How to Measure Wankel Engine Thermal Efficiency?

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Thermal Efficiency Background and Objectives

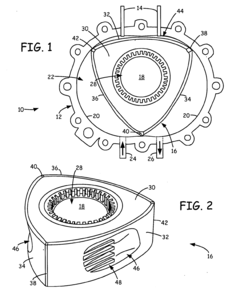

The Wankel rotary engine, first developed by German engineer Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique design features a triangular rotor that revolves within an epitrochoid-shaped housing, creating three combustion chambers that simultaneously perform intake, compression, combustion, and exhaust processes. This elegant mechanical solution offers advantages in terms of weight, size, and smoothness of operation compared to traditional engines.

The evolution of Wankel engine technology has been marked by periods of intense development followed by relative dormancy. After initial enthusiasm in the 1960s and 1970s, with manufacturers like NSU, Mazda, and Citroën incorporating rotary engines into production vehicles, interest waned due to persistent challenges with fuel efficiency and emissions. However, recent advancements in materials science, computational fluid dynamics, and manufacturing techniques have sparked renewed interest in rotary engine technology.

Thermal efficiency—the ratio of useful work output to energy input—remains the critical performance metric for any heat engine. For Wankel engines, this parameter has historically been their Achilles' heel, with typical thermal efficiencies ranging from 15-25%, compared to modern reciprocating engines achieving 30-40%. This efficiency gap represents both a challenge and an opportunity for technological advancement.

The measurement and improvement of Wankel engine thermal efficiency has become increasingly important in the context of stringent global emissions regulations and the push toward more sustainable transportation solutions. While electric propulsion dominates current green mobility discussions, optimized internal combustion engines, including advanced rotary designs, may play a vital role in specific applications or as range extenders in hybrid systems.

The primary objectives of investigating Wankel engine thermal efficiency measurement include establishing standardized testing protocols that account for the unique operational characteristics of rotary engines, developing accurate real-time monitoring systems for thermal performance, and creating predictive models that can guide design improvements. Additionally, there is significant interest in understanding how modern technologies such as direct injection, variable compression ratios, and advanced cooling systems might be adapted to enhance rotary engine efficiency.

Recent developments, particularly Mazda's announcement of rotary range extenders for electric vehicles and potential applications in drone and aerospace industries, underscore the importance of precise thermal efficiency measurement as a foundation for future innovation. The technology trajectory suggests potential convergence with hybrid systems, hydrogen combustion, and other alternative fuel applications, further emphasizing the need for sophisticated efficiency metrics.

The evolution of Wankel engine technology has been marked by periods of intense development followed by relative dormancy. After initial enthusiasm in the 1960s and 1970s, with manufacturers like NSU, Mazda, and Citroën incorporating rotary engines into production vehicles, interest waned due to persistent challenges with fuel efficiency and emissions. However, recent advancements in materials science, computational fluid dynamics, and manufacturing techniques have sparked renewed interest in rotary engine technology.

Thermal efficiency—the ratio of useful work output to energy input—remains the critical performance metric for any heat engine. For Wankel engines, this parameter has historically been their Achilles' heel, with typical thermal efficiencies ranging from 15-25%, compared to modern reciprocating engines achieving 30-40%. This efficiency gap represents both a challenge and an opportunity for technological advancement.

The measurement and improvement of Wankel engine thermal efficiency has become increasingly important in the context of stringent global emissions regulations and the push toward more sustainable transportation solutions. While electric propulsion dominates current green mobility discussions, optimized internal combustion engines, including advanced rotary designs, may play a vital role in specific applications or as range extenders in hybrid systems.

The primary objectives of investigating Wankel engine thermal efficiency measurement include establishing standardized testing protocols that account for the unique operational characteristics of rotary engines, developing accurate real-time monitoring systems for thermal performance, and creating predictive models that can guide design improvements. Additionally, there is significant interest in understanding how modern technologies such as direct injection, variable compression ratios, and advanced cooling systems might be adapted to enhance rotary engine efficiency.

Recent developments, particularly Mazda's announcement of rotary range extenders for electric vehicles and potential applications in drone and aerospace industries, underscore the importance of precise thermal efficiency measurement as a foundation for future innovation. The technology trajectory suggests potential convergence with hybrid systems, hydrogen combustion, and other alternative fuel applications, further emphasizing the need for sophisticated efficiency metrics.

