Solid-State Relay Heat Dissipation: Best Practices

SEP 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Thermal Management Background and Objectives

Solid-state relays (SSRs) have evolved significantly since their inception in the late 1960s, representing a revolutionary advancement over traditional electromechanical relays. The development trajectory of SSR technology has been characterized by continuous improvements in switching capabilities, reliability, and thermal management. Initially designed for simple on-off control applications, modern SSRs now serve critical functions across industrial automation, power distribution systems, and consumer electronics, where their silent operation and longevity provide substantial advantages.

The thermal management challenges associated with SSRs stem from their fundamental operating principle. Unlike mechanical relays that physically separate contacts, SSRs utilize semiconductor devices (typically thyristors, triacs, or MOSFETs) to control current flow. These semiconductor components generate significant heat during operation due to their inherent forward voltage drop, which typically ranges from 0.8V to 1.5V depending on the specific semiconductor technology employed. This voltage drop, multiplied by the current flowing through the device, results in power dissipation that manifests as heat.

Industry trends indicate a growing demand for higher-density power electronics with enhanced efficiency and reliability. This evolution has placed increased emphasis on effective thermal management strategies for SSRs, particularly as applications require handling higher current loads in more compact form factors. The miniaturization trend in electronics has further exacerbated thermal challenges, creating scenarios where heat dissipation becomes the primary limiting factor in SSR performance and reliability.

The primary technical objective in SSR thermal management is to maintain semiconductor junction temperatures below their maximum rated values under all operating conditions. This typically requires keeping junction temperatures below 125°C to 150°C, depending on the specific semiconductor technology. Effective thermal management directly impacts several critical performance parameters, including the SSR's current carrying capacity, long-term reliability, and mean time between failures (MTBF).

Recent technological advancements have introduced innovative approaches to SSR thermal management, including advanced materials with superior thermal conductivity, optimized heat sink designs, and intelligent thermal monitoring systems. The integration of wide-bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) has also emerged as a promising direction, offering reduced power losses and consequently lower heat generation.

This technical research aims to comprehensively evaluate current best practices in SSR thermal management, identify emerging technologies with potential to address persistent challenges, and establish a roadmap for future developments. The ultimate goal is to enable higher power densities while maintaining or improving reliability metrics, thereby supporting the broader industry trend toward more compact, efficient, and robust power control solutions.

The thermal management challenges associated with SSRs stem from their fundamental operating principle. Unlike mechanical relays that physically separate contacts, SSRs utilize semiconductor devices (typically thyristors, triacs, or MOSFETs) to control current flow. These semiconductor components generate significant heat during operation due to their inherent forward voltage drop, which typically ranges from 0.8V to 1.5V depending on the specific semiconductor technology employed. This voltage drop, multiplied by the current flowing through the device, results in power dissipation that manifests as heat.

Industry trends indicate a growing demand for higher-density power electronics with enhanced efficiency and reliability. This evolution has placed increased emphasis on effective thermal management strategies for SSRs, particularly as applications require handling higher current loads in more compact form factors. The miniaturization trend in electronics has further exacerbated thermal challenges, creating scenarios where heat dissipation becomes the primary limiting factor in SSR performance and reliability.

The primary technical objective in SSR thermal management is to maintain semiconductor junction temperatures below their maximum rated values under all operating conditions. This typically requires keeping junction temperatures below 125°C to 150°C, depending on the specific semiconductor technology. Effective thermal management directly impacts several critical performance parameters, including the SSR's current carrying capacity, long-term reliability, and mean time between failures (MTBF).

Recent technological advancements have introduced innovative approaches to SSR thermal management, including advanced materials with superior thermal conductivity, optimized heat sink designs, and intelligent thermal monitoring systems. The integration of wide-bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) has also emerged as a promising direction, offering reduced power losses and consequently lower heat generation.

This technical research aims to comprehensively evaluate current best practices in SSR thermal management, identify emerging technologies with potential to address persistent challenges, and establish a roadmap for future developments. The ultimate goal is to enable higher power densities while maintaining or improving reliability metrics, thereby supporting the broader industry trend toward more compact, efficient, and robust power control solutions.

