How to Monitor Solid-State Relay Output for Consistency

SEP 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Monitoring Technology Background and Objectives

Solid-State Relays (SSRs) have evolved significantly since their introduction in the 1970s as alternatives to electromechanical relays. These semiconductor-based switching devices have transformed industrial control systems by offering enhanced reliability, faster switching speeds, and elimination of mechanical wear. The technology has progressed from simple thyristor-based designs to sophisticated integrated circuits incorporating advanced monitoring capabilities.

The evolution of SSR technology has been driven by increasing demands for precision control in critical applications across manufacturing, medical equipment, and power distribution systems. As industrial automation continues to advance, the need for consistent and reliable relay operation has become paramount, particularly in safety-critical environments where component failure could lead to catastrophic consequences.

Current SSR monitoring technologies primarily focus on detecting complete failures rather than performance degradation or inconsistency. This reactive approach leaves systems vulnerable to unexpected downtime and potential safety hazards. The industry trend is clearly moving toward predictive monitoring solutions that can identify potential issues before they manifest as failures.

The primary objective of SSR output monitoring technology is to develop robust methods for real-time verification of relay switching consistency. This includes detecting partial failures, performance degradation over time, and inconsistent behavior under varying load conditions. Such monitoring must be non-intrusive to avoid affecting the primary function of the relay while providing accurate and timely diagnostic information.

Secondary objectives include minimizing false positives that could trigger unnecessary maintenance interventions, ensuring compatibility with existing industrial control systems, and developing standardized approaches that can be applied across different SSR types and manufacturers. The technology must also be cost-effective to implement at scale across industrial applications.

From a technical perspective, effective monitoring solutions must address several challenges including the high-speed nature of SSR switching, varying load characteristics, electromagnetic interference, and thermal considerations that affect performance. The ideal monitoring system should provide continuous assessment rather than periodic testing to capture intermittent issues that might otherwise go undetected.

The global push toward Industry 4.0 and smart manufacturing has accelerated the development of integrated monitoring solutions. These technologies aim to not only detect inconsistencies but also to provide actionable data for predictive maintenance systems, thereby reducing downtime and extending equipment lifespan. This aligns with broader industrial trends toward condition-based maintenance and real-time system health monitoring.

As industrial systems become increasingly interconnected, SSR monitoring technology must also evolve to support network integration, enabling remote monitoring capabilities and integration with broader industrial control and maintenance systems. This connectivity represents both an opportunity for enhanced monitoring and a challenge for ensuring cybersecurity in critical infrastructure applications.

The evolution of SSR technology has been driven by increasing demands for precision control in critical applications across manufacturing, medical equipment, and power distribution systems. As industrial automation continues to advance, the need for consistent and reliable relay operation has become paramount, particularly in safety-critical environments where component failure could lead to catastrophic consequences.

Current SSR monitoring technologies primarily focus on detecting complete failures rather than performance degradation or inconsistency. This reactive approach leaves systems vulnerable to unexpected downtime and potential safety hazards. The industry trend is clearly moving toward predictive monitoring solutions that can identify potential issues before they manifest as failures.

The primary objective of SSR output monitoring technology is to develop robust methods for real-time verification of relay switching consistency. This includes detecting partial failures, performance degradation over time, and inconsistent behavior under varying load conditions. Such monitoring must be non-intrusive to avoid affecting the primary function of the relay while providing accurate and timely diagnostic information.

Secondary objectives include minimizing false positives that could trigger unnecessary maintenance interventions, ensuring compatibility with existing industrial control systems, and developing standardized approaches that can be applied across different SSR types and manufacturers. The technology must also be cost-effective to implement at scale across industrial applications.

From a technical perspective, effective monitoring solutions must address several challenges including the high-speed nature of SSR switching, varying load characteristics, electromagnetic interference, and thermal considerations that affect performance. The ideal monitoring system should provide continuous assessment rather than periodic testing to capture intermittent issues that might otherwise go undetected.

The global push toward Industry 4.0 and smart manufacturing has accelerated the development of integrated monitoring solutions. These technologies aim to not only detect inconsistencies but also to provide actionable data for predictive maintenance systems, thereby reducing downtime and extending equipment lifespan. This aligns with broader industrial trends toward condition-based maintenance and real-time system health monitoring.