Market Analysis of Rotary Engine Applications

The rotary engine market has experienced significant shifts over the past decade, with applications expanding beyond traditional automotive uses. Currently, the global rotary engine market is valued at approximately 1.2 billion USD, with a compound annual growth rate of 3.7% projected through 2030. This growth is primarily driven by emerging applications in unmanned aerial vehicles (UAVs), marine propulsion systems, and specialized power generation units.

The automotive sector remains the largest application segment, accounting for roughly 45% of the total market share. However, this represents a decline from previous decades when automotive applications dominated over 70% of the market. Mazda's decision to discontinue mass production of rotary-powered vehicles in 2012 significantly impacted this segment, though their recent reintroduction of rotary technology as range extenders in hybrid vehicles signals renewed interest.

Aviation and UAV applications have emerged as the fastest-growing segment, with 22% annual growth. The rotary engine's favorable power-to-weight ratio makes it particularly suitable for small aircraft and drone applications where weight considerations are critical. Companies like UAV Engines Ltd and Austro Engine have developed specialized Wankel engines optimized for these applications.

The marine sector represents approximately 18% of current applications, with particular adoption in personal watercraft and small recreational boats. The compact design and smooth operation characteristics of rotary engines provide advantages in these applications where space constraints and vibration reduction are valued.

Power generation applications, including portable generators and specialized power units, constitute about 15% of the market. These applications benefit from the rotary engine's compact size and relatively low vibration characteristics.

Regional analysis shows Asia-Pacific leading market growth at 4.5% annually, driven by increasing industrial applications and rising demand in emerging economies. North America follows with 3.9% growth, primarily in specialized applications like UAVs and military equipment. Europe shows more modest growth at 2.8%, focused on high-end applications and research initiatives.

Market challenges include competition from increasingly efficient conventional engines and the rapid advancement of electric propulsion systems. The thermal efficiency limitations of Wankel engines remain a significant barrier to wider adoption, particularly in applications where fuel economy is prioritized. This underscores the importance of research into measuring and improving thermal efficiency as a key factor in expanding market potential.

The automotive sector remains the largest application segment, accounting for roughly 45% of the total market share. However, this represents a decline from previous decades when automotive applications dominated over 70% of the market. Mazda's decision to discontinue mass production of rotary-powered vehicles in 2012 significantly impacted this segment, though their recent reintroduction of rotary technology as range extenders in hybrid vehicles signals renewed interest.

Aviation and UAV applications have emerged as the fastest-growing segment, with 22% annual growth. The rotary engine's favorable power-to-weight ratio makes it particularly suitable for small aircraft and drone applications where weight considerations are critical. Companies like UAV Engines Ltd and Austro Engine have developed specialized Wankel engines optimized for these applications.

The marine sector represents approximately 18% of current applications, with particular adoption in personal watercraft and small recreational boats. The compact design and smooth operation characteristics of rotary engines provide advantages in these applications where space constraints and vibration reduction are valued.

Power generation applications, including portable generators and specialized power units, constitute about 15% of the market. These applications benefit from the rotary engine's compact size and relatively low vibration characteristics.

Regional analysis shows Asia-Pacific leading market growth at 4.5% annually, driven by increasing industrial applications and rising demand in emerging economies. North America follows with 3.9% growth, primarily in specialized applications like UAVs and military equipment. Europe shows more modest growth at 2.8%, focused on high-end applications and research initiatives.

Market challenges include competition from increasingly efficient conventional engines and the rapid advancement of electric propulsion systems. The thermal efficiency limitations of Wankel engines remain a significant barrier to wider adoption, particularly in applications where fuel economy is prioritized. This underscores the importance of research into measuring and improving thermal efficiency as a key factor in expanding market potential.

Current Challenges in Wankel Engine Efficiency Measurement

Despite significant advancements in internal combustion engine technology, the Wankel rotary engine presents unique challenges in thermal efficiency measurement that continue to perplex engineers and researchers. The non-conventional geometry and operating principles of the Wankel engine create fundamental difficulties in applying standard measurement methodologies developed for reciprocating engines.