Market Demand Analysis for Efficient SSR Solutions

The global market for Solid-State Relay (SSR) solutions with efficient heat dissipation capabilities has been experiencing robust growth, driven primarily by increasing automation across industries and the rising demand for more reliable switching technologies. Current market analysis indicates that the industrial automation sector represents the largest consumer of SSRs, accounting for approximately 40% of the total market share, followed by building automation and energy management systems.

Market research reveals a significant shift in customer preferences towards SSRs with enhanced thermal management capabilities. End-users are increasingly prioritizing energy efficiency and operational reliability over initial acquisition costs, recognizing that improved heat dissipation directly correlates with extended service life and reduced maintenance requirements. This trend is particularly pronounced in critical applications such as medical equipment, semiconductor manufacturing, and data centers where system downtime can result in substantial financial losses.

The demand for compact yet thermally efficient SSRs has seen remarkable growth in recent years. As electronic devices continue to shrink in size while increasing in functionality, manufacturers are facing mounting pressure to develop SSRs that can handle higher current loads within smaller form factors without compromising thermal performance. This miniaturization trend is expected to continue, with the market for micro-SSRs projected to grow at a compound annual rate exceeding the broader SSR market.

Regional analysis shows that Asia-Pacific currently leads the market for advanced SSR solutions, driven by rapid industrialization and manufacturing growth in countries like China, Japan, and South Korea. North America and Europe follow closely, with their demand primarily stemming from modernization initiatives in existing industrial infrastructure and stringent energy efficiency regulations.

Industry surveys indicate that customers are willing to pay a premium of up to 30% for SSRs with demonstrably superior heat dissipation capabilities, especially in applications where reliability is paramount. This price elasticity represents a significant opportunity for manufacturers who can effectively communicate the long-term cost benefits of their thermally optimized solutions.

The market is also witnessing increased demand for integrated solutions that combine SSRs with advanced thermal management features such as built-in temperature monitoring, adaptive cooling mechanisms, and predictive maintenance capabilities. This integration trend aligns with the broader Industry 4.0 movement, where smart, connected components are becoming the norm rather than the exception.

Environmental considerations are further shaping market dynamics, with growing regulatory pressure to reduce energy consumption and electronic waste. SSRs with efficient heat dissipation contribute positively to both objectives by consuming less power and lasting longer, thus reducing replacement frequency and associated waste.

Market research reveals a significant shift in customer preferences towards SSRs with enhanced thermal management capabilities. End-users are increasingly prioritizing energy efficiency and operational reliability over initial acquisition costs, recognizing that improved heat dissipation directly correlates with extended service life and reduced maintenance requirements. This trend is particularly pronounced in critical applications such as medical equipment, semiconductor manufacturing, and data centers where system downtime can result in substantial financial losses.

The demand for compact yet thermally efficient SSRs has seen remarkable growth in recent years. As electronic devices continue to shrink in size while increasing in functionality, manufacturers are facing mounting pressure to develop SSRs that can handle higher current loads within smaller form factors without compromising thermal performance. This miniaturization trend is expected to continue, with the market for micro-SSRs projected to grow at a compound annual rate exceeding the broader SSR market.

Regional analysis shows that Asia-Pacific currently leads the market for advanced SSR solutions, driven by rapid industrialization and manufacturing growth in countries like China, Japan, and South Korea. North America and Europe follow closely, with their demand primarily stemming from modernization initiatives in existing industrial infrastructure and stringent energy efficiency regulations.

Industry surveys indicate that customers are willing to pay a premium of up to 30% for SSRs with demonstrably superior heat dissipation capabilities, especially in applications where reliability is paramount. This price elasticity represents a significant opportunity for manufacturers who can effectively communicate the long-term cost benefits of their thermally optimized solutions.

The market is also witnessing increased demand for integrated solutions that combine SSRs with advanced thermal management features such as built-in temperature monitoring, adaptive cooling mechanisms, and predictive maintenance capabilities. This integration trend aligns with the broader Industry 4.0 movement, where smart, connected components are becoming the norm rather than the exception.

Environmental considerations are further shaping market dynamics, with growing regulatory pressure to reduce energy consumption and electronic waste. SSRs with efficient heat dissipation contribute positively to both objectives by consuming less power and lasting longer, thus reducing replacement frequency and associated waste.

