Wankel Engine Calibration in Automated Systems

AUG 26, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Evolution and Calibration Objectives

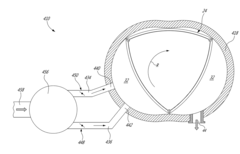

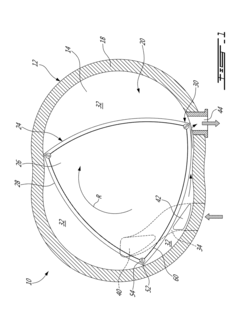

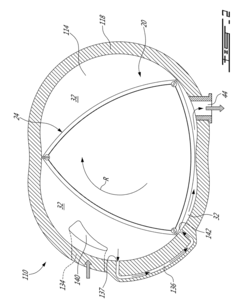

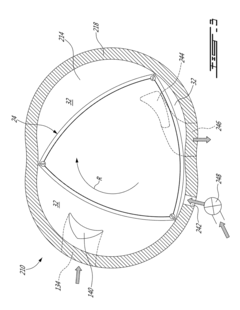

The Wankel rotary engine, first conceptualized by Felix Wankel in the 1920s and developed into a working prototype by 1957, represents a significant departure from conventional reciprocating piston engines. This innovative design utilizes a triangular rotor that revolves within an epitrochoid-shaped housing, creating three moving combustion chambers. The evolution of Wankel engines has been marked by continuous refinement aimed at addressing inherent challenges while capitalizing on their unique advantages.

Throughout the 1960s and 1970s, companies like NSU and Mazda pioneered commercial applications of the Wankel engine, with Mazda's commitment extending through several decades of development. The technology's evolution has been characterized by progressive improvements in sealing systems, combustion efficiency, and emissions control. Early iterations struggled with apex seal durability and high fuel consumption, issues that subsequent generations have incrementally addressed through materials science advancements and refined engineering approaches.

In recent years, the integration of Wankel engines into automated systems has emerged as a promising frontier, particularly as range extenders in hybrid electric vehicles. This application leverages the rotary engine's compact size, low vibration characteristics, and favorable power-to-weight ratio. However, this integration introduces new calibration challenges that differ significantly from those in traditional automotive applications.

The primary calibration objectives for Wankel engines in automated systems center on achieving optimal performance while maintaining reliability under varying operational conditions. These objectives include precise fuel delivery calibration to maximize efficiency across different load profiles, thermal management optimization to prevent overheating during extended operation, and emissions control calibration to meet increasingly stringent environmental regulations.

Another critical calibration objective involves adapting to the unique operational patterns of automated systems, where predictable load cycles may differ substantially from the variable demands of human-operated vehicles. This requires developing sophisticated control algorithms that can anticipate system needs and adjust engine parameters proactively rather than reactively.

Advanced sensor integration represents a further calibration objective, enabling real-time monitoring of critical parameters such as rotor position, combustion pressure, and exhaust gas composition. These data points inform adaptive calibration strategies that can optimize performance dynamically, compensating for factors like ambient temperature variations, fuel quality differences, and component wear over time.

The ultimate calibration goal for Wankel engines in automated systems is to achieve a balance between performance, efficiency, and longevity that maximizes the technology's inherent advantages while mitigating its traditional weaknesses. This requires a comprehensive understanding of both the engine's unique operating principles and the specific demands of the automated systems they power.

Throughout the 1960s and 1970s, companies like NSU and Mazda pioneered commercial applications of the Wankel engine, with Mazda's commitment extending through several decades of development. The technology's evolution has been characterized by progressive improvements in sealing systems, combustion efficiency, and emissions control. Early iterations struggled with apex seal durability and high fuel consumption, issues that subsequent generations have incrementally addressed through materials science advancements and refined engineering approaches.

In recent years, the integration of Wankel engines into automated systems has emerged as a promising frontier, particularly as range extenders in hybrid electric vehicles. This application leverages the rotary engine's compact size, low vibration characteristics, and favorable power-to-weight ratio. However, this integration introduces new calibration challenges that differ significantly from those in traditional automotive applications.

The primary calibration objectives for Wankel engines in automated systems center on achieving optimal performance while maintaining reliability under varying operational conditions. These objectives include precise fuel delivery calibration to maximize efficiency across different load profiles, thermal management optimization to prevent overheating during extended operation, and emissions control calibration to meet increasingly stringent environmental regulations.

