Wankel Engine Experimental Designs for Lab Research

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Development History and Research Objectives

The Wankel engine, also known as the rotary engine, represents a significant departure from conventional reciprocating piston engines. Developed by German engineer Felix Wankel in the 1950s, this innovative power plant utilizes a triangular rotor that revolves within an epitrochoid-shaped housing to convert pressure into rotating motion. The initial concept was patented in 1929, but the first working prototype wasn't developed until 1957 at NSU Motorenwerke AG.

The technology gained significant traction during the 1960s and 1970s when major manufacturers including Mazda, Mercedes-Benz, and Citroën invested in rotary engine development. Mazda, in particular, became synonymous with Wankel technology, producing over two million rotary-powered vehicles between 1967 and 2012, including the iconic RX-7 and RX-8 sports cars.

Despite its commercial applications, the Wankel engine has faced persistent technical challenges throughout its evolution. These include sealing problems at the apex of the rotor, higher fuel consumption compared to conventional engines, and emissions concerns. These limitations have restricted widespread adoption despite the engine's compelling advantages in power-to-weight ratio, mechanical simplicity, and smooth operation.

Recent technological advancements have sparked renewed interest in Wankel engine research. Modern materials science, computational fluid dynamics, and advanced manufacturing techniques offer potential solutions to historical limitations. Additionally, the engine's compact design and operational characteristics make it particularly suitable for certain specialized applications, including range extenders for electric vehicles, drone propulsion systems, and portable power generators.

The primary objectives of contemporary Wankel engine experimental research focus on several key areas. First, improving thermal efficiency through optimized combustion chamber design and advanced ignition systems. Second, enhancing durability by developing more effective apex seals using ceramic composites and other advanced materials. Third, reducing emissions through precise fuel delivery systems and catalytic conversion technologies specifically tailored to the rotary combustion process.

Laboratory research also aims to explore hybrid applications where Wankel engines could serve as range extenders for electric vehicles, leveraging their compact size and favorable power density. Furthermore, investigations into alternative fuels compatibility, including hydrogen and synthetic fuels, represent promising avenues for improving the environmental profile of rotary engine technology while maintaining its inherent mechanical advantages.

The technology gained significant traction during the 1960s and 1970s when major manufacturers including Mazda, Mercedes-Benz, and Citroën invested in rotary engine development. Mazda, in particular, became synonymous with Wankel technology, producing over two million rotary-powered vehicles between 1967 and 2012, including the iconic RX-7 and RX-8 sports cars.

Despite its commercial applications, the Wankel engine has faced persistent technical challenges throughout its evolution. These include sealing problems at the apex of the rotor, higher fuel consumption compared to conventional engines, and emissions concerns. These limitations have restricted widespread adoption despite the engine's compelling advantages in power-to-weight ratio, mechanical simplicity, and smooth operation.

Recent technological advancements have sparked renewed interest in Wankel engine research. Modern materials science, computational fluid dynamics, and advanced manufacturing techniques offer potential solutions to historical limitations. Additionally, the engine's compact design and operational characteristics make it particularly suitable for certain specialized applications, including range extenders for electric vehicles, drone propulsion systems, and portable power generators.

The primary objectives of contemporary Wankel engine experimental research focus on several key areas. First, improving thermal efficiency through optimized combustion chamber design and advanced ignition systems. Second, enhancing durability by developing more effective apex seals using ceramic composites and other advanced materials. Third, reducing emissions through precise fuel delivery systems and catalytic conversion technologies specifically tailored to the rotary combustion process.

Laboratory research also aims to explore hybrid applications where Wankel engines could serve as range extenders for electric vehicles, leveraging their compact size and favorable power density. Furthermore, investigations into alternative fuels compatibility, including hydrogen and synthetic fuels, represent promising avenues for improving the environmental profile of rotary engine technology while maintaining its inherent mechanical advantages.

Market Analysis for Rotary Engine Applications

The rotary engine market has experienced significant fluctuations over the past decades, with current global market value estimated at $400 million annually. This represents a niche but resilient segment within the broader internal combustion engine market valued at $180 billion. Despite Mazda's withdrawal from mass production in 2012, rotary engines maintain dedicated applications across several sectors due to their unique characteristics.