Current Challenges in SSR Heat Dissipation

Despite significant advancements in solid-state relay (SSR) technology, heat dissipation remains one of the most critical challenges facing their widespread implementation. The semiconductor switching elements in SSRs generate considerable heat during operation, particularly in high-power applications. This heat generation is primarily due to the inherent forward voltage drop across the semiconductor junction, which can range from 0.7V to 1.7V depending on the semiconductor material and design.

The thermal resistance between the semiconductor junction and the case (Rjc) presents a significant bottleneck in heat transfer. Current SSR designs struggle to minimize this resistance while maintaining electrical isolation properties. Even with advanced ceramic substrates and direct bonded copper (DBC) technology, the thermal pathway often remains insufficient for applications exceeding 40A continuous current.

Another persistent challenge is the limited temperature range of semiconductor materials. Silicon-based SSRs typically have maximum junction temperatures of 125°C to 150°C, which restricts their use in high-temperature environments. While wide bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN) offer improved temperature tolerance, their implementation in commercial SSRs remains limited due to cost constraints and manufacturing complexities.

The miniaturization trend in industrial control systems further exacerbates heat dissipation issues. As control cabinets become more compact, the available space for heat sinks and cooling systems diminishes. This spatial constraint often leads to thermal coupling between adjacent SSRs, creating hotspots that can accelerate component degradation and reduce overall system reliability.

Environmental factors also contribute significantly to heat dissipation challenges. Dust accumulation on heat sink surfaces can increase thermal resistance by up to 30%, while ambient temperature variations can cause thermal cycling that stresses the interface materials between semiconductors and heat sinks. These environmental factors are particularly problematic in industrial settings where regular maintenance may be limited.

Current cooling solutions present their own set of challenges. Passive cooling with heat sinks often proves inadequate for high-power applications, while active cooling methods introduce additional complexity, cost, and potential points of failure. Fan-based cooling systems require maintenance and are susceptible to dust accumulation, while liquid cooling systems, though effective, introduce concerns about leakage and compatibility with electrical systems.

The trade-off between thermal performance and electrical isolation represents perhaps the most fundamental challenge in SSR heat dissipation. Materials with excellent thermal conductivity often have poor electrical insulation properties, necessitating complex multi-layer designs that compromise overall thermal performance.

The thermal resistance between the semiconductor junction and the case (Rjc) presents a significant bottleneck in heat transfer. Current SSR designs struggle to minimize this resistance while maintaining electrical isolation properties. Even with advanced ceramic substrates and direct bonded copper (DBC) technology, the thermal pathway often remains insufficient for applications exceeding 40A continuous current.

Another persistent challenge is the limited temperature range of semiconductor materials. Silicon-based SSRs typically have maximum junction temperatures of 125°C to 150°C, which restricts their use in high-temperature environments. While wide bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN) offer improved temperature tolerance, their implementation in commercial SSRs remains limited due to cost constraints and manufacturing complexities.

The miniaturization trend in industrial control systems further exacerbates heat dissipation issues. As control cabinets become more compact, the available space for heat sinks and cooling systems diminishes. This spatial constraint often leads to thermal coupling between adjacent SSRs, creating hotspots that can accelerate component degradation and reduce overall system reliability.

Environmental factors also contribute significantly to heat dissipation challenges. Dust accumulation on heat sink surfaces can increase thermal resistance by up to 30%, while ambient temperature variations can cause thermal cycling that stresses the interface materials between semiconductors and heat sinks. These environmental factors are particularly problematic in industrial settings where regular maintenance may be limited.

Current cooling solutions present their own set of challenges. Passive cooling with heat sinks often proves inadequate for high-power applications, while active cooling methods introduce additional complexity, cost, and potential points of failure. Fan-based cooling systems require maintenance and are susceptible to dust accumulation, while liquid cooling systems, though effective, introduce concerns about leakage and compatibility with electrical systems.

The trade-off between thermal performance and electrical isolation represents perhaps the most fundamental challenge in SSR heat dissipation. Materials with excellent thermal conductivity often have poor electrical insulation properties, necessitating complex multi-layer designs that compromise overall thermal performance.