As industrial systems become increasingly interconnected, SSR monitoring technology must also evolve to support network integration, enabling remote monitoring capabilities and integration with broader industrial control and maintenance systems. This connectivity represents both an opportunity for enhanced monitoring and a challenge for ensuring cybersecurity in critical infrastructure applications.

Market Demand Analysis for SSR Consistency Monitoring

The global market for Solid-State Relay (SSR) consistency monitoring solutions is experiencing robust growth, driven primarily by increasing automation across industrial sectors. Current market analysis indicates that industries such as manufacturing, energy, telecommunications, and healthcare are rapidly adopting SSR technology due to its reliability advantages over mechanical relays. This adoption is creating a parallel demand for sophisticated monitoring systems that can ensure operational consistency.

Industrial automation represents the largest market segment, where SSR consistency monitoring is critical for maintaining production uptime. Manufacturing facilities implementing Industry 4.0 principles require real-time monitoring capabilities to prevent costly downtime. Market research shows that a single hour of unplanned downtime can cost manufacturers between $10,000 and $250,000 depending on the industry sector, making investment in reliable monitoring solutions economically justified.

The energy sector presents another significant market opportunity, particularly in power distribution systems and renewable energy installations. As power grids become more complex and decentralized, the need for reliable switching mechanisms with robust monitoring capabilities has increased substantially. Solar and wind energy systems, which often operate in remote locations, require dependable SSR monitoring to ensure consistent power delivery without frequent maintenance visits.

Healthcare applications represent a growing market segment where SSR consistency monitoring is essential for critical care equipment and facility infrastructure. The life-critical nature of these applications demands monitoring solutions with exceptional reliability and early failure detection capabilities.

Geographically, North America and Europe currently lead in adoption of advanced SSR monitoring solutions, but the Asia-Pacific region is showing the fastest growth rate as manufacturing automation accelerates across China, Japan, South Korea, and emerging economies in Southeast Asia.

Market forecasts indicate that the demand for SSR consistency monitoring solutions will continue to grow at a compound annual growth rate of approximately 7-9% over the next five years. This growth is further supported by regulatory trends requiring improved equipment reliability and safety standards across multiple industries.

Customer requirements are evolving toward integrated monitoring solutions that offer predictive maintenance capabilities rather than simple failure detection. End users increasingly demand monitoring systems that can detect subtle performance degradation before complete failure occurs, allowing for scheduled maintenance rather than emergency repairs.

Industrial automation represents the largest market segment, where SSR consistency monitoring is critical for maintaining production uptime. Manufacturing facilities implementing Industry 4.0 principles require real-time monitoring capabilities to prevent costly downtime. Market research shows that a single hour of unplanned downtime can cost manufacturers between $10,000 and $250,000 depending on the industry sector, making investment in reliable monitoring solutions economically justified.

The energy sector presents another significant market opportunity, particularly in power distribution systems and renewable energy installations. As power grids become more complex and decentralized, the need for reliable switching mechanisms with robust monitoring capabilities has increased substantially. Solar and wind energy systems, which often operate in remote locations, require dependable SSR monitoring to ensure consistent power delivery without frequent maintenance visits.

Healthcare applications represent a growing market segment where SSR consistency monitoring is essential for critical care equipment and facility infrastructure. The life-critical nature of these applications demands monitoring solutions with exceptional reliability and early failure detection capabilities.

Geographically, North America and Europe currently lead in adoption of advanced SSR monitoring solutions, but the Asia-Pacific region is showing the fastest growth rate as manufacturing automation accelerates across China, Japan, South Korea, and emerging economies in Southeast Asia.

Market forecasts indicate that the demand for SSR consistency monitoring solutions will continue to grow at a compound annual growth rate of approximately 7-9% over the next five years. This growth is further supported by regulatory trends requiring improved equipment reliability and safety standards across multiple industries.

Customer requirements are evolving toward integrated monitoring solutions that offer predictive maintenance capabilities rather than simple failure detection. End users increasingly demand monitoring systems that can detect subtle performance degradation before complete failure occurs, allowing for scheduled maintenance rather than emergency repairs.

