How to Choose Solid-State Relay for Motor Control Applications

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Technology Background and Objectives

Solid-state relays (SSRs) have evolved significantly since their introduction in the 1970s as alternatives to electromechanical relays. These semiconductor-based switching devices have transformed motor control applications by offering enhanced reliability, longer operational lifespans, and improved performance characteristics. The evolution of SSR technology has been driven by advancements in semiconductor materials, manufacturing processes, and integration capabilities, resulting in increasingly compact, efficient, and versatile solutions for industrial automation and motor control systems.

The technological trajectory of SSRs has been marked by several key innovations, including the transition from discrete components to integrated circuits, improvements in thermal management, and the development of specialized variants designed specifically for motor control applications. Modern SSRs incorporate sophisticated features such as zero-crossing detection, built-in snubber circuits, and enhanced isolation barriers that significantly improve their performance and safety profiles compared to earlier generations.

The primary objective of SSR implementation in motor control applications is to achieve precise, reliable, and efficient switching operations while minimizing electromagnetic interference, heat generation, and mechanical wear. These objectives align with broader industry trends toward energy efficiency, miniaturization, and increased automation in industrial processes. Additionally, SSRs aim to address the limitations of traditional electromechanical relays, particularly in applications requiring frequent switching operations, high-speed response, or operation in harsh environmental conditions.

Current market dynamics indicate a growing preference for SSRs in motor control applications across various industries, including manufacturing, HVAC systems, automotive, and renewable energy. This trend is driven by the increasing complexity of motor control requirements, the need for integration with digital control systems, and the push for greater energy efficiency in industrial operations.

The technical challenges that continue to shape SSR development include improving power handling capabilities, reducing on-state resistance, enhancing thermal performance, and ensuring compatibility with various motor types and control architectures. These challenges represent key areas of focus for ongoing research and development efforts in the field.

Looking forward, the evolution of SSR technology is expected to continue along several trajectories, including greater integration with digital control systems, improved energy efficiency, enhanced diagnostic capabilities, and adaptation to emerging motor technologies such as those used in electric vehicles and renewable energy systems. These developments will further expand the application scope and performance capabilities of SSRs in motor control applications.

The technological trajectory of SSRs has been marked by several key innovations, including the transition from discrete components to integrated circuits, improvements in thermal management, and the development of specialized variants designed specifically for motor control applications. Modern SSRs incorporate sophisticated features such as zero-crossing detection, built-in snubber circuits, and enhanced isolation barriers that significantly improve their performance and safety profiles compared to earlier generations.

The primary objective of SSR implementation in motor control applications is to achieve precise, reliable, and efficient switching operations while minimizing electromagnetic interference, heat generation, and mechanical wear. These objectives align with broader industry trends toward energy efficiency, miniaturization, and increased automation in industrial processes. Additionally, SSRs aim to address the limitations of traditional electromechanical relays, particularly in applications requiring frequent switching operations, high-speed response, or operation in harsh environmental conditions.

Current market dynamics indicate a growing preference for SSRs in motor control applications across various industries, including manufacturing, HVAC systems, automotive, and renewable energy. This trend is driven by the increasing complexity of motor control requirements, the need for integration with digital control systems, and the push for greater energy efficiency in industrial operations.

The technical challenges that continue to shape SSR development include improving power handling capabilities, reducing on-state resistance, enhancing thermal performance, and ensuring compatibility with various motor types and control architectures. These challenges represent key areas of focus for ongoing research and development efforts in the field.

Looking forward, the evolution of SSR technology is expected to continue along several trajectories, including greater integration with digital control systems, improved energy efficiency, enhanced diagnostic capabilities, and adaptation to emerging motor technologies such as those used in electric vehicles and renewable energy systems. These developments will further expand the application scope and performance capabilities of SSRs in motor control applications.

Market Demand Analysis for Motor Control SSRs

The global market for Solid-State Relays (SSRs) in motor control applications has experienced significant growth over the past decade, driven by increasing industrial automation and the need for more reliable and efficient control systems. The motor control segment represents approximately 30% of the total SSR market, with a compound annual growth rate of 6.8% projected through 2028.