Best Practices for SSR Heat Dissipation Implementation

01 Heat sink designs for solid-state relays

Various heat sink designs can be implemented to enhance heat dissipation in solid-state relays. These include finned heat sinks, aluminum extrusion heat sinks, and copper-based heat sinks that increase surface area for better thermal transfer. The design may incorporate multiple fins or specialized geometries to maximize airflow and heat exchange efficiency, ensuring the relay operates within safe temperature ranges.- Heat sink designs for solid-state relays: Various heat sink designs can be incorporated into solid-state relays to enhance heat dissipation. These designs include finned structures, specialized materials with high thermal conductivity, and optimized geometries that increase surface area for better heat transfer. The heat sinks can be integrated directly with the relay housing or attached as separate components, allowing for efficient cooling of the semiconductor elements within the relay.

- Thermal interface materials and mounting techniques: The use of thermal interface materials between solid-state relays and heat sinks significantly improves heat transfer efficiency. These materials include thermal pastes, pads, or adhesives that reduce thermal resistance at contact points. Additionally, specialized mounting techniques such as pressure mounting systems, spring-loaded mechanisms, or thermally conductive fasteners ensure optimal thermal contact while maintaining electrical isolation where required.

- Forced cooling systems for solid-state relays: Forced cooling systems enhance heat dissipation in solid-state relays through active air or liquid circulation. These systems include fans, blowers, or liquid cooling channels that accelerate the removal of heat from the relay components. Some designs incorporate temperature sensors and control circuits to adjust cooling intensity based on operating conditions, preventing overheating during high-load operations while optimizing energy efficiency.

- Integrated thermal management structures: Advanced solid-state relays incorporate integrated thermal management structures directly into their design. These include internal heat spreading layers, embedded heat pipes, thermally conductive encapsulation materials, and strategically positioned thermal vias. Such integrated approaches distribute heat more evenly throughout the device, preventing hotspots and allowing for more compact designs while maintaining safe operating temperatures.

- PCB layout and system-level thermal design: Optimized PCB layouts and system-level thermal designs significantly impact solid-state relay heat dissipation. These approaches include copper pour areas that act as heat spreaders, strategic component placement to prevent thermal interference, thermal isolation techniques for sensitive components, and overall enclosure designs that facilitate natural convection. Some designs also incorporate thermal modeling and simulation to predict and optimize heat flow patterns within the complete system.

02 Thermal interface materials and mounting techniques

The use of thermal interface materials between the solid-state relay and heat sink significantly improves heat transfer efficiency. Materials such as thermal paste, pads, or phase change materials reduce thermal resistance at the contact points. Proper mounting techniques, including appropriate pressure application and surface preparation, ensure optimal thermal conductivity and heat dissipation from the relay to the heat sink.Expand Specific Solutions03 Forced cooling systems for solid-state relays

Implementing forced cooling systems such as fans, blowers, or liquid cooling significantly enhances heat dissipation in solid-state relays. These active cooling methods create forced convection that removes heat more efficiently than passive cooling alone. The cooling systems can be designed with temperature sensors and control circuits to adjust cooling intensity based on the relay's operating temperature, preventing overheating during high-load conditions.Expand Specific Solutions04 Integrated cooling structures in relay packages

Solid-state relays can be designed with integrated cooling structures directly in their packages. These may include embedded heat pipes, vapor chambers, or specialized thermal pathways that efficiently conduct heat away from the semiconductor junction. The integration of cooling elements within the relay package reduces thermal resistance and allows for more compact designs while maintaining effective heat dissipation.Expand Specific Solutions05 Thermal management circuit designs

Advanced circuit designs can improve thermal management in solid-state relays. These include distributed component layouts that prevent hot spots, thermal feedback circuits that adjust relay operation based on temperature, and power management circuits that optimize switching to reduce heat generation. Some designs incorporate temperature sensors and protective shutdown mechanisms to prevent thermal damage during abnormal operating conditions.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The solid-state relay heat dissipation market is currently in a growth phase, with increasing adoption across industrial automation, automotive, and energy sectors. The global market size is estimated to reach $1.5-2 billion by 2025, driven by demand for reliable switching solutions in high-temperature environments. Technologically, companies are at varying maturity levels: OMRON, Panasonic, and Fujitsu lead with advanced thermal management innovations; while automotive players like DENSO, Toyota, and Nissan focus on specialized applications. Energy sector companies (State Grid Corp. of China, SMA Solar) are developing grid-specific solutions. Emerging players like Zonit and tiko Energy are introducing novel cooling approaches, while research institutions (Tsinghua University, Harbin Institute) are pioneering next-generation materials for enhanced thermal conductivity, positioning this technology for significant expansion in smart grid and renewable energy applications.

