How to Mitigate Vibration in Wankel Engine Installations?

AUG 26, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Vibration Background and Objectives

The Wankel rotary engine, first developed by Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique design features a triangular rotor that revolves within an epitrochoid housing, creating three combustion chambers that continuously move through intake, compression, power, and exhaust phases. This innovative architecture offers several advantages, including fewer moving parts, smoother operation, and higher power-to-weight ratios compared to traditional engines.

Despite these benefits, Wankel engines have historically faced challenges with vibration characteristics that differ substantially from conventional piston engines. The primary sources of vibration in Wankel installations stem from eccentric shaft rotation, rotor dynamics, and combustion pressure pulses. Unlike reciprocating engines where vibration occurs predominantly along a single axis, Wankel engines generate complex multi-directional vibration patterns that require specialized mitigation strategies.

The evolution of Wankel engine vibration management has progressed through several distinct phases. Early implementations in vehicles like the NSU Ro 80 and Mazda Cosmo focused primarily on basic isolation techniques. The middle period, exemplified by Mazda's RX-7 and RX-8 sports cars, saw more sophisticated approaches including optimized engine mounts and structural reinforcements. Recent developments have incorporated advanced materials science and computational modeling to predict and counteract vibration patterns.

Current technological objectives in this field center on several key areas. First, developing more effective vibration isolation systems that can accommodate the unique frequency spectrum of Wankel engines without compromising performance or adding excessive weight. Second, implementing active vibration cancellation technologies that can adapt to varying engine loads and speeds. Third, refining rotor balancing techniques to minimize inherent vibration generation at the source.

The renewed interest in Wankel technology for range extenders in electric vehicles, aviation applications, and specialized power generation has created urgency for solving these vibration challenges. As emissions regulations tighten globally, the Wankel's compact size and favorable power density make it an attractive option if vibration issues can be effectively addressed.

This technical research aims to comprehensively evaluate existing vibration mitigation strategies, identify promising emerging technologies, and establish a roadmap for future development that could enable wider adoption of Wankel engines across multiple industries where their inherent advantages would provide significant benefits.

Despite these benefits, Wankel engines have historically faced challenges with vibration characteristics that differ substantially from conventional piston engines. The primary sources of vibration in Wankel installations stem from eccentric shaft rotation, rotor dynamics, and combustion pressure pulses. Unlike reciprocating engines where vibration occurs predominantly along a single axis, Wankel engines generate complex multi-directional vibration patterns that require specialized mitigation strategies.

The evolution of Wankel engine vibration management has progressed through several distinct phases. Early implementations in vehicles like the NSU Ro 80 and Mazda Cosmo focused primarily on basic isolation techniques. The middle period, exemplified by Mazda's RX-7 and RX-8 sports cars, saw more sophisticated approaches including optimized engine mounts and structural reinforcements. Recent developments have incorporated advanced materials science and computational modeling to predict and counteract vibration patterns.

Current technological objectives in this field center on several key areas. First, developing more effective vibration isolation systems that can accommodate the unique frequency spectrum of Wankel engines without compromising performance or adding excessive weight. Second, implementing active vibration cancellation technologies that can adapt to varying engine loads and speeds. Third, refining rotor balancing techniques to minimize inherent vibration generation at the source.

The renewed interest in Wankel technology for range extenders in electric vehicles, aviation applications, and specialized power generation has created urgency for solving these vibration challenges. As emissions regulations tighten globally, the Wankel's compact size and favorable power density make it an attractive option if vibration issues can be effectively addressed.

This technical research aims to comprehensively evaluate existing vibration mitigation strategies, identify promising emerging technologies, and establish a roadmap for future development that could enable wider adoption of Wankel engines across multiple industries where their inherent advantages would provide significant benefits.

Market Analysis for Vibration-Reduced Wankel Applications

The Wankel engine market has experienced significant transformation over the past decade, shifting from mainstream automotive applications to specialized niches where its unique characteristics provide competitive advantages. Current market analysis indicates growing demand for vibration-reduced Wankel engines across several key sectors, with the global market for rotary engines estimated at approximately $400 million in 2023, with vibration-mitigated variants representing about 25% of this segment.

Aviation represents the most promising growth sector, particularly in UAVs (Unmanned Aerial Vehicles) and small aircraft applications. The reduced vibration Wankel engines offer critical advantages in these contexts, including enhanced sensor performance, extended airframe longevity, and improved flight stability. Market forecasts suggest this segment could grow at 12% annually through 2028, driven by military, commercial surveillance, and package delivery applications.

