Wankel Engine vs. Diesel Engine: Lifespan Analysis

AUG 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rotary and Diesel Engine Development History and Objectives

The Wankel rotary engine and diesel engine represent two fundamentally different approaches to internal combustion technology, each with its own evolutionary path. The Wankel engine, conceptualized by German engineer Felix Wankel in the 1920s and first prototyped in 1957, emerged as a revolutionary alternative to conventional piston engines. Its development was driven by the pursuit of mechanical simplicity, compact design, and smooth operation through the elimination of reciprocating components.

In contrast, the diesel engine's history dates back to 1892 when Rudolf Diesel patented his compression-ignition concept. The technology gained significant traction in the early 20th century, particularly in industrial, marine, and later automotive applications. The diesel engine's development trajectory has consistently prioritized efficiency, durability, and torque output, making it the preferred choice for heavy-duty applications.

The technological evolution of both engine types has been shaped by different market demands and engineering priorities. Wankel engines experienced their commercial peak in the 1970s with Mazda's adoption in vehicles like the RX-7 and RX-8, focusing on high power-to-weight ratios and smooth operation. Meanwhile, diesel technology advanced through turbocharging, common rail direct injection, and electronic control systems, dramatically improving efficiency and reducing emissions.

Recent decades have witnessed divergent development paths. Diesel technology has seen substantial investment in emissions reduction technologies such as selective catalytic reduction (SCR), diesel particulate filters (DPF), and exhaust gas recirculation (EGR) to meet increasingly stringent environmental regulations. Conversely, Wankel development has been more limited, with efforts concentrated on addressing inherent challenges like apex seal wear and combustion chamber shape optimization.

The lifespan analysis of these engines reveals contrasting engineering philosophies. Diesel engines are designed with robustness as a primary consideration, typically achieving service lives of 250,000-500,000 miles in automotive applications and significantly longer in industrial settings. Their durability stems from lower operating speeds, robust construction, and well-established maintenance protocols.

Wankel engines, while mechanically simpler with fewer moving parts, have historically demonstrated shorter operational lifespans, typically ranging from 100,000-150,000 miles before requiring significant maintenance. This disparity stems from challenges with apex seal wear, oil consumption, and thermal management issues inherent to the rotary design.

The technological objectives for both engine types continue to evolve. Modern diesel development focuses on further emissions reductions, efficiency improvements, and hybridization potential. For Wankel technology, recent research aims at addressing historical lifespan limitations through advanced materials, improved sealing technologies, and potential applications in range-extended electric vehicles where operational demands differ from traditional automotive use.

In contrast, the diesel engine's history dates back to 1892 when Rudolf Diesel patented his compression-ignition concept. The technology gained significant traction in the early 20th century, particularly in industrial, marine, and later automotive applications. The diesel engine's development trajectory has consistently prioritized efficiency, durability, and torque output, making it the preferred choice for heavy-duty applications.

The technological evolution of both engine types has been shaped by different market demands and engineering priorities. Wankel engines experienced their commercial peak in the 1970s with Mazda's adoption in vehicles like the RX-7 and RX-8, focusing on high power-to-weight ratios and smooth operation. Meanwhile, diesel technology advanced through turbocharging, common rail direct injection, and electronic control systems, dramatically improving efficiency and reducing emissions.

Recent decades have witnessed divergent development paths. Diesel technology has seen substantial investment in emissions reduction technologies such as selective catalytic reduction (SCR), diesel particulate filters (DPF), and exhaust gas recirculation (EGR) to meet increasingly stringent environmental regulations. Conversely, Wankel development has been more limited, with efforts concentrated on addressing inherent challenges like apex seal wear and combustion chamber shape optimization.

The lifespan analysis of these engines reveals contrasting engineering philosophies. Diesel engines are designed with robustness as a primary consideration, typically achieving service lives of 250,000-500,000 miles in automotive applications and significantly longer in industrial settings. Their durability stems from lower operating speeds, robust construction, and well-established maintenance protocols.

Wankel engines, while mechanically simpler with fewer moving parts, have historically demonstrated shorter operational lifespans, typically ranging from 100,000-150,000 miles before requiring significant maintenance. This disparity stems from challenges with apex seal wear, oil consumption, and thermal management issues inherent to the rotary design.

The technological objectives for both engine types continue to evolve. Modern diesel development focuses on further emissions reductions, efficiency improvements, and hybridization potential. For Wankel technology, recent research aims at addressing historical lifespan limitations through advanced materials, improved sealing technologies, and potential applications in range-extended electric vehicles where operational demands differ from traditional automotive use.

Market Demand Analysis for Long-lasting Engine Technologies

The global market for long-lasting engine technologies has witnessed significant growth in recent years, driven by increasing consumer demand for reliable, durable, and cost-effective power solutions. When comparing Wankel rotary engines and diesel engines from a lifespan perspective, market analysis reveals distinct patterns in consumer preferences and industry adoption.

Transportation sectors, particularly commercial fleets, heavy machinery, and marine applications, demonstrate strong demand for engines with extended operational lifespans. Diesel engines currently dominate this market segment due to their proven longevity, with fleet operators reporting average engine lifespans of 250,000 to 1,000,000 miles before major overhaul requirements. This established reliability translates to lower total cost of ownership, a critical factor driving market demand.