OMRON Corp.

Technical Solution: OMRON has developed advanced heat dissipation solutions for solid-state relays (SSRs) featuring their G3PE and G3NA series with integrated aluminum heat sinks and thermally conductive silicone sheets. Their technology employs direct bonded copper (DBC) substrates that reduce thermal resistance between semiconductor chips and heat sinks by up to 30% compared to conventional designs[1]. OMRON's SSRs incorporate thermal simulation-based designs with optimized heat sink fin structures that maximize natural convection cooling while maintaining compact form factors. Their latest G3PE models feature a thermal shutdown protection circuit that automatically cuts off current when internal temperatures exceed safe thresholds (typically 110°C), preventing thermal runaway and extending relay lifespan[2]. Additionally, OMRON has pioneered zero-cross switching technology that reduces heat generation by minimizing inrush current and switching losses, particularly beneficial for high-frequency applications.

Strengths: Superior thermal management through optimized heat sink designs and DBC substrate technology; built-in protection circuits prevent overheating damage; compact form factor with high power handling capability. Weaknesses: Premium pricing compared to mechanical relays; still requires adequate spacing and airflow in panel installations; performance degradation in extremely high ambient temperature environments.

Sumitomo Electric Industries Ltd.

Technical Solution: Sumitomo Electric has developed proprietary thermal management solutions for solid-state relays incorporating their advanced materials science expertise. Their SSR designs feature high thermal conductivity ceramic substrates (aluminum nitride) with thermal conductivity exceeding 170 W/m·K, significantly outperforming traditional alumina substrates (25 W/m·K)[1]. Sumitomo's approach includes sintered silver die-attach technology that reduces thermal resistance by up to 40% compared to conventional solder methods, enabling more efficient heat transfer from semiconductor junctions to heat sinks[2]. Their SSRs incorporate proprietary thermal interface materials with phase-change properties that maintain optimal contact between components across temperature cycles. Sumitomo has also pioneered micro-channel liquid cooling systems for high-power industrial SSR applications, achieving cooling efficiencies 3-5 times greater than conventional air-cooled designs while maintaining electrical isolation integrity[3].

Strengths: Superior thermal materials science expertise; innovative die-attach technology significantly reduces junction-to-case thermal resistance; advanced thermal interface materials maintain performance over time. Weaknesses: Higher manufacturing costs due to specialized materials; liquid cooling solutions require additional system complexity; some advanced cooling technologies still in limited production scale.

Key Innovations in SSR Thermal Design

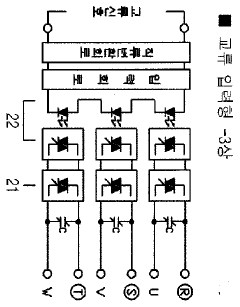

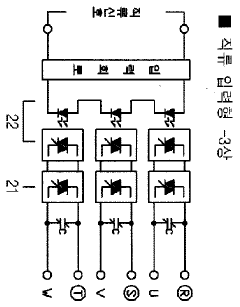

Solid state relay

PatentActiveUS20230283274A1

Innovation

- The development of improved packaging methods for solid state relays, including the use of multiple heat sink elements and a sub-miniature fan for efficient heat dissipation, allowing for the integration of solid state relays in small form factor devices, such as automatic transfer switches and power distribution components.

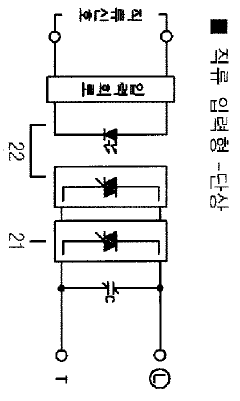

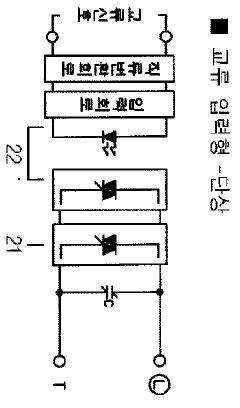

Solid state relay

PatentWO2012008713A2

Innovation

- The non-contact relay design features a vertically bent triac on the circuit board with a heat sink, allowing for improved heat dissipation and easy replacement, along with a detachable structure that includes a polymer resin upper case and a metal lower case with heat dissipation ribs and a lifting prevention mechanism, enhancing thermal conductivity and reducing environmental impact.

