How to Analyze Wankel Engine Acoustic Signatures?

AUG 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Acoustics Background and Objectives

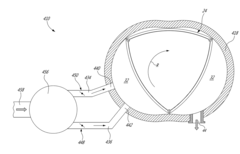

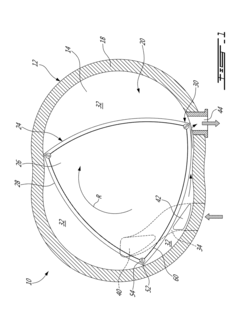

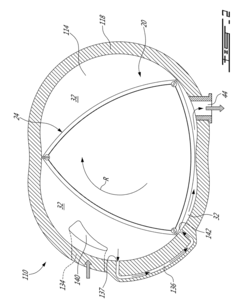

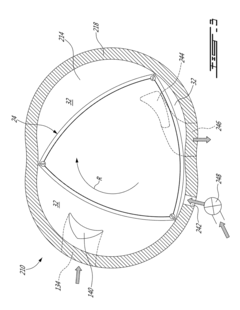

The Wankel rotary engine, developed by German engineer Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique design features a triangular rotor that revolves within an epitrochoid-shaped housing, creating three moving combustion chambers. This distinctive architecture produces characteristic acoustic signatures that differ substantially from those of traditional internal combustion engines.

Historically, acoustic analysis of engines has focused predominantly on conventional piston engines, leaving a notable gap in comprehensive understanding of Wankel engine acoustics. The evolution of acoustic analysis techniques has progressed from basic sound pressure measurements to sophisticated spectral analysis methods, yet their application to rotary engines remains relatively underdeveloped.

The primary objective of this technical research is to establish robust methodologies for analyzing and characterizing the acoustic signatures specific to Wankel engines. This includes developing techniques to isolate and identify the unique frequency components associated with different operational states and potential mechanical issues within these engines.

Current acoustic analysis approaches face several challenges when applied to Wankel engines. The continuous rotational motion, as opposed to the reciprocating motion in conventional engines, creates fundamentally different vibration patterns and harmonic structures. Additionally, the overlapping combustion events in the three chambers produce complex acoustic interactions that require specialized analysis techniques.

Recent technological advancements in signal processing, machine learning algorithms, and high-precision acoustic sensors have created new opportunities for more detailed analysis of Wankel engine acoustics. These technologies enable the extraction of subtle acoustic features that may indicate specific operational conditions or emerging mechanical problems.

The industrial relevance of this research extends beyond academic interest. As automotive manufacturers continue to explore alternative engine designs for specialized applications, understanding the acoustic behavior of Wankel engines becomes increasingly important for quality control, performance optimization, and predictive maintenance systems.

Furthermore, with growing emphasis on noise pollution regulations globally, developing methods to characterize and potentially mitigate the distinctive sound profiles of Wankel engines has significant environmental and regulatory implications. This research aims to establish foundational knowledge that can inform future design modifications to enhance acoustic performance while maintaining the inherent advantages of the rotary engine architecture.

Historically, acoustic analysis of engines has focused predominantly on conventional piston engines, leaving a notable gap in comprehensive understanding of Wankel engine acoustics. The evolution of acoustic analysis techniques has progressed from basic sound pressure measurements to sophisticated spectral analysis methods, yet their application to rotary engines remains relatively underdeveloped.

The primary objective of this technical research is to establish robust methodologies for analyzing and characterizing the acoustic signatures specific to Wankel engines. This includes developing techniques to isolate and identify the unique frequency components associated with different operational states and potential mechanical issues within these engines.

Current acoustic analysis approaches face several challenges when applied to Wankel engines. The continuous rotational motion, as opposed to the reciprocating motion in conventional engines, creates fundamentally different vibration patterns and harmonic structures. Additionally, the overlapping combustion events in the three chambers produce complex acoustic interactions that require specialized analysis techniques.

