Solid-State Relay vs Hybrid Relays: Application Efficiency

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Relay Technology Evolution and Objectives

Relay technology has undergone significant evolution since its inception in the early 19th century. Traditional electromechanical relays, characterized by physical moving contacts, dominated industrial applications for over a century. These devices, while reliable for their time, presented limitations in switching speed, size, and operational lifespan due to mechanical wear. The mid-20th century witnessed the emergence of solid-state relays (SSRs), which represented a paradigm shift by eliminating moving parts through semiconductor-based switching mechanisms.

The technological trajectory continued with the development of hybrid relays in the late 20th century, combining electromechanical components with solid-state elements to leverage the advantages of both technologies. This evolutionary path has been driven by increasing demands for energy efficiency, miniaturization, and enhanced reliability across diverse industrial applications.

Current market trends indicate a growing preference for advanced relay technologies that offer improved performance metrics, particularly in power management and industrial automation sectors. The global relay market is experiencing a compound annual growth rate of approximately 7%, with solid-state and hybrid variants capturing an increasing market share due to their superior application efficiency.

The primary technological objective in contemporary relay development focuses on optimizing the efficiency-reliability balance. Solid-state relays excel in switching speed and operational longevity but face challenges in heat dissipation and off-state leakage current. Conversely, hybrid relays offer enhanced isolation properties and lower power consumption during operation, though at higher initial cost points.

Industry projections suggest that future relay technologies will increasingly prioritize energy conservation, reduced form factors, and integration capabilities with smart systems. Research initiatives are actively exploring novel semiconductor materials and innovative thermal management solutions to address current limitations in solid-state relay performance.

The convergence of relay technology with Internet of Things (IoT) frameworks represents another significant objective, as modern industrial systems require seamless communication capabilities alongside traditional switching functions. This integration necessitates advancements in both hardware architecture and control software to enable predictive maintenance and real-time performance monitoring.

As industrial automation continues to advance, the technical objectives for relay technology increasingly emphasize adaptability across diverse operating environments, from extreme temperature conditions to high electromagnetic interference settings. This adaptability requirement is driving specialized research into environmentally robust designs that maintain consistent performance metrics regardless of external conditions.

The technological trajectory continued with the development of hybrid relays in the late 20th century, combining electromechanical components with solid-state elements to leverage the advantages of both technologies. This evolutionary path has been driven by increasing demands for energy efficiency, miniaturization, and enhanced reliability across diverse industrial applications.

Current market trends indicate a growing preference for advanced relay technologies that offer improved performance metrics, particularly in power management and industrial automation sectors. The global relay market is experiencing a compound annual growth rate of approximately 7%, with solid-state and hybrid variants capturing an increasing market share due to their superior application efficiency.

The primary technological objective in contemporary relay development focuses on optimizing the efficiency-reliability balance. Solid-state relays excel in switching speed and operational longevity but face challenges in heat dissipation and off-state leakage current. Conversely, hybrid relays offer enhanced isolation properties and lower power consumption during operation, though at higher initial cost points.

Industry projections suggest that future relay technologies will increasingly prioritize energy conservation, reduced form factors, and integration capabilities with smart systems. Research initiatives are actively exploring novel semiconductor materials and innovative thermal management solutions to address current limitations in solid-state relay performance.

The convergence of relay technology with Internet of Things (IoT) frameworks represents another significant objective, as modern industrial systems require seamless communication capabilities alongside traditional switching functions. This integration necessitates advancements in both hardware architecture and control software to enable predictive maintenance and real-time performance monitoring.

As industrial automation continues to advance, the technical objectives for relay technology increasingly emphasize adaptability across diverse operating environments, from extreme temperature conditions to high electromagnetic interference settings. This adaptability requirement is driving specialized research into environmentally robust designs that maintain consistent performance metrics regardless of external conditions.

Market Demand Analysis for Advanced Relay Solutions

The global relay market is experiencing significant transformation driven by industrial automation, smart grid development, and the Internet of Things (IoT) integration. Current market analysis indicates that the advanced relay market, encompassing both solid-state relays (SSRs) and hybrid relays, is projected to grow at a compound annual growth rate of 6.8% through 2028, reaching a market value of approximately 15.7 billion USD.