Industrial automation remains the primary demand driver, particularly in manufacturing sectors where precise motor control is critical for operational efficiency. Factory automation, robotics, and advanced manufacturing processes require increasingly sophisticated motor control solutions that traditional electromechanical relays cannot adequately provide. This has created substantial market pull for SSR technologies that offer superior performance characteristics.

HVAC systems represent another major growth segment, with building automation trends driving demand for more intelligent motor control solutions. The energy efficiency regulations in North America, Europe, and parts of Asia have accelerated adoption of variable speed drives and their associated control components, including SSRs. This regulatory environment has created a market premium for energy-efficient motor control solutions.

Consumer appliances constitute an emerging market for motor control SSRs, particularly in premium household products where noise reduction, reliability, and compact design are valued. Manufacturers of high-end washing machines, refrigerators, and kitchen appliances are increasingly incorporating SSRs to achieve better performance and longer product lifespans.

Regional analysis indicates that Asia-Pacific currently leads the market demand, accounting for approximately 42% of global consumption. This is primarily due to the region's manufacturing strength, particularly in China, Japan, and South Korea. North America follows with 28% market share, while Europe represents about 24% of global demand.

End-user segmentation reveals that automotive manufacturing, semiconductor production, and food processing industries are the top three consumers of motor control SSRs. These industries require precise control, high reliability, and resistance to harsh operating environments—all attributes that modern SSRs can provide.

Market research indicates a growing preference for SSRs with integrated diagnostic capabilities and network connectivity features, reflecting the broader Industry 4.0 trend. Customers increasingly demand products that not only perform the basic switching function but also provide operational data and predictive maintenance information.

Price sensitivity varies significantly by application segment. While consumer applications remain highly price-sensitive, industrial users typically prioritize reliability and performance over initial cost, recognizing the long-term economic benefits of reduced maintenance and downtime.

Industrial automation remains the primary demand driver, particularly in manufacturing sectors where precise motor control is critical for operational efficiency. Factory automation, robotics, and advanced manufacturing processes require increasingly sophisticated motor control solutions that traditional electromechanical relays cannot adequately provide. This has created substantial market pull for SSR technologies that offer superior performance characteristics.

HVAC systems represent another major growth segment, with building automation trends driving demand for more intelligent motor control solutions. The energy efficiency regulations in North America, Europe, and parts of Asia have accelerated adoption of variable speed drives and their associated control components, including SSRs. This regulatory environment has created a market premium for energy-efficient motor control solutions.

Consumer appliances constitute an emerging market for motor control SSRs, particularly in premium household products where noise reduction, reliability, and compact design are valued. Manufacturers of high-end washing machines, refrigerators, and kitchen appliances are increasingly incorporating SSRs to achieve better performance and longer product lifespans.

Regional analysis indicates that Asia-Pacific currently leads the market demand, accounting for approximately 42% of global consumption. This is primarily due to the region's manufacturing strength, particularly in China, Japan, and South Korea. North America follows with 28% market share, while Europe represents about 24% of global demand.

End-user segmentation reveals that automotive manufacturing, semiconductor production, and food processing industries are the top three consumers of motor control SSRs. These industries require precise control, high reliability, and resistance to harsh operating environments—all attributes that modern SSRs can provide.

Market research indicates a growing preference for SSRs with integrated diagnostic capabilities and network connectivity features, reflecting the broader Industry 4.0 trend. Customers increasingly demand products that not only perform the basic switching function but also provide operational data and predictive maintenance information.

Price sensitivity varies significantly by application segment. While consumer applications remain highly price-sensitive, industrial users typically prioritize reliability and performance over initial cost, recognizing the long-term economic benefits of reduced maintenance and downtime.

Current SSR Technology Challenges in Motor Applications

Despite the significant advancements in solid-state relay (SSR) technology, several challenges persist when implementing SSRs in motor control applications. One primary concern is heat dissipation, as SSRs generate considerable heat during operation, especially in high-current motor applications. This thermal management issue becomes particularly critical in compact control cabinets or environments with limited cooling capabilities, potentially leading to premature device failure if not properly addressed.

