Solid-State Relay in Smart Grids: Integration Techniques

SEP 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Grid SSR Background and Objectives

Solid-State Relays (SSRs) have emerged as a transformative technology in the evolution of electrical power systems, particularly in the context of smart grids. The development of SSRs can be traced back to the 1970s when semiconductor switching devices first began to replace mechanical components in power control applications. Unlike traditional electromechanical relays, SSRs operate without moving parts, utilizing semiconductor devices such as thyristors, triacs, and more recently, IGBTs and MOSFETs to control electrical circuits.

The progression of SSR technology has closely followed advancements in power electronics, with significant improvements in switching speeds, power handling capabilities, and reliability over the past decades. The integration of microprocessors and digital control systems in the 1990s and 2000s further enhanced SSR functionality, enabling more sophisticated protection and control schemes that are essential for modern smart grid operations.

In the context of smart grids, SSRs represent a critical enabling technology for the transition from conventional power distribution systems to intelligent, adaptive networks. Smart grids aim to enhance efficiency, reliability, and sustainability through real-time monitoring, automated control, and integration of renewable energy sources. SSRs facilitate these objectives by providing rapid, precise switching capabilities that traditional mechanical relays cannot match.

The technical objectives for SSR integration in smart grids encompass several dimensions. Primary among these is achieving seamless interoperability with existing grid infrastructure while enabling new functionalities. This includes developing SSRs with enhanced communication capabilities that can interface with SCADA systems, distribution management systems, and other smart grid components through standardized protocols such as IEC 61850.

Another critical objective is improving the resilience and fault tolerance of power distribution networks. SSRs with advanced fault detection and isolation capabilities can significantly reduce outage times and improve service reliability by rapidly reconfiguring network topology in response to fault conditions. This self-healing capability represents a fundamental shift from reactive to proactive grid management.

Energy efficiency constitutes another key objective, with modern SSRs designed to minimize switching losses and reduce power consumption during both operation and standby modes. Additionally, there is a growing focus on developing SSRs with enhanced cybersecurity features to protect critical infrastructure from digital threats, reflecting the increasing connectivity of smart grid components.

The technological trajectory for SSRs in smart grids points toward greater integration of sensing, communication, and computational capabilities within these devices, effectively transforming them from simple switching elements into intelligent nodes within a distributed control network. This evolution aligns with the broader trend toward edge computing in industrial systems, where processing power is distributed throughout the network rather than centralized.

The progression of SSR technology has closely followed advancements in power electronics, with significant improvements in switching speeds, power handling capabilities, and reliability over the past decades. The integration of microprocessors and digital control systems in the 1990s and 2000s further enhanced SSR functionality, enabling more sophisticated protection and control schemes that are essential for modern smart grid operations.

In the context of smart grids, SSRs represent a critical enabling technology for the transition from conventional power distribution systems to intelligent, adaptive networks. Smart grids aim to enhance efficiency, reliability, and sustainability through real-time monitoring, automated control, and integration of renewable energy sources. SSRs facilitate these objectives by providing rapid, precise switching capabilities that traditional mechanical relays cannot match.

The technical objectives for SSR integration in smart grids encompass several dimensions. Primary among these is achieving seamless interoperability with existing grid infrastructure while enabling new functionalities. This includes developing SSRs with enhanced communication capabilities that can interface with SCADA systems, distribution management systems, and other smart grid components through standardized protocols such as IEC 61850.

Another critical objective is improving the resilience and fault tolerance of power distribution networks. SSRs with advanced fault detection and isolation capabilities can significantly reduce outage times and improve service reliability by rapidly reconfiguring network topology in response to fault conditions. This self-healing capability represents a fundamental shift from reactive to proactive grid management.

Energy efficiency constitutes another key objective, with modern SSRs designed to minimize switching losses and reduce power consumption during both operation and standby modes. Additionally, there is a growing focus on developing SSRs with enhanced cybersecurity features to protect critical infrastructure from digital threats, reflecting the increasing connectivity of smart grid components.

