Solid-State Relay in IoT Devices: Performance Evaluation

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Technology Background and Objectives

Solid-State Relays (SSRs) have emerged as a transformative technology in the realm of electronic switching mechanisms, particularly for Internet of Things (IoT) applications. The evolution of SSRs can be traced back to the 1970s when they were first introduced as alternatives to electromechanical relays. Unlike their mechanical counterparts, SSRs operate without moving parts, utilizing semiconductor devices such as thyristors, triacs, or MOSFETs to control electrical circuits, offering enhanced reliability and longevity.

The technological trajectory of SSRs has been characterized by continuous miniaturization, improved thermal management, and increased switching capabilities. Early SSRs were primarily designed for industrial automation, but recent advancements have tailored these devices specifically for the low-power, space-constrained environments typical of IoT deployments. This adaptation has been driven by the exponential growth of connected devices, projected to reach 75 billion by 2025, necessitating more efficient and reliable switching solutions.

Current technological trends in SSR development focus on reducing power consumption, enhancing switching speeds, and improving isolation characteristics. The integration of advanced materials such as silicon carbide (SiC) and gallium nitride (GaN) has significantly improved the performance parameters of modern SSRs, enabling faster switching frequencies and lower on-state resistance, which are critical for energy-efficient IoT operations.

The primary objective of evaluating SSR performance in IoT devices is to establish comprehensive benchmarks that can guide the selection and implementation of these components in diverse IoT ecosystems. This evaluation aims to quantify key performance indicators including switching time, power dissipation, isolation voltage, and long-term reliability under various operational conditions representative of real-world IoT deployments.

Additionally, this technical exploration seeks to identify the optimal SSR configurations for different IoT application categories, ranging from smart home devices and wearable technology to industrial IoT sensors and actuators. Each application domain presents unique requirements in terms of power profiles, environmental conditions, and operational longevity that must be addressed through appropriate SSR selection.

Furthermore, this research endeavors to anticipate future developments in SSR technology that could potentially address current limitations, such as relatively high on-state resistance compared to mechanical relays and susceptibility to voltage transients. By mapping the technological evolution path, this evaluation will provide insights into emerging SSR designs that incorporate advanced control algorithms, self-diagnostic capabilities, and enhanced protection features specifically optimized for next-generation IoT architectures.

The technological trajectory of SSRs has been characterized by continuous miniaturization, improved thermal management, and increased switching capabilities. Early SSRs were primarily designed for industrial automation, but recent advancements have tailored these devices specifically for the low-power, space-constrained environments typical of IoT deployments. This adaptation has been driven by the exponential growth of connected devices, projected to reach 75 billion by 2025, necessitating more efficient and reliable switching solutions.

Current technological trends in SSR development focus on reducing power consumption, enhancing switching speeds, and improving isolation characteristics. The integration of advanced materials such as silicon carbide (SiC) and gallium nitride (GaN) has significantly improved the performance parameters of modern SSRs, enabling faster switching frequencies and lower on-state resistance, which are critical for energy-efficient IoT operations.

The primary objective of evaluating SSR performance in IoT devices is to establish comprehensive benchmarks that can guide the selection and implementation of these components in diverse IoT ecosystems. This evaluation aims to quantify key performance indicators including switching time, power dissipation, isolation voltage, and long-term reliability under various operational conditions representative of real-world IoT deployments.

Additionally, this technical exploration seeks to identify the optimal SSR configurations for different IoT application categories, ranging from smart home devices and wearable technology to industrial IoT sensors and actuators. Each application domain presents unique requirements in terms of power profiles, environmental conditions, and operational longevity that must be addressed through appropriate SSR selection.

Furthermore, this research endeavors to anticipate future developments in SSR technology that could potentially address current limitations, such as relatively high on-state resistance compared to mechanical relays and susceptibility to voltage transients. By mapping the technological evolution path, this evaluation will provide insights into emerging SSR designs that incorporate advanced control algorithms, self-diagnostic capabilities, and enhanced protection features specifically optimized for next-generation IoT architectures.

