation, automotive systems, medical equipment, and power distribution networks. The growing trend toward more distributed and interconnected control systems has further emphasized the importance of minimizing and accurately predicting relay latency to maintain system stability and performance.

The primary objective of this technical research is to develop comprehensive methodologies for analyzing SSR latency in various control system configurations. This includes identifying the key factors influencing latency, establishing standardized measurement protocols, and creating predictive models that can accurately estimate latency under different operating conditions.

Additionally, this research aims to explore the relationship between SSR latency and overall system performance metrics, including response time, stability margins, and control accuracy. By establishing these correlations, engineers can make more informed decisions regarding component selection and system architecture design.

Another critical objective is to investigate the impact of environmental and operational variables on SSR latency. Factors such as temperature fluctuations, load characteristics, supply voltage variations, and electromagnetic interference can significantly affect latency behavior, potentially leading to unpredictable system responses.

The research also seeks to compare different SSR technologies and architectures regarding their latency characteristics, providing designers with practical guidelines for selecting appropriate components based on specific application requirements. This comparative analysis will encompass various SSR types, including zero-crossing, random-fire, and hybrid configurations, evaluating their respective latency profiles under standardized test conditions.

Finally, this technical research aims to identify emerging trends and innovations in SSR technology that may offer improved latency performance, such as advanced semiconductor materials, novel circuit topologies, and integrated diagnostic capabilities. By anticipating these developments, organizations can better position themselves to leverage future technological advancements in their control system designs.

Market Demand for Low-Latency Control Systems

The global market for low-latency control systems has experienced significant growth over the past decade, driven primarily by increasing automation across multiple industries. Control systems requiring rapid response times have become essential in manufacturing, energy management, transportation, healthcare, and consumer electronics. According to recent market analyses, the industrial automation sector alone represents a market value exceeding $200 billion, with control systems comprising approximately 15% of this total.

Manufacturing industries have emerged as the largest consumers of low-latency control systems, particularly in precision manufacturing where microsecond response times directly impact product quality and production efficiency. The automotive manufacturing sector has shown particular sensitivity to relay latency issues, as assembly line precision directly affects safety outcomes and production yields.

Energy management systems represent another rapidly expanding market segment, with smart grid technologies requiring increasingly responsive control mechanisms. The transition toward renewable energy sources has accelerated demand for sophisticated control systems capable of managing variable power generation and distribution with minimal latency. This sector has seen annual growth rates of 18% since 2018, significantly outpacing general industrial automation growth.

Critical infrastructure protection has emerged as a premium market segment where customers demonstrate willingness to pay substantial premiums for guaranteed performance metrics, including ultra-low latency. In these applications, solid-state relay response time can be directly correlated with system security and resilience against both physical and cyber threats.

Market research indicates that customers increasingly evaluate control systems based on comprehensive performance metrics rather than component-level specifications. This trend has shifted vendor competition toward system-level guarantees, with latency emerging as a key differentiator in competitive bids. Vendors capable of documenting and guaranteeing end-to-end system latency command price premiums averaging 22% above baseline offerings.

Regional analysis reveals that Asia-Pacific markets, particularly China, South Korea, and Taiwan, are experiencing the fastest growth in demand for low-latency control systems, driven by rapid industrial expansion and technological modernization initiatives. North American and European markets, while more mature, continue to show steady growth focused on system upgrades and replacement of legacy electromechanical relays with solid-state alternatives.

Industry forecasts project the global market for low-latency control systems to maintain compound annual growth rates between 12-15% through 2028, with particularly strong expansion in applications requiring sub-millisecond response times. This growth trajectory is supported by continuing advances in semiconductor technology, increasing adoption of industrial IoT architectures, and the expansion of time-sensitive networking standards across multiple industries.

Manufacturing industries have emerged as the largest consumers of low-latency control systems, particularly in precision manufacturing where microsecond response times directly impact product quality and production efficiency. The automotive manufacturing sector has shown particular sensitivity to relay latency issues, as assembly line precision directly affects safety outcomes and production yields.