Industrial automation represents the largest demand segment, accounting for nearly 40% of the advanced relay market. Manufacturing facilities are increasingly replacing traditional electromechanical relays with solid-state and hybrid alternatives to improve production efficiency, reduce maintenance costs, and extend equipment lifespan. The automotive industry follows closely, with electric vehicles creating substantial demand for high-performance power management components.

Energy management systems constitute another rapidly expanding market segment. Smart grid implementations worldwide are driving demand for advanced relays capable of handling bidirectional power flow and providing enhanced protection features. Utility companies are particularly interested in hybrid relay solutions that combine the reliability of mechanical systems with the speed and intelligence of solid-state technology.

Consumer electronics manufacturers are adopting solid-state relays at an accelerated pace, primarily due to their compact size, silent operation, and compatibility with modern circuit designs. This segment shows the highest growth potential, with an estimated annual increase of 8.3% in relay component demand.

Regional analysis reveals Asia-Pacific as the dominant market, representing approximately 45% of global demand, followed by North America and Europe. China, Japan, and South Korea lead manufacturing capacity, while emerging economies in Southeast Asia show the fastest adoption rates for advanced relay technologies in their developing industrial sectors.

Customer requirements are evolving toward more integrated solutions. End-users increasingly demand relays with built-in diagnostic capabilities, remote monitoring features, and compatibility with industrial IoT platforms. This trend is particularly pronounced in critical infrastructure applications where system reliability and predictive maintenance capabilities command premium pricing.

Price sensitivity varies significantly across application domains. While consumer electronics manufacturers prioritize cost efficiency, industrial and utility customers demonstrate willingness to invest in premium relay solutions that offer superior performance metrics and longer operational lifespans. The total cost of ownership, rather than initial acquisition cost, has become the primary decision factor for many industrial procurement processes.

Industrial automation represents the largest demand segment, accounting for nearly 40% of the advanced relay market. Manufacturing facilities are increasingly replacing traditional electromechanical relays with solid-state and hybrid alternatives to improve production efficiency, reduce maintenance costs, and extend equipment lifespan. The automotive industry follows closely, with electric vehicles creating substantial demand for high-performance power management components.

Energy management systems constitute another rapidly expanding market segment. Smart grid implementations worldwide are driving demand for advanced relays capable of handling bidirectional power flow and providing enhanced protection features. Utility companies are particularly interested in hybrid relay solutions that combine the reliability of mechanical systems with the speed and intelligence of solid-state technology.

Consumer electronics manufacturers are adopting solid-state relays at an accelerated pace, primarily due to their compact size, silent operation, and compatibility with modern circuit designs. This segment shows the highest growth potential, with an estimated annual increase of 8.3% in relay component demand.

Regional analysis reveals Asia-Pacific as the dominant market, representing approximately 45% of global demand, followed by North America and Europe. China, Japan, and South Korea lead manufacturing capacity, while emerging economies in Southeast Asia show the fastest adoption rates for advanced relay technologies in their developing industrial sectors.

Customer requirements are evolving toward more integrated solutions. End-users increasingly demand relays with built-in diagnostic capabilities, remote monitoring features, and compatibility with industrial IoT platforms. This trend is particularly pronounced in critical infrastructure applications where system reliability and predictive maintenance capabilities command premium pricing.

Price sensitivity varies significantly across application domains. While consumer electronics manufacturers prioritize cost efficiency, industrial and utility customers demonstrate willingness to invest in premium relay solutions that offer superior performance metrics and longer operational lifespans. The total cost of ownership, rather than initial acquisition cost, has become the primary decision factor for many industrial procurement processes.

Current State and Challenges in Relay Technologies

The relay technology landscape has evolved significantly over the past decades, with solid-state relays (SSRs) and hybrid relays representing the current pinnacle of switching technology. Globally, the relay market is experiencing robust growth, projected to reach $15.5 billion by 2026, with solid-state and hybrid technologies accounting for an increasing share. This growth is driven by industrial automation, smart grid implementations, and the expanding electric vehicle sector.

Solid-state relays have achieved widespread adoption in numerous applications due to their reliability and longevity. These devices utilize semiconductor components like thyristors, triacs, and MOSFETs to perform switching operations without mechanical movement. However, they continue to face challenges related to heat dissipation, with operating temperatures often limited to 80-100°C before requiring additional cooling solutions. Furthermore, their relatively high ON-state resistance compared to mechanical contacts results in power losses that can reach 1-2% of the switched load.