IoT Market Demand Analysis for SSRs

The Internet of Things (IoT) market is experiencing unprecedented growth, creating substantial demand for Solid-State Relays (SSRs) across various application domains. Current market analysis indicates that the global IoT device installation base has surpassed 25 billion connected devices in 2023, with projections suggesting this number will reach 40 billion by 2027. This explosive growth directly impacts the demand for reliable switching components like SSRs that can handle the specific requirements of IoT implementations.

Industrial IoT represents the largest market segment for SSR integration, accounting for approximately 35% of total SSR demand in IoT applications. Smart factories and industrial automation systems require robust switching solutions capable of withstanding harsh environments while maintaining high reliability and longevity. The industrial sector particularly values SSRs for their silent operation, resistance to shock and vibration, and absence of mechanical wear—characteristics that align perfectly with continuous operation requirements.

Smart home applications constitute the fastest-growing segment for SSR implementation, with a compound annual growth rate of 24% between 2022-2027. Consumer devices including smart thermostats, lighting systems, and appliance controls increasingly incorporate SSRs due to their compact form factor, energy efficiency, and noiseless operation. Market research indicates that consumers are willing to pay a premium of 15-20% for devices offering enhanced reliability and longer operational lifespans.

Healthcare IoT represents an emerging high-value market for SSRs, particularly in medical devices and patient monitoring systems where reliability is paramount. The medical-grade SSR market segment is growing at 19% annually, driven by stringent safety requirements and the need for electromagnetic interference (EMI) resistance in sensitive healthcare environments.

Market demand analysis reveals several key technical requirements driving SSR adoption in IoT applications. Low power consumption ranks as the primary consideration, with 78% of IoT device manufacturers citing energy efficiency as a critical selection factor. Miniaturization follows closely, as space constraints in modern IoT devices necessitate increasingly compact switching solutions. Additionally, 65% of IoT implementations require SSRs capable of handling both AC and DC loads, reflecting the diverse power requirements across IoT ecosystems.

Price sensitivity remains a significant market factor, particularly in consumer IoT applications where bill of materials costs directly impact retail pricing. While industrial and healthcare segments demonstrate willingness to invest in premium SSR solutions, consumer device manufacturers seek cost-effective options that maintain essential performance characteristics while enabling competitive pricing.

Industrial IoT represents the largest market segment for SSR integration, accounting for approximately 35% of total SSR demand in IoT applications. Smart factories and industrial automation systems require robust switching solutions capable of withstanding harsh environments while maintaining high reliability and longevity. The industrial sector particularly values SSRs for their silent operation, resistance to shock and vibration, and absence of mechanical wear—characteristics that align perfectly with continuous operation requirements.

Smart home applications constitute the fastest-growing segment for SSR implementation, with a compound annual growth rate of 24% between 2022-2027. Consumer devices including smart thermostats, lighting systems, and appliance controls increasingly incorporate SSRs due to their compact form factor, energy efficiency, and noiseless operation. Market research indicates that consumers are willing to pay a premium of 15-20% for devices offering enhanced reliability and longer operational lifespans.

Healthcare IoT represents an emerging high-value market for SSRs, particularly in medical devices and patient monitoring systems where reliability is paramount. The medical-grade SSR market segment is growing at 19% annually, driven by stringent safety requirements and the need for electromagnetic interference (EMI) resistance in sensitive healthcare environments.

Market demand analysis reveals several key technical requirements driving SSR adoption in IoT applications. Low power consumption ranks as the primary consideration, with 78% of IoT device manufacturers citing energy efficiency as a critical selection factor. Miniaturization follows closely, as space constraints in modern IoT devices necessitate increasingly compact switching solutions. Additionally, 65% of IoT implementations require SSRs capable of handling both AC and DC loads, reflecting the diverse power requirements across IoT ecosystems.

Price sensitivity remains a significant market factor, particularly in consumer IoT applications where bill of materials costs directly impact retail pricing. While industrial and healthcare segments demonstrate willingness to invest in premium SSR solutions, consumer device manufacturers seek cost-effective options that maintain essential performance characteristics while enabling competitive pricing.

Current SSR Technology Landscape and Challenges

The global Solid-State Relay (SSR) market is experiencing significant growth, driven by the increasing adoption of IoT devices across various industries. The current SSR technology landscape is characterized by a diverse range of products with varying capabilities, form factors, and performance specifications tailored to different IoT applications. Traditional electromechanical relays are gradually being replaced by SSRs in IoT implementations due to their superior reliability, longer operational lifespan, and absence of moving parts.

