How to Evaluate Solid-State Relay Operation in Noise-Rich Environments

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Technology Background and Objectives

Solid-State Relays (SSRs) represent a significant advancement in switching technology, evolving from traditional electromechanical relays that dominated industrial applications throughout the 20th century. Since their commercial introduction in the 1970s, SSRs have steadily gained prominence across various industries due to their superior reliability, longevity, and performance characteristics. The fundamental innovation of SSRs lies in their semiconductor-based switching mechanism, eliminating moving parts and mechanical contacts that are prone to wear and failure.

The technological evolution of SSRs has been marked by continuous improvements in semiconductor materials, design architectures, and manufacturing processes. Early generations utilized primarily silicon-controlled rectifiers (SCRs) and triacs, while modern variants incorporate advanced MOSFETs, IGBTs, and integrated circuits that significantly enhance switching capabilities and noise immunity. This progression reflects broader trends in semiconductor miniaturization and increased integration density.

In contemporary industrial environments, electromagnetic interference (EMI) and radio frequency interference (RFI) present substantial challenges to reliable relay operation. These noise sources have proliferated with the increasing density of electronic equipment, wireless communications, and power switching devices in industrial settings. The susceptibility of SSRs to such interference represents a critical concern that demands systematic evaluation methodologies.

The primary technical objective of this research is to establish comprehensive protocols for evaluating SSR performance specifically within noise-rich environments. This includes developing standardized testing frameworks that accurately simulate real-world electromagnetic disturbances, quantifying SSR susceptibility to various noise profiles, and identifying optimal mitigation strategies. Such evaluation protocols must address both conducted and radiated interference across relevant frequency spectra.

Secondary objectives include characterizing the relationship between SSR design parameters and noise immunity, identifying critical failure modes under electromagnetic stress, and establishing performance benchmarks that can guide future product development. Additionally, this research aims to explore emerging technologies that may enhance SSR resilience against electromagnetic interference, including advanced isolation techniques, improved semiconductor materials, and innovative circuit topologies.

The anticipated outcome of this technical investigation is a comprehensive evaluation methodology that enables manufacturers and system integrators to accurately predict SSR performance under adverse electromagnetic conditions. This will ultimately contribute to more reliable industrial automation systems, power distribution networks, and critical infrastructure where unplanned downtime carries significant operational and financial consequences.

The technological evolution of SSRs has been marked by continuous improvements in semiconductor materials, design architectures, and manufacturing processes. Early generations utilized primarily silicon-controlled rectifiers (SCRs) and triacs, while modern variants incorporate advanced MOSFETs, IGBTs, and integrated circuits that significantly enhance switching capabilities and noise immunity. This progression reflects broader trends in semiconductor miniaturization and increased integration density.

In contemporary industrial environments, electromagnetic interference (EMI) and radio frequency interference (RFI) present substantial challenges to reliable relay operation. These noise sources have proliferated with the increasing density of electronic equipment, wireless communications, and power switching devices in industrial settings. The susceptibility of SSRs to such interference represents a critical concern that demands systematic evaluation methodologies.

The primary technical objective of this research is to establish comprehensive protocols for evaluating SSR performance specifically within noise-rich environments. This includes developing standardized testing frameworks that accurately simulate real-world electromagnetic disturbances, quantifying SSR susceptibility to various noise profiles, and identifying optimal mitigation strategies. Such evaluation protocols must address both conducted and radiated interference across relevant frequency spectra.

Secondary objectives include characterizing the relationship between SSR design parameters and noise immunity, identifying critical failure modes under electromagnetic stress, and establishing performance benchmarks that can guide future product development. Additionally, this research aims to explore emerging technologies that may enhance SSR resilience against electromagnetic interference, including advanced isolation techniques, improved semiconductor materials, and innovative circuit topologies.

The anticipated outcome of this technical investigation is a comprehensive evaluation methodology that enables manufacturers and system integrators to accurately predict SSR performance under adverse electromagnetic conditions. This will ultimately contribute to more reliable industrial automation systems, power distribution networks, and critical infrastructure where unplanned downtime carries significant operational and financial consequences.