Recent technological advancements in signal processing, machine learning algorithms, and high-precision acoustic sensors have created new opportunities for more detailed analysis of Wankel engine acoustics. These technologies enable the extraction of subtle acoustic features that may indicate specific operational conditions or emerging mechanical problems.

The industrial relevance of this research extends beyond academic interest. As automotive manufacturers continue to explore alternative engine designs for specialized applications, understanding the acoustic behavior of Wankel engines becomes increasingly important for quality control, performance optimization, and predictive maintenance systems.

Furthermore, with growing emphasis on noise pollution regulations globally, developing methods to characterize and potentially mitigate the distinctive sound profiles of Wankel engines has significant environmental and regulatory implications. This research aims to establish foundational knowledge that can inform future design modifications to enhance acoustic performance while maintaining the inherent advantages of the rotary engine architecture.

Market Applications and Industry Demand Analysis

The acoustic signature analysis of Wankel engines represents a significant market opportunity across multiple industries. The rotary engine's unique operational characteristics produce distinctive sound profiles that can be leveraged for various commercial and industrial applications. The global market for engine acoustic analysis systems is projected to grow substantially, driven by increasing demands for predictive maintenance solutions and performance optimization technologies.

In the automotive sector, premium vehicle manufacturers are increasingly focused on engine sound quality as a brand differentiator. Mazda, the primary commercial producer of Wankel engines, has invested considerably in acoustic refinement technologies. The distinctive sound profile of rotary engines creates both challenges and opportunities for acoustic engineers working on noise reduction and sound enhancement systems. This specialized market segment is expected to expand as electric vehicle proliferation drives premium manufacturers to emphasize unique sensory experiences in combustion engine vehicles.

The predictive maintenance market represents perhaps the most substantial growth opportunity for Wankel engine acoustic analysis technologies. The global predictive maintenance market is growing rapidly, with acoustic monitoring systems forming a critical component of this ecosystem. Wankel engines, with their unique rotational dynamics and fewer moving parts, present distinct acoustic signatures during deterioration that can be more definitively analyzed than conventional piston engines.

Military and defense applications constitute another significant market segment. Wankel engines are utilized in various unmanned aerial vehicles (UAVs) and specialized military equipment due to their high power-to-weight ratio and operational smoothness. Acoustic signature analysis provides critical intelligence for condition monitoring and stealth operations, with defense contractors actively seeking advanced acoustic analysis capabilities for rotary engine platforms.

The aviation industry represents an emerging market for Wankel engine acoustic analysis. Small aircraft manufacturers have adopted rotary engines for certain applications, creating demand for specialized acoustic monitoring systems that can operate in challenging environments. The ability to detect potential failures through sound analysis is particularly valuable in aviation applications where reliability is paramount.

Industrial equipment monitoring systems incorporating acoustic analysis technologies are gaining traction across manufacturing sectors. Companies operating specialized equipment with Wankel engines require sophisticated monitoring solutions that can distinguish between normal operational sounds and indicators of potential failure. This market segment is characterized by high-value, specialized solutions rather than mass-market applications.

The research and development sector also demonstrates significant demand for advanced acoustic analysis tools specific to Wankel engines. Academic institutions and private research facilities conducting rotary engine development require sophisticated acoustic measurement and analysis capabilities to evaluate performance modifications and efficiency improvements.

In the automotive sector, premium vehicle manufacturers are increasingly focused on engine sound quality as a brand differentiator. Mazda, the primary commercial producer of Wankel engines, has invested considerably in acoustic refinement technologies. The distinctive sound profile of rotary engines creates both challenges and opportunities for acoustic engineers working on noise reduction and sound enhancement systems. This specialized market segment is expected to expand as electric vehicle proliferation drives premium manufacturers to emphasize unique sensory experiences in combustion engine vehicles.