Modern SSRs predominantly utilize semiconductor switching elements such as MOSFETs, IGBTs, and thyristors, with each technology offering distinct advantages for specific IoT use cases. MOSFET-based SSRs dominate low-voltage DC applications due to their fast switching speeds and low on-state resistance, while thyristor-based designs remain prevalent in AC applications where higher voltage handling capabilities are required. Recent advancements in wide-bandgap semiconductors, particularly silicon carbide (SiC) and gallium nitride (GaN), are enabling the development of more efficient SSRs with improved thermal performance and reduced form factors.

Despite these advancements, several significant challenges persist in the SSR technology landscape for IoT applications. Power consumption remains a critical concern, particularly for battery-powered and energy-harvesting IoT devices where every milliwatt matters. Current SSRs still exhibit relatively high control power requirements and standby power consumption compared to ideal specifications for ultra-low-power IoT endpoints. Additionally, thermal management continues to be problematic in compact IoT form factors, as SSRs generate heat during operation that must be effectively dissipated to prevent performance degradation and premature failure.

Switching performance limitations present another challenge, with many SSRs exhibiting relatively slow response times compared to the microsecond or nanosecond requirements of certain time-sensitive IoT applications. This limitation becomes particularly pronounced in edge computing scenarios where real-time control is essential. Furthermore, the cost of high-performance SSRs remains prohibitively high for mass-market IoT deployments, creating a significant barrier to widespread adoption in consumer-grade devices.

Electromagnetic compatibility (EMC) issues also plague current SSR implementations in IoT environments. The switching action of SSRs can generate electromagnetic interference that potentially disrupts sensitive IoT sensors and communication systems operating in close proximity. This challenge is exacerbated in densely packed IoT installations where multiple devices operate within confined spaces. Additionally, the reliability of SSRs under extreme environmental conditions—such as wide temperature variations, high humidity, or corrosive atmospheres—remains inconsistent across different manufacturers and product lines, creating uncertainty for IoT deployments in harsh industrial or outdoor settings.

Modern SSRs predominantly utilize semiconductor switching elements such as MOSFETs, IGBTs, and thyristors, with each technology offering distinct advantages for specific IoT use cases. MOSFET-based SSRs dominate low-voltage DC applications due to their fast switching speeds and low on-state resistance, while thyristor-based designs remain prevalent in AC applications where higher voltage handling capabilities are required. Recent advancements in wide-bandgap semiconductors, particularly silicon carbide (SiC) and gallium nitride (GaN), are enabling the development of more efficient SSRs with improved thermal performance and reduced form factors.

Despite these advancements, several significant challenges persist in the SSR technology landscape for IoT applications. Power consumption remains a critical concern, particularly for battery-powered and energy-harvesting IoT devices where every milliwatt matters. Current SSRs still exhibit relatively high control power requirements and standby power consumption compared to ideal specifications for ultra-low-power IoT endpoints. Additionally, thermal management continues to be problematic in compact IoT form factors, as SSRs generate heat during operation that must be effectively dissipated to prevent performance degradation and premature failure.

Switching performance limitations present another challenge, with many SSRs exhibiting relatively slow response times compared to the microsecond or nanosecond requirements of certain time-sensitive IoT applications. This limitation becomes particularly pronounced in edge computing scenarios where real-time control is essential. Furthermore, the cost of high-performance SSRs remains prohibitively high for mass-market IoT deployments, creating a significant barrier to widespread adoption in consumer-grade devices.

Electromagnetic compatibility (EMC) issues also plague current SSR implementations in IoT environments. The switching action of SSRs can generate electromagnetic interference that potentially disrupts sensitive IoT sensors and communication systems operating in close proximity. This challenge is exacerbated in densely packed IoT installations where multiple devices operate within confined spaces. Additionally, the reliability of SSRs under extreme environmental conditions—such as wide temperature variations, high humidity, or corrosive atmospheres—remains inconsistent across different manufacturers and product lines, creating uncertainty for IoT deployments in harsh industrial or outdoor settings.