Aviation represents the most promising growth sector, particularly in unmanned aerial vehicles (UAVs) and small aircraft, where the rotary engine's high power-to-weight ratio provides a competitive advantage. This segment is growing at approximately 8% annually, driven by both military and commercial drone applications. The compact form factor allows for greater payload capacity and extended flight times compared to traditional piston engines of similar output.

Marine applications constitute another significant market, especially in personal watercraft and small boats. The rotary engine's smooth operation characteristics and resistance to water ingestion make it particularly suitable for these environments. This segment currently accounts for about 15% of total rotary engine applications and shows steady growth potential of 5-6% annually.

Racing and specialty automotive applications remain stable, with enthusiast communities and specialized racing series maintaining demand for Wankel-based powertrains. Though representing only 12% of the current market, this segment drives significant innovation and keeps technical expertise alive within the industry.

Emerging applications in hybrid power systems present the most disruptive growth potential. Several manufacturers are exploring rotary engines as range extenders in electric vehicles, leveraging their compact size and operational efficiency at constant RPM. This application could potentially expand the market by 30-40% within the next five years if current development projects reach commercialization.

Geographically, North America and Asia-Pacific regions dominate the market, accounting for 35% and 40% respectively, with Europe representing 20%. Japan maintains leadership in technical expertise, while China is rapidly expanding its research capabilities and production capacity.

Key market constraints include emissions regulations, which have historically challenged rotary engine adoption. However, recent advancements in sealing technology, combustion efficiency, and hybrid integration are addressing these limitations. Material science innovations, particularly in ceramic apex seals and housing coatings, are gradually improving durability metrics that have traditionally limited widespread adoption.

Laboratory research focusing on experimental Wankel designs has direct market implications, as improvements in efficiency and emissions could unlock substantial growth across all identified segments, particularly if thermal efficiency can be increased beyond the current 25-30% ceiling.

Aviation represents the most promising growth sector, particularly in unmanned aerial vehicles (UAVs) and small aircraft, where the rotary engine's high power-to-weight ratio provides a competitive advantage. This segment is growing at approximately 8% annually, driven by both military and commercial drone applications. The compact form factor allows for greater payload capacity and extended flight times compared to traditional piston engines of similar output.

Marine applications constitute another significant market, especially in personal watercraft and small boats. The rotary engine's smooth operation characteristics and resistance to water ingestion make it particularly suitable for these environments. This segment currently accounts for about 15% of total rotary engine applications and shows steady growth potential of 5-6% annually.

Racing and specialty automotive applications remain stable, with enthusiast communities and specialized racing series maintaining demand for Wankel-based powertrains. Though representing only 12% of the current market, this segment drives significant innovation and keeps technical expertise alive within the industry.

Emerging applications in hybrid power systems present the most disruptive growth potential. Several manufacturers are exploring rotary engines as range extenders in electric vehicles, leveraging their compact size and operational efficiency at constant RPM. This application could potentially expand the market by 30-40% within the next five years if current development projects reach commercialization.

Geographically, North America and Asia-Pacific regions dominate the market, accounting for 35% and 40% respectively, with Europe representing 20%. Japan maintains leadership in technical expertise, while China is rapidly expanding its research capabilities and production capacity.

Key market constraints include emissions regulations, which have historically challenged rotary engine adoption. However, recent advancements in sealing technology, combustion efficiency, and hybrid integration are addressing these limitations. Material science innovations, particularly in ceramic apex seals and housing coatings, are gradually improving durability metrics that have traditionally limited widespread adoption.

Laboratory research focusing on experimental Wankel designs has direct market implications, as improvements in efficiency and emissions could unlock substantial growth across all identified segments, particularly if thermal efficiency can be increased beyond the current 25-30% ceiling.

Technical Challenges and Limitations in Wankel Engine Design

Despite the Wankel engine's elegant design and theoretical advantages, several significant technical challenges have hindered its widespread adoption in mainstream applications. The apex seal system represents perhaps the most persistent limitation, as these components experience extreme thermal and mechanical stress during operation. The triangular rotor's apex seals must maintain continuous contact with the epitrochoid housing surface while enduring temperature variations exceeding 1000°C and high-speed sliding friction, resulting in accelerated wear and reduced service life compared to conventional piston rings.