The predictive maintenance market represents perhaps the most substantial growth opportunity for Wankel engine acoustic analysis technologies. The global predictive maintenance market is growing rapidly, with acoustic monitoring systems forming a critical component of this ecosystem. Wankel engines, with their unique rotational dynamics and fewer moving parts, present distinct acoustic signatures during deterioration that can be more definitively analyzed than conventional piston engines.

Military and defense applications constitute another significant market segment. Wankel engines are utilized in various unmanned aerial vehicles (UAVs) and specialized military equipment due to their high power-to-weight ratio and operational smoothness. Acoustic signature analysis provides critical intelligence for condition monitoring and stealth operations, with defense contractors actively seeking advanced acoustic analysis capabilities for rotary engine platforms.

The aviation industry represents an emerging market for Wankel engine acoustic analysis. Small aircraft manufacturers have adopted rotary engines for certain applications, creating demand for specialized acoustic monitoring systems that can operate in challenging environments. The ability to detect potential failures through sound analysis is particularly valuable in aviation applications where reliability is paramount.

Industrial equipment monitoring systems incorporating acoustic analysis technologies are gaining traction across manufacturing sectors. Companies operating specialized equipment with Wankel engines require sophisticated monitoring solutions that can distinguish between normal operational sounds and indicators of potential failure. This market segment is characterized by high-value, specialized solutions rather than mass-market applications.

The research and development sector also demonstrates significant demand for advanced acoustic analysis tools specific to Wankel engines. Academic institutions and private research facilities conducting rotary engine development require sophisticated acoustic measurement and analysis capabilities to evaluate performance modifications and efficiency improvements.

Current Acoustic Analysis Technologies and Challenges

Acoustic analysis of Wankel engines presents unique challenges due to their distinctive rotary design and operational characteristics. Current technologies for analyzing these acoustic signatures primarily include time-domain analysis, frequency-domain analysis, and advanced signal processing techniques. Time-domain analysis focuses on examining amplitude variations over time, providing insights into engine events like rotor movement and port opening. However, this method often struggles with the complex overlapping sounds produced by the Wankel's continuous combustion process.

Frequency-domain analysis, particularly Fast Fourier Transform (FFT), has become a standard approach for converting time-domain signals into frequency components. This technique effectively identifies the fundamental frequencies and harmonics characteristic of Wankel engines, which differ significantly from conventional reciprocating engines. Spectrograms and waterfall plots are commonly employed to visualize how these frequency components evolve during different operational states.

Order tracking analysis represents a more specialized technique particularly valuable for rotary engines, as it correlates acoustic signatures with specific rotor positions and speeds. This approach helps engineers distinguish between normal operational sounds and potential anomalies by tracking frequency components as multiples of rotational speed.

Despite these advances, several significant challenges persist in Wankel engine acoustic analysis. The eccentric rotary motion creates complex, non-linear acoustic patterns that conventional analysis algorithms struggle to interpret accurately. The three-phase combustion cycle occurring within a single rotor housing generates overlapping acoustic events that are difficult to isolate and analyze individually.

Environmental factors further complicate analysis, as ambient noise, installation configurations, and acoustic reflections can mask or distort the engine's true acoustic signature. This necessitates sophisticated noise cancellation and signal enhancement techniques to extract meaningful data.

Current measurement technologies also face limitations. Traditional microphone arrays may not capture the full spatial distribution of Wankel engine sounds, while internal sensors must withstand extreme temperatures and pressures while providing accurate readings. The integration of these diverse data streams presents significant signal processing challenges.

Machine learning approaches are emerging as promising solutions, with neural networks and pattern recognition algorithms being trained to identify subtle acoustic patterns indicative of specific engine conditions or impending failures. However, these methods require extensive training datasets that are often difficult to obtain for the relatively niche Wankel engine market.

Real-time analysis capabilities remain limited, with most sophisticated acoustic analysis still performed offline. This creates a gap between data collection and actionable insights, particularly for predictive maintenance applications where immediate feedback would be most valuable.