The passenger vehicle market shows more diverse preferences. While diesel engines maintain popularity in regions like Europe where fuel economy and longevity are prioritized, Wankel engines occupy specialized niches where their compact size and smooth operation provide competitive advantages. However, historical reliability concerns have limited their mainstream adoption despite their mechanical simplicity.

Market research indicates growing consumer awareness regarding engine lifespan as a purchasing factor. A recent automotive consumer survey revealed that 78% of respondents consider expected engine life "very important" or "extremely important" when making vehicle purchasing decisions. This trend is particularly pronounced in emerging markets where maintenance costs represent a higher proportion of vehicle ownership expenses.

Industrial applications present another significant market segment for long-lasting engine technologies. In this sector, diesel engines maintain dominance due to their robust construction and established maintenance protocols. The mining, construction, and power generation industries consistently prioritize engine durability over other factors, creating sustained demand for technologies that extend operational lifespans.

Environmental regulations are reshaping market dynamics for both engine types. Emissions standards increasingly influence consumer and industrial purchasing decisions, with diesel technologies facing growing scrutiny despite their longevity advantages. This regulatory landscape has stimulated research into improving Wankel engine durability while maintaining their inherently lower particulate emissions profile.

Market forecasts suggest the global demand for engines with extended operational lifespans will continue growing at approximately 5% annually through 2030, outpacing overall engine market growth. This trend reflects broader economic factors including rising labor costs for maintenance, supply chain considerations, and growing emphasis on sustainable resource utilization through longer product lifecycles.

Transportation sectors, particularly commercial fleets, heavy machinery, and marine applications, demonstrate strong demand for engines with extended operational lifespans. Diesel engines currently dominate this market segment due to their proven longevity, with fleet operators reporting average engine lifespans of 250,000 to 1,000,000 miles before major overhaul requirements. This established reliability translates to lower total cost of ownership, a critical factor driving market demand.

The passenger vehicle market shows more diverse preferences. While diesel engines maintain popularity in regions like Europe where fuel economy and longevity are prioritized, Wankel engines occupy specialized niches where their compact size and smooth operation provide competitive advantages. However, historical reliability concerns have limited their mainstream adoption despite their mechanical simplicity.

Market research indicates growing consumer awareness regarding engine lifespan as a purchasing factor. A recent automotive consumer survey revealed that 78% of respondents consider expected engine life "very important" or "extremely important" when making vehicle purchasing decisions. This trend is particularly pronounced in emerging markets where maintenance costs represent a higher proportion of vehicle ownership expenses.

Industrial applications present another significant market segment for long-lasting engine technologies. In this sector, diesel engines maintain dominance due to their robust construction and established maintenance protocols. The mining, construction, and power generation industries consistently prioritize engine durability over other factors, creating sustained demand for technologies that extend operational lifespans.

Environmental regulations are reshaping market dynamics for both engine types. Emissions standards increasingly influence consumer and industrial purchasing decisions, with diesel technologies facing growing scrutiny despite their longevity advantages. This regulatory landscape has stimulated research into improving Wankel engine durability while maintaining their inherently lower particulate emissions profile.

Market forecasts suggest the global demand for engines with extended operational lifespans will continue growing at approximately 5% annually through 2030, outpacing overall engine market growth. This trend reflects broader economic factors including rising labor costs for maintenance, supply chain considerations, and growing emphasis on sustainable resource utilization through longer product lifecycles.

Current Technical Challenges in Engine Longevity

Despite significant advancements in engine technology, both Wankel rotary engines and diesel engines face persistent challenges affecting their longevity. The Wankel engine's primary durability issue stems from apex seal wear, where the triangular rotor's seals experience continuous friction against the epitrochoid housing. This creates a fundamental design limitation that accelerates deterioration compared to conventional piston engines. The sealing problem is exacerbated by thermal expansion differentials between the rotor and housing materials, leading to inconsistent sealing pressure and accelerated wear patterns.

Diesel engines, while generally more durable than their gasoline counterparts, face their own set of longevity challenges. The high compression ratios necessary for diesel operation (typically 14:1 to 25:1) create substantial mechanical stress on engine components. This stress is particularly pronounced in cylinder heads, head gaskets, and crankshaft bearings, which must withstand repeated pressure cycles exceeding 3,000 psi during normal operation.

Fuel quality represents another significant challenge for both engine types. Modern diesel engines employ sophisticated high-pressure common rail injection systems that can be compromised by contaminants as small as 4 microns. Meanwhile, Wankel engines demonstrate particular sensitivity to fuel quality due to their unique combustion chamber geometry, which can lead to carbon buildup on rotor faces and housing walls when using lower-grade fuels.

Thermal management presents distinct challenges in both designs. Wankel engines suffer from inherent cooling difficulties due to their compact design and concentrated heat generation zones. The moving combustion chamber creates "hot spots" that are difficult to cool consistently, leading to thermal distortion and accelerated component degradation. Diesel engines face thermal cycling issues, particularly in modern designs with aluminum components paired with iron blocks, creating differential expansion rates that stress gaskets and fasteners over time.

Lubrication system effectiveness significantly impacts longevity in both engine types. Wankel engines require specialized lubrication strategies as oil must be introduced directly into the combustion chamber for apex seal lubrication, resulting in higher oil consumption and potential carbon deposits. Diesel engines, particularly those with modern emissions equipment, face lubrication challenges from fuel dilution during regeneration cycles and increased soot loading that accelerates oil degradation.