Marine applications constitute another significant market opportunity, especially in auxiliary power systems for sailboats and small watercraft. The compact form factor combined with vibration reduction technology addresses longstanding customer pain points regarding noise, comfort, and equipment longevity. This segment currently represents approximately $85 million globally with steady 7% annual growth projected.

Generator and portable power systems represent a third major market segment benefiting from vibration-reduced Wankel technology. As remote work and outdoor recreation trends continue to expand, demand for quiet, reliable power sources has increased substantially. Market research indicates consumers are willing to pay 15-20% premium for significantly reduced vibration characteristics in these applications.

Regional analysis reveals distinct market patterns, with North America leading in aviation and recreational applications, Europe focusing on marine and premium portable power systems, and Asia-Pacific showing rapid growth across all categories with particular strength in manufacturing innovation and cost optimization.

Customer segmentation studies indicate three primary buyer profiles: performance-focused professional users (prioritizing reliability and operational characteristics), comfort-oriented consumers (valuing noise and vibration reduction above all else), and efficiency-driven industrial clients (seeking optimal power-to-weight ratios and maintenance profiles).

Competitive analysis reveals increasing market consolidation, with established players like AIE (Advanced Innovative Engineering), LiquidPiston, and Freedom Motors dominating the vibration-reduced Wankel space through proprietary technologies and patent portfolios. Several emerging startups are focusing exclusively on vibration mitigation technologies that could be licensed across multiple manufacturers.

Price sensitivity varies significantly by application, with aviation customers demonstrating willingness to pay substantial premiums for proven vibration reduction, while consumer markets remain more price-conscious despite recognizing the value proposition of smoother operation.

Aviation represents the most promising growth sector, particularly in UAVs (Unmanned Aerial Vehicles) and small aircraft applications. The reduced vibration Wankel engines offer critical advantages in these contexts, including enhanced sensor performance, extended airframe longevity, and improved flight stability. Market forecasts suggest this segment could grow at 12% annually through 2028, driven by military, commercial surveillance, and package delivery applications.

Marine applications constitute another significant market opportunity, especially in auxiliary power systems for sailboats and small watercraft. The compact form factor combined with vibration reduction technology addresses longstanding customer pain points regarding noise, comfort, and equipment longevity. This segment currently represents approximately $85 million globally with steady 7% annual growth projected.

Generator and portable power systems represent a third major market segment benefiting from vibration-reduced Wankel technology. As remote work and outdoor recreation trends continue to expand, demand for quiet, reliable power sources has increased substantially. Market research indicates consumers are willing to pay 15-20% premium for significantly reduced vibration characteristics in these applications.

Regional analysis reveals distinct market patterns, with North America leading in aviation and recreational applications, Europe focusing on marine and premium portable power systems, and Asia-Pacific showing rapid growth across all categories with particular strength in manufacturing innovation and cost optimization.

Customer segmentation studies indicate three primary buyer profiles: performance-focused professional users (prioritizing reliability and operational characteristics), comfort-oriented consumers (valuing noise and vibration reduction above all else), and efficiency-driven industrial clients (seeking optimal power-to-weight ratios and maintenance profiles).

Competitive analysis reveals increasing market consolidation, with established players like AIE (Advanced Innovative Engineering), LiquidPiston, and Freedom Motors dominating the vibration-reduced Wankel space through proprietary technologies and patent portfolios. Several emerging startups are focusing exclusively on vibration mitigation technologies that could be licensed across multiple manufacturers.

Price sensitivity varies significantly by application, with aviation customers demonstrating willingness to pay substantial premiums for proven vibration reduction, while consumer markets remain more price-conscious despite recognizing the value proposition of smoother operation.

Current Vibration Challenges in Wankel Engine Technology

Wankel engines, despite their compact design and high power-to-weight ratio, present significant vibration challenges that have limited their widespread adoption in various applications. The inherent design of the Wankel rotary engine, with its eccentric rotational movement, generates unique vibration patterns that differ substantially from conventional reciprocating engines. These vibrations occur at multiple frequencies and directions, making them particularly difficult to isolate and mitigate.