Reliability Testing Standards for SSR Thermal Performance

Reliability testing standards for Solid-State Relays (SSRs) thermal performance have evolved significantly over the past decades to address the critical nature of heat management in these devices. Industry standards such as UL 508, IEC 60947-4-3, and IEEE 1547 provide comprehensive frameworks for evaluating SSR thermal resilience under various operational conditions. These standards typically require manufacturers to conduct thermal cycling tests, where relays are subjected to rapid temperature fluctuations between extremes (often -40°C to +125°C) for thousands of cycles to simulate years of operational stress.

The MIL-STD-750 and JEDEC JESD22-A104 standards specifically outline methodologies for thermal shock testing, requiring SSRs to maintain functionality after exposure to sudden temperature changes. These tests evaluate not only the semiconductor components but also the integrity of thermal interface materials and heat dissipation mechanisms under stress conditions.

Power cycling tests represent another critical reliability standard, where SSRs are repeatedly switched between on and off states while carrying rated current. This process generates internal heating and cooling cycles that stress the thermal management system. Industry standards typically require 10,000 to 100,000 power cycles without performance degradation for industrial-grade SSRs.

Long-term thermal endurance testing, as specified in IEC 60068-2-2, evaluates SSR performance under sustained high-temperature conditions. These tests typically run for 1,000 to 5,000 hours at maximum rated temperature to verify that thermal management solutions remain effective throughout the expected device lifespan.

Thermal resistance measurement standards, including JEDEC JESD51 series, provide methodologies for accurately quantifying the thermal resistance from junction to case (Rjc) and junction to ambient (Rja). These measurements have become increasingly standardized, allowing for meaningful comparisons between different SSR designs and thermal solutions.

Environmental testing standards such as IEC 60068 series incorporate humidity, altitude, and contamination factors into thermal performance evaluation. These tests recognize that real-world conditions often combine multiple stressors that can compromise thermal management systems in ways that single-factor tests might not reveal.

Recent developments in reliability standards have begun to address accelerated life testing methodologies specifically tailored for SSR thermal performance. These approaches use mathematical models like the Arrhenius equation to extrapolate long-term reliability from shorter-duration high-stress tests, providing more efficient evaluation protocols while maintaining predictive accuracy for real-world applications.

The MIL-STD-750 and JEDEC JESD22-A104 standards specifically outline methodologies for thermal shock testing, requiring SSRs to maintain functionality after exposure to sudden temperature changes. These tests evaluate not only the semiconductor components but also the integrity of thermal interface materials and heat dissipation mechanisms under stress conditions.

Power cycling tests represent another critical reliability standard, where SSRs are repeatedly switched between on and off states while carrying rated current. This process generates internal heating and cooling cycles that stress the thermal management system. Industry standards typically require 10,000 to 100,000 power cycles without performance degradation for industrial-grade SSRs.

Long-term thermal endurance testing, as specified in IEC 60068-2-2, evaluates SSR performance under sustained high-temperature conditions. These tests typically run for 1,000 to 5,000 hours at maximum rated temperature to verify that thermal management solutions remain effective throughout the expected device lifespan.

Thermal resistance measurement standards, including JEDEC JESD51 series, provide methodologies for accurately quantifying the thermal resistance from junction to case (Rjc) and junction to ambient (Rja). These measurements have become increasingly standardized, allowing for meaningful comparisons between different SSR designs and thermal solutions.

Environmental testing standards such as IEC 60068 series incorporate humidity, altitude, and contamination factors into thermal performance evaluation. These tests recognize that real-world conditions often combine multiple stressors that can compromise thermal management systems in ways that single-factor tests might not reveal.

Recent developments in reliability standards have begun to address accelerated life testing methodologies specifically tailored for SSR thermal performance. These approaches use mathematical models like the Arrhenius equation to extrapolate long-term reliability from shorter-duration high-stress tests, providing more efficient evaluation protocols while maintaining predictive accuracy for real-world applications.