Hybrid relays, which combine mechanical contacts with semiconductor switching elements, represent a technological compromise aimed at leveraging the strengths of both approaches. These devices have demonstrated impressive performance metrics, including switching speeds of under 5ms and lifespans exceeding 100 million operations. Nevertheless, they face integration challenges due to their complex architecture, which combines both electronic and mechanical components in a single package.

A significant technical hurdle for both technologies remains the management of inrush currents, particularly in capacitive and lighting loads where initial currents can reach 10-15 times the steady-state values. Current solutions employ various soft-start mechanisms, but these add complexity and cost to relay implementations.

Geographic distribution of relay technology development shows concentration in East Asia, particularly Japan and South Korea for advanced hybrid solutions, while North America leads in specialized high-power solid-state applications. European manufacturers have focused on hybrid relay innovations for automotive and industrial applications, creating a globally diverse technology landscape.

Regulatory challenges present another obstacle, with varying standards across regions creating compliance complexities. The IEC 60947 standard for low-voltage switchgear differs in implementation between European and North American markets, necessitating region-specific product variations that impede global standardization efforts.

The miniaturization trend continues to drive development, with the latest solid-state relays achieving footprints 40% smaller than previous generations. However, this miniaturization introduces thermal management challenges that current materials science has yet to fully resolve, particularly in high-density applications where multiple relays operate in close proximity.

Solid-state relays have achieved widespread adoption in numerous applications due to their reliability and longevity. These devices utilize semiconductor components like thyristors, triacs, and MOSFETs to perform switching operations without mechanical movement. However, they continue to face challenges related to heat dissipation, with operating temperatures often limited to 80-100°C before requiring additional cooling solutions. Furthermore, their relatively high ON-state resistance compared to mechanical contacts results in power losses that can reach 1-2% of the switched load.

Hybrid relays, which combine mechanical contacts with semiconductor switching elements, represent a technological compromise aimed at leveraging the strengths of both approaches. These devices have demonstrated impressive performance metrics, including switching speeds of under 5ms and lifespans exceeding 100 million operations. Nevertheless, they face integration challenges due to their complex architecture, which combines both electronic and mechanical components in a single package.

A significant technical hurdle for both technologies remains the management of inrush currents, particularly in capacitive and lighting loads where initial currents can reach 10-15 times the steady-state values. Current solutions employ various soft-start mechanisms, but these add complexity and cost to relay implementations.

Geographic distribution of relay technology development shows concentration in East Asia, particularly Japan and South Korea for advanced hybrid solutions, while North America leads in specialized high-power solid-state applications. European manufacturers have focused on hybrid relay innovations for automotive and industrial applications, creating a globally diverse technology landscape.

Regulatory challenges present another obstacle, with varying standards across regions creating compliance complexities. The IEC 60947 standard for low-voltage switchgear differs in implementation between European and North American markets, necessitating region-specific product variations that impede global standardization efforts.

The miniaturization trend continues to drive development, with the latest solid-state relays achieving footprints 40% smaller than previous generations. However, this miniaturization introduces thermal management challenges that current materials science has yet to fully resolve, particularly in high-density applications where multiple relays operate in close proximity.

Comparative Analysis of SSR and Hybrid Relay Solutions

01 Design improvements for solid-state relay efficiency

Various design improvements can enhance the efficiency of solid-state relays. These include optimized semiconductor structures, improved heat dissipation mechanisms, and advanced circuit configurations that reduce power losses during operation. These design elements help minimize voltage drops across the relay, decrease power consumption, and improve overall energy efficiency while maintaining reliable switching performance.- Solid-state relay design for improved efficiency: Solid-state relays can be designed with specific semiconductor configurations to reduce power losses and improve overall efficiency. These designs often incorporate advanced semiconductor materials and optimized gate drive circuits to minimize conduction losses and switching losses. The improved designs can include heat dissipation mechanisms and thermal management solutions to maintain optimal operating temperatures, further enhancing efficiency and reliability.