Market Demand Analysis for Noise-Resistant SSRs

The global market for noise-resistant Solid-State Relays (SSRs) has been experiencing significant growth, driven by increasing automation across industrial sectors and the growing need for reliable switching components in challenging environments. Industries such as manufacturing, energy, automotive, and telecommunications are increasingly deploying electronic systems in environments with high electromagnetic interference (EMI), radio frequency interference (RFI), and power line disturbances, creating substantial demand for SSRs that can maintain operational integrity under these conditions.

The industrial automation sector represents the largest market segment for noise-resistant SSRs, with manufacturing facilities requiring robust switching solutions that can withstand the electrical noise generated by heavy machinery, variable frequency drives, and power switching equipment. According to market research, the industrial automation segment accounts for approximately 40% of the total SSR market, with noise resistance being cited as a critical selection factor by procurement engineers.

Energy and power distribution applications form another significant market segment, where SSRs must operate reliably despite grid fluctuations, switching transients, and lightning-induced surges. The renewable energy sector, particularly solar and wind power installations, has emerged as a high-growth area for noise-resistant SSRs due to the challenging electrical environments of power inverters and the need for long-term reliability in remote locations.

Transportation systems, including railway signaling, automotive electronics, and aerospace applications, constitute a premium market segment where failure is not an option. These applications demand SSRs with superior noise immunity and often require compliance with stringent standards such as DO-160 for aerospace or EN 50121 for railway applications, driving the development of specialized noise-resistant SSR solutions.

Market analysis reveals a growing trend toward integrated diagnostic capabilities in noise-resistant SSRs, allowing real-time monitoring of relay performance in noisy environments. This feature commands a price premium but delivers significant value by enabling predictive maintenance and reducing costly downtime in critical applications.

Geographically, North America and Europe lead in the adoption of high-performance noise-resistant SSRs, primarily due to stringent regulatory requirements and the presence of industries with high-reliability demands. However, the Asia-Pacific region is showing the fastest growth rate, driven by rapid industrialization and infrastructure development in countries like China, India, and South Korea.

The market for noise-resistant SSRs is projected to grow at a compound annual growth rate exceeding the broader electronics component market, highlighting the increasing importance of noise immunity in modern electronic systems. This growth is further accelerated by the expansion of IoT and Industry 4.0 initiatives, which introduce more electronic controls into traditionally mechanical systems, often in electrically noisy environments.

The industrial automation sector represents the largest market segment for noise-resistant SSRs, with manufacturing facilities requiring robust switching solutions that can withstand the electrical noise generated by heavy machinery, variable frequency drives, and power switching equipment. According to market research, the industrial automation segment accounts for approximately 40% of the total SSR market, with noise resistance being cited as a critical selection factor by procurement engineers.

Energy and power distribution applications form another significant market segment, where SSRs must operate reliably despite grid fluctuations, switching transients, and lightning-induced surges. The renewable energy sector, particularly solar and wind power installations, has emerged as a high-growth area for noise-resistant SSRs due to the challenging electrical environments of power inverters and the need for long-term reliability in remote locations.

Transportation systems, including railway signaling, automotive electronics, and aerospace applications, constitute a premium market segment where failure is not an option. These applications demand SSRs with superior noise immunity and often require compliance with stringent standards such as DO-160 for aerospace or EN 50121 for railway applications, driving the development of specialized noise-resistant SSR solutions.

Market analysis reveals a growing trend toward integrated diagnostic capabilities in noise-resistant SSRs, allowing real-time monitoring of relay performance in noisy environments. This feature commands a price premium but delivers significant value by enabling predictive maintenance and reducing costly downtime in critical applications.

Geographically, North America and Europe lead in the adoption of high-performance noise-resistant SSRs, primarily due to stringent regulatory requirements and the presence of industries with high-reliability demands. However, the Asia-Pacific region is showing the fastest growth rate, driven by rapid industrialization and infrastructure development in countries like China, India, and South Korea.

The market for noise-resistant SSRs is projected to grow at a compound annual growth rate exceeding the broader electronics component market, highlighting the increasing importance of noise immunity in modern electronic systems. This growth is further accelerated by the expansion of IoT and Industry 4.0 initiatives, which introduce more electronic controls into traditionally mechanical systems, often in electrically noisy environments.

