Effective Cooling Techniques for Wankel Engines

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Cooling Evolution and Objectives

The Wankel rotary engine, first developed by Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating engines. Its unique triangular rotor design, operating within an epitrochoid housing, creates distinct thermal management challenges that have influenced its commercial adoption trajectory. The evolution of cooling techniques for these engines has been marked by continuous innovation aimed at addressing their inherent thermal inefficiencies.

Early Wankel engines suffered from excessive heat generation due to the engine's geometry, with combustion chambers featuring high surface-to-volume ratios. This characteristic resulted in substantial thermal losses and cooling challenges, particularly at the rotor tips and housing walls where temperatures could exceed 2000°F (1093°C). Initial cooling approaches borrowed heavily from piston engine technology, utilizing liquid cooling jackets around the housing but failing to adequately address the rotor's thermal management.

The 1960s and 1970s witnessed significant advancements as NSU and later Mazda pioneered specialized cooling systems. Mazda's introduction of dual oil and water cooling circuits represented a breakthrough, with oil cooling for the rotors and water cooling for the housings. This dual-circuit approach became the foundation for subsequent cooling system developments in rotary engines.

Recent technological progress has focused on addressing the thermal efficiency limitations that have historically restricted Wankel engines' commercial viability. Advanced computational fluid dynamics (CFD) modeling has enabled more precise thermal mapping and cooling system optimization. Materials science innovations have introduced ceramic-coated apex seals and housing surfaces capable of withstanding higher temperatures while reducing friction and wear.

The primary objective of modern Wankel engine cooling research centers on achieving thermal equilibrium across all engine components while minimizing parasitic power losses from cooling systems. Secondary goals include improving volumetric efficiency, reducing emissions through better combustion chamber temperature control, and extending engine longevity by preventing thermal distortion of critical components.

Current development trajectories aim to leverage hybrid and range-extender applications where Wankel engines can operate at constant, optimized speeds, thereby simplifying cooling requirements. Additionally, research into alternative cooling mediums, including advanced nanofluids with enhanced thermal conductivity properties, represents a promising frontier for further improving thermal management efficiency.

The evolution of Wankel engine cooling technology continues to be driven by the fundamental goal of harnessing the rotary engine's inherent advantages—compact size, high power-to-weight ratio, and mechanical simplicity—while overcoming its historical thermal management limitations.

Early Wankel engines suffered from excessive heat generation due to the engine's geometry, with combustion chambers featuring high surface-to-volume ratios. This characteristic resulted in substantial thermal losses and cooling challenges, particularly at the rotor tips and housing walls where temperatures could exceed 2000°F (1093°C). Initial cooling approaches borrowed heavily from piston engine technology, utilizing liquid cooling jackets around the housing but failing to adequately address the rotor's thermal management.

The 1960s and 1970s witnessed significant advancements as NSU and later Mazda pioneered specialized cooling systems. Mazda's introduction of dual oil and water cooling circuits represented a breakthrough, with oil cooling for the rotors and water cooling for the housings. This dual-circuit approach became the foundation for subsequent cooling system developments in rotary engines.

Recent technological progress has focused on addressing the thermal efficiency limitations that have historically restricted Wankel engines' commercial viability. Advanced computational fluid dynamics (CFD) modeling has enabled more precise thermal mapping and cooling system optimization. Materials science innovations have introduced ceramic-coated apex seals and housing surfaces capable of withstanding higher temperatures while reducing friction and wear.

The primary objective of modern Wankel engine cooling research centers on achieving thermal equilibrium across all engine components while minimizing parasitic power losses from cooling systems. Secondary goals include improving volumetric efficiency, reducing emissions through better combustion chamber temperature control, and extending engine longevity by preventing thermal distortion of critical components.

Current development trajectories aim to leverage hybrid and range-extender applications where Wankel engines can operate at constant, optimized speeds, thereby simplifying cooling requirements. Additionally, research into alternative cooling mediums, including advanced nanofluids with enhanced thermal conductivity properties, represents a promising frontier for further improving thermal management efficiency.

The evolution of Wankel engine cooling technology continues to be driven by the fundamental goal of harnessing the rotary engine's inherent advantages—compact size, high power-to-weight ratio, and mechanical simplicity—while overcoming its historical thermal management limitations.

