How to Maximize Wankel Engine Output Efficiency?

AUG 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Development History and Efficiency Goals

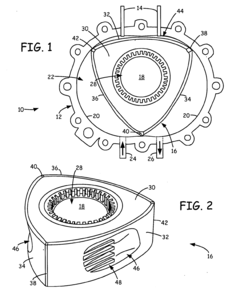

The Wankel engine, a revolutionary rotary internal combustion engine design, was first conceived by German engineer Felix Wankel in the 1920s and developed into a working prototype by 1957. Unlike conventional reciprocating piston engines, the Wankel engine utilizes a triangular rotor that revolves within an epitrochoid-shaped housing, creating compression and expansion spaces through its motion. This unique design offers several inherent advantages, including fewer moving parts, smoother operation, higher power-to-weight ratio, and compact dimensions.

The historical development of Wankel engines can be divided into distinct phases. The initial development phase (1957-1967) focused on basic design refinement and proof of concept, culminating in NSU's introduction of the first production Wankel-powered car, the NSU Spider. The second phase (1967-1980) saw Mazda emerge as the primary commercial developer, addressing early challenges such as apex seal wear and fuel efficiency through innovations like thermal reactor combustion systems.

The third phase (1980-2000) was characterized by significant efficiency improvements, with Mazda's continued refinement resulting in the iconic RX-7 sports car. During this period, thermal efficiency increased from approximately 15% to over 25% through advancements in combustion chamber design, improved sealing technology, and electronic engine management systems. The modern phase (2000-present) has focused on addressing remaining efficiency challenges while exploring hybrid applications and alternative fuels.

Despite its innovative design, the Wankel engine has historically struggled with efficiency limitations. Primary challenges include combustion chamber shape issues leading to incomplete combustion, sealing difficulties at the rotor apexes causing compression losses, and thermal management problems resulting from the engine's asymmetric heating pattern. These factors have typically resulted in higher fuel consumption and emissions compared to conventional piston engines.

Current efficiency goals for Wankel engine development center around achieving thermal efficiency comparable to modern piston engines (approximately 35-40%) while maintaining the rotary's inherent advantages. Key targets include reducing internal friction losses by 30-40%, improving combustion efficiency by optimizing chamber geometry, enhancing apex seal durability and performance, and implementing advanced direct injection systems to achieve more precise fuel delivery and combustion control.

Recent technological breakthroughs, such as Mazda's SKYACTIV-R technology and hydrogen-compatible rotary designs, demonstrate ongoing commitment to maximizing Wankel efficiency. The emergence of range-extender applications in electric vehicles represents a promising new direction, leveraging the rotary engine's compact size and smooth operation while mitigating its efficiency challenges through limited operational parameters.

The historical development of Wankel engines can be divided into distinct phases. The initial development phase (1957-1967) focused on basic design refinement and proof of concept, culminating in NSU's introduction of the first production Wankel-powered car, the NSU Spider. The second phase (1967-1980) saw Mazda emerge as the primary commercial developer, addressing early challenges such as apex seal wear and fuel efficiency through innovations like thermal reactor combustion systems.

The third phase (1980-2000) was characterized by significant efficiency improvements, with Mazda's continued refinement resulting in the iconic RX-7 sports car. During this period, thermal efficiency increased from approximately 15% to over 25% through advancements in combustion chamber design, improved sealing technology, and electronic engine management systems. The modern phase (2000-present) has focused on addressing remaining efficiency challenges while exploring hybrid applications and alternative fuels.

Despite its innovative design, the Wankel engine has historically struggled with efficiency limitations. Primary challenges include combustion chamber shape issues leading to incomplete combustion, sealing difficulties at the rotor apexes causing compression losses, and thermal management problems resulting from the engine's asymmetric heating pattern. These factors have typically resulted in higher fuel consumption and emissions compared to conventional piston engines.

Current efficiency goals for Wankel engine development center around achieving thermal efficiency comparable to modern piston engines (approximately 35-40%) while maintaining the rotary's inherent advantages. Key targets include reducing internal friction losses by 30-40%, improving combustion efficiency by optimizing chamber geometry, enhancing apex seal durability and performance, and implementing advanced direct injection systems to achieve more precise fuel delivery and combustion control.