- Hybrid relay technologies combining mechanical and solid-state elements: Hybrid relays integrate both mechanical contacts and semiconductor switching devices to leverage the advantages of each technology. These relays typically use solid-state components for fast switching and arc suppression while utilizing mechanical contacts for low conduction losses during steady-state operation. This combination results in improved efficiency by reducing heat generation and power consumption compared to traditional relays or pure solid-state solutions.

- Thermal management techniques for relay efficiency: Effective thermal management is crucial for maintaining relay efficiency, especially in solid-state and hybrid designs where heat generation can impact performance. Advanced cooling methods, heat sink designs, and thermal interface materials are employed to dissipate heat efficiently. Some designs incorporate temperature monitoring and adaptive control systems to optimize operation based on thermal conditions, preventing efficiency degradation under high-load situations.

- Control circuit innovations for relay efficiency: Sophisticated control circuits can significantly improve relay efficiency by optimizing switching timing, reducing switching losses, and minimizing power consumption in the control path. These innovations include adaptive gate drive techniques, intelligent power management algorithms, and precise timing control. Advanced control circuits can also implement zero-voltage or zero-current switching techniques to minimize energy losses during state transitions.

- Integration of digital intelligence for optimized relay operation: Modern relay systems incorporate microcontrollers and digital signal processors to continuously monitor and optimize operation for maximum efficiency. These intelligent systems can adapt to changing load conditions, predict potential failures, and adjust operating parameters in real-time. Digital intelligence enables features like soft-start capabilities, adaptive switching patterns, and communication with broader power management systems, all contributing to improved overall system efficiency.

02 Hybrid relay technologies combining mechanical and solid-state elements

Hybrid relays integrate both mechanical contacts and semiconductor components to leverage the advantages of each technology. These relays typically use solid-state components for the initial switching operation and mechanical contacts for the steady-state current flow, reducing heat generation and power losses. This hybrid approach offers improved efficiency by combining the low on-state resistance of mechanical relays with the fast, arc-free switching of solid-state devices.Expand Specific Solutions03 Thermal management solutions for relay efficiency

Effective thermal management is crucial for maintaining relay efficiency. Advanced cooling techniques, thermally conductive materials, and optimized heat sink designs help dissipate heat generated during relay operation. By preventing overheating, these solutions maintain optimal operating temperatures, reduce power losses, and extend the operational lifespan of both solid-state and hybrid relays while ensuring consistent performance under various load conditions.Expand Specific Solutions04 Control circuit innovations for improved relay efficiency

Sophisticated control circuits enhance relay efficiency through precise timing, optimized switching patterns, and adaptive control algorithms. These innovations include gate drive optimization, zero-crossing detection circuits, and microprocessor-controlled switching sequences that minimize switching losses. Advanced control strategies reduce power consumption during both standby and active states, improving overall system efficiency while maintaining reliable operation across varying load conditions.Expand Specific Solutions05 Application-specific relay efficiency optimizations

Relays can be specifically optimized for particular applications to maximize efficiency. These specialized designs consider factors such as load characteristics, switching frequency, environmental conditions, and power requirements. Application-specific optimizations may include custom semiconductor materials, tailored switching thresholds, or specialized packaging to meet the unique efficiency requirements of automotive, industrial, renewable energy, or consumer electronics applications.Expand Specific Solutions

Key Manufacturers and Competitive Landscape

The solid-state relay (SSR) versus hybrid relay market is currently in a growth phase, with increasing adoption across industrial automation, automotive, and energy sectors. The global market size is estimated to reach $1.5-2 billion by 2025, driven by demand for more reliable switching solutions with longer operational lifespans. Technologically, companies are at different maturity stages: TE Connectivity, Panasonic Electric Works, and Texas Instruments lead with advanced semiconductor-based solutions, while Hongfa Electric and Vertiv focus on hybrid technologies combining mechanical and solid-state elements. Newer entrants like Novosense Microelectronics are innovating with integrated circuit designs that improve efficiency. The competitive landscape shows traditional relay manufacturers expanding their portfolios while semiconductor companies leverage their expertise to develop more efficient, compact solutions with faster switching capabilities and reduced power consumption.