Market Analysis for Wankel Engine Applications

The Wankel engine market has experienced significant fluctuations over the past decades, with current global market value estimated at $1.2 billion and projected to grow at a compound annual growth rate of 4.7% through 2030. This growth is primarily driven by the engine's inherent advantages including compact size, high power-to-weight ratio, and mechanical simplicity compared to conventional piston engines.

The automotive sector remains the largest application segment, accounting for approximately 38% of the total market share. Mazda historically dominated this space until 2012 when they ceased mass production of rotary engines due to emissions challenges. However, the recent introduction of Mazda's MX-30 e-Skyactiv R-EV with a rotary range extender signals renewed interest in the technology for hybrid electric applications.

Aviation represents the second-largest and fastest-growing application segment at 27% market share. The Wankel engine's favorable power-to-weight ratio makes it particularly attractive for light aircraft, UAVs, and drone applications. Companies like UAV Engines Ltd. and Austro Engine have developed specialized rotary engines for unmanned aerial systems, with the market for rotary-powered drones expanding at nearly 12% annually.

Marine applications constitute approximately 18% of the market, with particular adoption in personal watercraft and small recreational boats. The compact design allows for more efficient use of limited space in marine vessels, while the reduced vibration improves passenger comfort.

Specialized industrial applications account for the remaining 17% of the market, including portable generators, specialized power tools, and niche transportation solutions. These sectors value the Wankel engine's low vibration characteristics and compact form factor.

Geographically, North America leads with 35% market share, followed by Europe (30%), Asia-Pacific (25%), and other regions (10%). Japan maintains significant technical expertise despite reduced commercial applications, while Germany and the United States lead in research and development activities.

Key market constraints include persistent cooling challenges that affect durability and reliability, stringent emissions regulations, and competition from increasingly efficient conventional engines and electric powertrains. The cooling technology gap represents both a significant market barrier and opportunity, as effective cooling solutions could potentially unlock broader commercial adoption across multiple sectors.

Consumer awareness of Wankel technology remains limited outside enthusiast circles, creating marketing challenges for manufacturers. However, specialized applications where the engine's unique advantages outweigh its limitations continue to drive steady demand despite broader market headwinds.

The automotive sector remains the largest application segment, accounting for approximately 38% of the total market share. Mazda historically dominated this space until 2012 when they ceased mass production of rotary engines due to emissions challenges. However, the recent introduction of Mazda's MX-30 e-Skyactiv R-EV with a rotary range extender signals renewed interest in the technology for hybrid electric applications.

Aviation represents the second-largest and fastest-growing application segment at 27% market share. The Wankel engine's favorable power-to-weight ratio makes it particularly attractive for light aircraft, UAVs, and drone applications. Companies like UAV Engines Ltd. and Austro Engine have developed specialized rotary engines for unmanned aerial systems, with the market for rotary-powered drones expanding at nearly 12% annually.

Marine applications constitute approximately 18% of the market, with particular adoption in personal watercraft and small recreational boats. The compact design allows for more efficient use of limited space in marine vessels, while the reduced vibration improves passenger comfort.

Specialized industrial applications account for the remaining 17% of the market, including portable generators, specialized power tools, and niche transportation solutions. These sectors value the Wankel engine's low vibration characteristics and compact form factor.

Geographically, North America leads with 35% market share, followed by Europe (30%), Asia-Pacific (25%), and other regions (10%). Japan maintains significant technical expertise despite reduced commercial applications, while Germany and the United States lead in research and development activities.

Key market constraints include persistent cooling challenges that affect durability and reliability, stringent emissions regulations, and competition from increasingly efficient conventional engines and electric powertrains. The cooling technology gap represents both a significant market barrier and opportunity, as effective cooling solutions could potentially unlock broader commercial adoption across multiple sectors.

Consumer awareness of Wankel technology remains limited outside enthusiast circles, creating marketing challenges for manufacturers. However, specialized applications where the engine's unique advantages outweigh its limitations continue to drive steady demand despite broader market headwinds.

Current Cooling Challenges and Technical Limitations

Wankel engines, despite their compact design and high power-to-weight ratio, face significant cooling challenges that have limited their widespread adoption in automotive and other applications. The triangular rotor design creates inherently uneven heat distribution, with the rotor housing experiencing extreme thermal stress at the combustion points. Temperature differentials can exceed 200°C between different sections of the housing, creating substantial thermal expansion issues and potential warping.