Current State and Challenges in SSR Output Monitoring

Solid-State Relay (SSR) output monitoring has evolved significantly over the past decade, yet remains a challenging aspect of industrial control systems. Current monitoring technologies range from basic voltage detection circuits to sophisticated microcontroller-based systems with integrated diagnostics. Despite these advancements, the industry continues to face substantial challenges in ensuring consistent and reliable SSR operation across diverse applications.

The primary monitoring approaches currently employed include current sensing, voltage detection across the load, thermal monitoring, and integrated diagnostic feedback systems. Current sensing methods typically utilize shunt resistors or Hall effect sensors to detect load current flow, providing indirect confirmation of SSR switching. Voltage detection systems measure potential differences across the load to verify proper switching states. These conventional methods, while functional, often lack the precision required for critical applications.

A significant challenge in SSR output monitoring stems from the semiconductor nature of these devices. Unlike mechanical relays with visible contacts, SSRs provide no direct visual confirmation of switching states. This inherent characteristic necessitates sophisticated electronic monitoring solutions that can reliably detect partial conduction, voltage drops, and other subtle failure modes that may not trigger conventional protection mechanisms.

The semiconductor industry's push toward miniaturization has created additional monitoring challenges. As SSRs become more compact and integrated into complex systems, the physical space for implementing monitoring circuits becomes increasingly constrained. This limitation often forces engineers to compromise between monitoring comprehensiveness and space efficiency.

Environmental factors present another layer of complexity. SSRs deployed in harsh industrial environments face temperature fluctuations, electromagnetic interference, and power quality issues that can affect both relay performance and monitoring accuracy. Current monitoring systems struggle to differentiate between environmentally induced variations and actual relay malfunctions.

Technologically, the industry faces a significant gap in standardization. Different manufacturers implement proprietary monitoring interfaces and protocols, creating interoperability challenges when integrating SSRs into larger control systems. This fragmentation impedes the development of universal monitoring solutions and increases implementation complexity.

Cost considerations remain a substantial barrier to advanced monitoring implementation. High-precision monitoring systems with comprehensive diagnostics often come with prohibitive price tags for mass deployment. This economic constraint has led to a bifurcated market where critical applications receive sophisticated monitoring while general-purpose implementations rely on basic protection schemes.

The geographical distribution of SSR technology development shows concentration in industrial hubs across North America, Europe, and East Asia, with emerging research centers in India and Brazil focusing on cost-effective monitoring solutions for developing markets. This global disparity in research focus creates uneven advancement in monitoring technologies across different market segments.

The primary monitoring approaches currently employed include current sensing, voltage detection across the load, thermal monitoring, and integrated diagnostic feedback systems. Current sensing methods typically utilize shunt resistors or Hall effect sensors to detect load current flow, providing indirect confirmation of SSR switching. Voltage detection systems measure potential differences across the load to verify proper switching states. These conventional methods, while functional, often lack the precision required for critical applications.

A significant challenge in SSR output monitoring stems from the semiconductor nature of these devices. Unlike mechanical relays with visible contacts, SSRs provide no direct visual confirmation of switching states. This inherent characteristic necessitates sophisticated electronic monitoring solutions that can reliably detect partial conduction, voltage drops, and other subtle failure modes that may not trigger conventional protection mechanisms.

The semiconductor industry's push toward miniaturization has created additional monitoring challenges. As SSRs become more compact and integrated into complex systems, the physical space for implementing monitoring circuits becomes increasingly constrained. This limitation often forces engineers to compromise between monitoring comprehensiveness and space efficiency.

Environmental factors present another layer of complexity. SSRs deployed in harsh industrial environments face temperature fluctuations, electromagnetic interference, and power quality issues that can affect both relay performance and monitoring accuracy. Current monitoring systems struggle to differentiate between environmentally induced variations and actual relay malfunctions.

Technologically, the industry faces a significant gap in standardization. Different manufacturers implement proprietary monitoring interfaces and protocols, creating interoperability challenges when integrating SSRs into larger control systems. This fragmentation impedes the development of universal monitoring solutions and increases implementation complexity.