One primary challenge lies in accurately defining the thermodynamic cycles within the Wankel engine. Unlike traditional piston engines with clearly defined strokes, the continuous rotational motion of the rotor creates overlapping cycles where intake, compression, combustion, and exhaust occur simultaneously in different chambers. This temporal and spatial overlap complicates the isolation of individual cycle phases for precise measurement.

Temperature distribution measurement presents another significant obstacle. The triangular rotor and epitrochoidal housing create complex thermal gradients that are difficult to map comprehensively. Critical hotspots form at the rotor tips and housing walls, but placing sufficient temperature sensors without disrupting normal operation remains problematic. Non-invasive thermal imaging techniques often struggle with the enclosed nature of the engine and the rapid movement of components.

Combustion efficiency analysis is further complicated by the elongated combustion chamber geometry. The flame propagation patterns in Wankel engines differ substantially from those in conventional engines, leading to potential incomplete combustion and variable pressure development. These factors make standard pressure-based efficiency calculations less reliable without significant adaptation.

Sealing system dynamics introduce additional measurement complexities. The apex seals, which maintain compression between chambers, experience variable friction and leakage depending on operating conditions. Quantifying these losses accurately requires specialized instrumentation that can monitor seal behavior during operation without compromising engine function.

Heat transfer characterization poses perhaps the most formidable challenge. The Wankel's higher surface-to-volume ratio compared to reciprocating engines results in greater heat rejection to cooling systems. However, distinguishing between productive work and waste heat becomes exceptionally difficult due to the engine's geometry and operational characteristics.

Standardization issues further complicate comparative analysis. While reciprocating engines benefit from well-established testing protocols and efficiency benchmarks, Wankel engines lack equivalent standardized methodologies. This absence of consensus on measurement approaches makes cross-platform comparisons problematic and hinders objective evaluation of technological improvements.

Finally, the limited commercial deployment of Wankel engines has restricted research investment, resulting in fewer specialized measurement tools and analytical frameworks compared to conventional engines. This resource limitation compounds the inherent technical challenges, creating a significant barrier to comprehensive thermal efficiency assessment.

One primary challenge lies in accurately defining the thermodynamic cycles within the Wankel engine. Unlike traditional piston engines with clearly defined strokes, the continuous rotational motion of the rotor creates overlapping cycles where intake, compression, combustion, and exhaust occur simultaneously in different chambers. This temporal and spatial overlap complicates the isolation of individual cycle phases for precise measurement.

Temperature distribution measurement presents another significant obstacle. The triangular rotor and epitrochoidal housing create complex thermal gradients that are difficult to map comprehensively. Critical hotspots form at the rotor tips and housing walls, but placing sufficient temperature sensors without disrupting normal operation remains problematic. Non-invasive thermal imaging techniques often struggle with the enclosed nature of the engine and the rapid movement of components.

Combustion efficiency analysis is further complicated by the elongated combustion chamber geometry. The flame propagation patterns in Wankel engines differ substantially from those in conventional engines, leading to potential incomplete combustion and variable pressure development. These factors make standard pressure-based efficiency calculations less reliable without significant adaptation.

Sealing system dynamics introduce additional measurement complexities. The apex seals, which maintain compression between chambers, experience variable friction and leakage depending on operating conditions. Quantifying these losses accurately requires specialized instrumentation that can monitor seal behavior during operation without compromising engine function.

Heat transfer characterization poses perhaps the most formidable challenge. The Wankel's higher surface-to-volume ratio compared to reciprocating engines results in greater heat rejection to cooling systems. However, distinguishing between productive work and waste heat becomes exceptionally difficult due to the engine's geometry and operational characteristics.

Standardization issues further complicate comparative analysis. While reciprocating engines benefit from well-established testing protocols and efficiency benchmarks, Wankel engines lack equivalent standardized methodologies. This absence of consensus on measurement approaches makes cross-platform comparisons problematic and hinders objective evaluation of technological improvements.

Finally, the limited commercial deployment of Wankel engines has restricted research investment, resulting in fewer specialized measurement tools and analytical frameworks compared to conventional engines. This resource limitation compounds the inherent technical challenges, creating a significant barrier to comprehensive thermal efficiency assessment.