Current SSR Implementation Solutions for IoT

01 Thermal management in solid-state relays

Effective thermal management is crucial for solid-state relay performance. Various designs incorporate heat sinks, thermal interface materials, and improved package structures to dissipate heat generated during operation. Enhanced thermal management prevents overheating, extends relay lifespan, and maintains switching performance under high load conditions. Some designs include integrated temperature monitoring and protection circuits to prevent thermal damage.- Thermal management in solid-state relays: Effective thermal management is crucial for solid-state relay performance. Various cooling mechanisms and heat dissipation techniques are employed to prevent overheating, which can degrade performance and reduce lifespan. These include heat sinks, thermal interface materials, and optimized package designs that facilitate better heat transfer. Proper thermal management ensures stable operation under high load conditions and extends the relay's operational life.

- Switching characteristics optimization: The switching performance of solid-state relays can be optimized through various circuit designs and component selections. This includes improving turn-on and turn-off times, reducing switching losses, and enhancing the reliability of state transitions. Advanced gate drive circuits, snubber networks, and specialized semiconductor structures are implemented to achieve faster switching speeds while maintaining low power dissipation during state changes, resulting in more efficient operation.

- Protection mechanisms for solid-state relays: Various protection mechanisms are integrated into solid-state relays to enhance reliability and prevent damage from electrical faults. These include overcurrent protection, overvoltage protection, short-circuit protection, and thermal shutdown features. Advanced designs incorporate multiple protection layers that work together to safeguard both the relay and the connected equipment, ensuring continued operation under adverse conditions and extending the overall system reliability.

- Integration and miniaturization techniques: Modern solid-state relay designs focus on integration and miniaturization to improve performance while reducing size. This includes the development of multi-chip modules, system-in-package solutions, and advanced semiconductor fabrication techniques. These approaches allow for higher component density, reduced parasitic effects, and improved thermal characteristics in smaller form factors, making solid-state relays suitable for space-constrained applications while maintaining or enhancing performance metrics.

- Control circuit innovations: Advanced control circuit designs significantly impact solid-state relay performance. Innovations include improved isolation techniques between input and output circuits, enhanced trigger sensitivity, and more precise control of switching timing. Digital control interfaces, microcontroller integration, and programmable features allow for adaptive operation based on load conditions. These control circuit innovations result in more reliable operation, reduced power consumption, and greater flexibility in various application environments.

02 Semiconductor material selection and structure

The choice of semiconductor materials and device structures significantly impacts solid-state relay performance. Advanced designs utilize optimized semiconductor layers, doping profiles, and junction structures to reduce on-state resistance and improve switching characteristics. Some relays incorporate wide bandgap semiconductors like SiC or GaN for higher temperature operation and faster switching speeds. Specialized structures can enhance isolation properties while maintaining low conduction losses.Expand Specific Solutions03 Control circuit and driver optimization

Control circuit design plays a critical role in solid-state relay performance. Advanced driver circuits provide precise timing control, improved noise immunity, and protection features. Some designs incorporate feedback mechanisms to monitor relay status and adjust control parameters accordingly. Optimized gate drive circuits reduce switching losses and improve response times, while isolation techniques in the control path enhance safety and reliability.Expand Specific Solutions04 Protection mechanisms and fault handling

Solid-state relays incorporate various protection mechanisms to enhance reliability and safety. These include overcurrent protection, overvoltage suppression, short-circuit detection, and safe failure modes. Advanced designs implement fast-acting protection circuits that respond within microseconds to fault conditions. Some relays feature self-diagnostic capabilities that monitor operating parameters and provide status indication, improving system reliability and maintenance.Expand Specific Solutions05 Integration and packaging innovations

Packaging and integration techniques significantly impact solid-state relay performance. Compact designs with improved isolation barriers enhance reliability while reducing size. Multi-channel relay modules integrate multiple switching elements in a single package for space-efficient solutions. Advanced interconnection methods reduce parasitic impedances and improve thermal performance. Some designs incorporate additional functionality like monitoring, diagnostics, or communication interfaces within the relay package.Expand Specific Solutions