Cost considerations remain a substantial barrier to advanced monitoring implementation. High-precision monitoring systems with comprehensive diagnostics often come with prohibitive price tags for mass deployment. This economic constraint has led to a bifurcated market where critical applications receive sophisticated monitoring while general-purpose implementations rely on basic protection schemes.

The geographical distribution of SSR technology development shows concentration in industrial hubs across North America, Europe, and East Asia, with emerging research centers in India and Brazil focusing on cost-effective monitoring solutions for developing markets. This global disparity in research focus creates uneven advancement in monitoring technologies across different market segments.

Current Technical Solutions for SSR Output Consistency

01 Design and structure of solid-state relays for consistent operation

Solid-state relays can be designed with specific structures to ensure consistent operation. These designs may include specialized semiconductor arrangements, thermal management systems, and protective circuitry that maintain reliable switching performance under various conditions. The structural elements work together to provide stable operation across temperature ranges and load variations, reducing inconsistencies in relay behavior.- Design and structure of solid-state relays for improved consistency: Solid-state relays can be designed with specific structural elements to enhance operational consistency. These designs may include specialized semiconductor arrangements, thermal management systems, and protective circuitry that ensure reliable switching operations. The physical layout and component selection significantly impact the relay's ability to maintain consistent performance across varying conditions and over extended periods of operation.

- Control mechanisms for maintaining switching consistency: Various control mechanisms can be implemented to maintain consistent operation of solid-state relays. These include gate drive circuits, feedback systems, and timing control elements that ensure precise switching behavior. Advanced control algorithms can compensate for variations in load conditions, input signals, and environmental factors, thereby maintaining consistent relay performance even under fluctuating operational parameters.

- Protection circuits for ensuring operational consistency: Protection circuits play a crucial role in maintaining the consistency of solid-state relays by preventing damage from overcurrent, overvoltage, and thermal events. These circuits may include snubber networks, current limiting components, and thermal shutdown mechanisms. By safeguarding the relay from extreme conditions, these protection features ensure that the relay maintains consistent performance characteristics throughout its operational life.

- Thermal management for consistent relay operation: Effective thermal management is essential for maintaining consistent operation of solid-state relays. Heat dissipation techniques, including heat sinks, thermal interface materials, and cooling systems, help prevent temperature-related performance variations. By maintaining stable operating temperatures, these thermal management solutions ensure that the relay's electrical characteristics remain consistent, preventing thermal drift and extending the relay's reliable operating range.

- Testing and monitoring methods for relay consistency: Various testing and monitoring methods can be employed to verify and maintain the consistency of solid-state relays. These include in-circuit testing, parameter monitoring, and diagnostic systems that can detect early signs of performance degradation. Real-time monitoring of key parameters such as switching times, voltage drops, and leakage currents allows for proactive maintenance and ensures that the relay maintains consistent performance throughout its service life.

02 Control mechanisms for improving relay consistency

Various control mechanisms can be implemented to improve the consistency of solid-state relays. These include advanced gate driving circuits, feedback systems that monitor relay performance, and timing control mechanisms that ensure precise switching. These control systems help maintain consistent operation by compensating for variations in input signals, load conditions, and environmental factors that might otherwise cause inconsistent relay behavior.Expand Specific Solutions03 Protection features for maintaining relay consistency

Protection features are essential for maintaining consistent operation of solid-state relays. These include overvoltage protection, overcurrent limiting, thermal shutdown mechanisms, and isolation techniques that prevent interference. By implementing these protective measures, solid-state relays can maintain consistent performance even when subjected to electrical disturbances, preventing damage that would lead to inconsistent operation or failure.Expand Specific Solutions04 Thermal management for consistent relay performance

Thermal management is crucial for maintaining consistent solid-state relay operation. Heat dissipation techniques, including specialized heat sinks, thermal interface materials, and cooling systems, help prevent temperature-related performance variations. By maintaining optimal operating temperatures, these thermal management solutions ensure that the semiconductor components within the relay operate consistently across varying load conditions and ambient temperatures.Expand Specific Solutions05 Integration and synchronization techniques for relay consistency