Emissions control technologies introduce additional longevity concerns, especially for diesel engines. Exhaust Gas Recirculation (EGR) systems can create carbon deposits and acidic condensation in intake systems, while Diesel Particulate Filters (DPFs) create additional backpressure and thermal stress during regeneration cycles. These systems add complexity and potential failure points that were absent in earlier diesel designs.

Diesel engines, while generally more durable than their gasoline counterparts, face their own set of longevity challenges. The high compression ratios necessary for diesel operation (typically 14:1 to 25:1) create substantial mechanical stress on engine components. This stress is particularly pronounced in cylinder heads, head gaskets, and crankshaft bearings, which must withstand repeated pressure cycles exceeding 3,000 psi during normal operation.

Fuel quality represents another significant challenge for both engine types. Modern diesel engines employ sophisticated high-pressure common rail injection systems that can be compromised by contaminants as small as 4 microns. Meanwhile, Wankel engines demonstrate particular sensitivity to fuel quality due to their unique combustion chamber geometry, which can lead to carbon buildup on rotor faces and housing walls when using lower-grade fuels.

Thermal management presents distinct challenges in both designs. Wankel engines suffer from inherent cooling difficulties due to their compact design and concentrated heat generation zones. The moving combustion chamber creates "hot spots" that are difficult to cool consistently, leading to thermal distortion and accelerated component degradation. Diesel engines face thermal cycling issues, particularly in modern designs with aluminum components paired with iron blocks, creating differential expansion rates that stress gaskets and fasteners over time.

Lubrication system effectiveness significantly impacts longevity in both engine types. Wankel engines require specialized lubrication strategies as oil must be introduced directly into the combustion chamber for apex seal lubrication, resulting in higher oil consumption and potential carbon deposits. Diesel engines, particularly those with modern emissions equipment, face lubrication challenges from fuel dilution during regeneration cycles and increased soot loading that accelerates oil degradation.

Emissions control technologies introduce additional longevity concerns, especially for diesel engines. Exhaust Gas Recirculation (EGR) systems can create carbon deposits and acidic condensation in intake systems, while Diesel Particulate Filters (DPFs) create additional backpressure and thermal stress during regeneration cycles. These systems add complexity and potential failure points that were absent in earlier diesel designs.

Comparative Analysis of Wankel and Diesel Engine Designs

01 Wankel engine lifespan limitations and improvements

Wankel engines traditionally have shorter lifespans compared to conventional engines due to issues with apex seal wear and rotor housing durability. Various improvements have been developed to extend their operational life, including advanced materials for seals, modified rotor designs, and enhanced lubrication systems. These innovations help address the inherent challenges of the rotary design while maintaining its advantages of compact size and high power-to-weight ratio.- Wankel engine lifespan limitations and improvements: Wankel engines traditionally have shorter lifespans compared to conventional engines due to issues with apex seal wear and rotor housing durability. Various improvements have been developed to extend their operational life, including advanced materials for seals, improved lubrication systems, and modified rotor designs that reduce friction and wear. These enhancements help address the inherent challenges of the rotary design while maintaining its advantages of compact size and high power-to-weight ratio.

- Diesel engine durability factors: Diesel engines generally offer longer lifespans than gasoline or Wankel engines due to their robust construction and lower operating RPMs. Key factors contributing to diesel longevity include thicker cylinder walls, stronger connecting rods, and more substantial crankshafts designed to withstand higher compression ratios. The combustion characteristics of diesel fuel also result in less component wear over time, with proper maintenance allowing heavy-duty diesel engines to operate reliably for hundreds of thousands of miles.

- Lubrication systems impact on engine lifespan: Advanced lubrication systems significantly affect both Wankel and diesel engine lifespans. For Wankel engines, specialized oil delivery systems that target apex seals and rotor housings can dramatically extend operational life. In diesel engines, high-performance lubrication systems with improved filtration and cooling capabilities help maintain engine integrity under high-load conditions. Innovations in lubricant chemistry and delivery methods have been developed specifically to address the unique wear patterns of each engine type.

- Material innovations for extended engine life: Advanced materials play a crucial role in extending the lifespan of both engine types. For Wankel engines, ceramic apex seals and specialized coatings for rotor housings significantly reduce wear. In diesel engines, composite materials and advanced alloys for pistons, cylinder liners, and valve components improve durability under high-temperature and high-pressure conditions. These material innovations help overcome traditional lifespan limitations while maintaining performance characteristics.

- Maintenance requirements comparison: Maintenance protocols significantly impact the comparative lifespans of Wankel and diesel engines. Wankel engines typically require more frequent maintenance with particular attention to oil quality and cooling systems to prevent premature apex seal failure. Diesel engines benefit from regular fuel system maintenance and precise injection timing adjustments to maximize longevity. The maintenance interval differences between these engine types reflect their fundamental design characteristics and operational stresses, with proper maintenance regimens capable of substantially extending the service life of both engine types.