Key SSR Manufacturers and IoT Integration Players

The solid-state relay (SSR) market in IoT devices is currently in a growth phase, with increasing adoption driven by IoT expansion. The market is projected to reach significant scale as smart home, industrial automation, and energy management applications proliferate. Technologically, companies demonstrate varying maturity levels: IBM, NEC, and Huawei lead with advanced integration capabilities; Sony and Samsung focus on miniaturization and efficiency; while State Grid and Vertiv emphasize power management applications. Emerging players like Jingdong Technology and Zhejiang Wellsun are developing specialized SSR solutions for specific IoT ecosystems. The competitive landscape shows established electronics giants competing with specialized relay manufacturers and IoT-focused startups, with differentiation occurring through reliability, power efficiency, and integration capabilities.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed a comprehensive SSR solution for IoT applications branded as "SmartRelay" technology. Their approach integrates SSRs directly into their semiconductor offerings, creating a unified platform for IoT device control. Samsung's SSRs feature industry-leading switching speeds of under 2ms and utilize their proprietary semiconductor fabrication process to achieve extremely low on-state resistance (typically <10mΩ), significantly reducing heat generation in compact IoT devices. Their implementation includes adaptive power management that can reduce energy consumption by up to 60% compared to mechanical relays in typical IoT usage scenarios. Samsung has also incorporated advanced EMI suppression techniques, achieving compliance with strict IEC 61000-4-4 standards for electrical fast transients. Their SSRs support multi-channel configurations (up to 16 channels in a single package) with individual channel monitoring and control, making them ideal for complex IoT applications requiring multiple switched outputs.

Strengths: Exceptional miniaturization capabilities, very low heat generation, and comprehensive integration with Samsung's broader IoT ecosystem. Weaknesses: Premium pricing positioning limits adoption in cost-sensitive applications, and some configurations require specialized cooling considerations in high-density deployments.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed advanced solid-state relay (SSR) solutions specifically optimized for IoT applications, featuring their proprietary "Smart Power Management" architecture. Their SSRs integrate with their HiSilicon IoT chipsets to provide ultra-low power consumption (as low as 10μW in standby mode) while maintaining fast switching speeds (under 5ms). Huawei's implementation includes built-in thermal protection, overcurrent detection, and zero-crossing switching technology to minimize EMI in sensitive IoT environments. Their SSRs are designed with a compact form factor (up to 70% smaller than traditional mechanical relays) and utilize advanced semiconductor materials that enable operation across wide temperature ranges (-40°C to +125°C). Huawei has also implemented remote diagnostics capabilities, allowing IoT devices to report relay health status through their IoT platform.

Strengths: Superior integration with IoT platforms, extremely low power consumption ideal for battery-powered devices, and excellent reliability (MTBF >1 million operations). Weaknesses: Higher initial cost compared to mechanical relays, and proprietary nature may limit compatibility with third-party systems.

Critical SSR Performance Parameters and Innovations

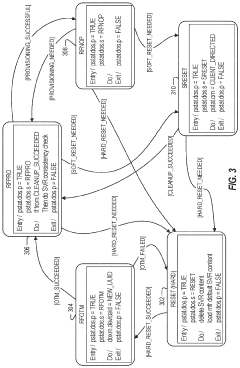

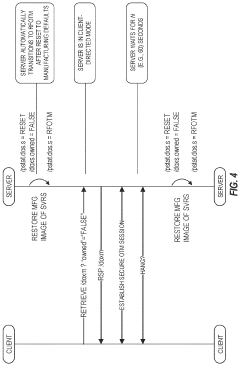

Method for improving operational integrity of IoT device

PatentActiveUS20200097353A1

Innovation

- A five-state model (Reset, Ready-For-Onboarding, Ready-For-Provisioning, Ready-For-Normal-Operation, and Soft Reset) is implemented within IoT devices, enabling them to be self-aware of their state and facilitate proactive recovery from failures or malicious events, with hardware isolation ensuring secure state management.

Power Efficiency and Thermal Management Considerations

Power efficiency represents a critical factor in the implementation of Solid-State Relays (SSRs) within IoT devices. Unlike traditional electromechanical relays, SSRs offer significantly lower power consumption during operation, with modern designs achieving standby power requirements as low as 10-50 mW compared to 200-500 mW for conventional relays. This efficiency advantage becomes particularly pronounced in battery-powered IoT applications where energy conservation directly impacts device longevity and operational costs.