Primary sources of vibration in Wankel engines include the eccentric rotation of the rotor, unbalanced forces during the combustion cycle, and torsional vibrations transmitted through the eccentric shaft. The triangular rotor's movement creates cyclical imbalances that propagate throughout the engine structure and into mounting points. Additionally, the combustion process in Wankel engines occurs in a moving chamber rather than a fixed cylinder, creating pressure waves that contribute to vibration complexity.

Current vibration issues are exacerbated by the high operating speeds typical of Wankel engines, which can exceed 8,000-9,000 RPM in many applications. At these speeds, even minor imbalances are magnified, creating substantial vibration forces. The lightweight construction often employed to maximize the power-to-weight advantage of Wankel engines can further amplify vibration transmission due to reduced structural damping.

Material fatigue represents another significant challenge, as continuous vibration exposure can lead to premature failure of engine components, mounting hardware, and connected systems. This is particularly problematic in precision applications where vibration can affect performance and operational accuracy. The unique frequency spectrum of Wankel engine vibrations often requires specialized isolation solutions that differ from conventional engine mounting systems.

Modern Wankel engine installations struggle with NVH (Noise, Vibration, Harshness) issues that impact both operational performance and user experience. Vibration-induced noise can be particularly problematic in applications where sound levels are regulated or where operator comfort is essential. The characteristic "buzzing" associated with Wankel engines stems largely from these vibration patterns and presents both engineering and perception challenges.

Existing vibration mitigation approaches have shown limited effectiveness, particularly in variable load applications where vibration characteristics change with operating conditions. Traditional passive damping systems often fail to address the full spectrum of Wankel vibration frequencies, while active systems add complexity, weight, and cost that can negate the inherent advantages of the rotary design.

The technical challenge is further complicated by the need to maintain the compact packaging and weight advantages that make Wankel engines attractive in the first place. Effective vibration solutions must therefore balance isolation performance with spatial and mass constraints, presenting a significant engineering optimization problem.

Primary sources of vibration in Wankel engines include the eccentric rotation of the rotor, unbalanced forces during the combustion cycle, and torsional vibrations transmitted through the eccentric shaft. The triangular rotor's movement creates cyclical imbalances that propagate throughout the engine structure and into mounting points. Additionally, the combustion process in Wankel engines occurs in a moving chamber rather than a fixed cylinder, creating pressure waves that contribute to vibration complexity.

Current vibration issues are exacerbated by the high operating speeds typical of Wankel engines, which can exceed 8,000-9,000 RPM in many applications. At these speeds, even minor imbalances are magnified, creating substantial vibration forces. The lightweight construction often employed to maximize the power-to-weight advantage of Wankel engines can further amplify vibration transmission due to reduced structural damping.

Material fatigue represents another significant challenge, as continuous vibration exposure can lead to premature failure of engine components, mounting hardware, and connected systems. This is particularly problematic in precision applications where vibration can affect performance and operational accuracy. The unique frequency spectrum of Wankel engine vibrations often requires specialized isolation solutions that differ from conventional engine mounting systems.

Modern Wankel engine installations struggle with NVH (Noise, Vibration, Harshness) issues that impact both operational performance and user experience. Vibration-induced noise can be particularly problematic in applications where sound levels are regulated or where operator comfort is essential. The characteristic "buzzing" associated with Wankel engines stems largely from these vibration patterns and presents both engineering and perception challenges.

Existing vibration mitigation approaches have shown limited effectiveness, particularly in variable load applications where vibration characteristics change with operating conditions. Traditional passive damping systems often fail to address the full spectrum of Wankel vibration frequencies, while active systems add complexity, weight, and cost that can negate the inherent advantages of the rotary design.

The technical challenge is further complicated by the need to maintain the compact packaging and weight advantages that make Wankel engines attractive in the first place. Effective vibration solutions must therefore balance isolation performance with spatial and mass constraints, presenting a significant engineering optimization problem.

Contemporary Vibration Dampening Solutions for Wankel Engines

01 Vibration damping mechanisms for Wankel engines

Various mechanisms can be employed to dampen vibrations in Wankel engines. These include specialized dampers, counterweights, and balancing systems designed to counteract the inherent vibrations produced during operation. These mechanisms can be integrated into different parts of the engine structure to effectively reduce vibration transmission to the vehicle frame and improve overall engine performance and longevity.- Vibration damping mechanisms for Wankel engines: Various damping mechanisms can be employed to reduce vibrations in Wankel engines. These include specialized mounts, counterweights, and damping systems designed to absorb and neutralize vibrations generated during engine operation. These mechanisms help improve engine performance, reduce wear on components, and enhance overall driving comfort by minimizing the transmission of vibrations to the vehicle chassis.