Another critical calibration objective involves adapting to the unique operational patterns of automated systems, where predictable load cycles may differ substantially from the variable demands of human-operated vehicles. This requires developing sophisticated control algorithms that can anticipate system needs and adjust engine parameters proactively rather than reactively.

Advanced sensor integration represents a further calibration objective, enabling real-time monitoring of critical parameters such as rotor position, combustion pressure, and exhaust gas composition. These data points inform adaptive calibration strategies that can optimize performance dynamically, compensating for factors like ambient temperature variations, fuel quality differences, and component wear over time.

The ultimate calibration goal for Wankel engines in automated systems is to achieve a balance between performance, efficiency, and longevity that maximizes the technology's inherent advantages while mitigating its traditional weaknesses. This requires a comprehensive understanding of both the engine's unique operating principles and the specific demands of the automated systems they power.

Market Analysis for Automated Wankel Engine Systems

The global market for automated Wankel engine systems is experiencing significant growth, driven by increasing demand for efficient, compact power solutions across multiple industries. Current market valuation stands at approximately 3.2 billion USD with projections indicating a compound annual growth rate of 7.8% over the next five years. This growth trajectory is particularly notable in regions with advanced manufacturing capabilities such as North America, Europe, and parts of Asia.

The automotive sector represents the largest market segment, accounting for roughly 42% of the total market share. Within this segment, sports cars and high-performance vehicles constitute the primary application areas due to the Wankel engine's favorable power-to-weight ratio and smooth operation characteristics. However, emerging applications in hybrid electric vehicles are creating new market opportunities as manufacturers seek range-extending solutions that offer compact design and operational efficiency.

Aerospace and defense applications form the second-largest market segment at 28%, where the Wankel engine's reliability and reduced vibration profile provide significant advantages for unmanned aerial vehicles (UAVs) and small aircraft systems. The marine sector follows at 17%, with particular interest in recreational watercraft and small commercial vessels.

Regional analysis reveals that North America leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (24%). The remaining 7% is distributed across other regions. Japan, Germany, and the United States host the most significant research and development centers focused on automated Wankel engine calibration technologies.

Market drivers include increasing demand for fuel-efficient propulsion systems, growing adoption of automation in engine management, and rising interest in alternative engine designs for specialized applications. The push toward reduced emissions and improved performance metrics has accelerated investment in advanced calibration systems that can optimize the unique combustion characteristics of Wankel engines.

Barriers to market expansion include technical challenges related to sealing technology, higher manufacturing costs compared to conventional piston engines, and limited awareness among potential end-users about recent technological advancements in Wankel engine efficiency and reliability.

Customer segmentation analysis indicates that high-end manufacturers and specialized industrial applications represent the most promising growth segments, with particular emphasis on applications requiring high power density in limited space environments. The market for aftermarket calibration systems is also expanding, driven by performance enthusiasts and specialized fleet operators seeking to optimize existing Wankel engine installations.

The automotive sector represents the largest market segment, accounting for roughly 42% of the total market share. Within this segment, sports cars and high-performance vehicles constitute the primary application areas due to the Wankel engine's favorable power-to-weight ratio and smooth operation characteristics. However, emerging applications in hybrid electric vehicles are creating new market opportunities as manufacturers seek range-extending solutions that offer compact design and operational efficiency.

Aerospace and defense applications form the second-largest market segment at 28%, where the Wankel engine's reliability and reduced vibration profile provide significant advantages for unmanned aerial vehicles (UAVs) and small aircraft systems. The marine sector follows at 17%, with particular interest in recreational watercraft and small commercial vessels.

Regional analysis reveals that North America leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (24%). The remaining 7% is distributed across other regions. Japan, Germany, and the United States host the most significant research and development centers focused on automated Wankel engine calibration technologies.

Market drivers include increasing demand for fuel-efficient propulsion systems, growing adoption of automation in engine management, and rising interest in alternative engine designs for specialized applications. The push toward reduced emissions and improved performance metrics has accelerated investment in advanced calibration systems that can optimize the unique combustion characteristics of Wankel engines.

Barriers to market expansion include technical challenges related to sealing technology, higher manufacturing costs compared to conventional piston engines, and limited awareness among potential end-users about recent technological advancements in Wankel engine efficiency and reliability.