Integration and synchronization techniques enhance the consistency of solid-state relay systems, particularly in multi-relay configurations. These include synchronized switching algorithms, phase control methods, and integrated circuit designs that coordinate multiple relays. By ensuring proper timing and coordination between relay components and systems, these techniques minimize inconsistencies in switching behavior and improve overall system reliability.Expand Specific Solutions

Key Industry Players in SSR Monitoring Solutions

The solid-state relay (SSR) output monitoring market is currently in a growth phase, driven by increasing industrial automation demands. The market size is expanding steadily, with significant adoption across power management, industrial control, and automotive sectors. Technologically, the field shows moderate maturity with ongoing innovation in monitoring techniques. Leading players include Littelfuse and Crouzet SAS, who focus on specialized monitoring solutions, while larger corporations like Schneider Electric and Siemens offer integrated systems. OMRON and Rockwell Automation are advancing diagnostic capabilities, while State Grid companies are implementing these technologies at scale in power infrastructure. The competitive landscape reflects a mix of specialized component manufacturers and diversified industrial automation providers working to enhance reliability and safety in SSR applications.

Littelfuse, Inc.

Technical Solution: Littelfuse has developed comprehensive solid-state relay (SSR) monitoring solutions that integrate diagnostic feedback circuits within their SSR modules. Their technology implements continuous monitoring through integrated current sensing elements that detect load current variations and compare them against expected values. The system features built-in microcontrollers that analyze switching patterns and detect anomalies in real-time. Littelfuse's approach includes thermal monitoring capabilities that track temperature fluctuations which could indicate potential relay degradation or failure. Their SSRs incorporate LED status indicators and digital communication interfaces (I2C/SPI) that provide detailed diagnostic information to control systems. The company's monitoring solution also features programmable threshold settings that can be customized based on specific application requirements, allowing for precise detection of inconsistencies in relay performance[1][3].

Strengths: Comprehensive integration of monitoring capabilities directly within SSR modules reduces system complexity and installation costs. Advanced diagnostic features enable predictive maintenance rather than reactive replacement. Weaknesses: Higher initial cost compared to basic SSRs without monitoring capabilities. Requires more sophisticated control systems to fully utilize the diagnostic data generated.

Schneider Electric Industries SASU

Technical Solution: Schneider Electric has developed an advanced SSR monitoring system that utilizes their EcoStruxure platform for comprehensive relay output consistency monitoring. Their solution implements a dual-verification approach where both the control signal and the actual load state are independently monitored. The system features integrated current transformers that provide real-time feedback on load current, allowing detection of partial failures or degradation. Schneider's technology incorporates adaptive threshold algorithms that automatically adjust to normal operational variations while still detecting abnormal conditions. Their monitoring system includes network connectivity options that enable remote monitoring and integration with facility management systems. The solution also features historical data logging capabilities that track relay performance over time, enabling trend analysis and predictive maintenance. Schneider's SSR monitoring technology is designed with redundant verification circuits that compare expected versus actual states to ensure reliable operation[2][5].

Strengths: Seamless integration with broader industrial automation and energy management systems provides comprehensive visibility. Advanced analytics capabilities enable predictive maintenance and optimization. Weaknesses: Higher complexity may require specialized knowledge for implementation and troubleshooting. System may be overengineered for simple applications with basic monitoring needs.

Core Patents and Innovations in SSR Monitoring

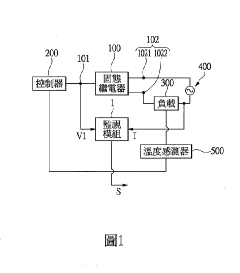

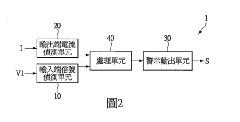

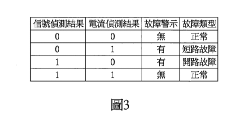

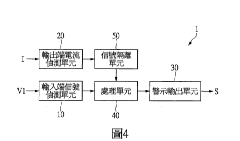

Monitoring module for solid state relay and furnace having the same

PatentActiveTW201814759A

Innovation

- A monitoring module for solid-state relays that includes an input terminal signal detection unit, output terminal current detection unit, warning output unit, and processing unit to judge relay faults based on signal and current detection results, sending fault warnings when necessary.