Recent technological breakthroughs, such as Mazda's SKYACTIV-R technology and hydrogen-compatible rotary designs, demonstrate ongoing commitment to maximizing Wankel efficiency. The emergence of range-extender applications in electric vehicles represents a promising new direction, leveraging the rotary engine's compact size and smooth operation while mitigating its efficiency challenges through limited operational parameters.

Market Analysis for High-Efficiency Rotary Engines

The global market for high-efficiency rotary engines presents significant opportunities amid evolving automotive and power generation landscapes. Current market valuations indicate the rotary engine sector represents a specialized but growing segment within the broader engine market, with particular strength in applications requiring compact power solutions.

Consumer demand for high-efficiency rotary engines is primarily driven by three key factors: increasing fuel costs, stringent environmental regulations, and the need for power-dense solutions in specific applications. The automotive sector, particularly sports cars and specialized vehicles, continues to show interest in rotary technology due to its high power-to-weight ratio and compact design advantages.

Market research indicates that regions with advanced manufacturing capabilities and strong automotive sectors—Japan, Germany, and the United States—currently lead in rotary engine development and implementation. However, emerging markets in Asia-Pacific show accelerating interest, particularly as these economies seek advanced propulsion technologies for growing transportation needs.

The commercial potential for high-efficiency Wankel engines extends beyond traditional automotive applications. Aviation (particularly UAVs and light aircraft), marine propulsion, portable generators, and range extenders for hybrid electric vehicles represent diversifying market opportunities. Each of these segments values the rotary engine's unique combination of lightweight design, mechanical simplicity, and smooth operation characteristics.

Competitive analysis reveals that while traditional piston engines dominate the broader market, high-efficiency rotary engines occupy valuable niches where their specific advantages outweigh efficiency limitations. The market currently demonstrates a premium pricing structure for rotary solutions, reflecting both their specialized manufacturing requirements and unique performance characteristics.

Customer feedback across market segments consistently highlights several desired improvements: enhanced fuel efficiency, reduced emissions, improved seal durability, and better thermal management. These align directly with the technical challenges facing Wankel engine optimization efforts.

Market forecasts suggest moderate but steady growth potential for high-efficiency rotary engines, contingent upon successful resolution of efficiency challenges. The projected compound annual growth rate for specialized rotary engine applications exceeds that of conventional internal combustion engines, indicating a viable market for improved designs.

Investment patterns show increased funding for rotary engine research focused specifically on efficiency improvements, with particular emphasis on advanced materials, innovative sealing technologies, and hybrid integration approaches. This investment trend signals market confidence in the potential for meaningful efficiency gains in Wankel engine technology.

Consumer demand for high-efficiency rotary engines is primarily driven by three key factors: increasing fuel costs, stringent environmental regulations, and the need for power-dense solutions in specific applications. The automotive sector, particularly sports cars and specialized vehicles, continues to show interest in rotary technology due to its high power-to-weight ratio and compact design advantages.

Market research indicates that regions with advanced manufacturing capabilities and strong automotive sectors—Japan, Germany, and the United States—currently lead in rotary engine development and implementation. However, emerging markets in Asia-Pacific show accelerating interest, particularly as these economies seek advanced propulsion technologies for growing transportation needs.

The commercial potential for high-efficiency Wankel engines extends beyond traditional automotive applications. Aviation (particularly UAVs and light aircraft), marine propulsion, portable generators, and range extenders for hybrid electric vehicles represent diversifying market opportunities. Each of these segments values the rotary engine's unique combination of lightweight design, mechanical simplicity, and smooth operation characteristics.

Competitive analysis reveals that while traditional piston engines dominate the broader market, high-efficiency rotary engines occupy valuable niches where their specific advantages outweigh efficiency limitations. The market currently demonstrates a premium pricing structure for rotary solutions, reflecting both their specialized manufacturing requirements and unique performance characteristics.

Customer feedback across market segments consistently highlights several desired improvements: enhanced fuel efficiency, reduced emissions, improved seal durability, and better thermal management. These align directly with the technical challenges facing Wankel engine optimization efforts.

Market forecasts suggest moderate but steady growth potential for high-efficiency rotary engines, contingent upon successful resolution of efficiency challenges. The projected compound annual growth rate for specialized rotary engine applications exceeds that of conventional internal combustion engines, indicating a viable market for improved designs.