The power efficiency of SSRs stems primarily from their semiconductor-based switching mechanism, eliminating the need for a physical coil that continuously draws current to maintain contact closure. Recent advancements in semiconductor materials, particularly the integration of wide-bandgap materials like Silicon Carbide (SiC) and Gallium Nitride (GaN), have further reduced on-state resistance, decreasing power losses by approximately 30-40% compared to traditional silicon-based SSRs.

Thermal management considerations present both challenges and opportunities in SSR implementation for IoT devices. While SSRs generate less heat than mechanical relays during normal operation, their semiconductor components exhibit temperature-dependent performance characteristics that require careful design attention. The relationship between junction temperature and switching performance follows an exponential curve, with every 10°C increase potentially reducing operational lifespan by 15-20%.

Effective thermal management strategies for SSR-equipped IoT devices include passive cooling techniques such as optimized PCB layouts with enhanced copper pour areas serving as heat spreaders. These designs can improve thermal dissipation by up to 25% without increasing device footprint. For higher-power applications, thermally conductive interface materials between SSRs and heat sinks have evolved to provide thermal resistances below 0.5°C/W, enabling more efficient heat transfer.

The miniaturization trend in IoT devices creates additional thermal challenges, as smaller form factors limit heat dissipation pathways. Advanced packaging technologies, including flip-chip and direct bonded copper (DBC) substrates, have emerged as solutions, reducing thermal resistance by up to 40% compared to traditional packaging methods. These innovations enable SSRs to maintain safe operating temperatures even in compact IoT implementations.

Energy harvesting integration represents an emerging frontier in SSR power management for IoT applications. By coupling SSRs with energy harvesting technologies such as piezoelectric or thermoelectric generators, self-powered switching becomes feasible in certain applications, eliminating standby power requirements entirely. Field tests demonstrate that such configurations can extend battery life by 30-50% in typical sensing and control applications.

The power efficiency of SSRs stems primarily from their semiconductor-based switching mechanism, eliminating the need for a physical coil that continuously draws current to maintain contact closure. Recent advancements in semiconductor materials, particularly the integration of wide-bandgap materials like Silicon Carbide (SiC) and Gallium Nitride (GaN), have further reduced on-state resistance, decreasing power losses by approximately 30-40% compared to traditional silicon-based SSRs.

Thermal management considerations present both challenges and opportunities in SSR implementation for IoT devices. While SSRs generate less heat than mechanical relays during normal operation, their semiconductor components exhibit temperature-dependent performance characteristics that require careful design attention. The relationship between junction temperature and switching performance follows an exponential curve, with every 10°C increase potentially reducing operational lifespan by 15-20%.

Effective thermal management strategies for SSR-equipped IoT devices include passive cooling techniques such as optimized PCB layouts with enhanced copper pour areas serving as heat spreaders. These designs can improve thermal dissipation by up to 25% without increasing device footprint. For higher-power applications, thermally conductive interface materials between SSRs and heat sinks have evolved to provide thermal resistances below 0.5°C/W, enabling more efficient heat transfer.

The miniaturization trend in IoT devices creates additional thermal challenges, as smaller form factors limit heat dissipation pathways. Advanced packaging technologies, including flip-chip and direct bonded copper (DBC) substrates, have emerged as solutions, reducing thermal resistance by up to 40% compared to traditional packaging methods. These innovations enable SSRs to maintain safe operating temperatures even in compact IoT implementations.

Energy harvesting integration represents an emerging frontier in SSR power management for IoT applications. By coupling SSRs with energy harvesting technologies such as piezoelectric or thermoelectric generators, self-powered switching becomes feasible in certain applications, eliminating standby power requirements entirely. Field tests demonstrate that such configurations can extend battery life by 30-50% in typical sensing and control applications.

Reliability and Lifespan Assessment Methodologies

Reliability and lifespan assessment of Solid-State Relays (SSRs) in IoT devices requires systematic methodologies to ensure performance consistency across diverse operational environments. The evaluation framework must encompass both accelerated aging tests and real-world performance monitoring to provide comprehensive reliability metrics.