Aptiv Technologies AG

Technical Solution: Aptiv has focused on developing specialized relay solutions for automotive and industrial applications, with particular emphasis on high-voltage systems for electric vehicles. Their solid-state relay technology utilizes silicon carbide (SiC) semiconductors that offer superior thermal performance and efficiency compared to traditional silicon-based devices, with switching losses reduced by approximately 80%. For applications requiring both reliability and efficiency, Aptiv's hybrid relay approach combines SiC solid-state elements with silver-alloy mechanical contacts in a hermetically sealed environment to prevent oxidation and contamination. Their proprietary control algorithms dynamically adjust the timing relationship between solid-state and mechanical elements based on load conditions, temperature, and voltage levels. Aptiv's latest innovations include intelligent power distribution modules that integrate multiple hybrid relays with advanced diagnostics and communication capabilities, allowing for real-time monitoring and predictive maintenance in safety-critical systems.

Strengths: SiC-based technology offers superior thermal performance and efficiency in high-power applications. Integrated diagnostics and communication capabilities enable smart power management. Weaknesses: SiC technology carries a significant cost premium over silicon-based alternatives. Complex integration with vehicle systems requires specialized expertise for implementation.

TE Connectivity Corp.

Technical Solution: TE Connectivity has developed a comprehensive portfolio addressing both solid-state and hybrid relay technologies. Their solid-state relay line features proprietary semiconductor designs optimized for specific voltage and current ranges, with their high-power modules capable of handling up to 100A continuous current while maintaining isolation voltages exceeding 4000V. TE's hybrid relay technology combines solid-state switching elements for arc-free operation with mechanical contacts for low conduction losses. Their patented "pre-make, post-break" architecture ensures the solid-state element activates milliseconds before and deactivates milliseconds after the mechanical contacts, virtually eliminating contact wear. TE's latest innovations include smart hybrid relays with integrated diagnostics that monitor contact resistance, temperature, and switching cycles to predict maintenance needs before failures occur, particularly valuable in critical infrastructure applications where downtime is costly.

Strengths: Extensive product range covering both technologies allows optimal selection for specific applications. Advanced diagnostic capabilities in hybrid solutions enable predictive maintenance. Weaknesses: Higher initial cost compared to traditional relays. Hybrid solutions have larger form factors than pure solid-state alternatives, limiting use in space-constrained applications.

Critical Patents and Innovations in Relay Technology

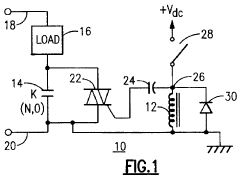

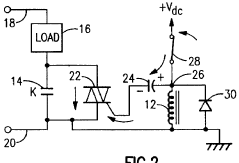

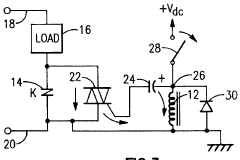

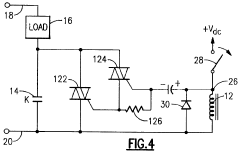

Solid state/electromechanical hybrid relay

PatentInactiveUS5699218A

Innovation

- A hybrid solid-state and electromechanical relay circuit that uses a triac device and capacitor to manage switching, where the triac carries make and break currents and the electromechanical contacts carry steady-state current, minimizing voltage drop and preventing arcing, with optical or magnetic isolation for efficient operation.

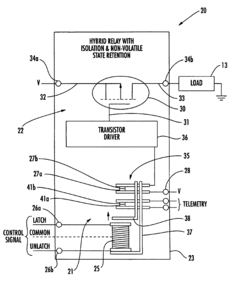

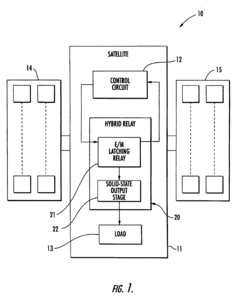

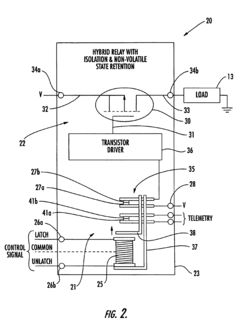

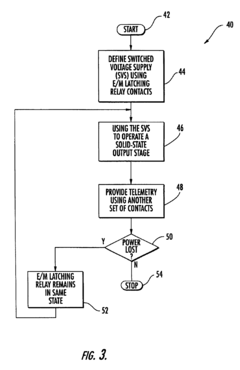

Hybrid relay including solid-state output and having non-volatile state-retention and associated methods

PatentInactiveUS6917500B2

Innovation

- A hybrid relay combining an electromagnetic coil with a latching mechanism and a solid-state output transistor, where the latching mechanism provides non-volatile state retention and allows pulsed control signals, using a switched voltage supply to operate the output transistor and include telemetry contacts for state verification.