Voltage spikes and transients present another significant challenge. Motors inherently produce inductive loads that generate substantial back-EMF (electromotive force) during switching operations, particularly during motor startup and shutdown phases. These voltage spikes can exceed the SSR's maximum ratings, potentially causing damage to the semiconductor components within the relay. While many modern SSRs incorporate snubber circuits to mitigate these effects, selecting appropriate protection for specific motor characteristics remains challenging.

The zero-crossing functionality, while beneficial for reducing electromagnetic interference (EMI), introduces response time limitations that can be problematic in applications requiring precise motor control. The inherent delay between command signal and actual switching action can impact applications where timing precision is critical, such as in coordinated multi-axis motion control systems.

Current SSR technology also faces challenges with motor inrush currents, which can be 6-10 times the normal operating current. This momentary high-current condition requires SSRs to have substantial surge current capabilities, often necessitating significant overrating of the relay or implementation of soft-start mechanisms, both of which increase system complexity and cost.

Leakage current represents another persistent issue in SSR applications. Even in the "off" state, SSRs typically allow a small leakage current to flow through the load, which can cause motors to exhibit minimal torque or heating when supposedly inactive. This phenomenon is particularly problematic in safety-critical applications or systems where even minimal unintended movement could cause issues.

The trade-off between SSR performance and cost continues to challenge engineers. High-performance SSRs with enhanced features like improved thermal management, faster switching speeds, and better surge protection command premium prices that may be difficult to justify in cost-sensitive applications, forcing compromises in system reliability or performance.

Finally, environmental factors such as ambient temperature fluctuations, humidity, and dust accumulation can significantly impact SSR performance in industrial motor control settings. These environmental challenges often necessitate additional protective measures or regular maintenance protocols, adding complexity to system design and operational requirements.

Voltage spikes and transients present another significant challenge. Motors inherently produce inductive loads that generate substantial back-EMF (electromotive force) during switching operations, particularly during motor startup and shutdown phases. These voltage spikes can exceed the SSR's maximum ratings, potentially causing damage to the semiconductor components within the relay. While many modern SSRs incorporate snubber circuits to mitigate these effects, selecting appropriate protection for specific motor characteristics remains challenging.

The zero-crossing functionality, while beneficial for reducing electromagnetic interference (EMI), introduces response time limitations that can be problematic in applications requiring precise motor control. The inherent delay between command signal and actual switching action can impact applications where timing precision is critical, such as in coordinated multi-axis motion control systems.

Current SSR technology also faces challenges with motor inrush currents, which can be 6-10 times the normal operating current. This momentary high-current condition requires SSRs to have substantial surge current capabilities, often necessitating significant overrating of the relay or implementation of soft-start mechanisms, both of which increase system complexity and cost.

Leakage current represents another persistent issue in SSR applications. Even in the "off" state, SSRs typically allow a small leakage current to flow through the load, which can cause motors to exhibit minimal torque or heating when supposedly inactive. This phenomenon is particularly problematic in safety-critical applications or systems where even minimal unintended movement could cause issues.

The trade-off between SSR performance and cost continues to challenge engineers. High-performance SSRs with enhanced features like improved thermal management, faster switching speeds, and better surge protection command premium prices that may be difficult to justify in cost-sensitive applications, forcing compromises in system reliability or performance.

Finally, environmental factors such as ambient temperature fluctuations, humidity, and dust accumulation can significantly impact SSR performance in industrial motor control settings. These environmental challenges often necessitate additional protective measures or regular maintenance protocols, adding complexity to system design and operational requirements.