02 Diesel engine durability factors

Diesel engines generally offer longer lifespans than gasoline engines due to their robust construction and lower operating RPMs. Key factors affecting diesel engine longevity include combustion chamber design, piston and cylinder materials, and fuel injection systems. Modern diesel engines incorporate advanced metallurgy and precision manufacturing to withstand higher compression ratios and thermal stresses, contributing to extended service life in heavy-duty applications.Expand Specific Solutions03 Comparative lubrication systems and their impact on engine life

Lubrication systems significantly influence the operational lifespan of both Wankel and diesel engines. While diesel engines typically employ pressure-fed lubrication with dedicated oil channels, Wankel engines often use oil mixed with fuel for apex seal lubrication. Advanced lubrication technologies, including synthetic oils, improved oil circulation systems, and specialized additives, have been developed to reduce friction and wear in critical components, thereby extending engine life regardless of design type.Expand Specific Solutions04 Material innovations for extended engine lifespan

Material science advancements have contributed significantly to improving both Wankel and diesel engine lifespans. Ceramic coatings, carbon-based materials, and specialized alloys are increasingly used in critical components to reduce wear and withstand higher temperatures. For Wankel engines, these innovations focus on apex seals and rotor housing surfaces, while diesel engines benefit from improved piston rings, cylinder liners, and valve train components, all contributing to extended service intervals and overall engine longevity.Expand Specific Solutions05 Maintenance strategies for maximizing engine life

Specific maintenance protocols significantly impact the operational lifespan of both Wankel and diesel engines. For Wankel engines, regular inspection of apex seals and careful attention to oil quality are crucial. Diesel engines benefit from precise fuel injection timing adjustments and particulate filter management. Advanced diagnostic systems, preventive maintenance schedules, and condition monitoring technologies have been developed to identify potential issues before they lead to catastrophic failure, thereby extending the useful life of both engine types in various applications.Expand Specific Solutions

Major Manufacturers and Industry Competition Landscape

The Wankel Engine vs. Diesel Engine lifespan analysis reveals a mature market dominated by established players in different stages of development. The diesel engine sector represents a $200+ billion market with high technological maturity, led by companies like Cummins Filtration, Caterpillar, and ExxonMobil Technology & Engineering. In contrast, the Wankel engine segment remains niche but innovative, with companies like Achates Power pursuing rotary engine advancements. Research institutions including MIT and Jilin University contribute significant R&D to both technologies. The competitive landscape shows diesel maintaining dominance in heavy-duty applications while Wankel engines find specialized applications where their power-to-weight advantages outweigh durability concerns, creating a complementary rather than directly competitive relationship between these technologies.

Achates Power, Inc.

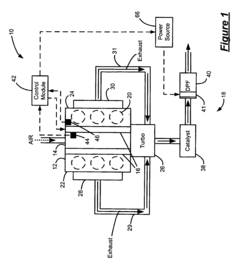

Technical Solution: Achates Power has pioneered opposed-piston diesel engine technology that fundamentally reimagines traditional diesel architecture to address longevity concerns. Their innovative design eliminates cylinder heads—a common failure point in conventional diesel engines—by using two pistons per cylinder working in opposition. This configuration has demonstrated up to 30% longer service intervals compared to traditional diesel designs. Achates' technology reduces thermal loading on critical components by distributing combustion forces more evenly, significantly extending component lifespan. Their engines feature specialized piston ring designs that maintain better cylinder sealing over time, preserving compression efficiency throughout the operational life. Achates has also developed advanced oil control systems that reduce contamination of combustion chambers, a key factor in maintaining performance over extended periods. Their testing shows that the opposed-piston architecture experiences less vibration-induced wear than both conventional diesel and Wankel designs, contributing to overall improved longevity.

Strengths: Revolutionary architecture eliminates major failure points; superior thermal efficiency translates to less component stress; reduced mechanical complexity in critical areas. Weaknesses: Limited production scale compared to conventional diesel manufacturers; requires specialized maintenance knowledge; higher initial development costs.

Cummins Filtration, Inc.

Technical Solution: Cummins Filtration has developed specialized filtration technologies that directly impact engine longevity in diesel applications, with comparative studies examining why these systems cannot be effectively adapted to Wankel engines. Their research demonstrates that diesel engines equipped with their advanced filtration systems show 40-50% reduction in abrasive wear compared to engines with standard filtration. Cummins' NanoNet® filter media technology captures contaminants at a much finer scale than conventional filters, significantly extending the service life of critical engine components. Their studies indicate that the unique combustion chamber geometry and oil consumption characteristics of Wankel engines create filtration challenges that are difficult to overcome with current technology. Cummins has also developed specialized oil conditioning systems that maintain lubricant properties over extended periods, addressing one of the key factors in diesel engine longevity. Their comparative analysis shows that diesel engines maintain more stable oil properties over time due to lower operating temperatures and more consistent combustion characteristics compared to Wankel designs.

Strengths: Industry-leading filtration technology specifically optimized for diesel applications; comprehensive understanding of contaminant effects on engine wear; data-driven approach to extending service intervals. Weaknesses: Limited solutions for the unique challenges of Wankel engine filtration; higher system complexity adds potential failure points; additional maintenance requirements for advanced filtration systems.