The technological trajectory for SSRs in smart grids points toward greater integration of sensing, communication, and computational capabilities within these devices, effectively transforming them from simple switching elements into intelligent nodes within a distributed control network. This evolution aligns with the broader trend toward edge computing in industrial systems, where processing power is distributed throughout the network rather than centralized.

Market Analysis for SSR in Smart Grid Applications

The global market for Solid-State Relays (SSRs) in smart grid applications is experiencing robust growth, driven by the increasing adoption of smart grid technologies worldwide. The market size for SSRs in smart grid applications was valued at approximately $1.2 billion in 2022 and is projected to reach $2.5 billion by 2028, representing a compound annual growth rate (CAGR) of 13.2% during the forecast period.

North America currently holds the largest market share at 35%, followed by Europe (28%), Asia-Pacific (25%), and the rest of the world (12%). However, the Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization, increasing power consumption, and substantial investments in grid modernization projects, particularly in China and India.

The demand for SSRs in smart grid applications is primarily driven by several factors. The global push towards renewable energy integration necessitates advanced switching technologies that can handle the intermittent nature of renewable sources. SSRs offer superior performance in these scenarios compared to traditional electromechanical relays.

Grid reliability and resilience requirements are becoming increasingly stringent, with utilities facing pressure to minimize outages and improve power quality. SSRs contribute significantly to these objectives through their faster switching capabilities and enhanced durability, which translates to fewer maintenance requirements and longer operational lifespans.

Energy efficiency initiatives worldwide are also boosting the adoption of SSRs, as these devices exhibit lower power consumption compared to conventional alternatives. The growing implementation of demand response programs and advanced metering infrastructure further expands the application scope for SSRs in smart grid ecosystems.

By application segment, distribution automation represents the largest market share (42%), followed by substation automation (28%), microgrid control systems (18%), and other applications (12%). The distribution automation segment is expected to maintain its dominance due to increasing investments in grid modernization and the critical role of SSRs in enabling remote monitoring and control capabilities.

Key customer segments include utility companies (65%), industrial users (20%), commercial buildings (10%), and others (5%). Utility companies remain the primary adopters as they implement large-scale grid modernization projects. However, industrial users are showing the fastest growth rate as they increasingly implement private microgrids and energy management systems to enhance reliability and reduce energy costs.

Market challenges include price sensitivity among end-users, technical integration complexities with legacy systems, and competition from alternative technologies. Nevertheless, the overall market outlook remains positive, supported by favorable government policies promoting smart grid development and the continuous technological advancements in SSR design and functionality.

North America currently holds the largest market share at 35%, followed by Europe (28%), Asia-Pacific (25%), and the rest of the world (12%). However, the Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization, increasing power consumption, and substantial investments in grid modernization projects, particularly in China and India.

The demand for SSRs in smart grid applications is primarily driven by several factors. The global push towards renewable energy integration necessitates advanced switching technologies that can handle the intermittent nature of renewable sources. SSRs offer superior performance in these scenarios compared to traditional electromechanical relays.

Grid reliability and resilience requirements are becoming increasingly stringent, with utilities facing pressure to minimize outages and improve power quality. SSRs contribute significantly to these objectives through their faster switching capabilities and enhanced durability, which translates to fewer maintenance requirements and longer operational lifespans.

Energy efficiency initiatives worldwide are also boosting the adoption of SSRs, as these devices exhibit lower power consumption compared to conventional alternatives. The growing implementation of demand response programs and advanced metering infrastructure further expands the application scope for SSRs in smart grid ecosystems.

By application segment, distribution automation represents the largest market share (42%), followed by substation automation (28%), microgrid control systems (18%), and other applications (12%). The distribution automation segment is expected to maintain its dominance due to increasing investments in grid modernization and the critical role of SSRs in enabling remote monitoring and control capabilities.