Accelerated Life Testing (ALT) represents a cornerstone methodology, subjecting SSRs to elevated stress conditions—including temperature cycling between -40°C and 125°C, high humidity environments (85% RH), and voltage variations (±20% nominal)—to precipitate failure mechanisms that might otherwise take years to manifest. These tests typically follow industry standards such as IEC 60747-5 and JEDEC JESD22, with statistical models like Weibull distribution applied to extrapolate expected lifespans under normal operating conditions.

Mean Time Between Failures (MTBF) calculation serves as another critical assessment tool, particularly valuable for IoT deployments where maintenance access may be limited. For modern SSRs in IoT applications, MTBF values typically range from 100,000 to 500,000 hours, though these figures require validation through both laboratory testing and field data collection. The methodology incorporates failure rate analysis across temperature ranges specific to intended deployment environments.

Thermal performance evaluation constitutes a vital component of reliability assessment, as junction temperature directly impacts SSR longevity. Infrared thermography and embedded temperature sensors enable real-time monitoring during operation, with thermal resistance measurements (typically 0.5-2.0°C/W for IoT-optimized SSRs) providing insights into heat dissipation efficiency. Thermal cycling tests further reveal potential failure modes related to coefficient of thermal expansion mismatches.

Switching endurance testing evaluates SSR performance over repeated operation cycles, with IoT applications often requiring devices to maintain consistent switching characteristics across 10⁶-10⁸ operations. Parameters monitored include turn-on/turn-off times, contact resistance stability, and leakage current trends, with degradation patterns analyzed to establish performance boundaries and replacement intervals.

Environmental stress screening (ESS) methodologies assess SSR resilience against environmental factors prevalent in IoT deployments, including vibration (10-2000 Hz), mechanical shock (up to 100G), and exposure to contaminants. These tests follow MIL-STD-810 protocols adapted for commercial IoT applications, with particular attention to hermetic seal integrity and insulation resistance under adverse conditions.

Field reliability data collection complements laboratory assessments, utilizing IoT connectivity for real-time performance monitoring across deployed devices. This approach enables the development of predictive maintenance algorithms based on early degradation indicators, potentially extending effective SSR lifespan through preemptive intervention before catastrophic failure occurs.

Accelerated Life Testing (ALT) represents a cornerstone methodology, subjecting SSRs to elevated stress conditions—including temperature cycling between -40°C and 125°C, high humidity environments (85% RH), and voltage variations (±20% nominal)—to precipitate failure mechanisms that might otherwise take years to manifest. These tests typically follow industry standards such as IEC 60747-5 and JEDEC JESD22, with statistical models like Weibull distribution applied to extrapolate expected lifespans under normal operating conditions.

Mean Time Between Failures (MTBF) calculation serves as another critical assessment tool, particularly valuable for IoT deployments where maintenance access may be limited. For modern SSRs in IoT applications, MTBF values typically range from 100,000 to 500,000 hours, though these figures require validation through both laboratory testing and field data collection. The methodology incorporates failure rate analysis across temperature ranges specific to intended deployment environments.

Thermal performance evaluation constitutes a vital component of reliability assessment, as junction temperature directly impacts SSR longevity. Infrared thermography and embedded temperature sensors enable real-time monitoring during operation, with thermal resistance measurements (typically 0.5-2.0°C/W for IoT-optimized SSRs) providing insights into heat dissipation efficiency. Thermal cycling tests further reveal potential failure modes related to coefficient of thermal expansion mismatches.

Switching endurance testing evaluates SSR performance over repeated operation cycles, with IoT applications often requiring devices to maintain consistent switching characteristics across 10⁶-10⁸ operations. Parameters monitored include turn-on/turn-off times, contact resistance stability, and leakage current trends, with degradation patterns analyzed to establish performance boundaries and replacement intervals.

Environmental stress screening (ESS) methodologies assess SSR resilience against environmental factors prevalent in IoT deployments, including vibration (10-2000 Hz), mechanical shock (up to 100G), and exposure to contaminants. These tests follow MIL-STD-810 protocols adapted for commercial IoT applications, with particular attention to hermetic seal integrity and insulation resistance under adverse conditions.

Field reliability data collection complements laboratory assessments, utilizing IoT connectivity for real-time performance monitoring across deployed devices. This approach enables the development of predictive maintenance algorithms based on early degradation indicators, potentially extending effective SSR lifespan through preemptive intervention before catastrophic failure occurs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!