Current Challenges in Noise-Rich Environments

Solid-state relays (SSRs) operating in noise-rich environments face significant challenges that impact their reliability and performance. Industrial settings, power distribution systems, and manufacturing facilities generate substantial electromagnetic interference (EMI), radio frequency interference (RFI), and power line disturbances that can compromise SSR functionality. These noise sources can trigger false switching operations, causing unintended activation or deactivation of connected equipment.

Thermal noise presents another critical challenge, particularly in high-temperature industrial environments. As ambient temperatures rise, the semiconductor materials within SSRs experience increased thermal noise, potentially leading to erratic behavior and reduced switching precision. This thermal instability can significantly impact applications requiring precise timing or load control.

Voltage transients and power surges represent perhaps the most damaging noise sources for SSRs. Lightning strikes, motor startups, and capacitor switching operations generate high-amplitude, short-duration voltage spikes that can exceed the SSR's rated voltage tolerance. Without adequate protection, these transients can cause permanent damage to the semiconductor junction, resulting in either permanent conduction (short circuit) or permanent non-conduction (open circuit) failures.

Ground loops and common-mode noise introduce additional complications in SSR evaluation. When control and load circuits share common ground paths with varying potentials, circulating currents can induce false triggering signals. This phenomenon is particularly problematic in distributed control systems where multiple SSRs operate across different ground reference points.

The increasing adoption of variable frequency drives (VFDs) and switch-mode power supplies (SMPS) introduces high-frequency switching noise that can couple into SSR control circuits. These modern power conversion technologies generate harmonic distortion and electromagnetic emissions that traditional SSR designs may not adequately reject.

Measurement and evaluation challenges compound these technical issues. Conventional multimeters and oscilloscopes may lack sufficient bandwidth or sampling rates to capture transient noise events affecting SSR operation. Additionally, the Galvanic isolation that makes SSRs valuable also complicates the placement of measurement probes without introducing additional noise or altering circuit characteristics.

Regulatory compliance adds another layer of complexity, as SSRs must maintain reliable operation while meeting increasingly stringent electromagnetic compatibility (EMC) standards. These regulations limit both the susceptibility to external noise and the emission of noise that might affect nearby equipment, creating a challenging design constraint for SSR manufacturers and system integrators.

Thermal noise presents another critical challenge, particularly in high-temperature industrial environments. As ambient temperatures rise, the semiconductor materials within SSRs experience increased thermal noise, potentially leading to erratic behavior and reduced switching precision. This thermal instability can significantly impact applications requiring precise timing or load control.

Voltage transients and power surges represent perhaps the most damaging noise sources for SSRs. Lightning strikes, motor startups, and capacitor switching operations generate high-amplitude, short-duration voltage spikes that can exceed the SSR's rated voltage tolerance. Without adequate protection, these transients can cause permanent damage to the semiconductor junction, resulting in either permanent conduction (short circuit) or permanent non-conduction (open circuit) failures.

Ground loops and common-mode noise introduce additional complications in SSR evaluation. When control and load circuits share common ground paths with varying potentials, circulating currents can induce false triggering signals. This phenomenon is particularly problematic in distributed control systems where multiple SSRs operate across different ground reference points.

The increasing adoption of variable frequency drives (VFDs) and switch-mode power supplies (SMPS) introduces high-frequency switching noise that can couple into SSR control circuits. These modern power conversion technologies generate harmonic distortion and electromagnetic emissions that traditional SSR designs may not adequately reject.

Measurement and evaluation challenges compound these technical issues. Conventional multimeters and oscilloscopes may lack sufficient bandwidth or sampling rates to capture transient noise events affecting SSR operation. Additionally, the Galvanic isolation that makes SSRs valuable also complicates the placement of measurement probes without introducing additional noise or altering circuit characteristics.

Regulatory compliance adds another layer of complexity, as SSRs must maintain reliable operation while meeting increasingly stringent electromagnetic compatibility (EMC) standards. These regulations limit both the susceptibility to external noise and the emission of noise that might affect nearby equipment, creating a challenging design constraint for SSR manufacturers and system integrators.