Current SSR Selection Methodologies for Motors

01 Basic structure and operation of solid-state relays

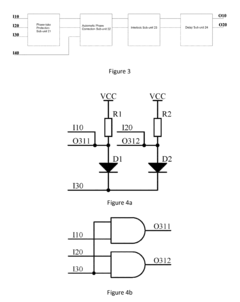

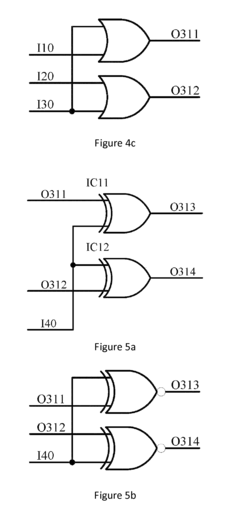

Solid-state relays (SSRs) are electronic switching devices that use semiconductor components instead of mechanical contacts to switch electrical loads. They typically consist of an input circuit with optical isolation, a semiconductor switching element (such as a TRIAC, MOSFET, or thyristor), and output circuitry. SSRs offer advantages including no moving parts, silent operation, fast switching speeds, and longer operational life compared to mechanical relays.- Basic structure and operation of solid-state relays: Solid-state relays (SSRs) are electronic switching devices that use semiconductor components instead of mechanical contacts to switch electrical loads. They typically consist of an input circuit with optical isolation, a semiconductor switching element (such as a TRIAC, MOSFET, or thyristor), and output circuitry. SSRs offer advantages including no moving parts, silent operation, fast switching speeds, and long operational life compared to mechanical relays.

- Protection circuits and thermal management in SSRs: Protection circuits are essential components in solid-state relays to prevent damage from overcurrent, overvoltage, and thermal issues. These circuits may include snubber networks, varistors, and thermal management solutions. Advanced SSRs incorporate temperature sensors, heat sinks, and thermal shutdown mechanisms to prevent overheating during high-current switching operations, ensuring reliable performance and extended device lifetime.

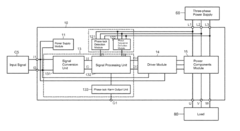

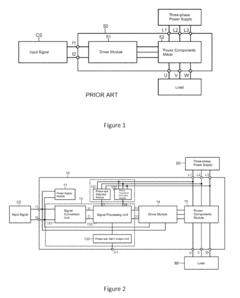

- Integration of SSRs in power control systems: Solid-state relays are increasingly integrated into sophisticated power control systems for industrial automation, smart grid applications, and energy management. These integrated systems may combine multiple SSRs with microcontrollers, communication interfaces, and diagnostic capabilities. The integration enables remote monitoring, programmable switching sequences, and coordination with other system components for efficient power distribution and control.

- Advanced semiconductor technologies for SSRs: Recent advancements in semiconductor technologies have significantly improved solid-state relay performance. Wide bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN) offer higher temperature operation, faster switching speeds, and lower conduction losses compared to traditional silicon-based devices. These advanced materials enable SSRs to handle higher power densities while maintaining reliability in harsh operating environments.

- Circuit design innovations for improved SSR performance: Innovative circuit designs enhance solid-state relay performance through improved driving methods, reduced power consumption, and enhanced isolation techniques. These designs may incorporate advanced gate driving circuits, optimized snubber networks, and novel isolation barriers. Some implementations feature bidirectional switching capabilities, zero-crossing detection for reduced electromagnetic interference, and intelligent control algorithms that adapt to varying load conditions.

02 Protection circuits in solid-state relays

Protection circuits are integrated into solid-state relays to prevent damage from overcurrent, overvoltage, and thermal conditions. These circuits may include snubber networks to suppress voltage spikes, current limiting components, thermal shutdown mechanisms, and fault detection systems. Advanced protection features help improve the reliability and durability of solid-state relays in harsh operating environments and protect both the relay and connected equipment.Expand Specific Solutions03 Semiconductor technologies for solid-state relays

Various semiconductor technologies are employed in solid-state relays to achieve different performance characteristics. These include MOSFETs for low on-resistance and high-speed switching, IGBTs for handling higher currents and voltages, thyristors for AC applications, and specialized integrated circuits that combine multiple functions. The choice of semiconductor technology affects the relay's switching speed, power handling capability, thermal performance, and overall efficiency.Expand Specific Solutions04 Thermal management in solid-state relays

