How to Document Wankel Engine Experimental Results?

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Documentation Background and Objectives

The Wankel rotary engine represents a significant departure from conventional reciprocating piston engines, offering unique advantages in terms of power-to-weight ratio, mechanical simplicity, and compact design. Since its invention by Felix Wankel in the 1950s, this engine has undergone various developmental phases, with notable commercial applications by manufacturers such as NSU, Mazda, and Norton Motorcycles. The evolution of this technology has been characterized by continuous refinement to address inherent challenges related to sealing, fuel efficiency, and emissions.

The documentation of Wankel engine experimental results has historically lacked standardization, creating challenges for researchers, engineers, and industry stakeholders in comparing findings across different studies. This technical pre-research aims to establish a comprehensive framework for documenting experimental results related to Wankel engines, facilitating more effective knowledge sharing and technological advancement in this specialized field.

Current technological trends indicate renewed interest in Wankel engines for specific applications, including range extenders for electric vehicles, drone propulsion systems, and specialized automotive applications where their unique characteristics provide competitive advantages. This resurgence necessitates improved documentation methodologies to support ongoing research and development efforts.

The primary objectives of this technical investigation include developing standardized protocols for recording experimental data specific to Wankel engine performance, establishing metrics that accurately reflect the unique operational characteristics of rotary engines, and creating documentation templates that facilitate meaningful comparison between different experimental setups and configurations.

Additionally, this research aims to incorporate modern digital documentation techniques, including real-time data acquisition systems, visualization tools, and simulation validation methodologies that can enhance the quality and accessibility of experimental results. These advancements would significantly improve the ability to analyze complex phenomena such as apex seal dynamics, thermal management, and combustion characteristics unique to the rotary design.

By establishing these documentation standards, we anticipate accelerating the pace of innovation in Wankel engine technology, potentially addressing long-standing challenges related to fuel efficiency and emissions that have historically limited wider adoption. The standardization of experimental documentation would also facilitate more effective collaboration between academic institutions, industry partners, and regulatory bodies.

The expected outcome of this technical pre-research is a comprehensive documentation framework that balances the need for technical rigor with practical usability, ensuring that experimental results can be effectively communicated, validated, and built upon by the broader engineering community interested in rotary engine technology.

The documentation of Wankel engine experimental results has historically lacked standardization, creating challenges for researchers, engineers, and industry stakeholders in comparing findings across different studies. This technical pre-research aims to establish a comprehensive framework for documenting experimental results related to Wankel engines, facilitating more effective knowledge sharing and technological advancement in this specialized field.

Current technological trends indicate renewed interest in Wankel engines for specific applications, including range extenders for electric vehicles, drone propulsion systems, and specialized automotive applications where their unique characteristics provide competitive advantages. This resurgence necessitates improved documentation methodologies to support ongoing research and development efforts.

The primary objectives of this technical investigation include developing standardized protocols for recording experimental data specific to Wankel engine performance, establishing metrics that accurately reflect the unique operational characteristics of rotary engines, and creating documentation templates that facilitate meaningful comparison between different experimental setups and configurations.

Additionally, this research aims to incorporate modern digital documentation techniques, including real-time data acquisition systems, visualization tools, and simulation validation methodologies that can enhance the quality and accessibility of experimental results. These advancements would significantly improve the ability to analyze complex phenomena such as apex seal dynamics, thermal management, and combustion characteristics unique to the rotary design.

By establishing these documentation standards, we anticipate accelerating the pace of innovation in Wankel engine technology, potentially addressing long-standing challenges related to fuel efficiency and emissions that have historically limited wider adoption. The standardization of experimental documentation would also facilitate more effective collaboration between academic institutions, industry partners, and regulatory bodies.

The expected outcome of this technical pre-research is a comprehensive documentation framework that balances the need for technical rigor with practical usability, ensuring that experimental results can be effectively communicated, validated, and built upon by the broader engineering community interested in rotary engine technology.

Market Analysis for Rotary Engine Applications

The rotary engine market has experienced significant fluctuations over the past decades, with current global market value estimated at $2.1 billion and projected to grow at a compound annual growth rate of 3.7% through 2030. This growth is primarily driven by niche applications where the Wankel engine's unique characteristics provide competitive advantages over traditional reciprocating engines.

Aviation represents the most promising sector for rotary engine applications, particularly in unmanned aerial vehicles (UAVs) and small aircraft. The rotary engine's high power-to-weight ratio makes it ideal for these applications, with the UAV segment alone expected to reach $1.3 billion by 2028. Military and surveillance applications constitute approximately 42% of this market, while commercial applications in agriculture, delivery services, and infrastructure inspection make up the remainder.

Marine applications form another significant market segment, valued at approximately $480 million. The compact design and smooth operation of Wankel engines make them suitable for small watercraft and auxiliary power units on larger vessels. This segment is growing steadily at 4.2% annually, driven by recreational boating and specialized commercial applications.