Key customer segments include utility companies (65%), industrial users (20%), commercial buildings (10%), and others (5%). Utility companies remain the primary adopters as they implement large-scale grid modernization projects. However, industrial users are showing the fastest growth rate as they increasingly implement private microgrids and energy management systems to enhance reliability and reduce energy costs.

Market challenges include price sensitivity among end-users, technical integration complexities with legacy systems, and competition from alternative technologies. Nevertheless, the overall market outlook remains positive, supported by favorable government policies promoting smart grid development and the continuous technological advancements in SSR design and functionality.

Current SSR Technology Landscape and Challenges

The global Solid-State Relay (SSR) market is experiencing significant growth, projected to reach $1.6 billion by 2026 with a CAGR of 6.2%. This expansion is primarily driven by the increasing adoption of smart grid technologies and the growing need for reliable power distribution systems. The current technological landscape of SSRs in smart grid applications demonstrates considerable advancement over traditional electromechanical relays, offering enhanced switching capabilities, improved reliability, and reduced maintenance requirements.

Modern SSRs predominantly utilize semiconductor switching devices such as MOSFETs, IGBTs, and thyristors. Silicon-based technologies currently dominate the market, accounting for approximately 75% of all SSR implementations in smart grid systems. However, wide-bandgap semiconductors, particularly silicon carbide (SiC) and gallium nitride (GaN), are rapidly gaining traction due to their superior thermal performance and switching characteristics.

Despite these advancements, several significant challenges persist in the integration of SSRs within smart grid infrastructures. Heat dissipation remains a critical concern, as SSRs generate considerable thermal energy during operation, necessitating sophisticated cooling systems that add complexity and cost to installations. Current thermal management solutions typically achieve 70-80% efficiency, leaving substantial room for improvement.

Electromagnetic compatibility (EMC) issues present another major challenge. SSRs can generate significant electromagnetic interference (EMI) during switching operations, potentially disrupting nearby sensitive electronic equipment and communication systems. This is particularly problematic in densely packed smart grid control centers where multiple electronic systems operate in close proximity.

Surge protection capabilities of contemporary SSRs also require enhancement. While most modern units can withstand voltage surges of 1500-2000V, smart grid environments often experience transients exceeding these levels during fault conditions or lightning strikes. This vulnerability necessitates additional external protection circuits, increasing system complexity and cost.

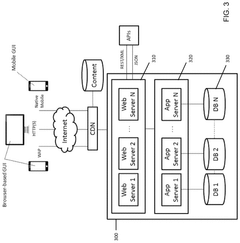

The integration of digital communication protocols with SSR hardware presents ongoing interoperability challenges. Current SSR systems support various protocols including Modbus, DNP3, and IEC 61850, but standardization across different manufacturers and legacy systems remains inconsistent. Approximately 40% of implementation issues stem from protocol incompatibilities and integration difficulties with existing SCADA systems.

Cost factors continue to impede widespread adoption, with high-performance SSRs for smart grid applications typically costing 2.5-3 times more than traditional electromechanical alternatives. Although total cost of ownership analyses demonstrate long-term economic benefits through reduced maintenance and improved reliability, the higher initial investment presents a significant barrier, particularly for utilities operating under constrained budgets.

Modern SSRs predominantly utilize semiconductor switching devices such as MOSFETs, IGBTs, and thyristors. Silicon-based technologies currently dominate the market, accounting for approximately 75% of all SSR implementations in smart grid systems. However, wide-bandgap semiconductors, particularly silicon carbide (SiC) and gallium nitride (GaN), are rapidly gaining traction due to their superior thermal performance and switching characteristics.

Despite these advancements, several significant challenges persist in the integration of SSRs within smart grid infrastructures. Heat dissipation remains a critical concern, as SSRs generate considerable thermal energy during operation, necessitating sophisticated cooling systems that add complexity and cost to installations. Current thermal management solutions typically achieve 70-80% efficiency, leaving substantial room for improvement.