Thermal management is critical in solid-state relay design to prevent overheating and ensure reliable operation. Techniques include the use of heat sinks, thermal interface materials, optimized package designs, and strategic component placement. Advanced thermal management solutions may incorporate active cooling, temperature sensors, and automatic thermal shutdown features. Effective thermal design extends the operational life of the relay and allows for higher current handling capabilities.Expand Specific Solutions05 Control and integration features of solid-state relays

Modern solid-state relays incorporate advanced control and integration features to enhance functionality and ease of use. These include microcontroller interfaces, digital communication capabilities, programmable switching parameters, status monitoring, and diagnostic functions. Some designs feature multiple channels in a single package, configurable operating modes, and compatibility with various control systems. These advancements enable solid-state relays to be seamlessly integrated into complex automation and power management systems.Expand Specific Solutions

Major SSR Manufacturers and Market Competition

The solid-state relay (SSR) market for motor control applications is currently in a growth phase, characterized by increasing adoption across industrial automation sectors. The market size is expanding steadily, driven by the transition from mechanical relays to more reliable electronic solutions. From a technical maturity perspective, companies like Littelfuse, Texas Instruments, and Siemens Industry have established strong positions with advanced SSR technologies featuring improved thermal management and noise immunity. Emerging players such as Novosense Microelectronics and Mornsun are gaining traction with cost-effective solutions, while specialized manufacturers like TE Connectivity and Efficient Power Conversion are pushing boundaries with GaN-based SSRs offering superior switching speeds. The competitive landscape is diversifying as automotive specialists including Hitachi Automotive Systems and Valeo increasingly integrate SSR technology into electric vehicle applications.

Littelfuse, Inc.

Technical Solution: Littelfuse has developed advanced solid-state relay solutions specifically optimized for motor control applications. Their technology employs MOSFET-based output stages with integrated thermal management systems that can handle inrush currents up to 6 times the nominal motor current. Their SSRs feature zero-crossing detection circuits that minimize electromagnetic interference during switching operations, critical for precision motor control. Littelfuse's motor control SSRs incorporate advanced diagnostic capabilities including overcurrent protection, short-circuit detection, and temperature monitoring with automatic shutdown functionality. Their latest generation implements proprietary heat dissipation technology allowing for compact designs with current ratings up to 40A continuous without external heatsinks. The company's motor control SSRs also feature adjustable turn-on/turn-off delay times to optimize motor starting characteristics and minimize mechanical stress.

Strengths: Superior thermal management allowing higher current ratings in smaller packages; comprehensive built-in protection features; zero-crossing technology for reduced EMI. Weaknesses: Higher cost compared to electromechanical relays; requires careful thermal design in high-ambient temperature environments.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has pioneered integrated solid-state relay solutions for motor control that combine driver circuits, protection features, and diagnostics in single-chip designs. Their technology utilizes advanced silicon-on-insulator (SOI) processes to achieve isolation ratings exceeding 4kV while maintaining fast switching speeds below 100μs. TI's motor control SSRs incorporate adaptive gate drive technology that optimizes switching characteristics based on load conditions, significantly reducing switching losses during motor operation. Their solutions feature programmable current limiting that can be adjusted via I2C or SPI interfaces, allowing dynamic protection thresholds based on motor operating states. TI has also developed specialized SSRs with integrated current sensing providing 0.5% accuracy for precise motor torque control applications. Their latest designs incorporate power density improvements of approximately 40% compared to previous generations through advanced packaging techniques and thermal optimization.

Strengths: High level of integration reducing component count; programmable protection features; excellent isolation characteristics with minimal parasitic capacitance. Weaknesses: May require additional programming/configuration compared to simpler solutions; higher complexity for basic applications.

Key Technical Parameters for Motor Control SSRs

Solid-state relay for running direction control of three-phase alternating current motor and method thereof

PatentActiveUS9559625B2

Innovation

- A solid state relay with integrated phase sequence detection, phase lack detection, automatic phase correction, and phase lack protection logic, utilizing discrete components to provide centralized, safe, and low-cost control of three-phase AC motor direction, eliminating the need for external MCU/DSP controllers.