Solid state relay protective device

PatentInactiveEP3031136A1

Innovation

- An electrical circuit with a switch element, sensing element, and feedback element that monitors operating parameters such as current or temperature, switching the solid-state relay to an energized or de-energized state to prevent overload and allow cooling, using a comparator and microprocessor-based control to manage the drive signal and prevent damage.

Reliability Standards and Compliance Requirements

Solid-state relay (SSR) monitoring systems must adhere to multiple international and industry-specific reliability standards to ensure operational safety and performance consistency. IEC 60947-4-3 specifically addresses semiconductor controllers and contactors for non-motor loads, establishing comprehensive requirements for SSR performance characteristics, including voltage drop, leakage current, and switching behavior under various conditions. This standard serves as the foundation for SSR reliability assessment in industrial applications.

For critical applications, IEC 61508 (Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems) provides essential guidelines for implementing safety integrity levels (SIL) in SSR monitoring systems. Organizations must determine appropriate SIL ratings based on risk assessment, with higher-risk applications requiring more robust monitoring solutions and redundancy mechanisms.

UL 508 certification represents another crucial standard for industrial control equipment in North America, establishing specific requirements for solid-state switching devices regarding thermal performance, dielectric strength, and endurance testing. Compliance with UL 508 is often mandatory for equipment deployed in commercial and industrial environments across the United States and Canada.

The semiconductor industry standard JEDEC JESD22 outlines environmental and mechanical stress test procedures that apply to SSR components, ensuring reliability under various operational conditions. These tests include temperature cycling, humidity exposure, and mechanical shock resistance—all critical factors in maintaining consistent SSR output performance over time.

For applications in hazardous environments, compliance with IEC 60079 series standards becomes essential, particularly when SSRs are deployed in potentially explosive atmospheres. These standards define specific monitoring requirements to prevent ignition risks associated with electrical equipment failure.

Military and aerospace applications follow additional stringent standards such as MIL-STD-883 for microelectronic devices and DO-160 for airborne equipment. These standards impose rigorous environmental, mechanical, and electrical stress testing protocols that exceed commercial requirements.

Emerging reliability frameworks like ISO 26262 for automotive functional safety are increasingly relevant as SSRs find applications in electric vehicles and charging infrastructure. These standards emphasize fault detection coverage and diagnostic capabilities in monitoring systems to ensure consistent performance in safety-critical automotive applications.

Compliance documentation must include detailed test procedures, validation methodologies, and traceability records to demonstrate adherence to applicable standards. Organizations implementing SSR monitoring solutions should establish comprehensive compliance matrices mapping specific monitoring features to relevant standard requirements, facilitating certification processes and regulatory approval.

For critical applications, IEC 61508 (Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems) provides essential guidelines for implementing safety integrity levels (SIL) in SSR monitoring systems. Organizations must determine appropriate SIL ratings based on risk assessment, with higher-risk applications requiring more robust monitoring solutions and redundancy mechanisms.

UL 508 certification represents another crucial standard for industrial control equipment in North America, establishing specific requirements for solid-state switching devices regarding thermal performance, dielectric strength, and endurance testing. Compliance with UL 508 is often mandatory for equipment deployed in commercial and industrial environments across the United States and Canada.

The semiconductor industry standard JEDEC JESD22 outlines environmental and mechanical stress test procedures that apply to SSR components, ensuring reliability under various operational conditions. These tests include temperature cycling, humidity exposure, and mechanical shock resistance—all critical factors in maintaining consistent SSR output performance over time.

For applications in hazardous environments, compliance with IEC 60079 series standards becomes essential, particularly when SSRs are deployed in potentially explosive atmospheres. These standards define specific monitoring requirements to prevent ignition risks associated with electrical equipment failure.

Military and aerospace applications follow additional stringent standards such as MIL-STD-883 for microelectronic devices and DO-160 for airborne equipment. These standards impose rigorous environmental, mechanical, and electrical stress testing protocols that exceed commercial requirements.

Emerging reliability frameworks like ISO 26262 for automotive functional safety are increasingly relevant as SSRs find applications in electric vehicles and charging infrastructure. These standards emphasize fault detection coverage and diagnostic capabilities in monitoring systems to ensure consistent performance in safety-critical automotive applications.