Established Methodologies for Thermal Efficiency Assessment

01 Cooling system improvements for thermal efficiency

Various cooling system designs have been developed to improve the thermal efficiency of Wankel engines. These include specialized cooling channels, improved heat dissipation mechanisms, and thermal management systems that help maintain optimal operating temperatures. By effectively managing heat distribution and preventing localized overheating, these cooling innovations help increase the overall thermal efficiency of the rotary engine.- Cooling system improvements for Wankel engines: Improved cooling systems are essential for enhancing the thermal efficiency of Wankel engines. These innovations include advanced cooling channels, optimized coolant flow paths, and specialized cooling structures for critical components like rotors and housings. By maintaining optimal operating temperatures and reducing thermal stress, these cooling systems prevent overheating and improve overall engine efficiency.

- Combustion chamber design optimization: Optimizing the combustion chamber design is crucial for improving the thermal efficiency of Wankel engines. Innovations include modified chamber geometries, improved sealing mechanisms, and enhanced fuel-air mixture control. These design improvements promote more complete combustion, reduce heat losses, and minimize energy waste, resulting in higher thermal efficiency and better fuel economy.

- Integration of waste heat recovery systems: Waste heat recovery systems can significantly enhance the thermal efficiency of Wankel engines by capturing and utilizing heat that would otherwise be lost. These systems include thermoelectric generators, exhaust heat recovery units, and regenerative systems that convert thermal energy into useful work. By recapturing waste heat, these innovations improve overall engine efficiency and reduce fuel consumption.

- Advanced materials and coatings for thermal management: The use of advanced materials and specialized coatings plays a significant role in improving the thermal efficiency of Wankel engines. These innovations include ceramic components, thermal barrier coatings, and high-temperature alloys that can withstand extreme operating conditions. By reducing heat transfer, improving wear resistance, and enabling higher operating temperatures, these materials enhance overall engine performance and efficiency.

- Hybrid and multi-fuel Wankel engine configurations: Hybrid and multi-fuel configurations represent innovative approaches to improving Wankel engine thermal efficiency. These designs incorporate electric motors, alternative fuels, or multiple energy sources to optimize performance under various operating conditions. By leveraging the strengths of different power sources and adapting to changing load requirements, these hybrid systems achieve higher overall thermal efficiency than conventional Wankel engines.

02 Combustion chamber design optimization

Modifications to the combustion chamber geometry and design have been implemented to enhance the thermal efficiency of Wankel engines. These innovations include changes to the rotor shape, housing configuration, and combustion pocket design. By optimizing the combustion chamber, these designs improve fuel burning efficiency, reduce heat losses, and enhance the thermodynamic cycle, resulting in better overall thermal efficiency.Expand Specific Solutions03 Advanced sealing technologies

Improved sealing systems have been developed to address one of the main efficiency challenges in Wankel engines. These innovations include enhanced apex seals, side seals, and oil sealing mechanisms that reduce leakage between chambers. By minimizing gas leakage during compression and power strokes, these sealing technologies help maintain higher compression ratios and improve the thermal efficiency of the rotary engine.Expand Specific Solutions04 Fuel delivery and ignition system enhancements

Innovations in fuel delivery and ignition systems have been implemented to improve the combustion process in Wankel engines. These include direct injection technologies, stratified charge systems, and advanced ignition timing control. By optimizing the fuel-air mixture and ensuring more complete combustion, these systems reduce fuel consumption and increase the thermal efficiency of the rotary engine.Expand Specific Solutions05 Waste heat recovery systems