Customer segmentation analysis indicates that high-end manufacturers and specialized industrial applications represent the most promising growth segments, with particular emphasis on applications requiring high power density in limited space environments. The market for aftermarket calibration systems is also expanding, driven by performance enthusiasts and specialized fleet operators seeking to optimize existing Wankel engine installations.

Technical Challenges in Wankel Engine Calibration

Wankel engines present unique calibration challenges that distinguish them from conventional reciprocating engines. The rotary design, while offering advantages in power-to-weight ratio and mechanical simplicity, introduces complex thermodynamic behaviors that complicate calibration processes. The triangular rotor moving within an epitrochoid housing creates continuously changing combustion chamber volumes, resulting in non-uniform combustion characteristics across different operating conditions.

One significant challenge is the optimization of fuel injection timing and quantity. Unlike conventional engines with distinct intake, compression, power, and exhaust strokes, the Wankel engine's phases overlap, creating zones where precise fuel delivery becomes critical. This overlap complicates the establishment of universal calibration parameters, requiring sophisticated mapping techniques that account for the engine's unique geometry.

Thermal management represents another formidable obstacle. The elongated combustion chamber design leads to uneven temperature distribution, with apex seals experiencing particularly high thermal stress. Calibration must account for these thermal gradients to prevent localized overheating while maintaining optimal combustion efficiency. The challenge intensifies in automated systems where real-time thermal compensation algorithms must operate without human intervention.

Emissions control presents perhaps the most pressing contemporary challenge. The inherent design of Wankel engines promotes incomplete combustion, particularly at chamber extremities, resulting in elevated hydrocarbon emissions. Modern calibration approaches must address this through precise air-fuel ratio management across all operating conditions, a task complicated by the engine's inherent geometric properties.

In automated systems, these challenges are amplified by the need for self-adaptive calibration protocols. Traditional lookup tables and static calibration maps prove insufficient for capturing the Wankel engine's dynamic behavior across varying loads, speeds, and environmental conditions. Advanced model-based calibration approaches are required, yet developing accurate predictive models for rotary engines remains difficult due to their complex internal fluid dynamics.

Sensor integration poses additional complications. Conventional engine sensors often require repositioning or redesign to accurately monitor the Wankel's unique combustion process. The optimal placement for temperature, pressure, and exhaust gas sensors differs significantly from traditional engines, necessitating specialized calibration methodologies that can interpret these differently positioned sensor inputs.

The scarcity of specialized expertise compounds these technical difficulties. With limited commercial deployment of Wankel engines in recent decades, the knowledge base for advanced calibration techniques has not evolved at the same pace as for conventional engines. This knowledge gap becomes particularly problematic when implementing machine learning algorithms for automated calibration systems, as training data sets are comparatively limited.

One significant challenge is the optimization of fuel injection timing and quantity. Unlike conventional engines with distinct intake, compression, power, and exhaust strokes, the Wankel engine's phases overlap, creating zones where precise fuel delivery becomes critical. This overlap complicates the establishment of universal calibration parameters, requiring sophisticated mapping techniques that account for the engine's unique geometry.

Thermal management represents another formidable obstacle. The elongated combustion chamber design leads to uneven temperature distribution, with apex seals experiencing particularly high thermal stress. Calibration must account for these thermal gradients to prevent localized overheating while maintaining optimal combustion efficiency. The challenge intensifies in automated systems where real-time thermal compensation algorithms must operate without human intervention.

Emissions control presents perhaps the most pressing contemporary challenge. The inherent design of Wankel engines promotes incomplete combustion, particularly at chamber extremities, resulting in elevated hydrocarbon emissions. Modern calibration approaches must address this through precise air-fuel ratio management across all operating conditions, a task complicated by the engine's inherent geometric properties.

In automated systems, these challenges are amplified by the need for self-adaptive calibration protocols. Traditional lookup tables and static calibration maps prove insufficient for capturing the Wankel engine's dynamic behavior across varying loads, speeds, and environmental conditions. Advanced model-based calibration approaches are required, yet developing accurate predictive models for rotary engines remains difficult due to their complex internal fluid dynamics.