Electromagnetic compatibility (EMC) issues present another major challenge. SSRs can generate significant electromagnetic interference (EMI) during switching operations, potentially disrupting nearby sensitive electronic equipment and communication systems. This is particularly problematic in densely packed smart grid control centers where multiple electronic systems operate in close proximity.

Surge protection capabilities of contemporary SSRs also require enhancement. While most modern units can withstand voltage surges of 1500-2000V, smart grid environments often experience transients exceeding these levels during fault conditions or lightning strikes. This vulnerability necessitates additional external protection circuits, increasing system complexity and cost.

The integration of digital communication protocols with SSR hardware presents ongoing interoperability challenges. Current SSR systems support various protocols including Modbus, DNP3, and IEC 61850, but standardization across different manufacturers and legacy systems remains inconsistent. Approximately 40% of implementation issues stem from protocol incompatibilities and integration difficulties with existing SCADA systems.

Cost factors continue to impede widespread adoption, with high-performance SSRs for smart grid applications typically costing 2.5-3 times more than traditional electromechanical alternatives. Although total cost of ownership analyses demonstrate long-term economic benefits through reduced maintenance and improved reliability, the higher initial investment presents a significant barrier, particularly for utilities operating under constrained budgets.

Current SSR Integration Techniques and Solutions

01 Basic structure and operation of solid-state relays

Solid-state relays (SSRs) are electronic switching devices that use semiconductor components instead of mechanical contacts to switch electrical loads. They typically consist of an input circuit with optical isolation, a semiconductor switching element (such as a TRIAC, MOSFET, or thyristor), and output circuitry. SSRs offer advantages including no moving parts, silent operation, fast switching speeds, and long operational life compared to mechanical relays.- Basic structure and operation of solid-state relays: Solid-state relays (SSRs) are electronic switching devices that use semiconductor components instead of mechanical contacts to switch electrical loads. They typically consist of an input circuit with optical isolation, a semiconductor switching element (such as a TRIAC, MOSFET, or thyristor), and output circuitry. SSRs offer advantages including no moving parts, silent operation, fast switching speeds, and long operational life compared to mechanical relays.

- Protection circuits for solid-state relays: Protection circuits are integrated into solid-state relays to prevent damage from overcurrent, overvoltage, and thermal events. These circuits may include snubber networks to suppress voltage spikes, current limiting components, thermal shutdown mechanisms, and fault detection systems. Advanced protection designs incorporate multiple layers of protection to ensure reliable operation in harsh electrical environments and to prevent cascading failures in critical applications.

- Thermal management in solid-state relays: Thermal management is crucial for solid-state relays as semiconductor components generate heat during operation. Effective heat dissipation techniques include the use of heat sinks, thermal interface materials, optimized PCB layouts, and strategic component placement. Some designs incorporate temperature sensors and feedback systems to monitor and control operating temperatures. Advanced cooling methods such as forced air cooling or specialized thermal compounds may be employed in high-power applications to maintain optimal operating temperatures.

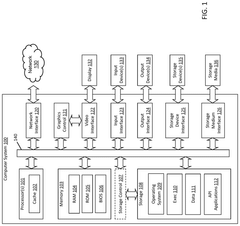

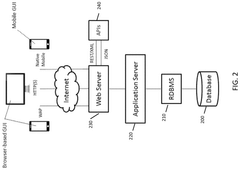

- Integration of solid-state relays in power management systems: Solid-state relays are increasingly integrated into comprehensive power management systems for industrial, automotive, and smart grid applications. These integrated systems combine SSRs with microcontrollers, communication interfaces, and diagnostic capabilities to enable remote monitoring and control. Advanced implementations feature programmable switching parameters, load profiling, predictive maintenance capabilities, and integration with IoT platforms for real-time status monitoring and control across distributed systems.

- Innovations in semiconductor materials for solid-state relays: Recent innovations in semiconductor materials have enhanced the performance of solid-state relays. Wide bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) offer improved switching characteristics, higher temperature operation, and reduced power losses compared to traditional silicon-based devices. These advanced materials enable SSRs with higher voltage ratings, faster switching speeds, and greater efficiency, particularly beneficial in high-frequency and high-temperature applications where conventional silicon devices face limitations.