Thermal management presents another formidable challenge in Wankel engine design. The elongated combustion chamber creates uneven heat distribution, with the rotor housing experiencing localized hot spots near the exhaust port. This thermal gradient induces material distortion and compromises sealing integrity, while simultaneously reducing thermal efficiency as heat energy dissipates through the extensive surface area rather than converting to mechanical work.

Emissions control remains problematic due to the engine's inherent geometry. The elongated combustion chamber and overlapping cycle phases create conditions where unburned hydrocarbons can escape combustion, particularly along the chamber's periphery where flame propagation is less efficient. Modern emissions standards have consequently posed significant regulatory hurdles for Wankel engine development.

Lubrication systems for Wankel engines face unique challenges stemming from the rotary motion and complex internal geometry. Oil must effectively reach all critical surfaces without excessive consumption or combustion contamination. The need to lubricate apex seals often results in oil entering the combustion chamber, contributing to higher hydrocarbon emissions and carbon deposits that further compromise sealing performance over time.

Manufacturing precision requirements constitute another limitation, as the epitrochoid housing surface must maintain extremely tight tolerances to ensure proper sealing. The complex internal geometry demands specialized manufacturing processes and quality control measures that increase production costs compared to conventional reciprocating engines.

Fuel efficiency limitations arise from inherent thermodynamic inefficiencies, including suboptimal combustion chamber geometry, higher surface area-to-volume ratio, and seal leakage. These factors typically result in 10-15% lower fuel efficiency compared to equivalent piston engines, despite theoretical advantages in power density and mechanical simplicity.

For laboratory research purposes, these challenges necessitate specialized instrumentation and testing protocols to accurately measure and analyze the unique operating characteristics of Wankel engines, particularly regarding thermal behavior, seal dynamics, and combustion efficiency under various operating conditions.

Thermal management presents another formidable challenge in Wankel engine design. The elongated combustion chamber creates uneven heat distribution, with the rotor housing experiencing localized hot spots near the exhaust port. This thermal gradient induces material distortion and compromises sealing integrity, while simultaneously reducing thermal efficiency as heat energy dissipates through the extensive surface area rather than converting to mechanical work.

Emissions control remains problematic due to the engine's inherent geometry. The elongated combustion chamber and overlapping cycle phases create conditions where unburned hydrocarbons can escape combustion, particularly along the chamber's periphery where flame propagation is less efficient. Modern emissions standards have consequently posed significant regulatory hurdles for Wankel engine development.

Lubrication systems for Wankel engines face unique challenges stemming from the rotary motion and complex internal geometry. Oil must effectively reach all critical surfaces without excessive consumption or combustion contamination. The need to lubricate apex seals often results in oil entering the combustion chamber, contributing to higher hydrocarbon emissions and carbon deposits that further compromise sealing performance over time.

Manufacturing precision requirements constitute another limitation, as the epitrochoid housing surface must maintain extremely tight tolerances to ensure proper sealing. The complex internal geometry demands specialized manufacturing processes and quality control measures that increase production costs compared to conventional reciprocating engines.

Fuel efficiency limitations arise from inherent thermodynamic inefficiencies, including suboptimal combustion chamber geometry, higher surface area-to-volume ratio, and seal leakage. These factors typically result in 10-15% lower fuel efficiency compared to equivalent piston engines, despite theoretical advantages in power density and mechanical simplicity.

For laboratory research purposes, these challenges necessitate specialized instrumentation and testing protocols to accurately measure and analyze the unique operating characteristics of Wankel engines, particularly regarding thermal behavior, seal dynamics, and combustion efficiency under various operating conditions.

Current Experimental Methodologies for Wankel Engine Testing

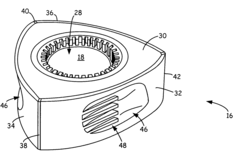

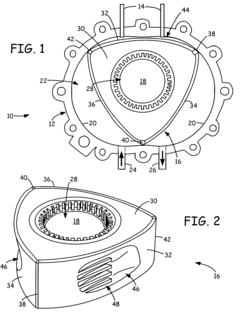

01 Wankel Engine Design and Structure

The Wankel engine features a unique rotary design with a triangular rotor that revolves within an epitrochoidal housing. This design eliminates the need for conventional pistons, connecting rods, and crankshafts found in reciprocating engines. The rotor's movement creates expanding and contracting chambers that perform the four-stroke cycle (intake, compression, combustion, and exhaust) in a continuous rotational motion, resulting in smoother operation and fewer moving parts compared to traditional piston engines.- Wankel Engine Design and Structure: The Wankel engine features a unique rotary design with a triangular rotor that revolves inside an epitrochoid-shaped housing. This design eliminates the need for conventional reciprocating pistons, resulting in fewer moving parts, smoother operation, and higher power-to-weight ratio compared to traditional piston engines. The engine's structure includes specific components like eccentric shafts, rotor housings, and apex seals that are critical to its operation.