Existing Noise Mitigation Solutions

01 Solid-state relay design and structure

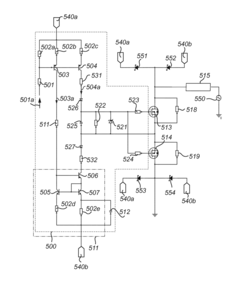

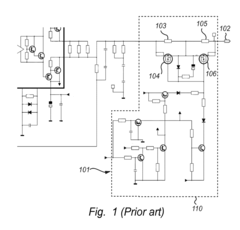

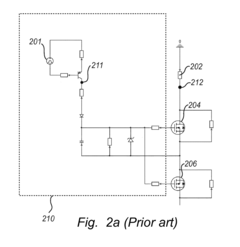

Solid-state relays (SSRs) are designed with semiconductor components instead of mechanical contacts, providing advantages such as no moving parts, longer lifespan, and faster switching speeds. The basic structure typically includes input control circuitry, isolation components, and output switching elements. Various designs incorporate different semiconductor technologies like MOSFETs, IGBTs, or thyristors depending on the application requirements and load characteristics.- Solid-state relay design and structure: Solid-state relays (SSRs) are designed with semiconductor components to perform switching operations without mechanical parts. The basic structure includes input control circuitry, isolation mechanisms, and output switching elements. These designs focus on improving reliability, reducing size, and enhancing performance characteristics compared to traditional mechanical relays. Various semiconductor materials and configurations are employed to optimize switching behavior and electrical isolation between input and output circuits.

- Thermal management and protection mechanisms: Thermal management is critical for solid-state relay operation evaluation as excessive heat can degrade performance and cause premature failure. Protection mechanisms include heat sinks, thermal sensors, and automatic shutdown circuits that activate when temperature thresholds are exceeded. Evaluation methods focus on measuring thermal resistance, temperature rise during operation, and effectiveness of cooling solutions. Advanced designs incorporate thermal modeling to predict behavior under various load conditions and ambient temperatures.

- Performance testing and reliability evaluation: Evaluation of solid-state relay performance involves testing parameters such as switching speed, on-state resistance, leakage current, and isolation voltage. Reliability assessment includes accelerated life testing, thermal cycling, and surge withstand capability. Methods for evaluating long-term stability under various environmental conditions are essential for predicting field performance. Testing protocols may include measuring response times, voltage drop across the relay, and immunity to electrical noise and interference.

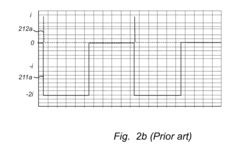

- Control circuit design and signal processing: Control circuit design for solid-state relays focuses on signal conditioning, trigger mechanisms, and isolation techniques. Evaluation methods assess the sensitivity of input circuits, noise immunity, and compatibility with various control signals. Advanced designs incorporate microcontroller-based intelligence for programmable operation, diagnostics, and communication capabilities. Signal processing techniques may include filtering, level shifting, and hysteresis to ensure reliable switching under varying input conditions.

- Application-specific performance evaluation: Evaluation methods for solid-state relays vary based on specific application requirements such as industrial automation, power distribution, automotive systems, or medical equipment. Testing focuses on parameters critical to each application, including load handling capability, switching frequency, EMI generation, and behavior under fault conditions. Specialized test setups simulate real-world operating conditions to assess performance in target environments. Evaluation criteria may include compliance with industry standards and regulations specific to the application domain.

02 Thermal management and protection mechanisms

Effective thermal management is crucial for solid-state relay operation evaluation as these devices generate heat during switching operations. Protection mechanisms include heat sinks, thermal sensors, and automatic shutdown features to prevent overheating. Advanced designs incorporate temperature monitoring circuits that can evaluate operating conditions and adjust performance parameters or trigger protective measures when thermal limits are approached.Expand Specific Solutions03 Performance evaluation methods and parameters

Evaluation of solid-state relay performance involves measuring various parameters including switching time, voltage drop, leakage current, isolation resistance, and load handling capability. Testing methods may include surge withstand capability tests, dielectric strength tests, and long-term reliability assessments. Advanced evaluation techniques utilize specialized equipment to measure response times in microseconds and analyze behavior under various load conditions.Expand Specific Solutions04 Control circuit innovations

Innovations in control circuits for solid-state relays focus on improving triggering precision, reducing power consumption, and enhancing noise immunity. Advanced control designs incorporate microcontrollers or digital signal processors that can dynamically adjust gate drive parameters based on operating conditions. Some implementations feature programmable threshold levels, adjustable switching speeds, and communication interfaces for remote monitoring and control.Expand Specific Solutions05 Application-specific evaluation criteria