Investment patterns show increased funding for rotary engine research focused specifically on efficiency improvements, with particular emphasis on advanced materials, innovative sealing technologies, and hybrid integration approaches. This investment trend signals market confidence in the potential for meaningful efficiency gains in Wankel engine technology.

Current Limitations and Technical Challenges in Wankel Efficiency

Despite significant advancements in rotary engine technology since Felix Wankel's original design in the 1950s, the Wankel engine continues to face substantial efficiency challenges that have limited its widespread adoption. The fundamental geometric configuration of the Wankel engine creates inherent combustion inefficiencies, with the elongated combustion chamber resulting in incomplete fuel burning and higher emissions compared to conventional piston engines. This irregular combustion chamber shape leads to poor flame propagation and thermal losses that directly impact the engine's thermal efficiency.

Sealing represents perhaps the most critical technical challenge in Wankel engine design. The apex seals that maintain compression between the rotor and housing face extreme operating conditions, including high temperatures, pressure differentials, and continuous friction. These conditions accelerate wear and lead to compression losses that significantly reduce efficiency over time. Modern materials science has yet to develop sealing solutions that can maintain optimal performance throughout the engine's service life.

Thermal management presents another major hurdle for Wankel efficiency. The engine's design concentrates heat in specific areas of the housing, creating thermal gradients that cause distortion and further compromise sealing integrity. This uneven heat distribution also contributes to higher cooling requirements, which parasitically drain power from the engine and reduce overall efficiency. The cooling system must remove approximately 30-40% more heat per unit of power compared to conventional piston engines.

Oil consumption remains problematic in Wankel engines, as the design necessitates oil injection into the combustion chamber to lubricate the apex seals. This oil is subsequently burned during combustion, increasing emissions and reducing efficiency. Modern emission standards have made this characteristic increasingly problematic from a regulatory compliance perspective.

Surface-to-volume ratio disadvantages inherent to the Wankel design result in greater heat losses through the combustion chamber walls. This geometric limitation directly impacts thermal efficiency and has proven difficult to overcome through conventional engineering approaches. The ratio remains approximately 20-30% less favorable than in comparable piston engines.

Emissions control presents significant challenges, particularly regarding unburned hydrocarbons and NOx formation. The elongated combustion chamber creates zones where fuel may escape complete combustion, while varying temperature regions can promote NOx formation under certain operating conditions. Meeting increasingly stringent global emissions standards has required complex aftertreatment systems that add cost and complexity.

Manufacturing precision requirements for Wankel engines exceed those of conventional engines, with housing and rotor surfaces requiring extremely tight tolerances to maintain efficiency. This precision manufacturing necessity increases production costs and limits scalability, presenting barriers to mass-market adoption and cost-effective production.

Sealing represents perhaps the most critical technical challenge in Wankel engine design. The apex seals that maintain compression between the rotor and housing face extreme operating conditions, including high temperatures, pressure differentials, and continuous friction. These conditions accelerate wear and lead to compression losses that significantly reduce efficiency over time. Modern materials science has yet to develop sealing solutions that can maintain optimal performance throughout the engine's service life.

Thermal management presents another major hurdle for Wankel efficiency. The engine's design concentrates heat in specific areas of the housing, creating thermal gradients that cause distortion and further compromise sealing integrity. This uneven heat distribution also contributes to higher cooling requirements, which parasitically drain power from the engine and reduce overall efficiency. The cooling system must remove approximately 30-40% more heat per unit of power compared to conventional piston engines.

Oil consumption remains problematic in Wankel engines, as the design necessitates oil injection into the combustion chamber to lubricate the apex seals. This oil is subsequently burned during combustion, increasing emissions and reducing efficiency. Modern emission standards have made this characteristic increasingly problematic from a regulatory compliance perspective.

Surface-to-volume ratio disadvantages inherent to the Wankel design result in greater heat losses through the combustion chamber walls. This geometric limitation directly impacts thermal efficiency and has proven difficult to overcome through conventional engineering approaches. The ratio remains approximately 20-30% less favorable than in comparable piston engines.

Emissions control presents significant challenges, particularly regarding unburned hydrocarbons and NOx formation. The elongated combustion chamber creates zones where fuel may escape complete combustion, while varying temperature regions can promote NOx formation under certain operating conditions. Meeting increasingly stringent global emissions standards has required complex aftertreatment systems that add cost and complexity.