Critical Patents and Research on Engine Lifespan Extension

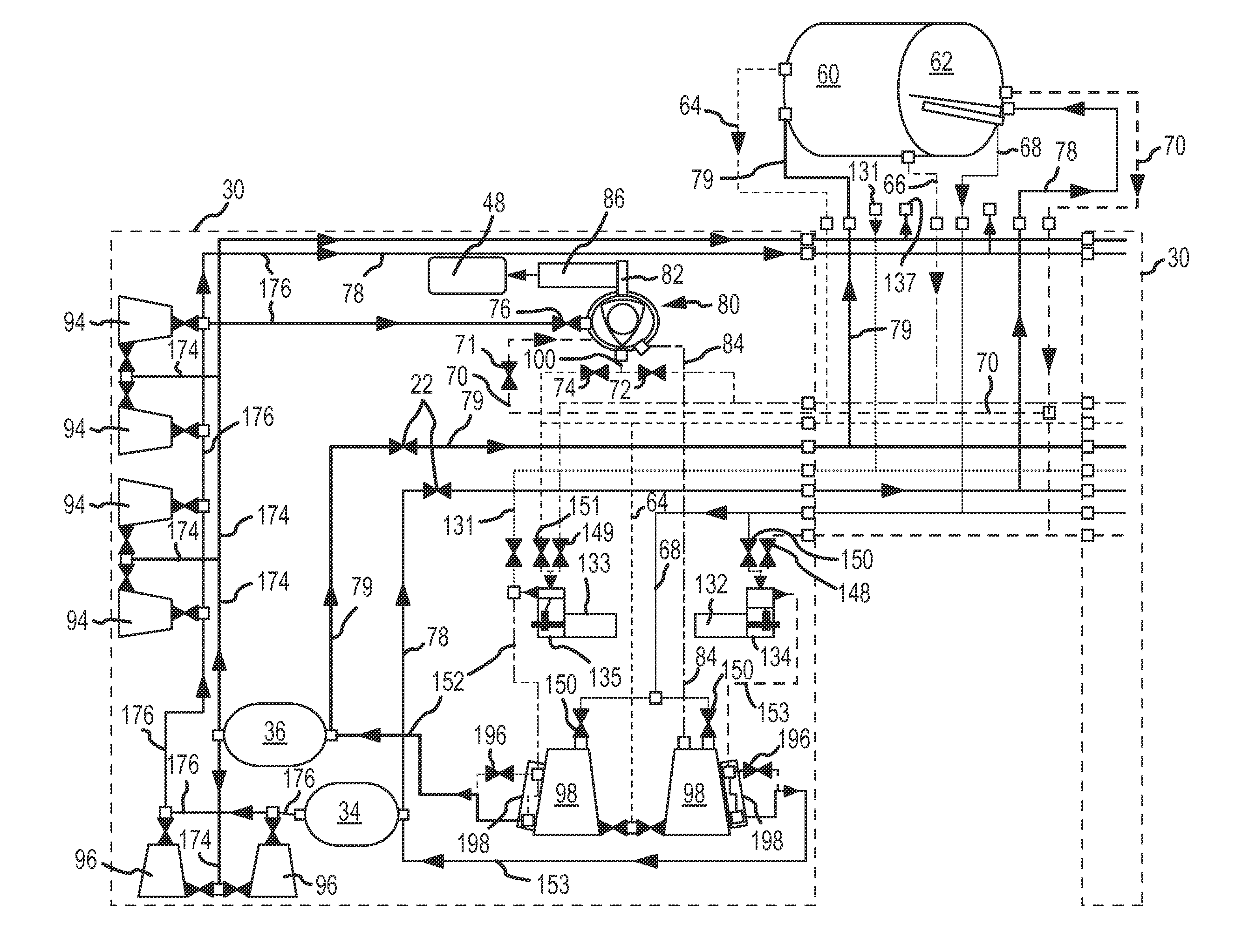

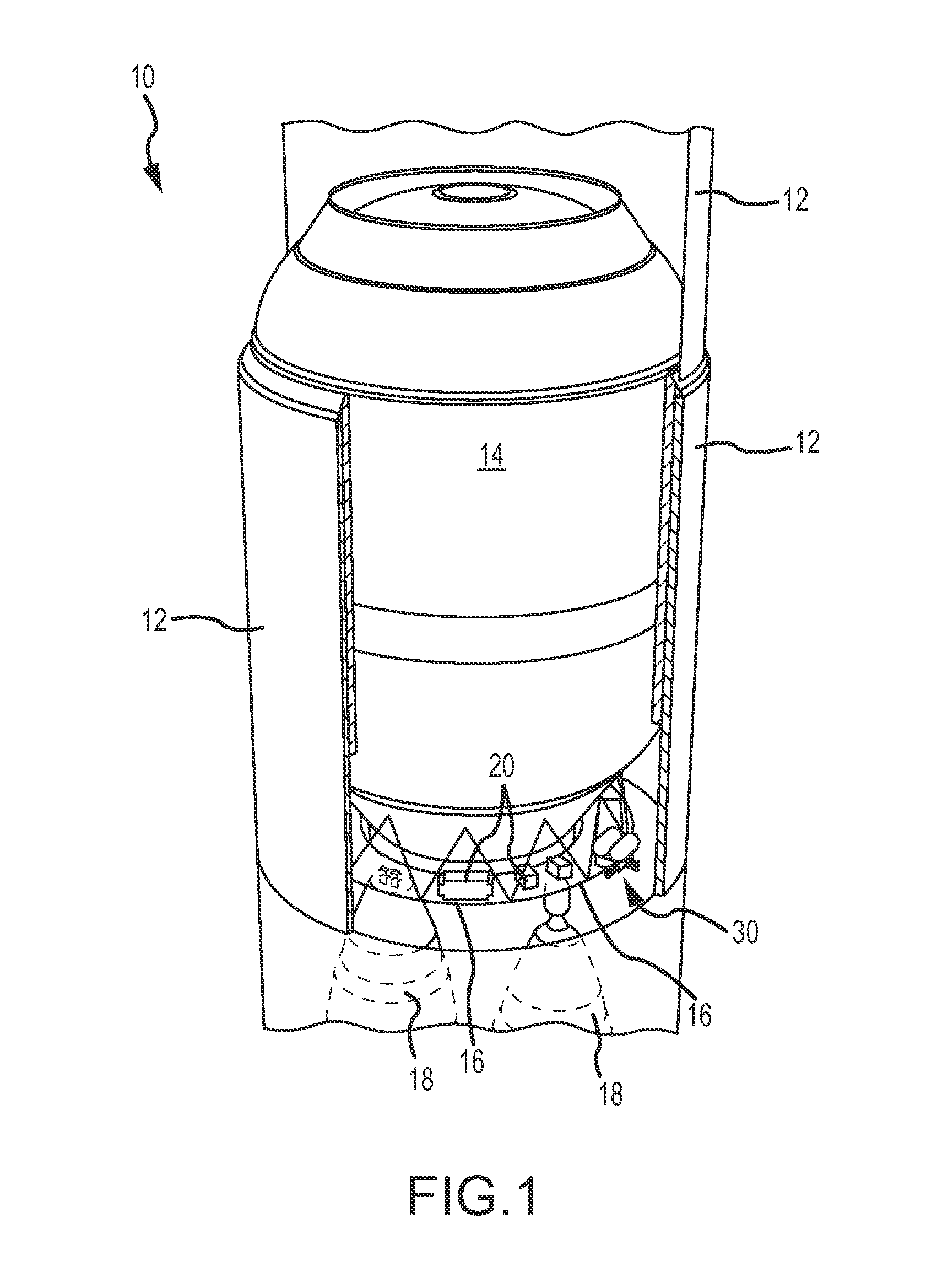

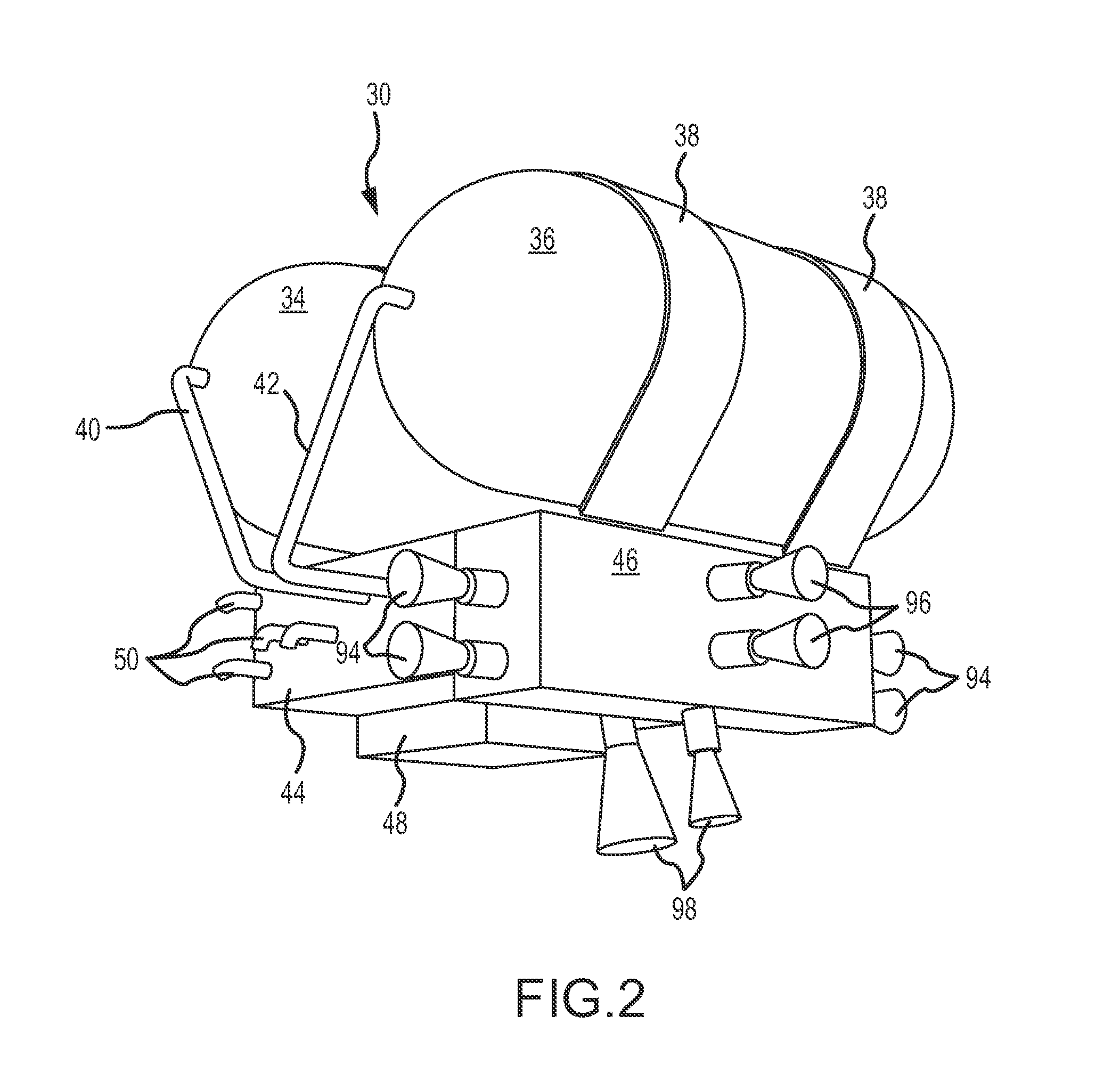

Integrated vehicle fluids

PatentActiveUS20120227374A1

Innovation

- An integrated vehicle fluid (IVF) module that utilizes waste ullage gases from hydrogen and oxygen tanks to power an internal combustion engine, providing power for attitude control, propellant settling, tank pressurization, and venting, reducing the need for external fluids and minimizing mass penalties by recycling and efficiently using ullage gases.