Different applications require specific evaluation criteria for solid-state relays. For high-frequency switching applications, turn-on and turn-off times are critical parameters. For power grid applications, surge handling capability and fail-safe operation are essential. Industrial automation systems may prioritize communication capabilities and diagnostic features. Medical equipment applications focus on leakage current and isolation strength, while automotive applications emphasize temperature range and vibration resistance.Expand Specific Solutions

Key Industry Players and Competitors

The solid-state relay (SSR) market is currently in a growth phase, with increasing demand for noise-resistant solutions in industrial automation and power management applications. The global market size is estimated to reach $1.5-2 billion by 2025, driven by Industry 4.0 adoption and smart grid implementations. Technical maturity varies across applications, with companies demonstrating different specialization levels. Xiamen Hongfa Electric leads in comprehensive relay solutions, while Phoenix Contact and TE Connectivity excel in industrial-grade SSRs with enhanced noise immunity. Crouzet SAS and Hengstler GmbH focus on specialized automation applications requiring high noise tolerance. Companies like Panasonic and LG Electronics integrate SSRs into consumer and commercial electronics with moderate noise resistance capabilities. Research collaborations between manufacturers and institutions like National University of Singapore are advancing noise mitigation technologies for next-generation SSRs.

Xiamen Hongfa Electric Appliance Co., Ltd.

Technical Solution: Hongfa has developed a comprehensive noise immunity testing framework for solid-state relays (SSRs) that combines hardware filtering and software algorithms. Their approach utilizes multi-stage RC filtering circuits at input terminals to attenuate high-frequency noise components while maintaining signal integrity. The company implements optical isolation technology with enhanced common-mode rejection ratios (CMRR) exceeding 120dB to prevent noise coupling between control and load circuits. Their proprietary Adaptive Noise Threshold Detection (ANTD) algorithm continuously monitors environmental noise levels and dynamically adjusts triggering thresholds to prevent false switching events. Hongfa's evaluation system includes automated test equipment that simulates various noise profiles including conducted EMI, radiated EMI, and power supply transients according to IEC 61000-4 standards to comprehensively assess SSR performance under real-world conditions.

Strengths: Industry-leading noise immunity with dynamic threshold adjustment capability; comprehensive testing methodology aligned with international standards; high integration of hardware and software noise mitigation techniques. Weaknesses: Higher component cost due to premium filtering components; slightly increased switching delay (typically 2-5ms) due to noise filtering algorithms; requires periodic recalibration in extremely variable noise environments.

Phoenix Contact Gmbh & Co. KG

Technical Solution: Phoenix Contact has engineered an advanced solid-state relay evaluation system specifically designed for industrial environments with high electromagnetic interference. Their COMPLETE line of SSRs incorporates a multi-layered approach to noise immunity, featuring specialized input circuits with Schmitt triggers that provide hysteresis to prevent chattering from noise-induced voltage fluctuations. The company's evaluation methodology includes proprietary CLIPLINE testing protocols that subject SSRs to standardized noise profiles derived from real-world industrial applications, including motor starting transients, welding equipment interference, and switchgear operations. Phoenix Contact implements digital signal processing techniques with moving average filters and frequency domain analysis to distinguish between legitimate control signals and noise. Their SSRs feature integrated surge protection components rated at 6kV (1.2/50μs waveform) that protect against both differential and common-mode transients while maintaining operational integrity in harsh industrial environments.

Strengths: Exceptional performance in high-voltage industrial environments; comprehensive testing methodology based on actual field conditions; integrated protection features reduce need for external components. Weaknesses: Higher initial cost compared to basic SSRs; larger form factor due to additional protection circuitry; slightly higher power consumption from protection and filtering circuits.

Critical Patents in SSR Noise Immunity

Static relay with condition detecting

PatentInactiveEP0895671A1

Innovation

- A static relay with a pair of light-emitting diodes connected in parallel head-to-tail and series with an RC circuit, optically coupled to transistors, which are connected in parallel with semiconductor components, allowing for state detection by monitoring voltage changes across the relay terminals during alternating current cycles.