Sensor integration poses additional complications. Conventional engine sensors often require repositioning or redesign to accurately monitor the Wankel's unique combustion process. The optimal placement for temperature, pressure, and exhaust gas sensors differs significantly from traditional engines, necessitating specialized calibration methodologies that can interpret these differently positioned sensor inputs.

The scarcity of specialized expertise compounds these technical difficulties. With limited commercial deployment of Wankel engines in recent decades, the knowledge base for advanced calibration techniques has not evolved at the same pace as for conventional engines. This knowledge gap becomes particularly problematic when implementing machine learning algorithms for automated calibration systems, as training data sets are comparatively limited.

Current Calibration Methodologies for Automated Systems

01 Calibration methods for Wankel engine performance optimization

Various calibration methods are employed to optimize the performance of Wankel engines. These methods involve adjusting parameters such as fuel injection timing, ignition timing, and air-fuel ratio to achieve optimal combustion efficiency. Advanced calibration techniques may include real-time monitoring and adjustment of engine parameters based on operating conditions, which helps to improve fuel economy and reduce emissions while maintaining power output.- Fuel injection and combustion control systems: Wankel engines require specialized fuel injection systems and combustion control mechanisms for proper calibration. These systems monitor and adjust fuel-air mixtures, ignition timing, and combustion parameters to optimize engine performance. Advanced electronic control units can dynamically adjust these parameters based on operating conditions, ensuring efficient combustion in the unique rotary chamber geometry.

- Rotor and housing geometry calibration: The precise calibration of rotor and housing geometry is critical for Wankel engine performance. This includes optimizing the epitrochoidal housing shape, rotor profile, apex seal configuration, and chamber volume ratios. Calibration techniques focus on maintaining proper clearances between moving parts while accounting for thermal expansion during operation, which directly impacts compression ratios and overall efficiency.

- Cooling system and thermal management calibration: Thermal management is essential for Wankel engine calibration due to the uneven heat distribution characteristic of rotary engines. Calibration techniques include optimizing coolant flow paths, adjusting cooling system parameters, and implementing temperature-based control strategies. Proper thermal calibration prevents localized overheating, reduces thermal stress on components, and maintains consistent operating temperatures for optimal performance.

- Emissions control and exhaust system calibration: Calibration of emissions control systems in Wankel engines addresses their unique combustion characteristics and exhaust profiles. This includes adjusting exhaust gas recirculation rates, catalytic converter parameters, and aftertreatment systems. Calibration strategies focus on reducing hydrocarbon emissions resulting from the elongated combustion chamber while maintaining performance and efficiency across various operating conditions.

- Sensor integration and diagnostic calibration: Modern Wankel engine calibration relies heavily on sensor integration and diagnostic systems. This includes calibrating pressure sensors, temperature monitors, rotational position sensors, and knock detection systems specific to rotary engine operation. Advanced diagnostic calibration enables real-time monitoring of engine parameters, facilitates adaptive control strategies, and provides data for performance optimization and troubleshooting.

02 Rotor geometry and sealing calibration techniques

Calibration of rotor geometry and sealing systems is crucial for Wankel engine efficiency. This involves precise measurement and adjustment of rotor apex seals, side seals, and housing surfaces to maintain optimal clearances. Proper calibration of these components minimizes leakage between chambers, improves compression, and enhances overall engine performance. Advanced techniques may include thermal compensation to account for expansion during operation.Expand Specific Solutions03 Electronic control systems for Wankel engine calibration

Modern Wankel engines utilize sophisticated electronic control systems for calibration. These systems incorporate sensors to monitor various engine parameters and microprocessors to analyze data and make real-time adjustments. Electronic calibration allows for precise control of fuel delivery, ignition timing, and emissions management across different operating conditions. Some advanced systems include adaptive learning algorithms that optimize engine performance based on usage patterns and environmental factors.Expand Specific Solutions04 Combustion chamber calibration for emissions control

Calibration of the combustion chamber geometry and processes in Wankel engines is essential for emissions control. This involves optimizing the shape of the combustion chamber, port design, and timing to ensure complete fuel burning and reduced pollutant formation. Advanced calibration techniques focus on reducing hydrocarbon emissions, which are traditionally higher in rotary engines due to their unique combustion characteristics. Proper calibration can significantly improve emissions performance while maintaining the power advantages of the Wankel design.Expand Specific Solutions05 Cooling system calibration for thermal management