Energy Efficiency and Heat Management Considerations

Energy efficiency represents a critical factor in relay selection, with solid-state relays (SSRs) and hybrid relays demonstrating distinct characteristics in this domain. SSRs typically consume more power during continuous operation due to their semiconductor components' inherent voltage drop, which generates heat even in the "on" state. This constant power dissipation ranges from 0.5W to 2W per relay depending on load current, creating thermal management challenges in high-density applications.

Heat generation in SSRs occurs primarily at the semiconductor junction, requiring effective thermal pathways to prevent performance degradation. Most industrial SSRs incorporate aluminum heat sinks or mounting plates, while advanced designs feature integrated thermal management solutions. Without proper heat dissipation, SSRs may experience thermal runaway, leading to premature failure or reduced operational lifespan.

Hybrid relays offer improved energy efficiency profiles by combining electromechanical contacts with semiconductor switching elements. During steady-state operation, hybrid relays consume minimal power as current flows through mechanical contacts with negligible resistance. This design reduces continuous power losses by up to 80% compared to equivalent SSRs, particularly beneficial in battery-powered or energy-sensitive applications.

Temperature rise measurements reveal that hybrid relays typically operate 15-25°C cooler than comparable SSRs under identical load conditions. This reduced thermal footprint enables higher packing density in control panels and extends component lifespan by minimizing thermal stress on surrounding components. Additionally, hybrid relays often eliminate the need for supplementary cooling infrastructure, reducing system complexity and associated energy costs.

Energy efficiency calculations must consider the complete operational cycle, including switching transitions and holding states. While SSRs excel in rapid switching applications with minimal inrush current, hybrid relays demonstrate superior efficiency in applications with extended on-periods. For installations operating at duty cycles exceeding 70%, hybrid relays typically deliver 30-40% energy savings over their operational lifetime compared to SSRs.

Recent advancements in semiconductor materials, particularly wide-bandgap technologies like silicon carbide (SiC) and gallium nitride (GaN), are progressively improving SSR thermal performance. These materials offer reduced on-state resistance and superior thermal conductivity, narrowing the efficiency gap with hybrid solutions while maintaining the reliability advantages of solid-state switching.

Heat generation in SSRs occurs primarily at the semiconductor junction, requiring effective thermal pathways to prevent performance degradation. Most industrial SSRs incorporate aluminum heat sinks or mounting plates, while advanced designs feature integrated thermal management solutions. Without proper heat dissipation, SSRs may experience thermal runaway, leading to premature failure or reduced operational lifespan.

Hybrid relays offer improved energy efficiency profiles by combining electromechanical contacts with semiconductor switching elements. During steady-state operation, hybrid relays consume minimal power as current flows through mechanical contacts with negligible resistance. This design reduces continuous power losses by up to 80% compared to equivalent SSRs, particularly beneficial in battery-powered or energy-sensitive applications.

Temperature rise measurements reveal that hybrid relays typically operate 15-25°C cooler than comparable SSRs under identical load conditions. This reduced thermal footprint enables higher packing density in control panels and extends component lifespan by minimizing thermal stress on surrounding components. Additionally, hybrid relays often eliminate the need for supplementary cooling infrastructure, reducing system complexity and associated energy costs.

Energy efficiency calculations must consider the complete operational cycle, including switching transitions and holding states. While SSRs excel in rapid switching applications with minimal inrush current, hybrid relays demonstrate superior efficiency in applications with extended on-periods. For installations operating at duty cycles exceeding 70%, hybrid relays typically deliver 30-40% energy savings over their operational lifetime compared to SSRs.

Recent advancements in semiconductor materials, particularly wide-bandgap technologies like silicon carbide (SiC) and gallium nitride (GaN), are progressively improving SSR thermal performance. These materials offer reduced on-state resistance and superior thermal conductivity, narrowing the efficiency gap with hybrid solutions while maintaining the reliability advantages of solid-state switching.