Solid state switch relay

PatentActiveUS20180006641A1

Innovation

- A solid state relay design using a pair of MOSFETs with a common gate and source junction, controlled by a positive current generator and a current mirror circuit, which sinks current from the source junction, reducing ghost currents and tolerances, and allowing for the same power supply as the amplifier, thus being cost-efficient and robust.

EMC Standards and Compliance

Electromagnetic Compatibility (EMC) standards play a crucial role in evaluating solid-state relay (SSR) operation in noise-rich environments. The International Electrotechnical Commission (IEC) has established several standards directly applicable to SSRs, including IEC 61000-4-4 for electrical fast transient immunity and IEC 61000-4-5 for surge immunity. These standards define test methodologies and acceptance criteria that manufacturers must meet to ensure reliable SSR operation under electromagnetic interference conditions.

For industrial applications, IEC 60947-4-3 specifically addresses semiconductor controllers and contactors for non-motor loads, providing EMC requirements for SSRs in industrial environments. This standard defines both emission and immunity requirements, recognizing the dual nature of EMC challenges faced by solid-state relays which can both generate and be affected by electromagnetic noise.

In the United States, UL 508 serves as a key standard for industrial control equipment including SSRs, while European markets require compliance with the EMC Directive 2014/30/EU. The latter mandates that all electronic equipment sold in the European Economic Area must demonstrate adequate immunity to electromagnetic disturbances and limited emission of such disturbances.

Testing for EMC compliance involves subjective evaluation methods that assess SSR performance under various electromagnetic disturbance scenarios. These include conducted emissions testing (measuring noise transmitted through power lines), radiated emissions testing (measuring electromagnetic fields generated by the device), and immunity testing (evaluating device performance when subjected to external electromagnetic interference).

The IEC 61000-4 series provides specific test methodologies for different types of electromagnetic disturbances. For example, IEC 61000-4-2 covers electrostatic discharge immunity, IEC 61000-4-3 addresses radiated RF electromagnetic field immunity, and IEC 61000-4-6 focuses on immunity to conducted disturbances induced by radio-frequency fields.

Performance criteria for SSRs under EMC testing typically fall into categories ranging from normal operation (Performance Criterion A) to temporary loss of function with self-recovery (Performance Criterion B) to loss of function requiring manual intervention (Performance Criterion C). For critical applications, SSRs are expected to maintain Performance Criterion A even under severe electromagnetic disturbances.

Recent updates to EMC standards have begun addressing emerging challenges such as high-frequency switching noise from modern power electronics and wireless communication interference. These evolving standards reflect the increasing complexity of electromagnetic environments in which SSRs must operate reliably.

For industrial applications, IEC 60947-4-3 specifically addresses semiconductor controllers and contactors for non-motor loads, providing EMC requirements for SSRs in industrial environments. This standard defines both emission and immunity requirements, recognizing the dual nature of EMC challenges faced by solid-state relays which can both generate and be affected by electromagnetic noise.

In the United States, UL 508 serves as a key standard for industrial control equipment including SSRs, while European markets require compliance with the EMC Directive 2014/30/EU. The latter mandates that all electronic equipment sold in the European Economic Area must demonstrate adequate immunity to electromagnetic disturbances and limited emission of such disturbances.

Testing for EMC compliance involves subjective evaluation methods that assess SSR performance under various electromagnetic disturbance scenarios. These include conducted emissions testing (measuring noise transmitted through power lines), radiated emissions testing (measuring electromagnetic fields generated by the device), and immunity testing (evaluating device performance when subjected to external electromagnetic interference).

The IEC 61000-4 series provides specific test methodologies for different types of electromagnetic disturbances. For example, IEC 61000-4-2 covers electrostatic discharge immunity, IEC 61000-4-3 addresses radiated RF electromagnetic field immunity, and IEC 61000-4-6 focuses on immunity to conducted disturbances induced by radio-frequency fields.

Performance criteria for SSRs under EMC testing typically fall into categories ranging from normal operation (Performance Criterion A) to temporary loss of function with self-recovery (Performance Criterion B) to loss of function requiring manual intervention (Performance Criterion C). For critical applications, SSRs are expected to maintain Performance Criterion A even under severe electromagnetic disturbances.

Recent updates to EMC standards have begun addressing emerging challenges such as high-frequency switching noise from modern power electronics and wireless communication interference. These evolving standards reflect the increasing complexity of electromagnetic environments in which SSRs must operate reliably.