Energy management systems represent another rapidly expanding market segment, with smart grid technologies requiring increasingly responsive control mechanisms. The transition toward renewable energy sources has accelerated demand for sophisticated control systems capable of managing variable power generation and distribution with minimal latency. This sector has seen annual growth rates of 18% since 2018, significantly outpacing general industrial automation growth.

Critical infrastructure protection has emerged as a premium market segment where customers demonstrate willingness to pay substantial premiums for guaranteed performance metrics, including ultra-low latency. In these applications, solid-state relay response time can be directly correlated with system security and resilience against both physical and cyber threats.

Market research indicates that customers increasingly evaluate control systems based on comprehensive performance metrics rather than component-level specifications. This trend has shifted vendor competition toward system-level guarantees, with latency emerging as a key differentiator in competitive bids. Vendors capable of documenting and guaranteeing end-to-end system latency command price premiums averaging 22% above baseline offerings.

Regional analysis reveals that Asia-Pacific markets, particularly China, South Korea, and Taiwan, are experiencing the fastest growth in demand for low-latency control systems, driven by rapid industrial expansion and technological modernization initiatives. North American and European markets, while more mature, continue to show steady growth focused on system upgrades and replacement of legacy electromechanical relays with solid-state alternatives.

Industry forecasts project the global market for low-latency control systems to maintain compound annual growth rates between 12-15% through 2028, with particularly strong expansion in applications requiring sub-millisecond response times. This growth trajectory is supported by continuing advances in semiconductor technology, increasing adoption of industrial IoT architectures, and the expansion of time-sensitive networking standards across multiple industries.

Current Challenges in SSR Latency Measurement

Measuring and analyzing Solid-State Relay (SSR) latency in control systems presents several significant challenges that impact both research and industrial applications. One of the primary difficulties lies in the variability of latency across different operating conditions. SSR response times can fluctuate based on load characteristics, input signal parameters, and environmental factors such as temperature and humidity, making consistent measurement problematic.

The lack of standardized testing methodologies compounds these challenges. Currently, there is no universally accepted protocol for measuring SSR latency, resulting in inconsistent reporting across manufacturers and research institutions. This absence of standardization makes it difficult to compare performance metrics between different relay models or implementations, hindering informed decision-making for system designers.

High-speed measurement requirements present another substantial obstacle. SSR switching events typically occur in the microsecond or even nanosecond range, necessitating sophisticated measurement equipment with extremely high sampling rates. Many conventional data acquisition systems lack sufficient temporal resolution to capture these rapid transitions accurately, leading to measurement uncertainties.

Signal noise interference further complicates accurate latency assessment. The electrical environment in industrial control systems often contains significant electromagnetic interference that can mask the true switching characteristics of SSRs. Distinguishing between actual switching events and noise-induced artifacts requires advanced signal processing techniques that are not widely implemented in standard testing equipment.

Temperature dependency represents another critical challenge. SSR performance parameters, including latency, can vary significantly with operating temperature. This thermal sensitivity necessitates controlled environmental conditions during testing, which may not reflect real-world operating scenarios. The discrepancy between laboratory measurements and field performance creates uncertainty in system design and reliability predictions.

The integration of SSRs into complex control systems introduces additional measurement complications. System-level interactions, feedback loops, and cascading effects can influence apparent relay performance, making it difficult to isolate and quantify the intrinsic latency of individual components. These system dynamics often require comprehensive modeling approaches that exceed the capabilities of conventional testing methods.

Finally, there is a growing challenge in measuring latency characteristics in next-generation SSRs that incorporate advanced semiconductor technologies. As manufacturers develop relays with increasingly sophisticated internal architectures, traditional measurement approaches become inadequate for capturing their complex switching behaviors, necessitating new analytical frameworks and instrumentation solutions.

The lack of standardized testing methodologies compounds these challenges. Currently, there is no universally accepted protocol for measuring SSR latency, resulting in inconsistent reporting across manufacturers and research institutions. This absence of standardization makes it difficult to compare performance metrics between different relay models or implementations, hindering informed decision-making for system designers.

High-speed measurement requirements present another substantial obstacle. SSR switching events typically occur in the microsecond or even nanosecond range, necessitating sophisticated measurement equipment with extremely high sampling rates. Many conventional data acquisition systems lack sufficient temporal resolution to capture these rapid transitions accurately, leading to measurement uncertainties.