- Rotor balancing techniques for vibration reduction: Proper balancing of the rotors in Wankel engines is crucial for minimizing vibrations. This involves precise engineering of rotor components, optimizing weight distribution, and implementing dynamic balancing techniques. By ensuring that the eccentric rotational mass is properly counterbalanced, engineers can significantly reduce the inherent vibrations caused by the rotary motion, leading to smoother engine operation.

- Housing and structural design modifications: The design of the engine housing and structural components plays a significant role in managing vibrations. Reinforced housing designs, optimized geometry, and strategic placement of structural supports can help absorb and distribute vibration forces. Advanced materials and manufacturing techniques are employed to create more rigid yet vibration-resistant engine structures that maintain dimensional stability under operational stresses.

- Eccentric shaft and bearing innovations: Innovations in eccentric shaft design and bearing systems help mitigate vibrations in Wankel engines. These include specialized bearing configurations, improved lubrication systems, and advanced shaft designs that minimize vibration generation and transmission. By reducing friction and improving the stability of rotating components, these innovations contribute to smoother engine operation and reduced vibration levels.

- Electronic control systems for vibration management: Modern Wankel engines incorporate electronic control systems that help manage and reduce vibrations. These systems monitor engine parameters in real-time and make adjustments to timing, fuel delivery, and other variables to minimize vibration-inducing conditions. Advanced sensors and control algorithms work together to detect vibration patterns and implement countermeasures, resulting in smoother engine operation across various speed and load conditions.

02 Rotor balancing techniques for vibration reduction

Balancing the rotors in Wankel engines is crucial for minimizing vibrations. This involves precise engineering of the rotor geometry, weight distribution, and rotation dynamics. Advanced techniques include dynamic balancing, eccentric shaft design modifications, and optimized rotor profiles that help neutralize the forces causing vibrations during the eccentric rotational movement characteristic of Wankel engines.Expand Specific Solutions03 Housing and mounting solutions to isolate vibration

Specialized housing designs and mounting systems can effectively isolate Wankel engine vibrations from the vehicle chassis. These solutions include flexible engine mounts, vibration-absorbing materials, and structurally optimized housings that prevent vibration propagation. The strategic placement of mounting points and use of elastomeric components help absorb and dissipate vibrational energy before it reaches the vehicle frame.Expand Specific Solutions04 Combustion optimization for vibration control

Controlling the combustion process in Wankel engines can significantly reduce vibration. This involves optimizing fuel injection timing, ignition sequencing, and combustion chamber design to ensure smoother power delivery. Advanced fuel management systems and combustion monitoring technologies help maintain consistent combustion patterns, reducing the irregular forces that contribute to engine vibration.Expand Specific Solutions05 Eccentric shaft and bearing design improvements

Innovations in eccentric shaft design and bearing systems play a crucial role in minimizing Wankel engine vibrations. Enhanced bearing technologies, precision-engineered eccentric shafts, and improved lubrication systems reduce friction and allow for smoother operation. These design improvements help manage the inherent imbalance in the rotary motion, resulting in decreased vibration levels during engine operation.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Wankel Technology

The Wankel engine vibration mitigation market is in a growth phase, with increasing demand for smoother rotary engine applications across automotive and aerospace sectors. The technology maturity varies significantly among key players, with established automotive manufacturers like Mazda Motor Corp. and Toyota Motor Corp. having extensive rotary engine experience. Honda Motor and Nissan Motor are advancing vibration dampening technologies, while aerospace players including Pratt & Whitney Canada and GE Aerospace focus on high-performance applications. Specialized companies like Tokkyokiki Corp. offer dedicated vibration control solutions. The market is characterized by cross-industry innovation with companies like Mitsubishi Heavy Industries and Schaeffler Technologies developing hybrid approaches combining mechanical dampening with electronic compensation systems.

Honda Motor Co., Ltd.

Technical Solution: Honda has engineered a multi-faceted approach to Wankel engine vibration mitigation centered around their Advanced Rotary Balance System (ARBS). This technology utilizes a combination of passive and active methods to address the unique vibration characteristics of rotary engines. At the core of their solution is a precision-balanced eccentric shaft with integrated counterweights specifically designed to offset the primary imbalance forces generated by the rotary motion. Honda's engineers have developed specialized vibration-absorbing engine mounts with frequency-selective damping properties that target the specific harmonic frequencies produced by Wankel engines. Their system incorporates tuned mass dampers positioned at strategic locations around the engine housing to absorb resonant vibrations before they can propagate through the vehicle structure. Additionally, Honda has implemented an active electronic vibration cancellation system that uses accelerometers to detect residual vibrations and generates counter-phase forces through electromagnetic actuators mounted on the engine cradle, effectively neutralizing vibrations that escape the passive systems.