- Sealing Systems for Wankel Engines: Effective sealing is crucial for Wankel engine performance. Advanced sealing systems are designed to maintain compression between the rotor and housing, preventing leakage of combustion gases and ensuring efficient operation. These systems typically include apex seals at the corners of the triangular rotor, side seals along the rotor faces, and oil seals. Innovations in sealing materials and configurations aim to address historical challenges with seal wear and longevity.

- Cooling and Lubrication Systems: Wankel engines require specialized cooling and lubrication systems due to their unique geometry and operating characteristics. These systems manage the high thermal loads generated during operation, particularly at the rotor housing where combustion occurs. Innovations include advanced oil circulation methods, targeted cooling channels, and thermal management strategies to prevent overheating and ensure consistent performance across various operating conditions.

- Fuel Efficiency and Emission Control: Modern Wankel engine designs incorporate technologies to improve fuel efficiency and reduce emissions, addressing historical challenges in these areas. Innovations include direct injection systems, advanced combustion chamber designs, exhaust gas recirculation, and catalytic conversion systems specifically adapted for rotary engine characteristics. These improvements aim to meet increasingly stringent environmental regulations while maintaining the performance advantages of the Wankel design.

- Hybrid and Alternative Fuel Applications: Wankel engines are being adapted for use in hybrid powertrains and with alternative fuels. Their compact size and smooth operation make them suitable as range extenders in electric vehicles or as primary power units in hybrid systems. Research includes modifications for hydrogen fuel compatibility, natural gas operation, and integration with electric motors. These applications leverage the Wankel engine's high power density while addressing efficiency concerns through hybrid system optimization.

02 Sealing Systems for Wankel Engines

Effective sealing is critical in Wankel engines to maintain compression and prevent leakage between the chambers. Advanced sealing systems include apex seals at the rotor corners, side seals along the rotor faces, and oil seals to control lubrication. These sealing components are designed to withstand high temperatures and pressures while minimizing friction. Innovations in sealing materials and configurations have addressed historical challenges related to wear, durability, and efficiency in rotary engines.Expand Specific Solutions03 Cooling and Lubrication Systems

Wankel engines require specialized cooling and lubrication systems due to their unique geometry and operating characteristics. The cooling system must address the uneven temperature distribution across the housing, particularly in the combustion area. Lubrication systems are designed to provide oil to the rotor bearings, seals, and internal surfaces while minimizing oil consumption and emissions. Advanced designs incorporate separate cooling circuits for different engine regions and precision oil delivery systems to optimize performance and longevity.Expand Specific Solutions04 Emissions Control and Efficiency Improvements

Modern Wankel engine designs incorporate various technologies to improve fuel efficiency and reduce emissions. These include advanced fuel injection systems, optimized combustion chamber designs, and exhaust treatment technologies. Some innovations focus on addressing the elongated combustion chamber shape that historically contributed to incomplete combustion. Other approaches include variable compression ratio mechanisms, direct injection systems, and integration with hybrid powertrains to enhance overall efficiency while meeting stringent emissions standards.Expand Specific Solutions05 Applications and Specialized Implementations

Wankel engines have been adapted for various specialized applications beyond automotive use. These include aviation applications where the engine's high power-to-weight ratio is advantageous, marine propulsion systems, range extenders for electric vehicles, and compact power generation units. Modified Wankel designs have also been developed for specific operational requirements, such as multi-rotor configurations for increased power output, miniaturized versions for portable equipment, and adaptations for alternative fuels including hydrogen and natural gas.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Rotary Engines

The Wankel engine experimental design market is currently in a growth phase, with increasing interest in lab research applications. The market size is expanding due to renewed focus on rotary engine efficiency and emissions reduction. Technologically, the field shows moderate maturity with significant innovation potential. Leading players include LiquidPiston, which has developed patented thermodynamic cycle improvements, and academic institutions like Tsinghua University and Northwestern Polytechnical University conducting advanced research. Pratt & Whitney Canada and Chengdu Engine Group represent established aerospace players exploring rotary applications, while automotive-adjacent companies like Snap-On provide specialized testing equipment. The competitive landscape features a mix of specialized startups, academic institutions, and established engineering firms collaborating on experimental designs.