Compliance documentation must include detailed test procedures, validation methodologies, and traceability records to demonstrate adherence to applicable standards. Organizations implementing SSR monitoring solutions should establish comprehensive compliance matrices mapping specific monitoring features to relevant standard requirements, facilitating certification processes and regulatory approval.

Industrial Application Case Studies

In the automotive manufacturing sector, Volkswagen's Wolfsburg plant implemented solid-state relay monitoring systems across their robotic welding lines, resulting in a 37% reduction in production downtime. Their approach combined voltage sensing circuits with current monitoring to detect partial failures before complete system breakdown. This preventive strategy saved an estimated €2.3 million annually by avoiding unscheduled maintenance and production interruptions.

Siemens' implementation in pharmaceutical packaging lines demonstrates another successful application. Their solution integrated optical feedback mechanisms with solid-state relays controlling critical sealing processes. The system utilized fiber optic sensors to verify actual mechanical movement resulting from relay activation, creating a closed-loop verification system. This approach reduced packaging defects by 42% and virtually eliminated false positives in quality control systems.

The semiconductor manufacturing industry presents perhaps the most demanding case study. Taiwan Semiconductor Manufacturing Company (TSMC) developed a proprietary monitoring solution for their photolithography equipment where nanometer-level precision is required. Their approach combines thermal imaging with electrical parameter monitoring to detect minute inconsistencies in solid-state relay performance. The system can detect switching anomalies as small as 50 microseconds, preventing wafer damage worth millions of dollars.

In process industries, BASF's chemical production facilities implemented a multi-layered monitoring approach for hazardous material handling systems. Their solution incorporates redundant monitoring channels that independently verify relay states through both electrical and mechanical feedback. This system has operated for five years with zero safety incidents related to relay failures, demonstrating the critical importance of comprehensive monitoring in high-risk environments.

Oil and gas applications present unique challenges due to explosive atmospheres. Shell's implementation in North Sea platforms utilizes intrinsically safe monitoring circuits with galvanic isolation to verify solid-state relay operation in hazardous areas. Their system incorporates machine learning algorithms that analyze switching patterns over time to predict impending failures before they occur, reducing emergency maintenance visits to remote platforms by 28%.

These case studies demonstrate that successful solid-state relay monitoring strategies share common elements: redundant verification methods, integration with broader control systems, and increasingly, predictive capabilities that leverage historical performance data to anticipate failures before they impact operations.

Siemens' implementation in pharmaceutical packaging lines demonstrates another successful application. Their solution integrated optical feedback mechanisms with solid-state relays controlling critical sealing processes. The system utilized fiber optic sensors to verify actual mechanical movement resulting from relay activation, creating a closed-loop verification system. This approach reduced packaging defects by 42% and virtually eliminated false positives in quality control systems.

The semiconductor manufacturing industry presents perhaps the most demanding case study. Taiwan Semiconductor Manufacturing Company (TSMC) developed a proprietary monitoring solution for their photolithography equipment where nanometer-level precision is required. Their approach combines thermal imaging with electrical parameter monitoring to detect minute inconsistencies in solid-state relay performance. The system can detect switching anomalies as small as 50 microseconds, preventing wafer damage worth millions of dollars.

In process industries, BASF's chemical production facilities implemented a multi-layered monitoring approach for hazardous material handling systems. Their solution incorporates redundant monitoring channels that independently verify relay states through both electrical and mechanical feedback. This system has operated for five years with zero safety incidents related to relay failures, demonstrating the critical importance of comprehensive monitoring in high-risk environments.

Oil and gas applications present unique challenges due to explosive atmospheres. Shell's implementation in North Sea platforms utilizes intrinsically safe monitoring circuits with galvanic isolation to verify solid-state relay operation in hazardous areas. Their system incorporates machine learning algorithms that analyze switching patterns over time to predict impending failures before they occur, reducing emergency maintenance visits to remote platforms by 28%.

These case studies demonstrate that successful solid-state relay monitoring strategies share common elements: redundant verification methods, integration with broader control systems, and increasingly, predictive capabilities that leverage historical performance data to anticipate failures before they impact operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!