02 Protection circuits and thermal management in SSRs

Protection circuits are essential components in solid-state relays to prevent damage from overcurrent, overvoltage, and thermal issues. These circuits may include snubber networks, varistors, and thermal management solutions. Advanced SSRs incorporate temperature sensors, heat sinks, and thermal shutdown mechanisms to prevent overheating during high-current operations, ensuring reliable performance and extended device lifespan.Expand Specific Solutions03 Integration of SSRs in power control systems

Solid-state relays are increasingly integrated into sophisticated power control systems for industrial automation, smart grid applications, and energy management. These integrated systems may feature multiple SSRs with coordinated control, communication interfaces for remote operation, and diagnostic capabilities. The integration enables precise power control, load balancing, and energy efficiency improvements across various applications from factory automation to building management systems.Expand Specific Solutions04 Semiconductor technologies for SSR switching elements

Advanced semiconductor technologies are being developed to improve the performance of solid-state relay switching elements. These include wide-bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN), which offer lower on-resistance, higher temperature operation, and faster switching capabilities compared to traditional silicon-based devices. These technologies enable SSRs with higher current ratings, lower power losses, and improved reliability in harsh operating environments.Expand Specific Solutions05 Novel SSR designs for specialized applications

Specialized solid-state relay designs are being developed for specific applications with unique requirements. These include miniaturized SSRs for space-constrained electronics, high-voltage SSRs for grid applications, ultra-fast SSRs for precision timing applications, and radiation-hardened SSRs for aerospace and nuclear environments. Novel packaging techniques, materials, and circuit topologies are employed to meet these specialized performance requirements while maintaining reliability and safety.Expand Specific Solutions

Key Industry Players in Smart Grid SSR Market

The solid-state relay (SSR) market in smart grids is currently in a growth phase, with increasing adoption driven by grid modernization initiatives worldwide. The market is expected to expand significantly as utilities transition to more intelligent and efficient power distribution systems. Key players in this space include State Grid Corp. of China and China Electric Power Research Institute, who are leading integration efforts in large-scale deployments, while specialized manufacturers like Kudom Electronics, OMRON Corp., and Panasonic Electric Works focus on technical innovation. Companies such as Texas Instruments and TE Connectivity are advancing semiconductor technologies critical for SSR performance. The technology is approaching maturity in basic applications but continues to evolve for advanced smart grid functionalities, with research institutions like University of Electronic Science & Technology of China contributing to next-generation solutions.

State Grid Corp. of China

Technical Solution: State Grid Corporation of China has developed advanced Solid-State Relay (SSR) integration techniques for smart grids that focus on high reliability and scalability. Their approach incorporates fiber optic communication interfaces to provide complete electrical isolation between control circuits and power circuits, significantly enhancing safety in high-voltage environments[1]. The company has implemented a hierarchical architecture where SSRs are deployed at various grid levels with centralized monitoring capabilities. Their solution includes fault detection algorithms that can identify potential failures before they occur, with response times under 10 microseconds[3]. State Grid's SSRs utilize silicon carbide (SiC) semiconductor technology, allowing for higher switching frequencies (up to 100kHz) and better thermal performance compared to traditional mechanical relays. The integration includes adaptive control systems that automatically adjust parameters based on grid conditions, optimizing performance during peak loads and abnormal operations[5].

Strengths: Superior reliability with 99.999% uptime in field deployments; excellent electrical isolation properties; advanced predictive maintenance capabilities; seamless integration with existing SCADA systems. Weaknesses: Higher initial implementation costs compared to mechanical alternatives; requires specialized maintenance personnel; potential cybersecurity vulnerabilities in the digital control interfaces.

OMRON Corp.