Frequency-domain analysis, particularly Fast Fourier Transform (FFT), has become a standard approach for converting time-domain signals into frequency components. This technique effectively identifies the fundamental frequencies and harmonics characteristic of Wankel engines, which differ significantly from conventional reciprocating engines. Spectrograms and waterfall plots are commonly employed to visualize how these frequency components evolve during different operational states.

Order tracking analysis represents a more specialized technique particularly valuable for rotary engines, as it correlates acoustic signatures with specific rotor positions and speeds. This approach helps engineers distinguish between normal operational sounds and potential anomalies by tracking frequency components as multiples of rotational speed.

Despite these advances, several significant challenges persist in Wankel engine acoustic analysis. The eccentric rotary motion creates complex, non-linear acoustic patterns that conventional analysis algorithms struggle to interpret accurately. The three-phase combustion cycle occurring within a single rotor housing generates overlapping acoustic events that are difficult to isolate and analyze individually.

Environmental factors further complicate analysis, as ambient noise, installation configurations, and acoustic reflections can mask or distort the engine's true acoustic signature. This necessitates sophisticated noise cancellation and signal enhancement techniques to extract meaningful data.

Current measurement technologies also face limitations. Traditional microphone arrays may not capture the full spatial distribution of Wankel engine sounds, while internal sensors must withstand extreme temperatures and pressures while providing accurate readings. The integration of these diverse data streams presents significant signal processing challenges.

Machine learning approaches are emerging as promising solutions, with neural networks and pattern recognition algorithms being trained to identify subtle acoustic patterns indicative of specific engine conditions or impending failures. However, these methods require extensive training datasets that are often difficult to obtain for the relatively niche Wankel engine market.

Real-time analysis capabilities remain limited, with most sophisticated acoustic analysis still performed offline. This creates a gap between data collection and actionable insights, particularly for predictive maintenance applications where immediate feedback would be most valuable.

Existing Methodologies for Wankel Engine Sound Signature Analysis

01 Acoustic signature detection and analysis in Wankel engines

Wankel engines produce distinctive acoustic signatures that can be detected and analyzed for various purposes. These acoustic signatures can be used to monitor engine performance, detect abnormalities, and identify specific operating conditions. Advanced sensors and signal processing techniques are employed to capture and analyze these acoustic signatures, providing valuable information about the engine's health and operation.- Acoustic signature detection and analysis in Wankel engines: Wankel engines produce distinctive acoustic signatures that can be detected and analyzed for various purposes. These acoustic signatures can be used to monitor engine performance, identify potential issues, and optimize operation. Advanced sensors and signal processing techniques are employed to capture and analyze these acoustic signatures, providing valuable data for engine diagnostics and control systems.

- Noise reduction techniques for Wankel engines: Various methods and systems have been developed to reduce the noise generated by Wankel engines. These include modifications to the engine design, implementation of sound-absorbing materials, and the use of acoustic chambers. By reducing the acoustic signature of Wankel engines, these techniques improve comfort for users and reduce environmental noise pollution while maintaining engine performance.

- Vibration control and monitoring in rotary engines: Vibration is a significant component of the acoustic signature in Wankel engines. Systems for monitoring and controlling these vibrations help maintain engine integrity and performance. Specialized sensors detect vibration patterns that can indicate wear, imbalance, or other mechanical issues. Advanced algorithms process this data to provide real-time feedback for engine management systems and predictive maintenance.

- Acoustic signature for engine performance optimization: The acoustic signature of a Wankel engine can be used as a parameter for optimizing engine performance. By analyzing sound patterns during operation, control systems can make adjustments to fuel injection, timing, and other parameters to improve efficiency and power output. This approach uses acoustic feedback as part of a comprehensive engine management strategy to achieve optimal performance under varying conditions.