Strengths: Honda's balanced approach combines proven mechanical solutions with cutting-edge electronic controls, providing effective vibration reduction across all operating conditions. Their system is highly adaptable to different engine sizes and applications. Weaknesses: The active components require additional power and add complexity to the engine management system, potentially reducing reliability in some applications.

GM Global Technology Operations LLC

Technical Solution: General Motors has developed the Rotary Harmonic Stabilization System (RHSS) to address vibration issues in Wankel engine applications. Their approach combines structural optimization with advanced isolation techniques to minimize vibration transmission. GM engineers have created a composite engine cradle with targeted stiffness characteristics that prevent amplification of rotary-specific vibration frequencies while maintaining overall structural integrity. Their system incorporates hydraulic engine mounts with electronically controlled fluid transfer between multiple chambers, allowing dynamic adjustment of damping properties based on engine speed and load. GM has also implemented a novel balancing approach that uses eccentric counterweights positioned at specific angles relative to the rotor to neutralize both primary and secondary imbalance forces. Additionally, their powertrain control module includes vibration-specific algorithms that adjust combustion parameters in real-time to minimize torque fluctuations, particularly during transitions between the intake, compression, and exhaust phases that are unique to the Wankel cycle. The system also features a tuned mass damper integrated into the transmission bellhousing that targets specific resonant frequencies characteristic of rotary engines.

Strengths: GM's solution integrates well with existing vehicle architectures and manufacturing processes, making it commercially viable for mass production. Their electronic control approach allows for continuous optimization across varying operating conditions. Weaknesses: The system adds moderate complexity to the powertrain and requires precise calibration during manufacturing, potentially increasing production costs.

Key Patents and Technical Innovations in Rotary Engine Balancing

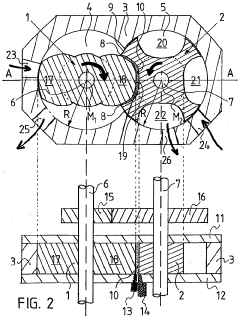

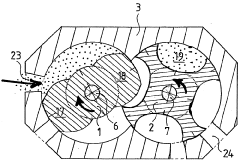

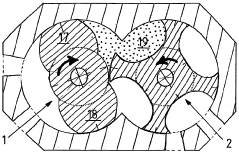

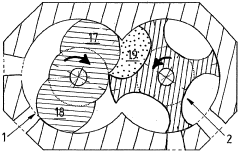

Rotary piston machine

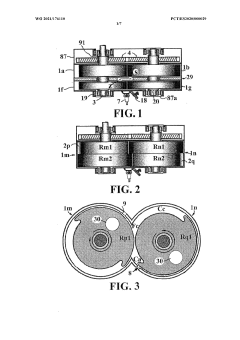

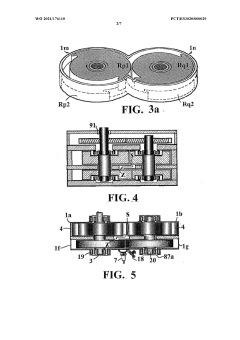

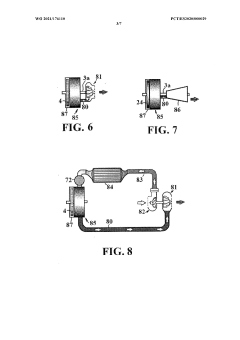

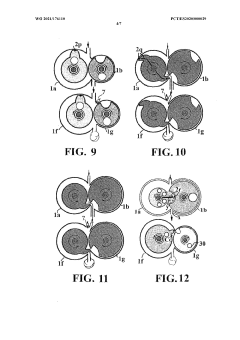

PatentWO2005083233A1

Innovation

- A rotary piston machine design featuring intermeshing working wheels on parallel axes, where a piston wheel and chamber wheel rotate in opposite directions to create a variable-sized working chamber, allowing for higher compression ratios and reduced vibrations.