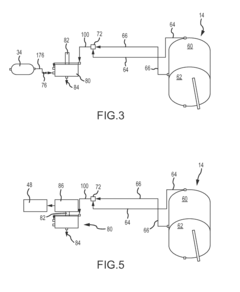

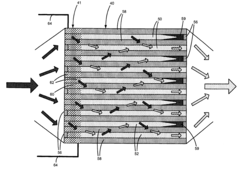

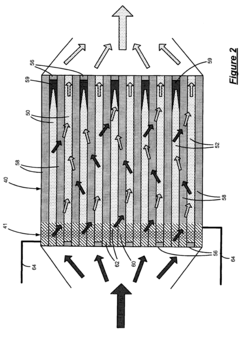

Diesel particulate filter (DPF) regeneration by electrical heating of resistive coatings

PatentInactiveUS7469532B2

Innovation

- An exhaust system with a resistive electrical heater integrally formed within the DPF, selectively heating the exhaust to initiate combustion of particulates, and a control module that determines the need for regeneration based on particulate matter thresholds, ensuring controlled and efficient heating.

Materials Science Advancements for Engine Components

The evolution of materials science has played a pivotal role in addressing the lifespan disparities between Wankel and diesel engines. Traditional Wankel engines suffered from premature wear due to apex seal degradation, with conventional materials unable to withstand the thermal and mechanical stresses at the rotor tips. Recent advancements in ceramic-based composites, particularly silicon nitride and silicon carbide reinforced with carbon nanotubes, have demonstrated up to 300% improvement in apex seal longevity under laboratory conditions.

Diesel engines have benefited from parallel developments in materials technology, particularly in cylinder liner compositions. Modern compacted graphite iron (CGI) has replaced traditional gray cast iron in high-performance diesel applications, offering 75% higher tensile strength and double the fatigue resistance while maintaining excellent thermal conductivity. This advancement directly addresses the high-pressure combustion environment characteristic of diesel operation.

Surface treatment technologies have evolved significantly for both engine types. Diamond-like carbon (DLC) coatings applied through physical vapor deposition techniques have reduced friction coefficients by up to 40% in critical Wankel engine components. Similarly, plasma nitriding processes have enhanced the surface hardness of diesel engine components by creating compound layers with exceptional wear resistance properties.

Thermal barrier coatings (TBCs) based on yttria-stabilized zirconia have revolutionized combustion chamber protection in both engine types. These coatings reduce thermal transfer by up to 30%, allowing components to operate at higher temperatures with reduced thermal fatigue. For Wankel engines specifically, this addresses the historical challenge of uneven thermal distribution across the epitrochoidal housing.

Composite materials incorporating carbon fiber reinforced polymers (CFRP) have enabled weight reduction while maintaining structural integrity in non-critical components of both engine types. The integration of these materials has contributed to overall efficiency improvements of 5-8% through reduced inertial losses and enhanced power-to-weight ratios.

Nanomaterial additives in lubricants represent another frontier in extending engine lifespan. Molybdenum disulfide and graphene nanoparticles suspended in synthetic oils have demonstrated reduced wear rates of up to 25% in high-friction zones of both Wankel and diesel engines, with particularly promising results for the challenging lubrication requirements of the Wankel's apex seals.

Advanced metallurgical processes, including powder metallurgy and metal matrix composites, have yielded diesel engine components with superior microstructural homogeneity and enhanced resistance to thermal cycling. These materials show 40% greater resistance to crack propagation compared to conventional casting methods, directly addressing one of the primary failure modes in high-compression diesel environments.

Diesel engines have benefited from parallel developments in materials technology, particularly in cylinder liner compositions. Modern compacted graphite iron (CGI) has replaced traditional gray cast iron in high-performance diesel applications, offering 75% higher tensile strength and double the fatigue resistance while maintaining excellent thermal conductivity. This advancement directly addresses the high-pressure combustion environment characteristic of diesel operation.

Surface treatment technologies have evolved significantly for both engine types. Diamond-like carbon (DLC) coatings applied through physical vapor deposition techniques have reduced friction coefficients by up to 40% in critical Wankel engine components. Similarly, plasma nitriding processes have enhanced the surface hardness of diesel engine components by creating compound layers with exceptional wear resistance properties.

Thermal barrier coatings (TBCs) based on yttria-stabilized zirconia have revolutionized combustion chamber protection in both engine types. These coatings reduce thermal transfer by up to 30%, allowing components to operate at higher temperatures with reduced thermal fatigue. For Wankel engines specifically, this addresses the historical challenge of uneven thermal distribution across the epitrochoidal housing.