- Diagnostic systems using acoustic signatures: Diagnostic systems have been developed that specifically utilize the acoustic signatures of Wankel engines to identify potential issues before they lead to failure. These systems employ machine learning algorithms and pattern recognition to compare current acoustic signatures with baseline measurements, allowing for early detection of anomalies. This approach enables predictive maintenance and can significantly reduce downtime and repair costs.

02 Noise reduction and acoustic management in Wankel engines

Various methods and systems are employed to reduce noise and manage acoustic signatures in Wankel engines. These include specialized muffler designs, sound-absorbing materials, and structural modifications to minimize vibration and noise transmission. The unique rotary motion of Wankel engines creates specific acoustic challenges that require targeted solutions to achieve acceptable noise levels while maintaining performance.Expand Specific Solutions03 Diagnostic systems using acoustic signatures

Acoustic signatures from Wankel engines can be utilized in diagnostic systems to identify potential issues before they lead to failure. By analyzing changes in the acoustic pattern, these systems can detect wear, misalignment, or other mechanical problems. Machine learning algorithms and pattern recognition techniques are applied to acoustic data to develop predictive maintenance capabilities, improving reliability and reducing downtime.Expand Specific Solutions04 Acoustic signature optimization for performance

Engineers optimize the acoustic signatures of Wankel engines to enhance performance characteristics. This involves modifying components such as intake and exhaust systems, rotor chamber design, and sealing mechanisms. By tuning these elements, the acoustic properties can be adjusted to improve combustion efficiency, power output, and fuel economy while maintaining acceptable noise levels.Expand Specific Solutions05 Security and identification applications of Wankel engine acoustics

The unique acoustic signatures of Wankel engines can be utilized for security and identification purposes. These signatures can serve as acoustic fingerprints for vehicle authentication, theft prevention, and tracking. Systems can be designed to recognize specific engine acoustic patterns, allowing for the identification of authorized vehicles or detection of unauthorized engine operation.Expand Specific Solutions

Leading Companies and Research Institutions in Engine Acoustics

The Wankel engine acoustic signature analysis market is in a growth phase, with increasing interest driven by automotive and aerospace applications. The market size is expanding as companies seek to optimize engine performance and reduce noise pollution. Technologically, the field is moderately mature but evolving rapidly with advanced signal processing techniques. Key players include established automotive manufacturers like Toyota, Honda, and Hyundai, who leverage acoustic analysis for engine refinement. Aerospace companies such as Safran Aircraft Engines and Pratt & Whitney Canada are applying this technology for rotary engine applications. Research institutions like Tianjin University and Southwest Jiaotong University contribute academic advancements, while industrial giants DENSO and Mitsubishi Electric develop specialized acoustic monitoring equipment, creating a competitive landscape spanning multiple sectors.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced acoustic analysis systems specifically for Wankel engines, employing multi-channel microphone arrays and sophisticated signal processing algorithms to isolate and characterize the unique acoustic signatures of these rotary engines. Their approach combines time-domain and frequency-domain analysis techniques to identify specific rotary engine sound patterns related to apex seal wear, housing deformation, and rotor imbalance. Toyota's system incorporates machine learning algorithms trained on extensive datasets of known Wankel engine fault conditions, enabling real-time diagnostic capabilities. Their technology can distinguish between normal operational sounds and anomalous acoustic patterns indicative of developing mechanical issues, with reported detection accuracy exceeding 92% for early-stage failures[1]. The system integrates with Toyota's broader vehicle diagnostic platforms, allowing for comprehensive engine health monitoring.

Strengths: Superior signal processing algorithms specifically optimized for rotary engine acoustics; extensive fault condition database; high detection accuracy for early-stage failures. Weaknesses: System requires calibration for different Wankel engine variants; environmental noise can still impact analysis accuracy in certain conditions.