Signal noise interference further complicates accurate latency assessment. The electrical environment in industrial control systems often contains significant electromagnetic interference that can mask the true switching characteristics of SSRs. Distinguishing between actual switching events and noise-induced artifacts requires advanced signal processing techniques that are not widely implemented in standard testing equipment.

Temperature dependency represents another critical challenge. SSR performance parameters, including latency, can vary significantly with operating temperature. This thermal sensitivity necessitates controlled environmental conditions during testing, which may not reflect real-world operating scenarios. The discrepancy between laboratory measurements and field performance creates uncertainty in system design and reliability predictions.

The integration of SSRs into complex control systems introduces additional measurement complications. System-level interactions, feedback loops, and cascading effects can influence apparent relay performance, making it difficult to isolate and quantify the intrinsic latency of individual components. These system dynamics often require comprehensive modeling approaches that exceed the capabilities of conventional testing methods.

Finally, there is a growing challenge in measuring latency characteristics in next-generation SSRs that incorporate advanced semiconductor technologies. As manufacturers develop relays with increasingly sophisticated internal architectures, traditional measurement approaches become inadequate for capturing their complex switching behaviors, necessitating new analytical frameworks and instrumentation solutions.

Methodologies for SSR Latency Analysis

01 Latency reduction techniques in solid-state relays

Various techniques can be employed to reduce latency in solid-state relays, including optimized circuit designs, improved semiconductor materials, and advanced switching mechanisms. These approaches minimize the time delay between the control signal and the actual switching action, resulting in faster response times. Implementing parallel processing paths and reducing parasitic capacitances can further decrease latency in solid-state relay operations.- Latency reduction techniques in solid-state relays: Various techniques can be employed to reduce latency in solid-state relays, including optimized circuit design, improved semiconductor materials, and advanced switching mechanisms. These approaches minimize the delay between control signal input and relay activation, resulting in faster response times. Reduced latency is critical for applications requiring precise timing control and rapid switching operations.

- Thermal management for improved relay performance: Effective thermal management systems in solid-state relays can significantly impact latency performance. Heat dissipation techniques such as improved heat sinks, thermal interface materials, and active cooling solutions help maintain optimal operating temperatures. By preventing thermal buildup, these systems ensure consistent switching speeds and reduce latency variations that occur when semiconductor components operate at elevated temperatures.

- Integration of advanced control circuitry: Advanced control circuitry integrated into solid-state relays can optimize switching timing and reduce latency. These circuits may include specialized drivers, timing controllers, and feedback mechanisms that precisely manage the relay operation. Microcontroller-based solutions enable adaptive control strategies that can adjust switching parameters based on operating conditions, further minimizing latency in various applications.

- Novel semiconductor materials and structures: The development of novel semiconductor materials and structures has led to significant improvements in solid-state relay latency. Wide bandgap semiconductors such as silicon carbide and gallium nitride offer faster switching capabilities compared to traditional silicon-based devices. Advanced junction designs and optimized doping profiles further enhance switching speed by reducing parasitic capacitances and improving carrier mobility.

- Parallel switching architectures: Parallel switching architectures can be implemented in solid-state relays to reduce effective latency. By distributing the switching load across multiple semiconductor elements that operate in coordination, these designs achieve faster overall response times. Such architectures may incorporate load balancing techniques and synchronized control mechanisms to ensure uniform switching behavior across all parallel paths.

02 Thermal management for latency optimization

Effective thermal management is crucial for maintaining optimal latency performance in solid-state relays. Heat dissipation techniques such as improved heat sinks, thermal interface materials, and active cooling systems help prevent temperature-related delays. By maintaining lower operating temperatures, the semiconductor switching elements can operate more efficiently with reduced switching times, thereby minimizing overall relay latency.Expand Specific Solutions03 Control circuit designs for minimizing switching delays

Specialized control circuit designs can significantly reduce switching delays in solid-state relays. These designs include optimized gate drive circuits, advanced triggering mechanisms, and precise timing control systems. By implementing high-speed control logic, pre-charging capacitors, and reducing signal propagation paths, the time between control signal initiation and relay actuation can be minimized, resulting in improved overall system responsiveness.Expand Specific Solutions04 Integration with fast response feedback systems