The elongated combustion chamber geometry presents a fundamental cooling challenge, as the flame front must travel a greater distance compared to conventional piston engines. This extended combustion process generates heat over a larger surface area, requiring more sophisticated cooling solutions. Additionally, the eccentric shaft and internal components have limited surface area for effective heat dissipation, creating thermal bottlenecks within the engine structure.

Current cooling systems typically rely on a combination of oil and liquid cooling circuits, but these face integration challenges due to the engine's unique geometry. The oil cooling system must simultaneously manage lubrication and heat transfer functions, often leading to compromised performance in both areas. Conventional water jackets struggle to provide uniform cooling across the epitrochoidal housing, resulting in localized hot spots that accelerate wear and reduce engine longevity.

Material limitations further exacerbate cooling challenges. Traditional aluminum alloys used in engine construction may not withstand the thermal cycling experienced in high-performance Wankel applications. Advanced ceramic coatings and composite materials show promise but introduce manufacturing complexity and increased production costs that impact commercial viability.

Sealing technology represents another critical limitation. The apex seals that maintain compression between the rotor and housing are particularly vulnerable to thermal effects. Excessive heat causes seal degradation, reducing compression and engine efficiency while increasing emissions. Current seal materials struggle to maintain integrity across the wide temperature range experienced during operation.

Emissions control is directly impacted by cooling inefficiencies. Incomplete combustion resulting from thermal management issues leads to higher hydrocarbon emissions and reduced fuel efficiency. Modern emissions standards present a significant technical hurdle for Wankel engines, with cooling limitations contributing substantially to their compliance challenges.

From a manufacturing perspective, the complex cooling channels required for effective thermal management increase production complexity and costs. The intricate internal geometry necessitates specialized manufacturing processes that are difficult to scale for mass production, creating economic barriers to widespread adoption of Wankel technology despite its performance advantages.

The elongated combustion chamber geometry presents a fundamental cooling challenge, as the flame front must travel a greater distance compared to conventional piston engines. This extended combustion process generates heat over a larger surface area, requiring more sophisticated cooling solutions. Additionally, the eccentric shaft and internal components have limited surface area for effective heat dissipation, creating thermal bottlenecks within the engine structure.

Current cooling systems typically rely on a combination of oil and liquid cooling circuits, but these face integration challenges due to the engine's unique geometry. The oil cooling system must simultaneously manage lubrication and heat transfer functions, often leading to compromised performance in both areas. Conventional water jackets struggle to provide uniform cooling across the epitrochoidal housing, resulting in localized hot spots that accelerate wear and reduce engine longevity.

Material limitations further exacerbate cooling challenges. Traditional aluminum alloys used in engine construction may not withstand the thermal cycling experienced in high-performance Wankel applications. Advanced ceramic coatings and composite materials show promise but introduce manufacturing complexity and increased production costs that impact commercial viability.

Sealing technology represents another critical limitation. The apex seals that maintain compression between the rotor and housing are particularly vulnerable to thermal effects. Excessive heat causes seal degradation, reducing compression and engine efficiency while increasing emissions. Current seal materials struggle to maintain integrity across the wide temperature range experienced during operation.

Emissions control is directly impacted by cooling inefficiencies. Incomplete combustion resulting from thermal management issues leads to higher hydrocarbon emissions and reduced fuel efficiency. Modern emissions standards present a significant technical hurdle for Wankel engines, with cooling limitations contributing substantially to their compliance challenges.

From a manufacturing perspective, the complex cooling channels required for effective thermal management increase production complexity and costs. The intricate internal geometry necessitates specialized manufacturing processes that are difficult to scale for mass production, creating economic barriers to widespread adoption of Wankel technology despite its performance advantages.