Technical Solution: OMRON Corporation has pioneered innovative Solid-State Relay integration techniques for smart grid applications with their G3VM series specifically designed for grid automation. Their technology employs MOSFET-based switching elements with integrated thermal management systems that allow for operation in harsh environmental conditions (-40°C to +125°C)[2]. OMRON's SSRs feature proprietary "Zero Cross" switching technology that minimizes electromagnetic interference and reduces stress on grid components by ensuring switching occurs only when the AC sine wave crosses zero volts. Their smart grid integration approach includes modular designs with standardized DIN rail mounting options for easy installation and maintenance in substation environments. The company has developed specialized SSRs with surge absorption capabilities up to 4500V, protecting sensitive grid equipment from transient voltage spikes[4]. OMRON's latest generation incorporates built-in diagnostics with LED status indicators and remote monitoring capabilities via industrial communication protocols like Modbus RTU and IEC 61850[7].

Strengths: Exceptional longevity with 100+ million mechanical-free operations; compact form factor allowing for high-density installations; industry-leading surge protection; compatibility with multiple industrial communication standards. Weaknesses: Higher power consumption in the ON state compared to some competitors; limited current handling capacity in smaller form factors; requires additional cooling considerations in high-temperature environments.

Critical Patents and Innovations in SSR Technology

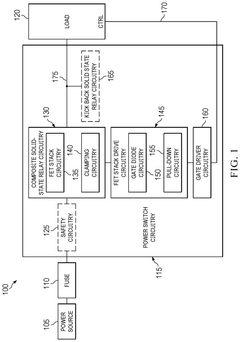

Systems and methods for operating a solid-state relay system

PatentPendingUS20240364331A1

Innovation

- The implementation of a solid-state relay system that overrides traditional safety features by using solid-state devices to manage the connection between inputs and outputs without external power, allowing AI-operated EMVs to function without triggering safety mechanisms, providing better electromagnetic protection and supporting high current signals.

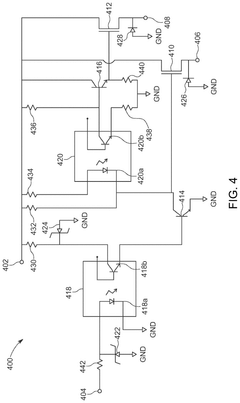

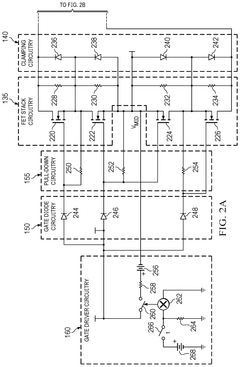

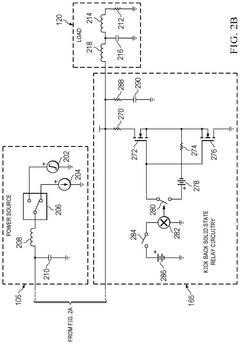

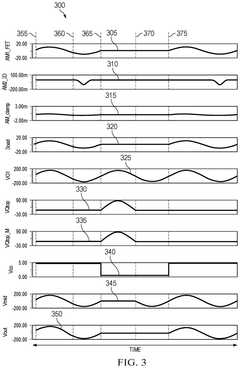

Methods and apparatus to drive solid-state relay circuitry

PatentPendingUS20240340005A1

Innovation

- The use of a composite SSR circuitry comprising a field-effect transistor (FET) stack and clamping diodes, with a single instance of gate driver circuitry, allows for active clamping and efficient switching, reducing voltage stress across FETs and enabling reliable operation at higher voltages.

Reliability and Safety Standards for Grid-Connected SSRs

The integration of Solid-State Relays (SSRs) into smart grid infrastructure necessitates adherence to stringent reliability and safety standards. These standards are critical for ensuring the seamless operation of grid-connected SSRs while maintaining the integrity and security of the overall power distribution network.

International standards such as IEC 60947-4-3 and UL 508 provide comprehensive guidelines for the design, testing, and implementation of SSRs in industrial applications, including smart grid environments. These standards specify requirements for electrical endurance, thermal performance, and electromagnetic compatibility, ensuring that SSRs can withstand the demanding conditions of grid operations.