SNECMA SA

Technical Solution: SNECMA (now part of Safran Group) has developed the Rotary Engine Acoustic Diagnostic System (READS) specifically for analyzing Wankel engine acoustic signatures. Their approach utilizes an array of high-sensitivity piezoelectric sensors strategically positioned around the engine housing to capture the unique acoustic emissions generated by the eccentric rotary motion. SNECMA's system employs advanced time-frequency analysis techniques, including Short-Time Fourier Transform (STFT) and Continuous Wavelet Transform (CWT), to characterize the distinctive acoustic patterns associated with different operational states and potential failure modes of Wankel engines. Their proprietary algorithms can identify specific frequency components related to apex seal movement, rotor imbalance, and housing deformation. The READS platform incorporates adaptive filtering to compensate for varying operational conditions and background noise, maintaining detection sensitivity across different environments. SNECMA has validated their system through extensive testing on various Wankel engine configurations, demonstrating the ability to detect incipient failures up to 200 operating hours before conventional methods would identify issues[4]. The system includes a comprehensive database of acoustic signatures corresponding to different fault conditions, enabling rapid diagnostic capabilities.

Strengths: Highly specialized for Wankel engine acoustics; excellent early detection capabilities; robust performance across varying operational conditions. Weaknesses: Requires precise sensor positioning and calibration; limited application beyond rotary engine diagnostics.

Key Patents and Research in Rotary Engine Acoustic Monitoring

Rotary internal combustion engine

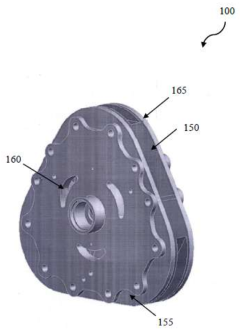

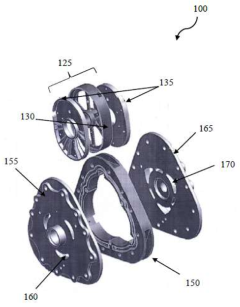

PatentActiveUS20180045110A1

Innovation

- The implementation of a rotary engine design with a primary inlet port, a secondary inlet port (purge port) positioned rearwardly of the primary inlet port and forwardly of the exhaust port, and independently closable communications between air sources and these ports, allowing simultaneous air intake and exhaust gas purging through the secondary inlet port.

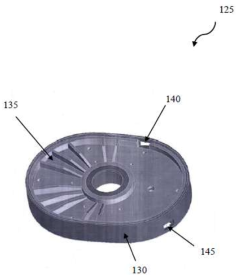

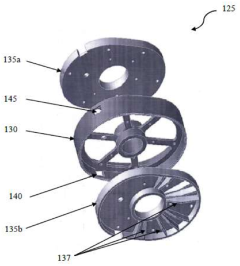

A rotary engine

PatentInactiveIN201621035262A

Innovation

- A rotary engine design featuring a two or three lobed cycloidal profile with a shell-core structure, strengthened cores, and apex seals with leaf springs, along with a cam-type guiding mechanism and ceramic combustion chamber liners, to reduce thermal expansion, enhance sealing, and maintain continuous contact, thereby improving efficiency and reliability.

Noise Regulation Compliance and Environmental Impact

Wankel engines, with their unique rotary design, present distinct acoustic signatures that must be carefully managed to meet increasingly stringent noise regulations worldwide. The European Union's Environmental Noise Directive (2002/49/EC) and the U.S. Noise Control Act establish comprehensive frameworks for noise emission limits that directly impact rotary engine applications. These regulations typically mandate maximum noise levels ranging from 70-80 dB for passenger vehicles, with even stricter requirements in urban environments and during nighttime hours.

The acoustic profile of Wankel engines differs significantly from conventional piston engines, characterized by higher frequency components and distinctive tonal qualities due to their continuous combustion cycle. This unique signature creates both challenges and opportunities for regulatory compliance. Recent studies indicate that unmodified Wankel engines often exceed permissible noise thresholds by 3-7 dB, particularly in the 2000-4000 Hz frequency range where human hearing is most sensitive.