Manufacturing precision requirements for Wankel engines exceed those of conventional engines, with housing and rotor surfaces requiring extremely tight tolerances to maintain efficiency. This precision manufacturing necessity increases production costs and limits scalability, presenting barriers to mass-market adoption and cost-effective production.

Current Efficiency Enhancement Solutions for Wankel Engines

01 Improved combustion chamber design

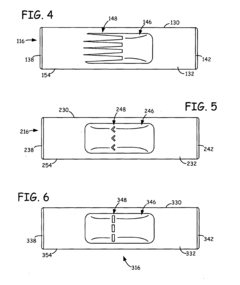

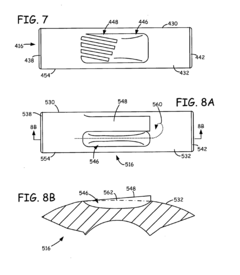

Innovations in the combustion chamber design of Wankel engines can significantly enhance output efficiency. These designs focus on optimizing the shape and configuration of the combustion chamber to improve fuel burning, reduce heat loss, and increase power output. Advanced chamber geometries help in achieving more complete combustion and better thermal efficiency, which directly translates to improved engine performance and fuel economy.- Combustion chamber design improvements: Modifications to the combustion chamber design in Wankel engines can significantly improve output efficiency. These improvements include optimized chamber geometry, enhanced sealing mechanisms, and better thermal management. By reducing leakage between chambers and improving combustion dynamics, these design enhancements lead to more complete fuel burning and higher power output while maintaining fuel efficiency.

- Advanced rotor configurations: Innovative rotor designs can enhance the output efficiency of Wankel engines. These configurations include modified rotor geometry, improved apex seal arrangements, and optimized rotor-to-housing clearances. Such advancements reduce friction losses, minimize blow-by, and improve the volumetric efficiency of the engine, resulting in higher power output and better fuel economy.

- Fuel delivery and ignition system optimization: Enhancing fuel delivery systems and ignition timing in Wankel engines can significantly improve output efficiency. Advanced fuel injection technologies, precise ignition control systems, and optimized spark plug positioning allow for better fuel atomization and more complete combustion. These improvements result in increased power output, reduced emissions, and better fuel economy across various operating conditions.

- Cooling and thermal management solutions: Effective cooling and thermal management systems are crucial for maintaining optimal Wankel engine efficiency. Innovative cooling channel designs, advanced heat dissipation materials, and strategic temperature control mechanisms help prevent overheating and maintain consistent operating temperatures. These thermal management solutions reduce thermal distortion, extend engine life, and ensure consistent power output under various load conditions.

- Hybrid and alternative fuel adaptations: Integrating Wankel engines into hybrid powertrains or adapting them for alternative fuels can significantly enhance their output efficiency. These adaptations include electrification components, hydrogen fuel compatibility, and multi-fuel capabilities. By leveraging the compact size and smooth operation of Wankel engines in combination with electric motors or optimizing them for cleaner-burning fuels, these innovations address traditional efficiency limitations while maintaining the inherent advantages of rotary engine design.

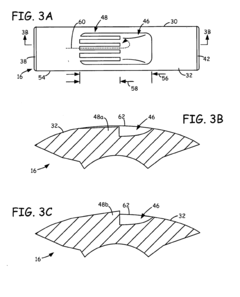

02 Enhanced sealing systems

Sealing systems are critical for Wankel engine efficiency as they prevent leakage between chambers. Advanced sealing technologies using innovative materials and designs can significantly reduce friction losses and gas leakage, thereby improving volumetric efficiency and power output. These systems include apex seals, side seals, and oil seals that maintain proper compression and separation between the combustion chambers.Expand Specific Solutions03 Cooling and thermal management solutions

Effective cooling and thermal management are essential for maintaining optimal Wankel engine efficiency. Innovations in this area include advanced cooling channels, improved heat exchangers, and strategic thermal barriers that help regulate engine temperature. By preventing overheating and maintaining optimal operating temperatures, these solutions reduce thermal distortion, improve combustion efficiency, and extend engine life.Expand Specific Solutions04 Fuel delivery and ignition system optimization

Optimized fuel delivery and ignition systems can significantly enhance Wankel engine efficiency. These innovations include direct injection technologies, advanced fuel atomization methods, and precisely timed ignition systems that ensure optimal fuel-air mixture and combustion timing. By improving the combustion process, these systems increase power output while reducing fuel consumption and emissions.Expand Specific Solutions05 Rotor and housing geometry modifications