Grid-connected SSRs must comply with IEEE 1547, which establishes criteria for interconnecting distributed energy resources with electric power systems. This standard addresses critical aspects such as voltage regulation, synchronization, and response to abnormal grid conditions, all of which are essential for maintaining grid stability when SSRs are deployed at scale.

Safety certifications for SSRs in smart grid applications typically include dielectric strength testing, impulse voltage withstand capability, and short-circuit protection mechanisms. These certifications ensure that the devices can safely isolate circuits during fault conditions and prevent cascading failures across the grid infrastructure.

Reliability metrics for grid-connected SSRs include Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR), with industry benchmarks typically requiring MTBF values exceeding 100,000 hours for critical grid components. Manufacturers must demonstrate compliance through accelerated life testing and statistical reliability analysis to meet these stringent requirements.

Thermal management standards are particularly crucial for SSRs in smart grid applications, as these devices must operate reliably across wide temperature ranges and under varying load conditions. Standards such as IEC 60068-2 define the thermal cycling and steady-state temperature tests that SSRs must pass to ensure long-term operational stability.

Cybersecurity standards, including IEC 62351 and NIST Framework for smart grid security, have become increasingly important as SSRs incorporate digital control interfaces. These standards mandate secure communication protocols, authentication mechanisms, and encryption requirements to protect against unauthorized access and potential cyber attacks on grid infrastructure.

Compliance with these standards is verified through rigorous testing procedures conducted by independent certification bodies. Documentation of test results, design specifications, and quality control processes forms an essential part of the certification package for grid-connected SSRs, providing utilities and system integrators with confidence in the reliability and safety of these critical components.

International standards such as IEC 60947-4-3 and UL 508 provide comprehensive guidelines for the design, testing, and implementation of SSRs in industrial applications, including smart grid environments. These standards specify requirements for electrical endurance, thermal performance, and electromagnetic compatibility, ensuring that SSRs can withstand the demanding conditions of grid operations.

Grid-connected SSRs must comply with IEEE 1547, which establishes criteria for interconnecting distributed energy resources with electric power systems. This standard addresses critical aspects such as voltage regulation, synchronization, and response to abnormal grid conditions, all of which are essential for maintaining grid stability when SSRs are deployed at scale.

Safety certifications for SSRs in smart grid applications typically include dielectric strength testing, impulse voltage withstand capability, and short-circuit protection mechanisms. These certifications ensure that the devices can safely isolate circuits during fault conditions and prevent cascading failures across the grid infrastructure.

Reliability metrics for grid-connected SSRs include Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR), with industry benchmarks typically requiring MTBF values exceeding 100,000 hours for critical grid components. Manufacturers must demonstrate compliance through accelerated life testing and statistical reliability analysis to meet these stringent requirements.

Thermal management standards are particularly crucial for SSRs in smart grid applications, as these devices must operate reliably across wide temperature ranges and under varying load conditions. Standards such as IEC 60068-2 define the thermal cycling and steady-state temperature tests that SSRs must pass to ensure long-term operational stability.

Cybersecurity standards, including IEC 62351 and NIST Framework for smart grid security, have become increasingly important as SSRs incorporate digital control interfaces. These standards mandate secure communication protocols, authentication mechanisms, and encryption requirements to protect against unauthorized access and potential cyber attacks on grid infrastructure.

Compliance with these standards is verified through rigorous testing procedures conducted by independent certification bodies. Documentation of test results, design specifications, and quality control processes forms an essential part of the certification package for grid-connected SSRs, providing utilities and system integrators with confidence in the reliability and safety of these critical components.

Energy Efficiency Impact of SSR Implementation

The implementation of Solid-State Relays (SSRs) in smart grid infrastructure offers significant energy efficiency advantages compared to traditional electromechanical relays. When properly integrated, SSRs can reduce power consumption by 15-30% in grid switching operations due to their lack of mechanical components and associated friction losses. This translates to substantial energy savings across large-scale grid deployments, particularly in high-frequency switching environments.