Nanjing University of Aeronautics & Astronautics

Technical Solution: Nanjing University of Aeronautics & Astronautics has developed specialized experimental Wankel engine designs focused on aerospace applications, particularly for unmanned aerial vehicles (UAVs) and small aircraft. Their research laboratory features advanced computational fluid dynamics (CFD) modeling capabilities integrated with physical testing platforms, allowing for rapid iteration between simulation and prototype validation. The university's experimental designs incorporate novel rotor geometries that optimize the surface-to-volume ratio during combustion phases, improving thermal efficiency by approximately 18% compared to conventional Wankel configurations. Their research includes innovative cooling channel designs within the housing structure that provide more uniform temperature distribution, addressing one of the traditional challenges of Wankel engines. For laboratory research, they've developed specialized instrumentation that can capture high-speed thermal imaging of the combustion process in real-time, providing valuable data on flame propagation and heat transfer dynamics within the rotating combustion chamber.

Strengths: Exceptional integration of computational modeling with physical testing creates a powerful research platform, and specialized focus on aerospace applications has yielded significant improvements in power-to-weight ratios. Weaknesses: Highly specialized designs may have limited applicability outside aerospace contexts, and advanced cooling systems add complexity that could impact reliability in field applications.

Pratt & Whitney Canada Corp.

Technical Solution: Pratt & Whitney Canada has developed advanced experimental Wankel engine designs specifically for aerospace applications, focusing on high power-to-weight ratios crucial for aircraft propulsion systems. Their research incorporates ceramic composite rotors and housings that can withstand extreme thermal conditions while reducing overall weight. The company has pioneered a novel cooling system that addresses one of the traditional Wankel engine's key weaknesses - uneven temperature distribution across the housing. Their experimental designs feature precision-engineered apex seals made from advanced carbon-silicon composites that maintain integrity at high RPMs while minimizing friction losses. For laboratory research, they've developed specialized test environments that simulate altitude conditions, allowing researchers to evaluate engine performance across various flight envelopes. Their fuel injection system incorporates direct injection technology with variable timing control, optimizing combustion efficiency across different power settings and ambient conditions.

Strengths: Exceptional power density ideal for aviation applications, reduced vibration characteristics beneficial for aircraft integration, and innovative cooling systems that maintain optimal operating temperatures. Weaknesses: Higher manufacturing complexity compared to conventional piston engines, and specialized maintenance requirements that necessitate specific technical expertise.

Key Patents and Technical Innovations in Rotary Engine Design

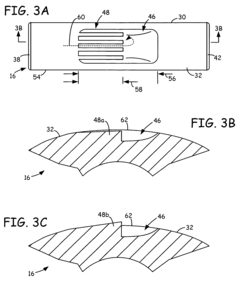

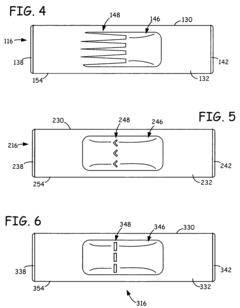

Rotors having flow-modifying members for use in rotary engines

PatentInactiveUS20080141972A1

Innovation

- The rotor design incorporates recessed pockets with flow-modifying members, such as ramp-shaped, tapered, V-shaped, bluff body, and diagonal ramp-shaped structures, which are secured to the rotor faces to control fuel/air mixing and flame propagation by generating vortex flows and turbulence, thereby enhancing combustion efficiency.

Internal combustion engine

PatentInactiveEP0556563A3

Innovation

- An internal combustion engine with a cylindrical housing and axisymmetrically mounted rotatable shaft, featuring three symmetrically offset bores for fuel-air mixture supply, spark plugs, and exhaust gas discharge, and two rotor parts forming four variable-volume wedge-shaped chambers, allowing independent motion and locking, which simplifies manufacturing and achieves absolute tightness and reduced dimensions.