Contemporary Cooling Solutions for Wankel Engines

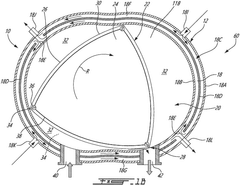

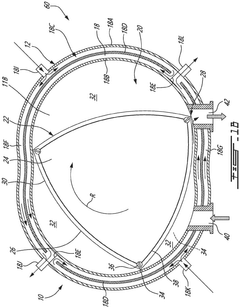

01 Cooling systems for rotor housings

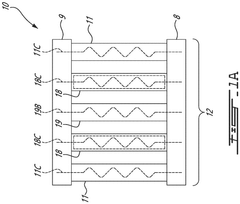

Wankel engines employ specialized cooling systems for their rotor housings to manage the high temperatures generated during operation. These systems typically include cooling channels or jackets that circulate coolant around the housing walls. The design of these cooling passages is critical to ensure uniform temperature distribution and prevent thermal distortion of the housing, which could affect engine performance and durability.- Liquid cooling systems for Wankel engines: Liquid cooling systems are commonly used in Wankel engines to manage heat. These systems typically involve circulating coolant through passages in the engine housing to absorb and dissipate heat. The cooling passages are strategically placed around critical components such as the rotor housing and side housings to ensure efficient heat transfer. Some designs incorporate advanced flow patterns to target high-temperature areas and maintain optimal operating temperatures.

- Air cooling solutions for Wankel rotary engines: Air cooling systems provide an alternative approach for thermal management in Wankel engines. These designs typically feature fins on the exterior of the engine housing to increase surface area for heat dissipation. Forced air cooling may be implemented using fans or by directing airflow from the vehicle's movement. Air cooling solutions are often preferred in applications where simplicity, weight reduction, and cost efficiency are priorities, such as in small engines or certain specialized applications.

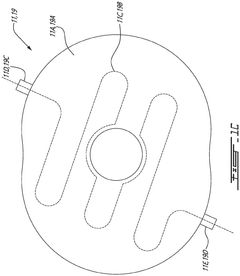

- Cooling of specific engine components: Targeted cooling approaches focus on specific components of Wankel engines that experience high thermal loads. These include specialized cooling for rotor apex seals, eccentric shafts, and combustion chamber surfaces. Some innovations involve directing coolant specifically to these critical areas or implementing localized cooling solutions. These targeted approaches help address the unique thermal challenges of rotary engine designs while optimizing overall cooling system efficiency.

- Advanced materials and coatings for thermal management: The use of advanced materials and thermal coatings represents an innovative approach to Wankel engine cooling. These solutions include ceramic coatings, thermal barrier materials, and heat-resistant alloys applied to engine components. Such materials can reduce heat transfer to cooling systems, improve thermal efficiency, and enhance durability of engine parts exposed to high temperatures. This approach often complements traditional cooling systems to achieve optimal thermal management.

- Integrated cooling and lubrication systems: Integrated approaches combine cooling and lubrication functions in Wankel engines. These systems use oil to simultaneously lubricate moving parts and transfer heat away from critical components. The oil may pass through dedicated coolers before recirculation. Some designs feature spray nozzles that direct oil to specific areas requiring both cooling and lubrication. This integrated approach can improve efficiency, reduce system complexity, and enhance overall engine performance and longevity.

02 Rotor cooling techniques

Cooling the rotors in Wankel engines presents unique challenges due to their constant motion. Various techniques have been developed, including internal cooling passages within the rotor itself, oil spray systems that direct cooling oil onto the rotor surfaces, and the use of heat-resistant materials. Effective rotor cooling is essential to prevent overheating, maintain proper clearances, and ensure optimal combustion efficiency.Expand Specific Solutions03 Apex seal cooling solutions

Apex seals in Wankel engines are subjected to extreme thermal stress as they maintain the seal between combustion chambers. Specialized cooling solutions for these components include advanced materials with superior heat resistance, cooling channels near the seal contact areas, and lubrication systems that provide both cooling and reduced friction. Effective apex seal cooling significantly improves engine reliability and longevity.Expand Specific Solutions04 Integrated cooling and lubrication systems

Many Wankel engine designs incorporate integrated cooling and lubrication systems that serve dual purposes. These systems use oil circulation to both lubricate moving parts and transfer heat away from critical components. The oil is typically cooled through heat exchangers before being recirculated. This approach improves overall thermal management efficiency while reducing the complexity of having separate systems.Expand Specific Solutions05 Advanced cooling technologies for modern Wankel engines