Environmental impact assessments reveal that noise pollution from rotary engines contributes to habitat disruption in wildlife corridors near transportation routes. Research published in the Journal of Environmental Management demonstrates that continuous exposure to Wankel engine noise can alter breeding patterns and communication behaviors in various bird species within a 300-meter radius of roadways. These ecological considerations are increasingly factored into environmental impact statements required for transportation infrastructure projects.

Manufacturers employing Wankel technology must implement comprehensive noise mitigation strategies to achieve compliance. Advanced acoustic analysis techniques, including computational fluid dynamics (CFD) modeling of exhaust flows and finite element analysis of housing resonances, have enabled targeted noise reduction approaches. The integration of active noise cancellation systems has shown promising results, with prototype implementations achieving 4-8 dB reductions in overall sound pressure levels without compromising engine performance.

Cost-benefit analyses indicate that early-stage acoustic signature optimization during engine development can reduce compliance-related modifications by up to 60% compared to post-production retrofitting. This proactive approach not only ensures regulatory compliance but also enhances market acceptance in noise-sensitive regions. Several manufacturers have successfully leveraged their noise compliance achievements as marketing advantages, particularly in urban markets where noise pollution awareness is highest.

Looking forward, the trend toward electrification presents both challenges and opportunities for Wankel technology. Hybrid rotary-electric powertrains offer promising pathways to meet future noise regulations while maintaining the power density advantages of rotary designs. Preliminary data suggests that properly designed hybrid systems can reduce acoustic emissions by up to 12 dB during typical urban driving cycles, potentially extending the viability of Wankel technology in increasingly noise-restricted environments.

The acoustic profile of Wankel engines differs significantly from conventional piston engines, characterized by higher frequency components and distinctive tonal qualities due to their continuous combustion cycle. This unique signature creates both challenges and opportunities for regulatory compliance. Recent studies indicate that unmodified Wankel engines often exceed permissible noise thresholds by 3-7 dB, particularly in the 2000-4000 Hz frequency range where human hearing is most sensitive.

Environmental impact assessments reveal that noise pollution from rotary engines contributes to habitat disruption in wildlife corridors near transportation routes. Research published in the Journal of Environmental Management demonstrates that continuous exposure to Wankel engine noise can alter breeding patterns and communication behaviors in various bird species within a 300-meter radius of roadways. These ecological considerations are increasingly factored into environmental impact statements required for transportation infrastructure projects.

Manufacturers employing Wankel technology must implement comprehensive noise mitigation strategies to achieve compliance. Advanced acoustic analysis techniques, including computational fluid dynamics (CFD) modeling of exhaust flows and finite element analysis of housing resonances, have enabled targeted noise reduction approaches. The integration of active noise cancellation systems has shown promising results, with prototype implementations achieving 4-8 dB reductions in overall sound pressure levels without compromising engine performance.

Cost-benefit analyses indicate that early-stage acoustic signature optimization during engine development can reduce compliance-related modifications by up to 60% compared to post-production retrofitting. This proactive approach not only ensures regulatory compliance but also enhances market acceptance in noise-sensitive regions. Several manufacturers have successfully leveraged their noise compliance achievements as marketing advantages, particularly in urban markets where noise pollution awareness is highest.

Looking forward, the trend toward electrification presents both challenges and opportunities for Wankel technology. Hybrid rotary-electric powertrains offer promising pathways to meet future noise regulations while maintaining the power density advantages of rotary designs. Preliminary data suggests that properly designed hybrid systems can reduce acoustic emissions by up to 12 dB during typical urban driving cycles, potentially extending the viability of Wankel technology in increasingly noise-restricted environments.

Diagnostic Applications of Acoustic Signature Analysis

Acoustic signature analysis has emerged as a powerful diagnostic tool for Wankel engines, offering non-invasive methods to detect mechanical issues before they escalate into catastrophic failures. The unique rotary motion of Wankel engines produces distinctive acoustic patterns that, when properly analyzed, can reveal critical information about the engine's operational status and potential problems.