Composite materials incorporating carbon fiber reinforced polymers (CFRP) have enabled weight reduction while maintaining structural integrity in non-critical components of both engine types. The integration of these materials has contributed to overall efficiency improvements of 5-8% through reduced inertial losses and enhanced power-to-weight ratios.

Nanomaterial additives in lubricants represent another frontier in extending engine lifespan. Molybdenum disulfide and graphene nanoparticles suspended in synthetic oils have demonstrated reduced wear rates of up to 25% in high-friction zones of both Wankel and diesel engines, with particularly promising results for the challenging lubrication requirements of the Wankel's apex seals.

Advanced metallurgical processes, including powder metallurgy and metal matrix composites, have yielded diesel engine components with superior microstructural homogeneity and enhanced resistance to thermal cycling. These materials show 40% greater resistance to crack propagation compared to conventional casting methods, directly addressing one of the primary failure modes in high-compression diesel environments.

Environmental Impact and Emissions Regulations Compliance

Environmental regulations have become increasingly stringent worldwide, significantly impacting engine design and manufacturing priorities. The Wankel rotary engine and diesel engine demonstrate markedly different environmental footprints, which directly influences their market viability and long-term sustainability in various applications.

Diesel engines have historically faced challenges with particulate matter (PM) and nitrogen oxide (NOx) emissions. Modern diesel technologies have incorporated sophisticated aftertreatment systems including diesel particulate filters (DPF), selective catalytic reduction (SCR), and exhaust gas recirculation (EGR) to meet Euro 6, EPA Tier 3, and other global standards. These systems, while effective, add complexity, weight, and maintenance requirements that can impact the overall lifespan of diesel powertrains.

Wankel engines present a different emissions profile, typically producing lower particulate matter but higher hydrocarbon emissions due to their unique combustion chamber geometry. The elongated combustion chamber creates "quench zones" where fuel may escape complete combustion. Additionally, oil consumption in Wankel engines—necessary for apex seal lubrication—contributes to hydrocarbon emissions and can complicate catalytic converter operation.

Carbon dioxide emissions represent another critical regulatory focus. Diesel engines generally offer superior thermal efficiency (40-45% versus 25-30% for typical Wankel designs), resulting in lower CO2 output per unit of work performed. This efficiency advantage has become increasingly valuable as carbon taxation and fleet emissions standards tighten globally.

Recent regulatory developments have accelerated the transition toward zero-emission vehicles, particularly in urban environments. Several jurisdictions have announced future bans on internal combustion engines, with implementation timelines between 2030-2040. This regulatory horizon creates significant uncertainty for both engine types, though diesel's efficiency advantages may provide a temporary compliance edge in transitional periods.

Adaptation strategies differ significantly between these technologies. Diesel manufacturers have invested heavily in emissions control technologies, while Wankel development has increasingly focused on hybrid applications where the rotary engine serves as a range extender for electric vehicles—a configuration that mitigates some emissions concerns while leveraging the rotary's compact size and smooth operation.

The cost of emissions compliance has become a major factor in engine lifespan economics. Diesel aftertreatment systems can represent 15-20% of total engine cost and require periodic maintenance or replacement of components like DPF filters. Wankel engines face similar challenges with catalyst systems designed to address their specific emissions profile, though their mechanical simplicity offers potential cost advantages in other areas.

Diesel engines have historically faced challenges with particulate matter (PM) and nitrogen oxide (NOx) emissions. Modern diesel technologies have incorporated sophisticated aftertreatment systems including diesel particulate filters (DPF), selective catalytic reduction (SCR), and exhaust gas recirculation (EGR) to meet Euro 6, EPA Tier 3, and other global standards. These systems, while effective, add complexity, weight, and maintenance requirements that can impact the overall lifespan of diesel powertrains.

Wankel engines present a different emissions profile, typically producing lower particulate matter but higher hydrocarbon emissions due to their unique combustion chamber geometry. The elongated combustion chamber creates "quench zones" where fuel may escape complete combustion. Additionally, oil consumption in Wankel engines—necessary for apex seal lubrication—contributes to hydrocarbon emissions and can complicate catalytic converter operation.

Carbon dioxide emissions represent another critical regulatory focus. Diesel engines generally offer superior thermal efficiency (40-45% versus 25-30% for typical Wankel designs), resulting in lower CO2 output per unit of work performed. This efficiency advantage has become increasingly valuable as carbon taxation and fleet emissions standards tighten globally.

Recent regulatory developments have accelerated the transition toward zero-emission vehicles, particularly in urban environments. Several jurisdictions have announced future bans on internal combustion engines, with implementation timelines between 2030-2040. This regulatory horizon creates significant uncertainty for both engine types, though diesel's efficiency advantages may provide a temporary compliance edge in transitional periods.

Adaptation strategies differ significantly between these technologies. Diesel manufacturers have invested heavily in emissions control technologies, while Wankel development has increasingly focused on hybrid applications where the rotary engine serves as a range extender for electric vehicles—a configuration that mitigates some emissions concerns while leveraging the rotary's compact size and smooth operation.

The cost of emissions compliance has become a major factor in engine lifespan economics. Diesel aftertreatment systems can represent 15-20% of total engine cost and require periodic maintenance or replacement of components like DPF filters. Wankel engines face similar challenges with catalyst systems designed to address their specific emissions profile, though their mechanical simplicity offers potential cost advantages in other areas.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!