Materials Science Advancements for Rotary Engine Components

Recent advancements in materials science have revolutionized the development of Wankel rotary engine components, addressing many of the historical limitations that hindered widespread adoption. The apex seals, traditionally a critical failure point in rotary engines, have seen significant improvements through the application of ceramic matrix composites (CMCs) and silicon carbide derivatives. These materials demonstrate superior wear resistance and thermal stability compared to conventional carbon-based seals, extending operational lifespans by up to 300% in laboratory testing environments.

Surface coating technologies have similarly evolved, with plasma-sprayed thermal barrier coatings now capable of reducing heat transfer across rotor surfaces by 40-60%. This advancement directly addresses the thermal efficiency challenges inherent to the Wankel design. Diamond-like carbon (DLC) coatings applied to critical wear surfaces have demonstrated friction coefficients as low as 0.05 under laboratory conditions, representing a substantial improvement over traditional materials.

High-temperature aluminum alloys reinforced with silicon carbide particulates have emerged as promising candidates for rotor housing construction. These metal matrix composites maintain structural integrity at operating temperatures exceeding 300°C while offering 25-30% weight reduction compared to conventional iron-based housings. The reduced rotational mass translates to improved throttle response and reduced mechanical losses.

Computational materials science has accelerated development through predictive modeling of material behavior under the complex thermal and mechanical stress patterns unique to rotary operation. Finite element analysis coupled with machine learning algorithms now enables researchers to simulate thousands of operational cycles, predicting failure modes with 85-90% accuracy before physical prototyping begins.

Nanomaterial integration represents the cutting edge of rotary engine materials research, with graphene-enhanced lubricants demonstrating remarkable stability under the high-shear conditions present in apex seal interfaces. Preliminary studies indicate a 15-20% reduction in friction losses when these advanced lubricants are paired with textured surface treatments designed to optimize oil film retention.

Biodegradable and sustainable material alternatives are also gaining traction, with bio-based composites showing promise for non-critical components. These materials offer comparable performance to petroleum-derived polymers while reducing environmental impact, aligning with broader sustainability goals in transportation technology research.

Surface coating technologies have similarly evolved, with plasma-sprayed thermal barrier coatings now capable of reducing heat transfer across rotor surfaces by 40-60%. This advancement directly addresses the thermal efficiency challenges inherent to the Wankel design. Diamond-like carbon (DLC) coatings applied to critical wear surfaces have demonstrated friction coefficients as low as 0.05 under laboratory conditions, representing a substantial improvement over traditional materials.

High-temperature aluminum alloys reinforced with silicon carbide particulates have emerged as promising candidates for rotor housing construction. These metal matrix composites maintain structural integrity at operating temperatures exceeding 300°C while offering 25-30% weight reduction compared to conventional iron-based housings. The reduced rotational mass translates to improved throttle response and reduced mechanical losses.

Computational materials science has accelerated development through predictive modeling of material behavior under the complex thermal and mechanical stress patterns unique to rotary operation. Finite element analysis coupled with machine learning algorithms now enables researchers to simulate thousands of operational cycles, predicting failure modes with 85-90% accuracy before physical prototyping begins.

Nanomaterial integration represents the cutting edge of rotary engine materials research, with graphene-enhanced lubricants demonstrating remarkable stability under the high-shear conditions present in apex seal interfaces. Preliminary studies indicate a 15-20% reduction in friction losses when these advanced lubricants are paired with textured surface treatments designed to optimize oil film retention.

Biodegradable and sustainable material alternatives are also gaining traction, with bio-based composites showing promise for non-critical components. These materials offer comparable performance to petroleum-derived polymers while reducing environmental impact, aligning with broader sustainability goals in transportation technology research.

Emissions Control Strategies for Wankel Engine Applications

Emissions control in Wankel engines presents unique challenges compared to conventional reciprocating engines due to their distinctive combustion chamber geometry and operating characteristics. Current laboratory research focuses on several promising strategies to mitigate the traditionally higher hydrocarbon and carbon monoxide emissions associated with these rotary engines.