Testing Methodologies for SSR Performance

Evaluating Solid-State Relay (SSR) performance requires comprehensive testing methodologies that account for the complex noise environments these devices often operate within. Standard testing approaches typically include electrical parameter verification, thermal performance assessment, and switching characteristics analysis. However, these conventional methods must be adapted specifically for noise-rich environments.

Bench testing represents the foundation of SSR evaluation, where controlled laboratory conditions allow for precise measurement of turn-on/turn-off times, voltage drop, and leakage current. For noise immunity assessment, specialized equipment including spectrum analyzers, oscilloscopes with high sampling rates, and electromagnetic interference (EMI) generators are essential. These tools enable the simulation of various noise profiles that SSRs might encounter in industrial settings.

Environmental chamber testing forms another critical component, subjecting SSRs to temperature extremes, humidity variations, and vibration while simultaneously introducing controlled electromagnetic interference. This approach reveals how environmental factors may compound with electrical noise to affect relay performance. Data collected during these tests should track changes in switching characteristics and failure rates across different environmental conditions.

Conducted and radiated immunity testing follows IEC 61000-4 standards, particularly sections 4-2 (electrostatic discharge), 4-3 (radiated RF fields), 4-4 (electrical fast transients), and 4-5 (surge immunity). These standardized procedures ensure SSRs can withstand common electromagnetic disturbances without false triggering or performance degradation. The test setup typically involves subjecting the SSR to calibrated electromagnetic disturbances while monitoring its operational state.

Field testing complements laboratory evaluation by placing SSRs in actual application environments where they experience real-world noise conditions. This approach often reveals issues not identified during controlled testing. Data logging equipment should record both environmental parameters and SSR performance metrics over extended periods, enabling correlation analysis between specific noise events and relay behavior.

Statistical analysis of test results provides crucial insights into SSR reliability. Mean Time Between Failures (MTBF) calculations under various noise conditions help quantify reliability expectations. Additionally, Failure Mode and Effects Analysis (FMEA) specifically focused on noise-induced failures helps identify the most vulnerable aspects of SSR design and implementation.

Comparative testing between different SSR models and manufacturers offers valuable benchmarking data. This approach should utilize standardized test conditions to ensure fair comparison, with particular attention to noise immunity thresholds and performance degradation patterns under increasing noise levels.

Bench testing represents the foundation of SSR evaluation, where controlled laboratory conditions allow for precise measurement of turn-on/turn-off times, voltage drop, and leakage current. For noise immunity assessment, specialized equipment including spectrum analyzers, oscilloscopes with high sampling rates, and electromagnetic interference (EMI) generators are essential. These tools enable the simulation of various noise profiles that SSRs might encounter in industrial settings.

Environmental chamber testing forms another critical component, subjecting SSRs to temperature extremes, humidity variations, and vibration while simultaneously introducing controlled electromagnetic interference. This approach reveals how environmental factors may compound with electrical noise to affect relay performance. Data collected during these tests should track changes in switching characteristics and failure rates across different environmental conditions.

Conducted and radiated immunity testing follows IEC 61000-4 standards, particularly sections 4-2 (electrostatic discharge), 4-3 (radiated RF fields), 4-4 (electrical fast transients), and 4-5 (surge immunity). These standardized procedures ensure SSRs can withstand common electromagnetic disturbances without false triggering or performance degradation. The test setup typically involves subjecting the SSR to calibrated electromagnetic disturbances while monitoring its operational state.

Field testing complements laboratory evaluation by placing SSRs in actual application environments where they experience real-world noise conditions. This approach often reveals issues not identified during controlled testing. Data logging equipment should record both environmental parameters and SSR performance metrics over extended periods, enabling correlation analysis between specific noise events and relay behavior.

Statistical analysis of test results provides crucial insights into SSR reliability. Mean Time Between Failures (MTBF) calculations under various noise conditions help quantify reliability expectations. Additionally, Failure Mode and Effects Analysis (FMEA) specifically focused on noise-induced failures helps identify the most vulnerable aspects of SSR design and implementation.

Comparative testing between different SSR models and manufacturers offers valuable benchmarking data. This approach should utilize standardized test conditions to ensure fair comparison, with particular attention to noise immunity thresholds and performance degradation patterns under increasing noise levels.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!