Industry-Specific Application Requirements and Standards

Different industries have established specific requirements and standards for relay applications that significantly influence the selection between solid-state relays (SSRs) and hybrid relays. In the medical equipment sector, stringent reliability standards necessitate relays with exceptional longevity and minimal electromagnetic interference. SSRs are often preferred in critical patient monitoring systems and diagnostic equipment due to their silent operation and resistance to vibration, while hybrid relays find application in power management systems where both isolation and surge handling capabilities are essential.

The automotive industry presents unique challenges with extreme temperature variations and constant vibration. Vehicle manufacturers typically require relays to operate reliably from -40°C to 125°C while withstanding mechanical shock. Hybrid relays have gained traction in electric vehicle battery management systems, offering both the arc-free switching benefits of SSRs and the robust overcurrent protection of electromechanical relays. Meanwhile, SSRs dominate in advanced driver assistance systems where rapid switching and EMI reduction are paramount.

Industrial automation environments demand relays capable of withstanding harsh conditions including dust, moisture, and chemical exposure. IEC 60947 standards govern industrial relay applications, with particular emphasis on switching capacity and electrical endurance. Process control industries typically require SIL (Safety Integrity Level) certification for critical applications, where hybrid relays often provide the necessary redundancy features while maintaining solid-state benefits.

The energy sector, particularly in renewable energy systems, requires relays that can handle high DC voltages and provide galvanic isolation. Solar inverter manufacturers frequently specify SSRs for their panel disconnection mechanisms due to their high switching frequency capabilities and long operational life. Conversely, grid connection systems often employ hybrid relays to manage fault conditions while maintaining efficiency during normal operation.

Building automation systems must comply with energy efficiency standards like ASHRAE 90.1, influencing relay selection based on standby power consumption. SSRs typically offer advantages in HVAC applications requiring frequent cycling, while hybrid solutions are increasingly adopted in smart building systems where both energy efficiency and surge protection are necessary. Fire safety systems universally require UL certification, with specific requirements for fail-safe operation that often favor hybrid relay technologies.

Telecommunications infrastructure demands relays with exceptional EMC performance to standards like ETSI EN 300 386, where SSRs excel in high-density applications requiring minimal crosstalk. However, power distribution units in data centers often implement hybrid relays to balance switching efficiency with overcurrent protection capabilities, particularly in facilities pursuing energy efficiency certifications like ENERGY STAR for Data Centers.

The automotive industry presents unique challenges with extreme temperature variations and constant vibration. Vehicle manufacturers typically require relays to operate reliably from -40°C to 125°C while withstanding mechanical shock. Hybrid relays have gained traction in electric vehicle battery management systems, offering both the arc-free switching benefits of SSRs and the robust overcurrent protection of electromechanical relays. Meanwhile, SSRs dominate in advanced driver assistance systems where rapid switching and EMI reduction are paramount.

Industrial automation environments demand relays capable of withstanding harsh conditions including dust, moisture, and chemical exposure. IEC 60947 standards govern industrial relay applications, with particular emphasis on switching capacity and electrical endurance. Process control industries typically require SIL (Safety Integrity Level) certification for critical applications, where hybrid relays often provide the necessary redundancy features while maintaining solid-state benefits.

The energy sector, particularly in renewable energy systems, requires relays that can handle high DC voltages and provide galvanic isolation. Solar inverter manufacturers frequently specify SSRs for their panel disconnection mechanisms due to their high switching frequency capabilities and long operational life. Conversely, grid connection systems often employ hybrid relays to manage fault conditions while maintaining efficiency during normal operation.

Building automation systems must comply with energy efficiency standards like ASHRAE 90.1, influencing relay selection based on standby power consumption. SSRs typically offer advantages in HVAC applications requiring frequent cycling, while hybrid solutions are increasingly adopted in smart building systems where both energy efficiency and surge protection are necessary. Fire safety systems universally require UL certification, with specific requirements for fail-safe operation that often favor hybrid relay technologies.

Telecommunications infrastructure demands relays with exceptional EMC performance to standards like ETSI EN 300 386, where SSRs excel in high-density applications requiring minimal crosstalk. However, power distribution units in data centers often implement hybrid relays to balance switching efficiency with overcurrent protection capabilities, particularly in facilities pursuing energy efficiency certifications like ENERGY STAR for Data Centers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!