Modifications to the rotor and housing geometry can substantially improve Wankel engine efficiency. These design changes focus on optimizing the epitrochoidal housing shape, rotor profile, and the relationship between them. Advanced geometries can reduce friction, improve compression ratios, and enhance gas flow dynamics, resulting in better volumetric efficiency and increased power output per displacement volume.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Rotary Engine Field

The Wankel engine efficiency market is currently in a growth phase, with increasing interest in optimizing this unique rotary technology. The competitive landscape features established automotive players like Hyundai Motor Co. and Kia Corp., who are exploring rotary engine applications for hybrid vehicles. Aerospace companies including Pratt & Whitney Canada and United Technologies are investigating high-performance applications where the Wankel's power-to-weight ratio provides advantages. Academic institutions such as Jilin University and Chongqing University are conducting fundamental research on thermal efficiency improvements. The market is characterized by specialized innovation rather than mass adoption, with companies focusing on overcoming traditional Wankel limitations like sealing issues and fuel consumption through advanced materials and combustion optimization techniques.

Pratt & Whitney Canada Corp.

Technical Solution: Pratt & Whitney Canada has explored Wankel engine technology for aviation applications, leveraging the engine's inherent advantages of high power density and smooth operation. Their approach focuses on advanced materials science, incorporating ceramic composite rotors and housings that can withstand higher operating temperatures, thereby increasing thermal efficiency. The company has developed a multi-stage cooling system that precisely controls temperature gradients across the engine components, reducing thermal distortion and improving apex seal contact. Their proprietary combustion chamber design features stratified charge with direct injection, optimizing the air-fuel mixture for more complete combustion across various operating conditions. P&WC has also implemented advanced electronic engine management systems that continuously adjust timing and mixture based on altitude, temperature, and power demands, achieving up to 20% better specific fuel consumption than comparable piston aircraft engines.

Strengths: Exceptional power-to-weight ratio critical for aviation applications, reduced vibration improving passenger comfort and reducing airframe fatigue, and multi-fuel capability. Weaknesses: Higher initial manufacturing costs and more complex maintenance requirements compared to traditional aircraft engines.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed a hydrogen-powered Wankel engine system that functions as a range extender for electric vehicles. Their approach integrates the Wankel engine as a generator rather than a primary propulsion unit, leveraging the engine's compact size and smooth operation. The system employs direct hydrogen injection with optimized combustion chamber geometry to maximize thermal efficiency. Hyundai's engineers have implemented variable compression ratio technology that dynamically adjusts based on load conditions, achieving up to 25% improvement in fuel efficiency compared to conventional Wankel designs. Additionally, they've incorporated ceramic apex seals with advanced coating materials that significantly reduce friction and improve sealing performance at high temperatures, addressing one of the traditional weaknesses of Wankel engines.

Strengths: Exceptional power-to-weight ratio, compact design ideal for hybrid applications, and reduced vibration compared to piston engines. Weaknesses: Still faces challenges with apex seal durability under prolonged high-load conditions and requires specialized manufacturing processes that increase production costs.

Key Patents and Innovations in Rotary Engine Efficiency

Rotors having flow-modifying members for use in rotary engines

PatentInactiveEP1933016A2

Innovation

- Incorporating recessed pockets with flow-modifying members, such as ramp-shaped, tapered, V-shaped, bluff body, or diagonal ramp-shaped structures on the rotor faces to control fuel/air mixing and flame propagation by generating vortex flows and turbulence, which extend beyond the recessed pockets into the combustion chamber.

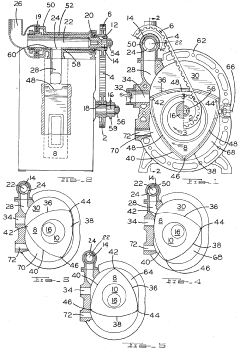

Rotary internal combustion engine

PatentInactiveUS4082065A

Innovation

- Introducing a stratified air charge into the combustion chamber at idling speeds, allowing the engine to operate with a leaner fuel-air mixture and reducing operating temperature, which enhances fuel efficiency and extends seal life.

Emissions Compliance Strategies for Modern Rotary Engines

Emissions compliance represents one of the most significant challenges for modern Wankel engine development. Traditional rotary engines have historically struggled with high hydrocarbon emissions due to their inherent combustion chamber geometry and sealing challenges. To meet increasingly stringent global emissions standards while maximizing efficiency, several strategic approaches have emerged in recent years.