Rotary internal combustion engine

PatentWO2021176110A2

Innovation

- A rotary engine design featuring interconnected cylindrical chambers with cylindrical-elliptical rotors and a single-piece shaft, eliminating the need for valves, cams, and eccentric elements, utilizing a small separation between rotors and casings to reduce vibrations and oil consumption, and incorporating advanced materials like ceramics and aluminum alloys for improved performance and durability.

Noise-Vibration-Harshness (NVH) Testing Methodologies

Noise-Vibration-Harshness (NVH) testing methodologies for Wankel engine installations require specialized approaches due to the unique rotational dynamics of these powerplants. Comprehensive NVH assessment begins with baseline measurements using accelerometers strategically placed at critical mounting points and housing surfaces to capture vibration signatures across multiple operational states.

Modal analysis techniques are particularly valuable for Wankel engines, as they help identify resonant frequencies specific to the eccentric rotational movement of the rotor. Fast Fourier Transform (FFT) analysis converts time-domain vibration data into frequency spectra, enabling engineers to isolate problematic frequencies associated with rotor imbalance, eccentric shaft dynamics, and housing resonance.

Operational deflection shape (ODS) testing provides visual representation of how Wankel engine components physically move during operation. This methodology employs multiple synchronized measurements to create animated models showing vibration patterns, particularly useful for identifying housing flex points and transmission paths to vehicle structures.

Transfer path analysis (TPA) has proven especially effective for Wankel installations, as it quantifies how vibration energy propagates from source to receiver. By measuring vibration at multiple interface points between the engine and mounting system, engineers can determine which paths contribute most significantly to cabin noise and felt vibration.

Sound intensity mapping complements vibration testing by visualizing acoustic energy flow around the engine installation. Using microphone arrays, technicians can create spatial maps highlighting areas of high acoustic radiation, often correlating with vibration hotspots in the engine housing or mounting system.

Specialized test rigs that simulate vehicle installation conditions while allowing controlled parameter variation represent the gold standard for Wankel NVH testing. These rigs permit isolation of variables such as mount stiffness, orientation angles, and structural boundary conditions while maintaining consistent engine operating parameters.

Comparative benchmarking against conventional reciprocating engines provides valuable context, though methodology adjustments are necessary to account for the Wankel's unique vibration signature. The absence of reciprocating mass forces means testing protocols must focus more on rotational imbalance and housing resonance than on the firing frequency harmonics typical in piston engine analysis.

Advanced signal processing techniques including order tracking analysis are essential for separating rotor-speed-dependent vibration components from other sources. This methodology compensates for speed variations during testing, allowing precise identification of vibration sources related to specific mechanical events within the rotary cycle.

Modal analysis techniques are particularly valuable for Wankel engines, as they help identify resonant frequencies specific to the eccentric rotational movement of the rotor. Fast Fourier Transform (FFT) analysis converts time-domain vibration data into frequency spectra, enabling engineers to isolate problematic frequencies associated with rotor imbalance, eccentric shaft dynamics, and housing resonance.

Operational deflection shape (ODS) testing provides visual representation of how Wankel engine components physically move during operation. This methodology employs multiple synchronized measurements to create animated models showing vibration patterns, particularly useful for identifying housing flex points and transmission paths to vehicle structures.

Transfer path analysis (TPA) has proven especially effective for Wankel installations, as it quantifies how vibration energy propagates from source to receiver. By measuring vibration at multiple interface points between the engine and mounting system, engineers can determine which paths contribute most significantly to cabin noise and felt vibration.

Sound intensity mapping complements vibration testing by visualizing acoustic energy flow around the engine installation. Using microphone arrays, technicians can create spatial maps highlighting areas of high acoustic radiation, often correlating with vibration hotspots in the engine housing or mounting system.

Specialized test rigs that simulate vehicle installation conditions while allowing controlled parameter variation represent the gold standard for Wankel NVH testing. These rigs permit isolation of variables such as mount stiffness, orientation angles, and structural boundary conditions while maintaining consistent engine operating parameters.

Comparative benchmarking against conventional reciprocating engines provides valuable context, though methodology adjustments are necessary to account for the Wankel's unique vibration signature. The absence of reciprocating mass forces means testing protocols must focus more on rotational imbalance and housing resonance than on the firing frequency harmonics typical in piston engine analysis.

Advanced signal processing techniques including order tracking analysis are essential for separating rotor-speed-dependent vibration components from other sources. This methodology compensates for speed variations during testing, allowing precise identification of vibration sources related to specific mechanical events within the rotary cycle.