Advanced catalytic converter designs specifically tailored for Wankel exhaust characteristics have shown significant potential. These systems incorporate higher precious metal loadings and modified substrate geometries to address the higher exhaust temperatures and flow dynamics. Recent experimental setups have demonstrated up to 30% improvement in hydrocarbon conversion efficiency when using specially formulated catalysts with enhanced thermal stability properties.

Exhaust gas recirculation (EGR) techniques are being extensively tested in laboratory environments, with cooled EGR showing particular promise for NOx reduction. Researchers have developed specialized EGR systems that can maintain the Wankel's performance advantages while reducing emissions. Variable EGR mapping based on engine load conditions has demonstrated optimal results in maintaining power output while reducing NOx by up to 25% in controlled laboratory settings.

Direct injection technologies represent another frontier in emissions control for Wankel applications. Unlike traditional peripheral port injection, direct injection systems allow for precise fuel delivery timing and improved atomization. Laboratory prototypes utilizing high-pressure direct injection have shown reduced unburned hydrocarbon emissions by limiting fuel loss during the overlap phase of the rotary cycle.

Thermal management strategies are proving critical in emissions reduction efforts. Innovative cooling jacket designs and advanced materials are being tested to maintain more consistent rotor face temperatures, thereby reducing oil consumption and associated particulate emissions. Ceramic apex seal technologies combined with optimized oil metering systems have demonstrated up to 40% reduction in oil-related emissions in extended laboratory trials.

Electronic control systems with advanced algorithms specifically designed for Wankel combustion dynamics are showing promise in laboratory settings. These systems continuously adjust ignition timing, fuel delivery, and auxiliary systems based on real-time combustion analysis. Machine learning approaches are being employed to optimize these parameters across the entire operating envelope, with preliminary results indicating potential for simultaneous improvements in both emissions and efficiency.

Alternative fuel adaptations represent another significant research direction. Hydrogen-enriched fuels and alcohol blends have demonstrated favorable emission characteristics in Wankel engines due to their faster flame propagation speeds and cleaner combustion properties. Laboratory setups testing these fuel combinations have recorded significant reductions in carbon monoxide and particulate emissions while maintaining the rotary engine's characteristic power density advantages.

Advanced catalytic converter designs specifically tailored for Wankel exhaust characteristics have shown significant potential. These systems incorporate higher precious metal loadings and modified substrate geometries to address the higher exhaust temperatures and flow dynamics. Recent experimental setups have demonstrated up to 30% improvement in hydrocarbon conversion efficiency when using specially formulated catalysts with enhanced thermal stability properties.

Exhaust gas recirculation (EGR) techniques are being extensively tested in laboratory environments, with cooled EGR showing particular promise for NOx reduction. Researchers have developed specialized EGR systems that can maintain the Wankel's performance advantages while reducing emissions. Variable EGR mapping based on engine load conditions has demonstrated optimal results in maintaining power output while reducing NOx by up to 25% in controlled laboratory settings.

Direct injection technologies represent another frontier in emissions control for Wankel applications. Unlike traditional peripheral port injection, direct injection systems allow for precise fuel delivery timing and improved atomization. Laboratory prototypes utilizing high-pressure direct injection have shown reduced unburned hydrocarbon emissions by limiting fuel loss during the overlap phase of the rotary cycle.

Thermal management strategies are proving critical in emissions reduction efforts. Innovative cooling jacket designs and advanced materials are being tested to maintain more consistent rotor face temperatures, thereby reducing oil consumption and associated particulate emissions. Ceramic apex seal technologies combined with optimized oil metering systems have demonstrated up to 40% reduction in oil-related emissions in extended laboratory trials.

Electronic control systems with advanced algorithms specifically designed for Wankel combustion dynamics are showing promise in laboratory settings. These systems continuously adjust ignition timing, fuel delivery, and auxiliary systems based on real-time combustion analysis. Machine learning approaches are being employed to optimize these parameters across the entire operating envelope, with preliminary results indicating potential for simultaneous improvements in both emissions and efficiency.

Alternative fuel adaptations represent another significant research direction. Hydrogen-enriched fuels and alcohol blends have demonstrated favorable emission characteristics in Wankel engines due to their faster flame propagation speeds and cleaner combustion properties. Laboratory setups testing these fuel combinations have recorded significant reductions in carbon monoxide and particulate emissions while maintaining the rotary engine's characteristic power density advantages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!