Environmental Impact of SSR Cooling Solutions

The environmental implications of Solid-State Relay (SSR) cooling solutions have become increasingly significant as industries prioritize sustainability alongside performance. Traditional cooling methods for SSRs often involve materials and processes that carry substantial environmental footprints. Heat sinks commonly manufactured from aluminum require energy-intensive extraction and processing, contributing to greenhouse gas emissions. When copper is used instead, though offering superior thermal conductivity, its mining and refinement generate significant ecological disruption and water pollution.

Cooling fans integrated into SSR systems present additional environmental concerns through their consumption of electricity throughout the operational lifespan of the device. This ongoing energy requirement translates to increased carbon emissions, particularly in regions where power generation relies heavily on fossil fuels. Furthermore, the electronic components in cooling fans often contain rare earth elements and other materials whose extraction creates environmental degradation in mining regions.

The disposal phase of SSR cooling solutions presents another environmental challenge. Heat sinks, while theoretically recyclable, often end up in landfills due to the complexity of separating them from attached components. Cooling fans contribute to electronic waste streams, releasing potentially harmful substances if not properly processed. Thermal interface materials, especially those containing silicone or ceramic compounds, may persist in the environment for extended periods.

Recent innovations have begun addressing these environmental concerns through several approaches. Passive cooling designs that eliminate the need for powered fans reduce lifetime energy consumption. Bio-based thermal interface materials derived from renewable resources offer lower environmental impact alternatives to traditional petroleum-based compounds. Heat sink designs optimized through computational fluid dynamics allow for material reduction while maintaining thermal performance, decreasing the embodied energy and resource requirements.

The regulatory landscape is evolving to address these environmental considerations. The European Union's RoHS and WEEE directives restrict hazardous substances in electronic components and mandate proper disposal procedures. Energy efficiency standards increasingly influence cooling solution designs, pushing manufacturers toward lower-power options. Carbon footprint certifications are becoming competitive differentiators in the industrial electronics market, incentivizing environmentally conscious design choices in SSR cooling systems.

Life cycle assessment studies indicate that the most significant environmental impact often occurs during the operational phase of SSR cooling systems. Therefore, designs that prioritize energy efficiency during operation frequently deliver the greatest environmental benefits, even when manufacturing impacts are slightly higher. This insight is driving the development of smart cooling solutions that adjust their performance based on actual thermal loads, optimizing the balance between cooling effectiveness and environmental impact.

Cooling fans integrated into SSR systems present additional environmental concerns through their consumption of electricity throughout the operational lifespan of the device. This ongoing energy requirement translates to increased carbon emissions, particularly in regions where power generation relies heavily on fossil fuels. Furthermore, the electronic components in cooling fans often contain rare earth elements and other materials whose extraction creates environmental degradation in mining regions.

The disposal phase of SSR cooling solutions presents another environmental challenge. Heat sinks, while theoretically recyclable, often end up in landfills due to the complexity of separating them from attached components. Cooling fans contribute to electronic waste streams, releasing potentially harmful substances if not properly processed. Thermal interface materials, especially those containing silicone or ceramic compounds, may persist in the environment for extended periods.

Recent innovations have begun addressing these environmental concerns through several approaches. Passive cooling designs that eliminate the need for powered fans reduce lifetime energy consumption. Bio-based thermal interface materials derived from renewable resources offer lower environmental impact alternatives to traditional petroleum-based compounds. Heat sink designs optimized through computational fluid dynamics allow for material reduction while maintaining thermal performance, decreasing the embodied energy and resource requirements.

The regulatory landscape is evolving to address these environmental considerations. The European Union's RoHS and WEEE directives restrict hazardous substances in electronic components and mandate proper disposal procedures. Energy efficiency standards increasingly influence cooling solution designs, pushing manufacturers toward lower-power options. Carbon footprint certifications are becoming competitive differentiators in the industrial electronics market, incentivizing environmentally conscious design choices in SSR cooling systems.

Life cycle assessment studies indicate that the most significant environmental impact often occurs during the operational phase of SSR cooling systems. Therefore, designs that prioritize energy efficiency during operation frequently deliver the greatest environmental benefits, even when manufacturing impacts are slightly higher. This insight is driving the development of smart cooling solutions that adjust their performance based on actual thermal loads, optimizing the balance between cooling effectiveness and environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!