Thermal management through cooling system calibration is critical for Wankel engine reliability and efficiency. This involves precise adjustment of coolant flow rates, temperatures, and distribution to maintain optimal operating temperatures across different engine components. Proper calibration prevents localized overheating, which is particularly important for Wankel engines due to their unique geometry and heat distribution characteristics. Advanced cooling system calibration may include variable flow control and targeted cooling for specific high-temperature regions of the engine housing.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Wankel Engine Calibration in Automated Systems market is in a growth phase, with increasing integration into specialized applications despite limited mainstream adoption. The market size is expanding moderately, driven by efficiency improvements and automation trends. Technologically, the field shows varied maturity levels across players: established automotive giants like GM, Ford, and BMW possess advanced calibration capabilities; specialized engineering firms such as AVL List and Robert Bosch lead in precision control systems; while emerging players like Bright Machines and AIM Intelligent Machines are introducing AI-driven calibration innovations. BorgWarner and Honeywell are leveraging their powertrain expertise to enhance rotary engine performance in automated environments.

AVL List GmbH

Technical Solution: AVL List GmbH has developed a comprehensive Wankel Engine Calibration System specifically designed for automated applications. Their solution integrates advanced model-based calibration techniques with real-time monitoring capabilities. The system employs a dual-approach methodology combining physical models with data-driven algorithms to optimize the unique triangular rotor dynamics of Wankel engines. AVL's calibration platform features specialized tools for addressing the distinctive combustion chamber geometry and sealing challenges inherent to rotary engines. Their automated calibration process utilizes machine learning algorithms to continuously refine parameters such as fuel injection timing, ignition timing, and emissions control across various operating conditions. The system incorporates thermal management optimization specifically tailored to address the asymmetric heating issues common in Wankel designs. AVL's solution also includes specialized diagnostic tools for monitoring apex seal wear and housing distortion - critical factors in Wankel engine performance and longevity.

Strengths: Industry-leading expertise in engine calibration with specialized knowledge of rotary engine dynamics; comprehensive testing facilities allowing for rapid iteration and validation. Weaknesses: Higher implementation costs compared to conventional engine calibration systems; requires specialized training for technicians unfamiliar with Wankel engine architecture.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has engineered an advanced Wankel Engine Management System (WEMS) for automated calibration applications. Their technology leverages high-precision sensors and actuators integrated with sophisticated control algorithms specifically adapted to the unique characteristics of rotary engines. Bosch's system employs predictive modeling to anticipate and compensate for the thermal expansion challenges inherent in Wankel designs, particularly at the rotor housing interfaces. Their calibration approach utilizes a multi-phase optimization strategy that addresses the three distinct combustion phases occurring simultaneously in different chambers of the rotary engine. The WEMS incorporates specialized fuel mapping algorithms that account for the elongated combustion chamber geometry and variable compression ratios throughout the rotation cycle. Bosch has developed proprietary software tools that enable automated calibration of critical parameters including rotor timing, port opening duration, and emissions control strategies. Their system features adaptive learning capabilities that continuously refine calibration parameters based on operational data, allowing for optimization across varying environmental conditions and fuel qualities.

Strengths: Extensive experience in engine management systems with robust global support infrastructure; seamless integration with other Bosch automotive components. Weaknesses: Solution primarily optimized for automotive applications with less focus on industrial or specialized applications of Wankel engines; relatively high initial implementation costs.

Key Patents and Innovations in Wankel Engine Control

Internal combustion engine

PatentInactiveEP0556563A3

Innovation

- An internal combustion engine with a cylindrical housing and axisymmetrically mounted rotatable shaft, featuring three symmetrically offset bores for fuel-air mixture supply, spark plugs, and exhaust gas discharge, and two rotor parts forming four variable-volume wedge-shaped chambers, allowing independent motion and locking, which simplifies manufacturing and achieves absolute tightness and reduced dimensions.

Rotary internal combustion engine

PatentActiveUS20180045110A1

Innovation

- The implementation of a rotary engine design with a primary inlet port, a secondary inlet port (purge port) positioned rearwardly of the primary inlet port and forwardly of the exhaust port, and independently closable communications between air sources and these ports, allowing simultaneous air intake and exhaust gas purging through the secondary inlet port.