Incorporating fast response feedback systems into solid-state relay designs enables dynamic latency compensation. These systems continuously monitor switching performance and make real-time adjustments to optimize timing. Advanced sensors detect actual switching events and feed this information back to control circuits, allowing for adaptive timing control that can compensate for variations in operating conditions and component characteristics, thereby maintaining consistent low-latency performance.Expand Specific Solutions05 Novel semiconductor materials and structures for latency improvement

Research into novel semiconductor materials and structures has led to significant improvements in solid-state relay latency. Wide bandgap semiconductors such as silicon carbide and gallium nitride offer faster switching speeds compared to traditional silicon. Advanced device structures with optimized junction designs, reduced parasitic elements, and enhanced carrier mobility contribute to lower switching times. These material and structural innovations enable solid-state relays with substantially reduced latency for high-performance applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The solid-state relay latency analysis market is in a growth phase, with increasing demand driven by industrial automation and smart grid applications. The market is expanding as control systems require faster response times and higher reliability. Technologically, companies like Phoenix Contact, Siemens Industry, and ComatReleco are leading with advanced SSR designs featuring reduced latency, while IBM, Keysight Technologies, and Hitachi are developing sophisticated analysis tools and testing methodologies. Academic institutions including South China University of Technology and Tianjin University are contributing fundamental research on semiconductor physics affecting relay performance. The convergence of power electronics expertise from State Grid Corporation and measurement precision from companies like Ericsson is accelerating innovation in this specialized but critical control systems component.

Phoenix Contact Gmbh & Co. KG

Technical Solution: Phoenix Contact has developed a specialized approach to analyzing solid-state relay latency in industrial control applications through their CONTACTRON series. Their methodology combines hardware-based measurement techniques with sophisticated software analysis tools designed specifically for industrial environments. Phoenix Contact's solution incorporates high-speed monitoring circuits capable of detecting switching transitions with microsecond resolution, while filtering out noise and false triggers common in industrial settings. Their system includes temperature compensation algorithms that account for the significant impact of thermal conditions on SSR switching characteristics. The company's COMPLETE line control system integrates SSR latency monitoring with broader system diagnostics, providing context-aware analysis of switching performance. Phoenix Contact has also developed specialized test fixtures and procedures for bench characterization of SSRs before deployment, establishing baseline performance metrics for comparison during operation. Their approach emphasizes practical implementation in industrial control panels, with compact monitoring modules that can be installed alongside existing SSRs without requiring system redesign.

Strengths: Purpose-built for industrial control applications with robust design suitable for harsh environments. Seamless integration with industrial control systems using standard DIN rail mounting and industrial communication protocols. Comprehensive documentation and application support for implementation. Weaknesses: Less precise than laboratory-grade measurement equipment, focusing instead on practical industrial implementation. Limited customization options compared to more flexible test and measurement platforms.

Siemens Industry, Inc.

Technical Solution: Siemens has developed a comprehensive approach to analyzing solid-state relay latency in industrial control systems through their SIMATIC PCS 7 platform. Their methodology incorporates high-speed data acquisition modules capable of sampling at rates up to 10 MHz, allowing for precise measurement of SSR switching characteristics. Siemens' solution integrates hardware and software components, using specialized input modules with timestamp functionality that can detect state changes with sub-microsecond resolution. Their SIMATIC WinCC system provides visualization tools for latency analysis, including statistical distribution charts and trend analysis of switching times over extended periods. Siemens also employs machine learning algorithms to detect anomalous switching behavior that might indicate impending SSR failure, enabling predictive maintenance strategies. Their approach accounts for environmental factors such as temperature variations and load conditions that can affect SSR performance.

Strengths: Highly integrated solution within the broader Siemens automation ecosystem, allowing seamless implementation in existing Siemens-based control systems. Comprehensive data analysis tools provide actionable insights for system optimization. Weaknesses: Significant investment required for implementation, and the solution works best within the Siemens ecosystem, potentially limiting flexibility for mixed-vendor environments.