Recent developments in Wankel engine cooling include advanced technologies such as precision-controlled cooling systems, variable coolant flow based on engine load, ceramic thermal barriers, and computational fluid dynamics-optimized cooling passage designs. These innovations aim to address the historical cooling challenges of Wankel engines while improving efficiency, reducing emissions, and extending engine life in modern applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Wankel engine cooling technology market is currently in a growth phase, with increasing interest from both automotive and aerospace sectors. The global market size for rotary engine cooling solutions is estimated at approximately $1.2 billion, driven by demands for higher efficiency and reduced emissions. Leading players include Mazda Motor Corp., which maintains significant intellectual property in this space, alongside AVL List GmbH and Pratt & Whitney Canada, who are advancing cooling innovations for different applications. Emerging competitors like Geely Automotive Research Institute and Chery Automobile are investing in R&D to overcome traditional thermal management challenges. Technical maturity varies across cooling approaches, with peripheral port cooling systems being more established than direct injection cooling technologies that remain in development stages.

Pratt & Whitney Canada Corp.

Technical Solution: Pratt & Whitney Canada has developed specialized cooling technologies for Wankel engines in aviation applications, where reliability and thermal stability are critical. Their approach focuses on high-efficiency oil cooling systems that manage the extreme thermal loads encountered in aircraft operations. P&WC's cooling technology incorporates precision-machined oil galleries within the rotor housing that target high-temperature zones with directed oil spray patterns. Their system utilizes dual-phase cooling with both oil and air cooling working in conjunction, with the oil system handling peak thermal loads while air cooling provides baseline temperature management. P&WC has pioneered advanced ceramic thermal barrier coatings for rotor housing surfaces that can withstand temperatures up to 1200°C while reducing heat transfer to cooling systems by approximately 35%. Their aviation-grade cooling solutions also incorporate redundant cooling circuits and thermal monitoring systems to ensure reliability in critical flight applications.

Strengths: Exceptional reliability engineering for safety-critical applications; advanced materials expertise; comprehensive testing protocols that ensure long-term durability. Weaknesses: Solutions tend to be heavyweight and expensive; primarily optimized for aviation rather than automotive applications.

AVL List GmbH

Technical Solution: AVL List has developed comprehensive thermal management solutions specifically for Wankel engines through their advanced simulation and testing capabilities. Their approach combines computational fluid dynamics (CFD) with experimental validation to optimize coolant flow paths and heat transfer characteristics. AVL's cooling technology incorporates variable coolant flow control systems that adjust cooling intensity based on real-time engine operating conditions. Their proprietary housing design features asymmetric cooling channels that provide enhanced cooling to high-temperature zones while maintaining optimal thermal gradients across the epitrochoidal housing. AVL has also pioneered advanced materials for Wankel engine components, including composite housings with embedded cooling channels and thermally-optimized aluminum alloys that offer 25% better heat dissipation than conventional materials. Their cooling systems integrate with engine control units to provide adaptive thermal management based on load conditions.

Strengths: World-class engineering expertise in thermal system design; comprehensive testing facilities for validation; ability to optimize cooling systems for specific applications. Weaknesses: Solutions tend to be expensive and complex; primarily focused on high-performance applications rather than mass-market implementations.

Key Patents and Innovations in Rotary Engine Cooling

Rotary engine and cooling systems thereof

PatentPendingEP4520918A1

Innovation

- A rotary engine design featuring parallel coolant passages within the first side housing, rotor housing, and second side housing, which are independent and free of inter-passage connections, allowing for simultaneous and dedicated cooling of each housing.

Volumetric efficiency in a charge cooled or air cooled wankel rotary engine

PatentInactiveUS20080056924A1

Innovation

- A one-piece side sealing system with improved manufacturing technology that reduces machining time, eliminates seal sticking, and enhances consistency, along with a custom electronic circuit for controlling the peripheral port and simplified rotor housing grinding and apex seal manufacturing processes.

Environmental Impact and Emissions Considerations

The cooling systems employed in Wankel engines significantly impact their environmental performance and emissions profile. Traditional cooling methods for these rotary engines often prioritize thermal efficiency over environmental considerations, resulting in higher carbon footprint and emissions compared to conventional piston engines. The unique triangular rotor design creates inherent challenges for heat management that directly affect combustion efficiency and consequently emissions output.