Emissions Compliance and Regulatory Framework

The regulatory landscape for Wankel engine emissions presents unique challenges due to the rotary engine's distinctive combustion characteristics. Current emissions standards, including Euro 6d in Europe, Tier 3 in the United States, and China 6 regulations, impose increasingly stringent limits on nitrogen oxides (NOx), particulate matter, and hydrocarbon emissions. These standards have historically disadvantaged Wankel engines, which typically exhibit higher hydrocarbon emissions due to their elongated combustion chamber geometry and inherent fuel trapping in rotor housing crevices.

Automated calibration systems for Wankel engines must navigate a complex matrix of regulatory requirements that vary significantly across global markets. The European Commission's Real Driving Emissions (RDE) testing protocol, implemented alongside laboratory-based Worldwide Harmonized Light Vehicles Test Procedure (WLTP), demands robust on-road performance across diverse driving conditions. This presents particular challenges for rotary engine calibration, requiring sophisticated emissions control strategies beyond traditional approaches.

Compliance strategies for modern Wankel engines increasingly incorporate advanced aftertreatment systems, including three-way catalytic converters specifically designed for rotary applications, lean NOx traps, and particulate filters optimized for the unique exhaust gas composition. The calibration of these systems must account for the Wankel's characteristic high exhaust temperatures and distinctive emission profiles, particularly during cold-start conditions when hydrocarbon emissions are most problematic.

Regulatory frameworks are evolving toward lifecycle emissions assessment, with carbon neutrality targets influencing compliance strategies. Several jurisdictions now incorporate well-to-wheel or even cradle-to-grave emissions accounting, affecting how Wankel engines are evaluated against alternative powertrains. This shift necessitates calibration approaches that optimize not only for tailpipe emissions but also for overall efficiency to minimize carbon footprint across the vehicle lifecycle.

The integration of Wankel engines into hybrid powertrains offers promising pathways for emissions compliance, with several manufacturers exploring range-extender applications where the rotary engine operates primarily within its optimal efficiency window. Automated calibration systems for these applications must balance emissions performance with noise, vibration, and harshness (NVH) characteristics, particularly during engine start-stop events that are frequent in hybrid operation.

Looking forward, emerging regulatory frameworks for synthetic fuels and hydrogen compatibility may create new opportunities for Wankel engine applications. The rotary engine's fuel flexibility represents a potential advantage in markets developing regulatory pathways for carbon-neutral fuels. Calibration systems must therefore incorporate adaptability to alternative fuel compositions while maintaining compliance with conventional emissions standards during the transition period.

Automated calibration systems for Wankel engines must navigate a complex matrix of regulatory requirements that vary significantly across global markets. The European Commission's Real Driving Emissions (RDE) testing protocol, implemented alongside laboratory-based Worldwide Harmonized Light Vehicles Test Procedure (WLTP), demands robust on-road performance across diverse driving conditions. This presents particular challenges for rotary engine calibration, requiring sophisticated emissions control strategies beyond traditional approaches.

Compliance strategies for modern Wankel engines increasingly incorporate advanced aftertreatment systems, including three-way catalytic converters specifically designed for rotary applications, lean NOx traps, and particulate filters optimized for the unique exhaust gas composition. The calibration of these systems must account for the Wankel's characteristic high exhaust temperatures and distinctive emission profiles, particularly during cold-start conditions when hydrocarbon emissions are most problematic.

Regulatory frameworks are evolving toward lifecycle emissions assessment, with carbon neutrality targets influencing compliance strategies. Several jurisdictions now incorporate well-to-wheel or even cradle-to-grave emissions accounting, affecting how Wankel engines are evaluated against alternative powertrains. This shift necessitates calibration approaches that optimize not only for tailpipe emissions but also for overall efficiency to minimize carbon footprint across the vehicle lifecycle.

The integration of Wankel engines into hybrid powertrains offers promising pathways for emissions compliance, with several manufacturers exploring range-extender applications where the rotary engine operates primarily within its optimal efficiency window. Automated calibration systems for these applications must balance emissions performance with noise, vibration, and harshness (NVH) characteristics, particularly during engine start-stop events that are frequent in hybrid operation.

Looking forward, emerging regulatory frameworks for synthetic fuels and hydrogen compatibility may create new opportunities for Wankel engine applications. The rotary engine's fuel flexibility represents a potential advantage in markets developing regulatory pathways for carbon-neutral fuels. Calibration systems must therefore incorporate adaptability to alternative fuel compositions while maintaining compliance with conventional emissions standards during the transition period.