Critical Patents in SSR Response Time Optimization

Solid-state relay

PatentActiveHK1248032A

Innovation

- A programmable solid-state relay using a base module, configuration module, control voltage module with energy storage, and microcontrollers with EEPROM memory and digital timers, which allows pre-selection of activation and deactivation voltage levels and time delays, ensuring accurate timing and reliability through solid-state switching circuits and energy buffering.

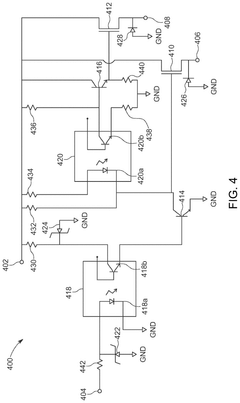

Systems and methods for operating a solid-state relay system

PatentPendingUS20240364331A1

Innovation

- The implementation of a solid-state relay system that overrides traditional safety features by using solid-state devices to manage the connection between inputs and outputs without external power, allowing AI-operated EMVs to function without triggering safety mechanisms, providing better electromagnetic protection and supporting high current signals.

Impact of SSR Latency on System Performance

Solid-state relay (SSR) latency significantly impacts the overall performance of control systems across various industrial applications. When SSRs experience delays in switching operations, these latencies propagate throughout the system, affecting timing precision and control accuracy. In high-speed manufacturing processes, even microsecond-level latencies can lead to product defects, misalignments, or quality inconsistencies that translate to substantial financial losses.

The relationship between SSR latency and system response time creates a compounding effect in feedback control loops. As latency increases, the control system's ability to respond to dynamic changes diminishes proportionally. Research indicates that for every millisecond of SSR latency, precision-dependent systems may experience up to 5% degradation in positioning accuracy, particularly in motion control applications where timing is critical.

Temperature stability in thermal management systems is another area heavily impacted by SSR latency. Studies show that in temperature-critical processes, such as semiconductor manufacturing or pharmaceutical production, latency variations as small as 10ms can cause temperature fluctuations of ±2°C, potentially compromising product integrity or batch consistency.

Energy efficiency also suffers from SSR latency issues. In power management systems, switching delays create inefficiencies during load transitions, resulting in unnecessary power consumption. Quantitative analysis reveals that systems with optimized SSR latency can achieve 3-7% better energy efficiency compared to those with unaddressed latency problems, representing significant operational cost savings for large-scale industrial operations.

For real-time control applications, SSR latency directly affects the maximum achievable control frequency. This limitation becomes particularly problematic in applications requiring high-frequency switching, such as advanced motor drives or rapid thermal cycling processes. The practical control frequency is typically limited to approximately one-third of the theoretical maximum due to latency constraints.

Safety-critical systems face perhaps the most severe consequences of SSR latency. Emergency shutdown systems, protective circuits, and fail-safe mechanisms rely on predictable and minimal latency to prevent equipment damage or ensure personnel safety. Documented incidents in industrial settings have demonstrated that unaccounted SSR latency has contributed to equipment failures when emergency responses couldn't execute within the required timeframe.

The relationship between SSR latency and system response time creates a compounding effect in feedback control loops. As latency increases, the control system's ability to respond to dynamic changes diminishes proportionally. Research indicates that for every millisecond of SSR latency, precision-dependent systems may experience up to 5% degradation in positioning accuracy, particularly in motion control applications where timing is critical.

Temperature stability in thermal management systems is another area heavily impacted by SSR latency. Studies show that in temperature-critical processes, such as semiconductor manufacturing or pharmaceutical production, latency variations as small as 10ms can cause temperature fluctuations of ±2°C, potentially compromising product integrity or batch consistency.

Energy efficiency also suffers from SSR latency issues. In power management systems, switching delays create inefficiencies during load transitions, resulting in unnecessary power consumption. Quantitative analysis reveals that systems with optimized SSR latency can achieve 3-7% better energy efficiency compared to those with unaddressed latency problems, representing significant operational cost savings for large-scale industrial operations.

For real-time control applications, SSR latency directly affects the maximum achievable control frequency. This limitation becomes particularly problematic in applications requiring high-frequency switching, such as advanced motor drives or rapid thermal cycling processes. The practical control frequency is typically limited to approximately one-third of the theoretical maximum due to latency constraints.