Various waste heat recovery mechanisms have been developed to capture and utilize thermal energy that would otherwise be lost in Wankel engines. These systems include exhaust heat recovery, regenerative cycles, and thermoelectric generators. By recapturing waste heat and converting it to useful energy, these innovations significantly improve the overall thermal efficiency of the rotary engine system.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Wankel engine thermal efficiency measurement landscape is currently in a growth phase, with increasing market interest driven by renewed focus on rotary engine applications. The market size remains relatively niche but is expanding as automotive and energy sectors seek alternative engine technologies. From a technical maturity perspective, research institutions like Beihang University, Xi'an Jiaotong University, and Tohoku University are leading academic advancements, while companies including GM Global Technology Operations, Mitsubishi Motors, and Exency Ltd. are developing practical measurement methodologies. Volkswagen AG and Mazda have historically invested in rotary engine technology, with recent innovations focusing on hybrid applications requiring more sophisticated thermal efficiency measurement techniques. The field is characterized by specialized expertise concentrated among a limited number of players working to overcome traditional rotary engine efficiency challenges.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced thermal efficiency measurement systems for Wankel engines that utilize direct and indirect measurement approaches. Their direct method employs in-cylinder pressure sensors and crankshaft position encoders to calculate indicated thermal efficiency through pressure-volume diagrams. For brake thermal efficiency, GM uses high-precision dynamometers to measure output power while simultaneously monitoring fuel consumption with Coriolis flow meters. They've implemented a comprehensive heat balance analysis system that tracks energy distribution through the engine, including exhaust gas calorimetry and cooling system heat rejection measurements. GM's approach incorporates infrared thermal imaging to identify hotspots and thermal gradients across the epitrochoid housing, helping optimize cooling strategies. Their testing protocols include standardized operating conditions across various loads and speeds to generate efficiency maps that accurately represent real-world performance characteristics.

Strengths: Comprehensive measurement approach combining multiple data points for high accuracy; advanced instrumentation for precise real-time monitoring; standardized testing protocols ensure repeatability. Weaknesses: Complex measurement system requires significant expertise; expensive specialized equipment increases testing costs; thermal imaging analysis requires careful interpretation.

Volkswagen AG

Technical Solution: Volkswagen AG has developed a comprehensive thermal efficiency measurement methodology for Wankel engines that integrates both laboratory and computational approaches. Their system employs high-precision fuel consumption measurement using Coriolis flow meters with accuracy better than ±0.1%, combined with power output measurement via AC dynamometers. VW's approach features specialized in-chamber pressure sensors installed at multiple points along the epitrochoid housing to capture the complete pressure profile throughout the eccentric rotation cycle. Their methodology incorporates a detailed heat balance analysis that quantifies energy distribution through exhaust gas enthalpy measurement, cooling system heat rejection, oil system heat transfer, and radiation losses. VW has implemented advanced exhaust gas analysis using FTIR spectroscopy to determine combustion completeness and identify efficiency-reducing incomplete combustion products. Their system includes specialized correction algorithms that account for the geometric complexities of the Wankel's combustion chamber and the resulting impact on thermodynamic calculations. VW's approach also incorporates computational fluid dynamics (CFD) validation to correlate measured data with theoretical models, allowing for identification of efficiency improvement opportunities.

Strengths: Highly accurate fuel measurement system provides precise input energy values; multi-point pressure sensing captures complete thermodynamic cycle; integration of experimental and computational approaches enhances analysis depth. Weaknesses: Complex measurement infrastructure requires significant capital investment; specialized sensors need frequent calibration to maintain accuracy; CFD model validation requires extensive expertise in rotary engine thermodynamics.

Key Patents and Research in Rotary Engine Thermodynamics

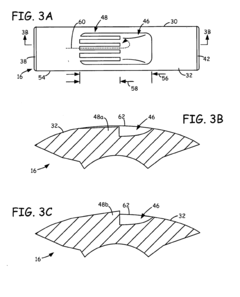

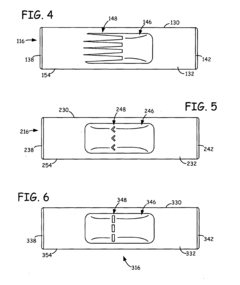

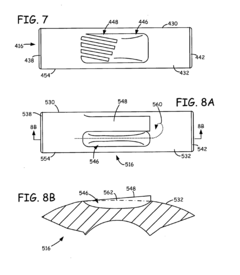

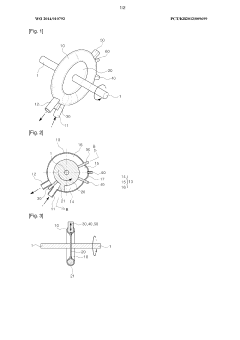

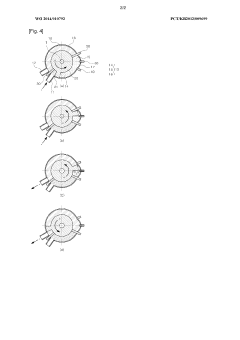

Rotors having flow-modifying members for use in rotary engines

PatentInactiveEP1933016A2

Innovation

- Incorporating recessed pockets with flow-modifying members, such as ramp-shaped, tapered, V-shaped, bluff body, or diagonal ramp-shaped structures on the rotor faces to control fuel/air mixing and flame propagation by generating vortex flows and turbulence, which extend beyond the recessed pockets into the combustion chamber.