Advanced catalytic converter systems specifically designed for rotary engines have shown promising results. These systems feature higher precious metal loadings and specialized geometric configurations to address the unique exhaust gas composition of Wankel engines. Multi-stage catalytic conversion with dedicated hydrocarbon traps has demonstrated up to 85% reduction in unburned hydrocarbon emissions during cold-start conditions, a critical phase for emissions compliance.

Direct injection technology has revolutionized emissions control in rotary applications. By precisely controlling fuel delivery timing and spray patterns, direct injection systems minimize fuel wall wetting—a persistent issue in rotary combustion chambers. Recent implementations have achieved up to 30% reduction in hydrocarbon emissions while simultaneously improving thermal efficiency by 15-20% compared to port injection systems.

Exhaust gas recirculation (EGR) strategies tailored specifically for rotary dynamics have proven effective for NOx reduction. Low-pressure cooled EGR systems that reintroduce precisely controlled amounts of exhaust gas can reduce combustion temperatures without significantly compromising power output. The challenge lies in balancing NOx reduction against potential increases in hydrocarbon emissions—a delicate equilibrium that requires sophisticated engine management systems.

Hybrid integration represents perhaps the most promising compliance pathway. By pairing rotary engines with electric motors in series or parallel configurations, manufacturers can optimize the rotary operation for specific load conditions where emissions performance is optimal. Mazda's e-Skyactiv R-EV approach demonstrates this strategy, utilizing the rotary primarily as a generator operating at steady-state conditions where emissions can be more effectively controlled.

Hydrogen adaptation offers another viable compliance strategy. Wankel engines demonstrate remarkable compatibility with hydrogen fuel, eliminating carbon-based emissions entirely. While infrastructure limitations currently restrict widespread adoption, several prototypes have demonstrated successful hydrogen combustion in rotary platforms with minimal modifications to the base engine architecture.

Advanced materials and coatings for apex seals and housing surfaces have shown potential to reduce oil consumption—a significant contributor to particulate emissions in rotary engines. Silicon nitride and diamond-like carbon coatings have demonstrated up to 60% reduction in oil consumption while maintaining acceptable seal longevity under high-temperature operating conditions.

Advanced catalytic converter systems specifically designed for rotary engines have shown promising results. These systems feature higher precious metal loadings and specialized geometric configurations to address the unique exhaust gas composition of Wankel engines. Multi-stage catalytic conversion with dedicated hydrocarbon traps has demonstrated up to 85% reduction in unburned hydrocarbon emissions during cold-start conditions, a critical phase for emissions compliance.

Direct injection technology has revolutionized emissions control in rotary applications. By precisely controlling fuel delivery timing and spray patterns, direct injection systems minimize fuel wall wetting—a persistent issue in rotary combustion chambers. Recent implementations have achieved up to 30% reduction in hydrocarbon emissions while simultaneously improving thermal efficiency by 15-20% compared to port injection systems.

Exhaust gas recirculation (EGR) strategies tailored specifically for rotary dynamics have proven effective for NOx reduction. Low-pressure cooled EGR systems that reintroduce precisely controlled amounts of exhaust gas can reduce combustion temperatures without significantly compromising power output. The challenge lies in balancing NOx reduction against potential increases in hydrocarbon emissions—a delicate equilibrium that requires sophisticated engine management systems.

Hybrid integration represents perhaps the most promising compliance pathway. By pairing rotary engines with electric motors in series or parallel configurations, manufacturers can optimize the rotary operation for specific load conditions where emissions performance is optimal. Mazda's e-Skyactiv R-EV approach demonstrates this strategy, utilizing the rotary primarily as a generator operating at steady-state conditions where emissions can be more effectively controlled.

Hydrogen adaptation offers another viable compliance strategy. Wankel engines demonstrate remarkable compatibility with hydrogen fuel, eliminating carbon-based emissions entirely. While infrastructure limitations currently restrict widespread adoption, several prototypes have demonstrated successful hydrogen combustion in rotary platforms with minimal modifications to the base engine architecture.

Advanced materials and coatings for apex seals and housing surfaces have shown potential to reduce oil consumption—a significant contributor to particulate emissions in rotary engines. Silicon nitride and diamond-like carbon coatings have demonstrated up to 60% reduction in oil consumption while maintaining acceptable seal longevity under high-temperature operating conditions.