Safety-critical systems face perhaps the most severe consequences of SSR latency. Emergency shutdown systems, protective circuits, and fail-safe mechanisms rely on predictable and minimal latency to prevent equipment damage or ensure personnel safety. Documented incidents in industrial settings have demonstrated that unaccounted SSR latency has contributed to equipment failures when emergency responses couldn't execute within the required timeframe.

Standards and Certification Requirements

Solid-state relay (SSR) implementations in control systems must adhere to rigorous standards and certification requirements to ensure safety, reliability, and interoperability. The International Electrotechnical Commission (IEC) has established IEC 60947-4-3 as the primary standard governing solid-state contactors and starters, which includes specific provisions for latency performance metrics and acceptable response time variations. This standard mandates that manufacturers clearly document turn-on and turn-off delay times under various load conditions.

For industrial automation applications, IEC 61131-2 provides additional requirements for programmable logic controllers (PLCs) that interface with SSRs, specifying maximum allowable system response times that directly impact relay latency considerations. These standards establish testing methodologies for measuring and validating latency performance across temperature ranges, load variations, and over the device's expected operational lifetime.

UL 508 certification in North America and its international equivalent IEC 60947 require comprehensive testing of SSR switching characteristics, including latency measurements under defined test conditions. These certifications mandate that manufacturers provide detailed specifications regarding turn-on and turn-off times, with maximum deviation tolerances clearly documented. Control system designers must verify that selected SSRs meet these certification requirements to ensure system performance remains within acceptable parameters.

The European Union's Machinery Directive 2006/42/EC and the associated harmonized standards impose additional requirements for safety-critical applications where relay latency directly impacts emergency stop functions or safety circuits. For such applications, IEC 61508 (Functional Safety) establishes Safety Integrity Levels (SIL) that may necessitate redundant relay configurations or continuous monitoring of switching performance to detect latency degradation.

Industry-specific standards impose additional requirements in specialized sectors. For medical equipment (IEC 60601), aerospace (DO-160), and automotive applications (ISO 26262), more stringent latency requirements apply, often requiring certification to demonstrate compliance with microsecond-level response time specifications. These standards typically mandate accelerated life testing to verify that latency characteristics remain stable throughout the device's operational lifetime.

Testing and certification procedures for SSR latency typically involve standardized test fixtures that measure response times under various electrical and environmental conditions. Certification bodies require statistical analysis of multiple samples to establish confidence in the consistency of latency performance. Documentation of these test results becomes part of the technical file required for product certification and market access in most jurisdictions.

For industrial automation applications, IEC 61131-2 provides additional requirements for programmable logic controllers (PLCs) that interface with SSRs, specifying maximum allowable system response times that directly impact relay latency considerations. These standards establish testing methodologies for measuring and validating latency performance across temperature ranges, load variations, and over the device's expected operational lifetime.

UL 508 certification in North America and its international equivalent IEC 60947 require comprehensive testing of SSR switching characteristics, including latency measurements under defined test conditions. These certifications mandate that manufacturers provide detailed specifications regarding turn-on and turn-off times, with maximum deviation tolerances clearly documented. Control system designers must verify that selected SSRs meet these certification requirements to ensure system performance remains within acceptable parameters.

The European Union's Machinery Directive 2006/42/EC and the associated harmonized standards impose additional requirements for safety-critical applications where relay latency directly impacts emergency stop functions or safety circuits. For such applications, IEC 61508 (Functional Safety) establishes Safety Integrity Levels (SIL) that may necessitate redundant relay configurations or continuous monitoring of switching performance to detect latency degradation.

Industry-specific standards impose additional requirements in specialized sectors. For medical equipment (IEC 60601), aerospace (DO-160), and automotive applications (ISO 26262), more stringent latency requirements apply, often requiring certification to demonstrate compliance with microsecond-level response time specifications. These standards typically mandate accelerated life testing to verify that latency characteristics remain stable throughout the device's operational lifetime.

Testing and certification procedures for SSR latency typically involve standardized test fixtures that measure response times under various electrical and environmental conditions. Certification bodies require statistical analysis of multiple samples to establish confidence in the consistency of latency performance. Documentation of these test results becomes part of the technical file required for product certification and market access in most jurisdictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!