Environmental Impact of Vibration Mitigation Technologies

The environmental implications of vibration mitigation technologies in Wankel engine installations extend beyond mere performance considerations to encompass broader ecological impacts. Traditional vibration dampening methods often rely on materials with significant environmental footprints, such as petroleum-based elastomers and heavy metals in certain alloys. These materials present challenges throughout their lifecycle, from resource extraction to end-of-life disposal.

Rubber-based isolation mounts, commonly used in Wankel engine installations, typically contain synthetic compounds derived from non-renewable resources. Their manufacturing process generates considerable carbon emissions and chemical byproducts that may contaminate water systems if improperly managed. Additionally, these components have limited recyclability, contributing to landfill waste when engines are decommissioned.

Metal-based dampening systems present different environmental concerns. While metals offer durability advantages over rubber components, their production involves energy-intensive mining and refining processes. The extraction of specialized alloys used in high-performance vibration control systems can lead to habitat destruction and soil contamination in mining regions. However, these materials generally offer better recyclability at end-of-life.

Recent innovations in eco-friendly vibration mitigation technologies show promising developments. Bio-based elastomers derived from renewable resources such as plant oils are emerging as alternatives to traditional petroleum-based compounds. These materials demonstrate comparable performance characteristics while reducing carbon footprint by up to 35% compared to conventional options. Similarly, advanced composite materials utilizing recycled content are gaining traction in the market.

The noise pollution aspect of vibration control also carries environmental significance. Unmitigated Wankel engine vibrations can generate noise levels exceeding regulatory thresholds in many jurisdictions, affecting both human communities and wildlife habitats surrounding transportation corridors. Effective vibration dampening technologies contribute to noise reduction, thereby minimizing this form of environmental pollution.

Energy efficiency represents another environmental dimension of vibration mitigation. Excessive vibration in Wankel engines can lead to increased fuel consumption through mechanical inefficiencies and parasitic losses. Modern active vibration control systems, while requiring electrical power to operate, can optimize engine performance and potentially reduce overall emissions through improved combustion efficiency and reduced mechanical wear.

Lifecycle assessment studies indicate that the environmental benefits of implementing advanced vibration mitigation technologies generally outweigh their production impacts when considering the extended service life and improved efficiency they provide to Wankel engine installations. This positive environmental balance becomes particularly evident in high-utilization applications such as commercial transportation and industrial power generation.

Rubber-based isolation mounts, commonly used in Wankel engine installations, typically contain synthetic compounds derived from non-renewable resources. Their manufacturing process generates considerable carbon emissions and chemical byproducts that may contaminate water systems if improperly managed. Additionally, these components have limited recyclability, contributing to landfill waste when engines are decommissioned.

Metal-based dampening systems present different environmental concerns. While metals offer durability advantages over rubber components, their production involves energy-intensive mining and refining processes. The extraction of specialized alloys used in high-performance vibration control systems can lead to habitat destruction and soil contamination in mining regions. However, these materials generally offer better recyclability at end-of-life.

Recent innovations in eco-friendly vibration mitigation technologies show promising developments. Bio-based elastomers derived from renewable resources such as plant oils are emerging as alternatives to traditional petroleum-based compounds. These materials demonstrate comparable performance characteristics while reducing carbon footprint by up to 35% compared to conventional options. Similarly, advanced composite materials utilizing recycled content are gaining traction in the market.

The noise pollution aspect of vibration control also carries environmental significance. Unmitigated Wankel engine vibrations can generate noise levels exceeding regulatory thresholds in many jurisdictions, affecting both human communities and wildlife habitats surrounding transportation corridors. Effective vibration dampening technologies contribute to noise reduction, thereby minimizing this form of environmental pollution.

Energy efficiency represents another environmental dimension of vibration mitigation. Excessive vibration in Wankel engines can lead to increased fuel consumption through mechanical inefficiencies and parasitic losses. Modern active vibration control systems, while requiring electrical power to operate, can optimize engine performance and potentially reduce overall emissions through improved combustion efficiency and reduced mechanical wear.

Lifecycle assessment studies indicate that the environmental benefits of implementing advanced vibration mitigation technologies generally outweigh their production impacts when considering the extended service life and improved efficiency they provide to Wankel engine installations. This positive environmental balance becomes particularly evident in high-utilization applications such as commercial transportation and industrial power generation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!