Integration Challenges with Modern Control Systems

The integration of Wankel rotary engines with modern control systems presents significant technical challenges that must be addressed for successful implementation in automated systems. Traditional electronic control units (ECUs) designed for reciprocating engines often struggle to properly interpret and respond to the unique operational characteristics of rotary engines. The three-phase combustion cycle of Wankel engines requires specialized timing algorithms that differ substantially from conventional four-stroke engines, creating compatibility issues with standardized control architectures.

One primary integration challenge lies in sensor placement and data interpretation. The geometric configuration of rotary engines means conventional sensor locations may not provide accurate readings, while the data patterns generated require different interpretation models. For instance, temperature and pressure sensors must account for the continuous rotational movement rather than the reciprocating motion found in piston engines, necessitating specialized calibration methodologies and signal processing algorithms.

Communication protocols present another significant hurdle. Most modern vehicle control systems utilize standardized protocols like CAN, AUTOSAR, or FlexRay that were developed with conventional engine architectures in mind. Adapting these protocols to accommodate the unique timing requirements and operational parameters of Wankel engines requires substantial modification to existing communication frameworks, potentially introducing latency issues that could compromise real-time control performance.

The thermal management integration poses particular difficulties due to the Wankel engine's distinctive heat distribution patterns. Modern control systems must be reconfigured to monitor and regulate thermal conditions across the epitrochoidal housing and rotor faces - areas without direct counterparts in conventional engines. This requires development of specialized thermal models and control algorithms that can accurately predict and manage heat distribution during various operational states.

Emissions control integration represents perhaps the most challenging aspect from a regulatory perspective. Modern control systems designed for conventional engines utilize predictable combustion event timing for precise emissions management. The continuous combustion characteristics of Wankel engines require fundamentally different approaches to catalyst management, exhaust gas recirculation control, and emissions monitoring. Control systems must be extensively modified to accommodate these differences while still meeting increasingly stringent emissions standards.

Lastly, diagnostic and fault detection systems face significant integration challenges. Standard OBD-II protocols and diagnostic trouble codes were developed primarily for conventional engine architectures, making fault identification and isolation in Wankel engines problematic without substantial reconfiguration of diagnostic algorithms and fault trees. This creates complications for both development engineers and service technicians working with automated systems powered by rotary engines.

One primary integration challenge lies in sensor placement and data interpretation. The geometric configuration of rotary engines means conventional sensor locations may not provide accurate readings, while the data patterns generated require different interpretation models. For instance, temperature and pressure sensors must account for the continuous rotational movement rather than the reciprocating motion found in piston engines, necessitating specialized calibration methodologies and signal processing algorithms.

Communication protocols present another significant hurdle. Most modern vehicle control systems utilize standardized protocols like CAN, AUTOSAR, or FlexRay that were developed with conventional engine architectures in mind. Adapting these protocols to accommodate the unique timing requirements and operational parameters of Wankel engines requires substantial modification to existing communication frameworks, potentially introducing latency issues that could compromise real-time control performance.

The thermal management integration poses particular difficulties due to the Wankel engine's distinctive heat distribution patterns. Modern control systems must be reconfigured to monitor and regulate thermal conditions across the epitrochoidal housing and rotor faces - areas without direct counterparts in conventional engines. This requires development of specialized thermal models and control algorithms that can accurately predict and manage heat distribution during various operational states.

Emissions control integration represents perhaps the most challenging aspect from a regulatory perspective. Modern control systems designed for conventional engines utilize predictable combustion event timing for precise emissions management. The continuous combustion characteristics of Wankel engines require fundamentally different approaches to catalyst management, exhaust gas recirculation control, and emissions monitoring. Control systems must be extensively modified to accommodate these differences while still meeting increasingly stringent emissions standards.

Lastly, diagnostic and fault detection systems face significant integration challenges. Standard OBD-II protocols and diagnostic trouble codes were developed primarily for conventional engine architectures, making fault identification and isolation in Wankel engines problematic without substantial reconfiguration of diagnostic algorithms and fault trees. This creates complications for both development engineers and service technicians working with automated systems powered by rotary engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!