Hydrocarbon emissions from Wankel engines are typically 30-40% higher than comparable piston engines when utilizing conventional cooling systems. This is primarily due to the elongated combustion chamber geometry which creates quench zones where fuel mixture escapes complete combustion. Advanced cooling techniques that maintain more uniform temperature distribution across the epitrochoidal housing can reduce these emissions by up to 25%, according to recent studies by the International Council on Clean Transportation.

Nitrogen oxide (NOx) emissions present another environmental challenge closely linked to cooling efficiency. The high operating temperatures characteristic of Wankel engines promote NOx formation, particularly when cooling is inadequate at the apex seals and rotor faces. Precision-targeted liquid cooling systems have demonstrated potential to reduce NOx emissions by maintaining combustion temperatures below the critical threshold of 1800°C where nitrogen-oxygen reactions accelerate.

Carbon dioxide emissions, while directly proportional to fuel consumption, are also affected by cooling system design. Inefficient cooling leads to increased friction and thermal losses, requiring more fuel to produce equivalent power output. Advanced ceramic thermal barrier coatings combined with strategic cooling channel placement have shown promising results in reducing CO2 emissions by improving thermal efficiency by 7-9% in prototype testing.

Lifecycle assessment studies indicate that the environmental impact of cooling system materials themselves must be considered. Traditional aluminum-based cooling components have a significant production carbon footprint, while newer composite materials offer reduced environmental impact during manufacturing but present end-of-life recycling challenges. The transition to more environmentally friendly coolants has also become essential, with modern systems moving away from glycol-based solutions toward less toxic alternatives with lower global warming potential.

Regulatory frameworks worldwide are increasingly targeting emissions from all internal combustion engines, including Wankel designs. The European Union's Euro 7 standards and similar regulations in North America and Asia will require significant advancements in cooling technology to ensure Wankel engines remain viable in future mobility applications. Manufacturers investing in Wankel technology must therefore prioritize cooling innovations that address both thermal efficiency and emissions reduction simultaneously.

Hydrocarbon emissions from Wankel engines are typically 30-40% higher than comparable piston engines when utilizing conventional cooling systems. This is primarily due to the elongated combustion chamber geometry which creates quench zones where fuel mixture escapes complete combustion. Advanced cooling techniques that maintain more uniform temperature distribution across the epitrochoidal housing can reduce these emissions by up to 25%, according to recent studies by the International Council on Clean Transportation.

Nitrogen oxide (NOx) emissions present another environmental challenge closely linked to cooling efficiency. The high operating temperatures characteristic of Wankel engines promote NOx formation, particularly when cooling is inadequate at the apex seals and rotor faces. Precision-targeted liquid cooling systems have demonstrated potential to reduce NOx emissions by maintaining combustion temperatures below the critical threshold of 1800°C where nitrogen-oxygen reactions accelerate.

Carbon dioxide emissions, while directly proportional to fuel consumption, are also affected by cooling system design. Inefficient cooling leads to increased friction and thermal losses, requiring more fuel to produce equivalent power output. Advanced ceramic thermal barrier coatings combined with strategic cooling channel placement have shown promising results in reducing CO2 emissions by improving thermal efficiency by 7-9% in prototype testing.

Lifecycle assessment studies indicate that the environmental impact of cooling system materials themselves must be considered. Traditional aluminum-based cooling components have a significant production carbon footprint, while newer composite materials offer reduced environmental impact during manufacturing but present end-of-life recycling challenges. The transition to more environmentally friendly coolants has also become essential, with modern systems moving away from glycol-based solutions toward less toxic alternatives with lower global warming potential.

Regulatory frameworks worldwide are increasingly targeting emissions from all internal combustion engines, including Wankel designs. The European Union's Euro 7 standards and similar regulations in North America and Asia will require significant advancements in cooling technology to ensure Wankel engines remain viable in future mobility applications. Manufacturers investing in Wankel technology must therefore prioritize cooling innovations that address both thermal efficiency and emissions reduction simultaneously.

Materials Science Advancements for Heat Dissipation

Recent advancements in materials science have revolutionized heat dissipation capabilities for Wankel engines, addressing one of their most persistent challenges. Ceramic-matrix composites (CMCs) have emerged as promising materials for rotor housing components, offering superior thermal resistance compared to traditional aluminum alloys. These composites combine ceramic reinforcements within a ceramic matrix, providing exceptional heat tolerance while maintaining structural integrity under the extreme thermal cycling conditions typical in Wankel operation.