Structure of rotary internal combustion engine

PatentWO2014010792A1

Innovation

- A rotary internal combustion engine structure that converts up-and-down linear motion to rotary motion by rotating a piston connected to a rotary shaft, simplifying the engine design and reducing noise and vibration, while enhancing thermal efficiency through an optimized exhaust cycle.

Environmental Impact and Emissions Considerations

The environmental impact of Wankel engines is intrinsically linked to their thermal efficiency measurement methodologies. Traditional Wankel rotary engines have historically faced criticism for higher fuel consumption and emissions compared to conventional piston engines, making accurate efficiency measurement crucial for environmental assessment.

Emissions testing for Wankel engines requires specialized protocols that account for their unique combustion characteristics. The elongated combustion chamber and moving rotor create distinctive emission profiles that standard testing procedures may not adequately capture. Particularly, the measurement of unburned hydrocarbons (UHC) requires careful consideration due to the engine's geometry allowing fuel to escape combustion more readily than in piston engines.

Carbon dioxide emissions correlate directly with thermal efficiency measurements, as improved efficiency generally results in reduced CO2 output per unit of work produced. When measuring Wankel engine efficiency, researchers must simultaneously monitor CO2 emissions to validate efficiency improvements and ensure environmental benefits. This dual measurement approach provides a more comprehensive understanding of the engine's ecological footprint.

Nitrogen oxide (NOx) emissions present a particular challenge in Wankel efficiency testing. The high operating temperatures that can improve thermal efficiency may simultaneously increase NOx formation. Efficiency measurement protocols must therefore incorporate NOx monitoring to prevent optimization scenarios that improve efficiency at the expense of increased harmful emissions.

Modern emissions regulations have significantly impacted Wankel engine development and efficiency measurement practices. Testing methodologies must now align with increasingly stringent standards such as Euro 6d and EPA Tier 3. This regulatory landscape necessitates more sophisticated measurement approaches that consider the complete emissions profile alongside traditional efficiency metrics.

The potential application of Wankel engines as range extenders in hybrid electric vehicles introduces new environmental considerations for efficiency measurement. In these applications, measuring thermal efficiency must account for intermittent operation patterns and integration with electrical systems, requiring modified testing protocols that reflect real-world usage scenarios rather than continuous operation.

Lifecycle assessment approaches are increasingly being incorporated into comprehensive Wankel efficiency evaluations. These methods consider not only operational emissions but also manufacturing impacts and end-of-life disposal, providing a more holistic environmental perspective that extends beyond simple thermal efficiency measurements.

Emissions testing for Wankel engines requires specialized protocols that account for their unique combustion characteristics. The elongated combustion chamber and moving rotor create distinctive emission profiles that standard testing procedures may not adequately capture. Particularly, the measurement of unburned hydrocarbons (UHC) requires careful consideration due to the engine's geometry allowing fuel to escape combustion more readily than in piston engines.

Carbon dioxide emissions correlate directly with thermal efficiency measurements, as improved efficiency generally results in reduced CO2 output per unit of work produced. When measuring Wankel engine efficiency, researchers must simultaneously monitor CO2 emissions to validate efficiency improvements and ensure environmental benefits. This dual measurement approach provides a more comprehensive understanding of the engine's ecological footprint.

Nitrogen oxide (NOx) emissions present a particular challenge in Wankel efficiency testing. The high operating temperatures that can improve thermal efficiency may simultaneously increase NOx formation. Efficiency measurement protocols must therefore incorporate NOx monitoring to prevent optimization scenarios that improve efficiency at the expense of increased harmful emissions.

Modern emissions regulations have significantly impacted Wankel engine development and efficiency measurement practices. Testing methodologies must now align with increasingly stringent standards such as Euro 6d and EPA Tier 3. This regulatory landscape necessitates more sophisticated measurement approaches that consider the complete emissions profile alongside traditional efficiency metrics.