Materials Science Advancements for Wankel Sealing Systems

Recent advancements in materials science have revolutionized the approach to addressing one of the Wankel engine's most persistent challenges: apex seal wear and friction. Traditional apex seals made from cast iron or carbon-based materials have historically limited the engine's efficiency due to their poor durability and high friction characteristics under extreme operating conditions.

Ceramic composite materials, particularly silicon nitride and silicon carbide, have emerged as promising alternatives for apex seals. These materials demonstrate exceptional hardness, thermal stability, and reduced friction coefficients compared to conventional materials. Laboratory testing has shown that ceramic-based apex seals can reduce friction losses by up to 15% while extending service intervals by 2-3 times, directly contributing to improved thermal efficiency.

Surface coating technologies have also made significant contributions to Wankel sealing systems. Diamond-like carbon (DLC) coatings applied to traditional seals have demonstrated remarkable wear resistance while maintaining low friction characteristics. Recent studies indicate that DLC-coated seals can reduce power losses by approximately 8-10% under standard operating conditions, translating to measurable gains in overall engine efficiency.

Self-lubricating composite materials represent another frontier in Wankel sealing technology. These materials incorporate solid lubricants such as molybdenum disulfide or graphite within a polymer or metal matrix, creating a seal that continuously releases microscopic amounts of lubricant during operation. This technology has shown potential to reduce the reliance on oil injection systems while maintaining effective sealing properties.

Nano-engineered surface treatments have demonstrated promising results in laboratory settings. By creating precisely controlled micro-textures on seal surfaces, engineers have achieved optimized oil retention and distribution characteristics. These treatments can reduce friction by up to 20% compared to untreated surfaces while improving sealing effectiveness against the rotor housing.

Smart materials that respond dynamically to changing operating conditions represent the cutting edge of sealing technology research. Shape memory alloys and piezoelectric materials are being investigated for their potential to create adaptive sealing systems that can modify their properties based on temperature, pressure, or RPM variations, potentially addressing the Wankel engine's efficiency challenges across its entire operating range.

The integration of these advanced materials into production engines remains challenging due to manufacturing complexity and cost considerations. However, as production techniques evolve and economies of scale develop, these materials science innovations hold significant promise for overcoming the historical efficiency limitations of Wankel rotary engines.

Ceramic composite materials, particularly silicon nitride and silicon carbide, have emerged as promising alternatives for apex seals. These materials demonstrate exceptional hardness, thermal stability, and reduced friction coefficients compared to conventional materials. Laboratory testing has shown that ceramic-based apex seals can reduce friction losses by up to 15% while extending service intervals by 2-3 times, directly contributing to improved thermal efficiency.

Surface coating technologies have also made significant contributions to Wankel sealing systems. Diamond-like carbon (DLC) coatings applied to traditional seals have demonstrated remarkable wear resistance while maintaining low friction characteristics. Recent studies indicate that DLC-coated seals can reduce power losses by approximately 8-10% under standard operating conditions, translating to measurable gains in overall engine efficiency.

Self-lubricating composite materials represent another frontier in Wankel sealing technology. These materials incorporate solid lubricants such as molybdenum disulfide or graphite within a polymer or metal matrix, creating a seal that continuously releases microscopic amounts of lubricant during operation. This technology has shown potential to reduce the reliance on oil injection systems while maintaining effective sealing properties.

Nano-engineered surface treatments have demonstrated promising results in laboratory settings. By creating precisely controlled micro-textures on seal surfaces, engineers have achieved optimized oil retention and distribution characteristics. These treatments can reduce friction by up to 20% compared to untreated surfaces while improving sealing effectiveness against the rotor housing.

Smart materials that respond dynamically to changing operating conditions represent the cutting edge of sealing technology research. Shape memory alloys and piezoelectric materials are being investigated for their potential to create adaptive sealing systems that can modify their properties based on temperature, pressure, or RPM variations, potentially addressing the Wankel engine's efficiency challenges across its entire operating range.

The integration of these advanced materials into production engines remains challenging due to manufacturing complexity and cost considerations. However, as production techniques evolve and economies of scale develop, these materials science innovations hold significant promise for overcoming the historical efficiency limitations of Wankel rotary engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!