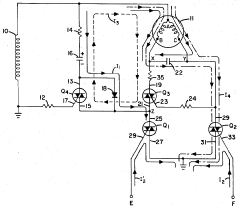

Solid-state motor control circuit using triac elements

PatentInactiveUS3579064A

Innovation

- A solid-state motor control circuit utilizing triacs coupled to a single-phase motor and an AC power source, with a capacitor, allowing for direction control and braking by gating specific triac combinations, reducing space and cost while enhancing reliability.

Thermal Management Considerations for SSR Implementation

Thermal management represents a critical aspect of solid-state relay (SSR) implementation in motor control applications. When SSRs conduct current, they generate heat that must be effectively dissipated to prevent thermal runaway and potential device failure. The primary heat generation occurs at the semiconductor junction within the SSR, where power dissipation is proportional to the square of the load current multiplied by the on-state resistance (P = I²R). For motor control applications, which often involve high inrush currents during startup, this thermal consideration becomes particularly significant.

Proper heat sink selection forms the foundation of effective thermal management for SSRs. Heat sinks increase the surface area available for heat dissipation and should be sized according to the maximum anticipated power dissipation. The thermal resistance of the heat sink (measured in °C/W) must be calculated based on the maximum allowable junction temperature, ambient temperature, and power dissipation. For motor control applications, oversizing the heat sink by 20-30% provides a safety margin for unexpected load variations.

Thermal interface materials (TIMs) play a crucial role in establishing efficient thermal pathways between the SSR and heat sink. These materials—including thermal greases, phase change materials, and thermal pads—fill microscopic air gaps at the interface, significantly improving heat transfer efficiency. The selection of appropriate TIMs depends on factors such as thermal conductivity requirements, application environment, and maintenance considerations.

Environmental factors substantially impact SSR thermal performance in motor control systems. Ambient temperature, airflow conditions, and installation orientation all affect heat dissipation capabilities. In environments with elevated ambient temperatures, derating the SSR current capacity becomes necessary to maintain safe operating temperatures. Similarly, restricted airflow situations may require forced cooling solutions such as fans or blowers to enhance convection cooling.

Temperature monitoring represents a prudent practice for critical motor control applications. Implementing temperature sensors near the SSR can provide early warning of potential thermal issues, enabling protective measures before failure occurs. Some advanced SSR modules incorporate built-in temperature monitoring and protection circuits that automatically disconnect the load if thermal limits are exceeded.

For high-power motor applications, additional cooling strategies may be necessary. These include forced-air cooling systems, liquid cooling solutions for extreme environments, or distributing the load across multiple SSRs operating in parallel. The latter approach not only divides the thermal load but also provides redundancy in critical applications.

Proper heat sink selection forms the foundation of effective thermal management for SSRs. Heat sinks increase the surface area available for heat dissipation and should be sized according to the maximum anticipated power dissipation. The thermal resistance of the heat sink (measured in °C/W) must be calculated based on the maximum allowable junction temperature, ambient temperature, and power dissipation. For motor control applications, oversizing the heat sink by 20-30% provides a safety margin for unexpected load variations.

Thermal interface materials (TIMs) play a crucial role in establishing efficient thermal pathways between the SSR and heat sink. These materials—including thermal greases, phase change materials, and thermal pads—fill microscopic air gaps at the interface, significantly improving heat transfer efficiency. The selection of appropriate TIMs depends on factors such as thermal conductivity requirements, application environment, and maintenance considerations.

Environmental factors substantially impact SSR thermal performance in motor control systems. Ambient temperature, airflow conditions, and installation orientation all affect heat dissipation capabilities. In environments with elevated ambient temperatures, derating the SSR current capacity becomes necessary to maintain safe operating temperatures. Similarly, restricted airflow situations may require forced cooling solutions such as fans or blowers to enhance convection cooling.

Temperature monitoring represents a prudent practice for critical motor control applications. Implementing temperature sensors near the SSR can provide early warning of potential thermal issues, enabling protective measures before failure occurs. Some advanced SSR modules incorporate built-in temperature monitoring and protection circuits that automatically disconnect the load if thermal limits are exceeded.