Thermal barrier coatings (TBCs) derived from yttria-stabilized zirconia (YSZ) have demonstrated remarkable effectiveness when applied to rotor surfaces. These coatings create a thermal gradient that protects underlying metal components while allowing controlled heat transfer. Research indicates that advanced TBCs can reduce peak metal temperatures by 50-100°C, significantly extending component lifespan and improving thermal efficiency.

Carbon-carbon composites, originally developed for aerospace applications, are now being adapted for Wankel engine cooling systems. These materials exhibit exceptional thermal conductivity (up to 500 W/m·K) while maintaining low thermal expansion characteristics, making them ideal for components requiring rapid heat dissipation without dimensional instability. Their lightweight nature provides additional efficiency benefits through reduced rotational mass.

Nanomaterial integration represents another frontier in Wankel engine cooling technology. Aluminum alloys enhanced with carbon nanotubes have demonstrated thermal conductivity improvements of 15-25% compared to conventional alloys. Similarly, graphene-reinforced polymers are being explored for peripheral cooling components, offering weight reduction while maintaining or improving thermal performance.

Phase-change materials (PCMs) embedded within engine components present an innovative approach to thermal management. These materials absorb excess heat during high-load operation by changing phase, then release it gradually during lower-load periods, effectively "buffering" thermal spikes. Metallic PCMs based on bismuth-tin alloys have shown particular promise for Wankel applications due to their appropriate melting points and high volumetric heat capacity.

Advanced metal matrix composites (MMCs) combining aluminum with silicon carbide particles have demonstrated superior wear resistance while maintaining excellent thermal conductivity. These materials are particularly valuable for apex seal components, where both thermal management and tribological properties are critical for engine longevity and performance.

The integration of these advanced materials into Wankel engine designs requires sophisticated manufacturing techniques, including additive manufacturing and precision coating processes. While implementation costs remain high, the performance benefits—including improved thermal efficiency, reduced emissions, and extended service intervals—suggest a compelling value proposition for high-performance and specialized applications where the unique advantages of Wankel engines are particularly valuable.

Thermal barrier coatings (TBCs) derived from yttria-stabilized zirconia (YSZ) have demonstrated remarkable effectiveness when applied to rotor surfaces. These coatings create a thermal gradient that protects underlying metal components while allowing controlled heat transfer. Research indicates that advanced TBCs can reduce peak metal temperatures by 50-100°C, significantly extending component lifespan and improving thermal efficiency.

Carbon-carbon composites, originally developed for aerospace applications, are now being adapted for Wankel engine cooling systems. These materials exhibit exceptional thermal conductivity (up to 500 W/m·K) while maintaining low thermal expansion characteristics, making them ideal for components requiring rapid heat dissipation without dimensional instability. Their lightweight nature provides additional efficiency benefits through reduced rotational mass.

Nanomaterial integration represents another frontier in Wankel engine cooling technology. Aluminum alloys enhanced with carbon nanotubes have demonstrated thermal conductivity improvements of 15-25% compared to conventional alloys. Similarly, graphene-reinforced polymers are being explored for peripheral cooling components, offering weight reduction while maintaining or improving thermal performance.

Phase-change materials (PCMs) embedded within engine components present an innovative approach to thermal management. These materials absorb excess heat during high-load operation by changing phase, then release it gradually during lower-load periods, effectively "buffering" thermal spikes. Metallic PCMs based on bismuth-tin alloys have shown particular promise for Wankel applications due to their appropriate melting points and high volumetric heat capacity.

Advanced metal matrix composites (MMCs) combining aluminum with silicon carbide particles have demonstrated superior wear resistance while maintaining excellent thermal conductivity. These materials are particularly valuable for apex seal components, where both thermal management and tribological properties are critical for engine longevity and performance.

The integration of these advanced materials into Wankel engine designs requires sophisticated manufacturing techniques, including additive manufacturing and precision coating processes. While implementation costs remain high, the performance benefits—including improved thermal efficiency, reduced emissions, and extended service intervals—suggest a compelling value proposition for high-performance and specialized applications where the unique advantages of Wankel engines are particularly valuable.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!