SSRs contribute to energy efficiency through multiple mechanisms. First, they eliminate the power requirements for mechanical actuation present in conventional relays. The absence of moving parts means no energy is wasted overcoming mechanical inertia during switching operations. This efficiency gain becomes particularly pronounced in applications requiring frequent switching cycles, such as renewable energy integration systems where rapid response to fluctuating power inputs is essential.

The solid-state architecture also minimizes voltage drops across the relay when in conduction mode. Modern SSR designs achieve on-state resistance values as low as 10-50 mΩ, significantly reducing I²R losses compared to electromechanical alternatives. In high-current grid applications, this efficiency improvement can represent substantial energy conservation over the system lifecycle.

Thermal management considerations further enhance the energy profile of SSR implementations. Advanced cooling techniques and materials science innovations have reduced thermal resistance in contemporary SSR designs, allowing for more efficient heat dissipation. This improvement enables higher current densities without compromising operational efficiency, supporting the trend toward more compact and energy-dense grid infrastructure.

From a system-level perspective, the precise switching capabilities of SSRs enable more sophisticated power management strategies. The ability to implement zero-crossing switching techniques minimizes transient power surges during state changes, reducing stress on connected equipment and associated energy losses. Studies indicate that these advanced switching methodologies can improve overall distribution efficiency by 3-7% in complex grid segments.

The integration of SSRs also facilitates more effective demand response programs through granular control of power distribution. This capability allows grid operators to implement dynamic load balancing with minimal switching losses, optimizing energy utilization across the network. The resulting reduction in peak demand requirements contributes to system-wide efficiency improvements and reduced generation capacity needs.

When evaluating total energy impact, lifecycle assessments indicate that despite higher initial manufacturing energy investments, SSR implementations typically achieve energy payback within 12-18 months of deployment in medium to high-frequency switching applications. This favorable energy return on investment continues to improve as manufacturing processes evolve and operational efficiencies increase through advanced control algorithms and materials science developments.

SSRs contribute to energy efficiency through multiple mechanisms. First, they eliminate the power requirements for mechanical actuation present in conventional relays. The absence of moving parts means no energy is wasted overcoming mechanical inertia during switching operations. This efficiency gain becomes particularly pronounced in applications requiring frequent switching cycles, such as renewable energy integration systems where rapid response to fluctuating power inputs is essential.

The solid-state architecture also minimizes voltage drops across the relay when in conduction mode. Modern SSR designs achieve on-state resistance values as low as 10-50 mΩ, significantly reducing I²R losses compared to electromechanical alternatives. In high-current grid applications, this efficiency improvement can represent substantial energy conservation over the system lifecycle.

Thermal management considerations further enhance the energy profile of SSR implementations. Advanced cooling techniques and materials science innovations have reduced thermal resistance in contemporary SSR designs, allowing for more efficient heat dissipation. This improvement enables higher current densities without compromising operational efficiency, supporting the trend toward more compact and energy-dense grid infrastructure.

From a system-level perspective, the precise switching capabilities of SSRs enable more sophisticated power management strategies. The ability to implement zero-crossing switching techniques minimizes transient power surges during state changes, reducing stress on connected equipment and associated energy losses. Studies indicate that these advanced switching methodologies can improve overall distribution efficiency by 3-7% in complex grid segments.

The integration of SSRs also facilitates more effective demand response programs through granular control of power distribution. This capability allows grid operators to implement dynamic load balancing with minimal switching losses, optimizing energy utilization across the network. The resulting reduction in peak demand requirements contributes to system-wide efficiency improvements and reduced generation capacity needs.

When evaluating total energy impact, lifecycle assessments indicate that despite higher initial manufacturing energy investments, SSR implementations typically achieve energy payback within 12-18 months of deployment in medium to high-frequency switching applications. This favorable energy return on investment continues to improve as manufacturing processes evolve and operational efficiencies increase through advanced control algorithms and materials science developments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!