For high-power motor applications, additional cooling strategies may be necessary. These include forced-air cooling systems, liquid cooling solutions for extreme environments, or distributing the load across multiple SSRs operating in parallel. The latter approach not only divides the thermal load but also provides redundancy in critical applications.

Safety Standards and Compliance Requirements

When selecting solid-state relays (SSRs) for motor control applications, compliance with safety standards is paramount to ensure operational reliability, personnel safety, and legal conformity. The International Electrotechnical Commission (IEC) provides several key standards that manufacturers and system integrators must adhere to, including IEC 60947-4-3 for AC semiconductor controllers and starters, and IEC 60947-5-1 for control circuit devices. These standards establish requirements for electrical ratings, thermal performance, and electromagnetic compatibility.

In North America, UL 508 serves as the primary standard for industrial control equipment, including solid-state relays used in motor control applications. This standard specifies requirements for construction, performance, and marking of industrial control equipment. Additionally, CSA C22.2 No. 14 provides similar requirements for industrial control equipment in Canada, ensuring cross-border compatibility for manufacturers serving the North American market.

European markets require compliance with the Low Voltage Directive (2014/35/EU) and Electromagnetic Compatibility Directive (2014/30/EU), with CE marking indicating conformity. For motor control applications in hazardous environments, additional standards such as ATEX Directive 2014/34/EU in Europe or UL 1203 in North America may apply, requiring specially designed SSRs with appropriate certifications.

The International Protection (IP) rating system, defined by IEC 60529, specifies the environmental protection provided by the enclosure of electrical equipment. For motor control applications in harsh industrial environments, SSRs with higher IP ratings (typically IP54 or above) are recommended to protect against dust and moisture ingress.

Safety Integrity Level (SIL) certification according to IEC 61508 becomes critical for motor control applications in safety-critical systems. This standard defines requirements for ensuring that systems perform safety functions with a specified level of reliability. For applications requiring functional safety, selecting SSRs with appropriate SIL certification is essential.

RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) compliance are increasingly important environmental considerations, particularly for products destined for European markets. These regulations limit the use of certain hazardous materials in electrical and electronic equipment, affecting the manufacturing processes and material selection for solid-state relays.

When selecting SSRs for specific applications, engineers should verify that the chosen components meet all relevant regional and application-specific standards, as non-compliance can lead to product recalls, legal liabilities, and safety hazards. Documentation of compliance through test reports, certificates, and declarations of conformity should be maintained as part of the product development and quality assurance process.

In North America, UL 508 serves as the primary standard for industrial control equipment, including solid-state relays used in motor control applications. This standard specifies requirements for construction, performance, and marking of industrial control equipment. Additionally, CSA C22.2 No. 14 provides similar requirements for industrial control equipment in Canada, ensuring cross-border compatibility for manufacturers serving the North American market.

European markets require compliance with the Low Voltage Directive (2014/35/EU) and Electromagnetic Compatibility Directive (2014/30/EU), with CE marking indicating conformity. For motor control applications in hazardous environments, additional standards such as ATEX Directive 2014/34/EU in Europe or UL 1203 in North America may apply, requiring specially designed SSRs with appropriate certifications.

The International Protection (IP) rating system, defined by IEC 60529, specifies the environmental protection provided by the enclosure of electrical equipment. For motor control applications in harsh industrial environments, SSRs with higher IP ratings (typically IP54 or above) are recommended to protect against dust and moisture ingress.

Safety Integrity Level (SIL) certification according to IEC 61508 becomes critical for motor control applications in safety-critical systems. This standard defines requirements for ensuring that systems perform safety functions with a specified level of reliability. For applications requiring functional safety, selecting SSRs with appropriate SIL certification is essential.

RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) compliance are increasingly important environmental considerations, particularly for products destined for European markets. These regulations limit the use of certain hazardous materials in electrical and electronic equipment, affecting the manufacturing processes and material selection for solid-state relays.

When selecting SSRs for specific applications, engineers should verify that the chosen components meet all relevant regional and application-specific standards, as non-compliance can lead to product recalls, legal liabilities, and safety hazards. Documentation of compliance through test reports, certificates, and declarations of conformity should be maintained as part of the product development and quality assurance process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!