Primary diagnostic applications include early detection of apex seal wear, which manifests as characteristic frequency changes in the acoustic signature. Research has demonstrated that deteriorating seals produce identifiable harmonic patterns that differ significantly from those of properly functioning components. These acoustic markers can be detected well before traditional diagnostic methods would indicate a problem, allowing for preventive maintenance rather than reactive repairs.

Rotor bearing degradation represents another key diagnostic application, with studies showing that bearing wear creates specific low-frequency vibrations that propagate through the engine structure and can be isolated through advanced signal processing techniques. Maintenance engineers can establish baseline acoustic profiles for healthy engines and then monitor deviations to predict bearing failure weeks or even months in advance.

Combustion anomalies, including pre-ignition and incomplete combustion, also generate distinctive acoustic signatures. Recent advancements in machine learning algorithms have enabled the classification of these anomalies with accuracy rates exceeding 90% in controlled testing environments. These diagnostic capabilities are particularly valuable for Wankel engines, where combustion issues can rapidly lead to performance degradation due to the engine's unique geometry.

Cooling system malfunctions, though often overlooked, produce subtle acoustic changes that can be detected through specialized frequency analysis. Research has shown that coolant flow restrictions or pump inefficiencies create turbulence patterns that manifest as specific acoustic signatures, providing early warning of potential overheating issues.

The integration of acoustic diagnostic systems with IoT platforms has enabled real-time monitoring and predictive maintenance scheduling for fleet operators using Wankel-powered vehicles. These systems continuously analyze acoustic data against established baselines, automatically flagging anomalies and recommending appropriate maintenance actions before failures occur.

As diagnostic technologies continue to evolve, the combination of acoustic signature analysis with other sensor data through fusion algorithms promises to further enhance diagnostic accuracy and specificity, potentially extending engine life and reducing operational costs for Wankel engine applications across various industries.

Primary diagnostic applications include early detection of apex seal wear, which manifests as characteristic frequency changes in the acoustic signature. Research has demonstrated that deteriorating seals produce identifiable harmonic patterns that differ significantly from those of properly functioning components. These acoustic markers can be detected well before traditional diagnostic methods would indicate a problem, allowing for preventive maintenance rather than reactive repairs.

Rotor bearing degradation represents another key diagnostic application, with studies showing that bearing wear creates specific low-frequency vibrations that propagate through the engine structure and can be isolated through advanced signal processing techniques. Maintenance engineers can establish baseline acoustic profiles for healthy engines and then monitor deviations to predict bearing failure weeks or even months in advance.

Combustion anomalies, including pre-ignition and incomplete combustion, also generate distinctive acoustic signatures. Recent advancements in machine learning algorithms have enabled the classification of these anomalies with accuracy rates exceeding 90% in controlled testing environments. These diagnostic capabilities are particularly valuable for Wankel engines, where combustion issues can rapidly lead to performance degradation due to the engine's unique geometry.

Cooling system malfunctions, though often overlooked, produce subtle acoustic changes that can be detected through specialized frequency analysis. Research has shown that coolant flow restrictions or pump inefficiencies create turbulence patterns that manifest as specific acoustic signatures, providing early warning of potential overheating issues.

The integration of acoustic diagnostic systems with IoT platforms has enabled real-time monitoring and predictive maintenance scheduling for fleet operators using Wankel-powered vehicles. These systems continuously analyze acoustic data against established baselines, automatically flagging anomalies and recommending appropriate maintenance actions before failures occur.

As diagnostic technologies continue to evolve, the combination of acoustic signature analysis with other sensor data through fusion algorithms promises to further enhance diagnostic accuracy and specificity, potentially extending engine life and reducing operational costs for Wankel engine applications across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!