The potential application of Wankel engines as range extenders in hybrid electric vehicles introduces new environmental considerations for efficiency measurement. In these applications, measuring thermal efficiency must account for intermittent operation patterns and integration with electrical systems, requiring modified testing protocols that reflect real-world usage scenarios rather than continuous operation.

Lifecycle assessment approaches are increasingly being incorporated into comprehensive Wankel efficiency evaluations. These methods consider not only operational emissions but also manufacturing impacts and end-of-life disposal, providing a more holistic environmental perspective that extends beyond simple thermal efficiency measurements.

Comparative Analysis with Conventional Engine Technologies

When comparing the Wankel engine's thermal efficiency measurement with conventional reciprocating engines, several fundamental differences emerge. The Wankel's unique rotary design creates distinct thermodynamic behaviors that require specialized measurement approaches. Traditional reciprocating engines typically achieve thermal efficiencies between 25-30% for gasoline and 35-45% for diesel variants, while Wankel engines historically demonstrate lower efficiencies, ranging from 15-25% under standard operating conditions.

The measurement methodologies differ significantly between these engine types. Conventional engines benefit from well-established testing protocols with standardized equipment and procedures developed over a century of refinement. In contrast, Wankel efficiency measurement requires specialized instrumentation to account for its unique combustion chamber geometry and dynamic sealing characteristics.

Heat transfer mechanisms represent another critical difference. Reciprocating engines exhibit more predictable heat distribution patterns with clearly defined cylinder walls and cooling passages. The Wankel's epitrochoidal housing creates irregular heat flux patterns that complicate thermal mapping and efficiency calculations, requiring more sophisticated thermal imaging and sensor placement strategies.

Combustion efficiency analysis also varies substantially between these engine architectures. Conventional engines maintain relatively consistent combustion chamber volumes throughout the power cycle, whereas the Wankel's continuously changing chamber geometry creates variable combustion conditions that must be accounted for in efficiency measurements. This necessitates more complex sampling techniques to accurately capture exhaust gas composition and unburned fuel content.

From a practical measurement perspective, conventional engines allow for more straightforward instrumentation access points. Their design permits direct sensor placement at critical locations without significantly disrupting normal operation. Wankel engines present greater challenges for instrumentation integration due to their compact design and moving components, often requiring custom-engineered measurement solutions.

The efficiency gap between these technologies has narrowed in recent years through innovations in Wankel sealing technology, advanced materials, and optimized combustion strategies. Modern measurement techniques utilizing computational fluid dynamics (CFD) modeling, high-precision thermal imaging, and real-time exhaust gas analysis have enabled more accurate efficiency comparisons between these fundamentally different engine architectures.

The measurement methodologies differ significantly between these engine types. Conventional engines benefit from well-established testing protocols with standardized equipment and procedures developed over a century of refinement. In contrast, Wankel efficiency measurement requires specialized instrumentation to account for its unique combustion chamber geometry and dynamic sealing characteristics.

Heat transfer mechanisms represent another critical difference. Reciprocating engines exhibit more predictable heat distribution patterns with clearly defined cylinder walls and cooling passages. The Wankel's epitrochoidal housing creates irregular heat flux patterns that complicate thermal mapping and efficiency calculations, requiring more sophisticated thermal imaging and sensor placement strategies.

Combustion efficiency analysis also varies substantially between these engine architectures. Conventional engines maintain relatively consistent combustion chamber volumes throughout the power cycle, whereas the Wankel's continuously changing chamber geometry creates variable combustion conditions that must be accounted for in efficiency measurements. This necessitates more complex sampling techniques to accurately capture exhaust gas composition and unburned fuel content.

From a practical measurement perspective, conventional engines allow for more straightforward instrumentation access points. Their design permits direct sensor placement at critical locations without significantly disrupting normal operation. Wankel engines present greater challenges for instrumentation integration due to their compact design and moving components, often requiring custom-engineered measurement solutions.

The efficiency gap between these technologies has narrowed in recent years through innovations in Wankel sealing technology, advanced materials, and optimized combustion strategies. Modern measurement techniques utilizing computational fluid dynamics (CFD) modeling, high-precision thermal imaging, and real-time exhaust gas analysis have enabled more accurate efficiency comparisons between these fundamentally different engine architectures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!