Automotive applications have declined substantially since Mazda discontinued its RX series, but specialized applications persist in racing, classic car restoration, and concept vehicles. This segment represents approximately $290 million annually, with enthusiast markets showing remarkable stability despite limited mainstream adoption.

Generator sets and portable power applications constitute an emerging market for rotary engines, valued at $210 million and growing at 5.1% annually. The engines' compact size, low vibration, and multi-fuel capability make them attractive for emergency power, remote operations, and military applications where these attributes are highly valued.

Regional analysis shows Asia-Pacific leading market growth at 4.9% annually, driven by Japan's historical expertise and emerging manufacturing capabilities in China and South Korea. North America follows at 3.8% growth, with strong demand in military and specialized industrial applications. Europe maintains a stable market share with 2.9% growth, primarily in aviation and premium automotive applications.

Consumer demand patterns indicate increasing interest in fuel efficiency and emissions performance, areas where traditional Wankel designs have faced challenges. However, recent technological developments addressing these limitations, including direct injection systems and improved apex seal materials, have renewed market interest. The potential for rotary engines in hybrid powertrains and as range extenders for electric vehicles represents a significant opportunity, with several manufacturers exploring these configurations.

Aviation represents the most promising sector for rotary engine applications, particularly in unmanned aerial vehicles (UAVs) and small aircraft. The rotary engine's high power-to-weight ratio makes it ideal for these applications, with the UAV segment alone expected to reach $1.3 billion by 2028. Military and surveillance applications constitute approximately 42% of this market, while commercial applications in agriculture, delivery services, and infrastructure inspection make up the remainder.

Marine applications form another significant market segment, valued at approximately $480 million. The compact design and smooth operation of Wankel engines make them suitable for small watercraft and auxiliary power units on larger vessels. This segment is growing steadily at 4.2% annually, driven by recreational boating and specialized commercial applications.

Automotive applications have declined substantially since Mazda discontinued its RX series, but specialized applications persist in racing, classic car restoration, and concept vehicles. This segment represents approximately $290 million annually, with enthusiast markets showing remarkable stability despite limited mainstream adoption.

Generator sets and portable power applications constitute an emerging market for rotary engines, valued at $210 million and growing at 5.1% annually. The engines' compact size, low vibration, and multi-fuel capability make them attractive for emergency power, remote operations, and military applications where these attributes are highly valued.

Regional analysis shows Asia-Pacific leading market growth at 4.9% annually, driven by Japan's historical expertise and emerging manufacturing capabilities in China and South Korea. North America follows at 3.8% growth, with strong demand in military and specialized industrial applications. Europe maintains a stable market share with 2.9% growth, primarily in aviation and premium automotive applications.

Consumer demand patterns indicate increasing interest in fuel efficiency and emissions performance, areas where traditional Wankel designs have faced challenges. However, recent technological developments addressing these limitations, including direct injection systems and improved apex seal materials, have renewed market interest. The potential for rotary engines in hybrid powertrains and as range extenders for electric vehicles represents a significant opportunity, with several manufacturers exploring these configurations.

Current Documentation Challenges in Rotary Engine Testing

The documentation of Wankel engine experimental results faces significant challenges that impede efficient research progress and knowledge transfer. Traditional documentation methods often fail to capture the unique three-dimensional motion and thermodynamic processes inherent to rotary engines. Engineers frequently struggle with standardization issues, as rotary engine testing lacks the well-established protocols that exist for reciprocating engines.

Data volume management presents a formidable obstacle, with modern sensors generating terabytes of information during extended testing periods. This data deluge includes high-frequency measurements of rotor position, combustion chamber pressure, temperature gradients, and emissions data that must be properly organized and stored. Many research facilities rely on outdated documentation systems that were designed for conventional piston engines, creating compatibility issues when applied to Wankel's unique geometry and operating principles.

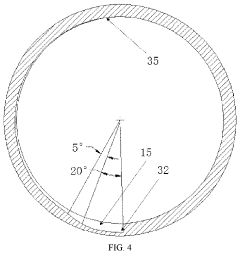

Visualization challenges are particularly acute when documenting rotary engine performance. The epitrochoidal housing and triangular rotor create complex spatial relationships that are difficult to represent in traditional two-dimensional formats. Current documentation methods often fail to adequately illustrate the dynamic sealing interactions between the rotor apex seals and housing walls—a critical aspect of Wankel engine performance and efficiency.

Temporal correlation of data streams represents another significant documentation hurdle. Engineers must synchronize measurements from multiple sensors with precise rotor position data to accurately analyze combustion events that occur at different locations within the housing. Without proper documentation frameworks, this temporal alignment becomes error-prone and inconsistent across research teams.

Terminology inconsistencies further complicate documentation efforts. Unlike conventional engines with standardized nomenclature, rotary engine components and phenomena often have varying descriptions across different research institutions and manufacturers. This linguistic fragmentation makes it difficult to compare results between studies or build upon previous research findings.

Knowledge preservation poses a long-term challenge, as expertise in rotary engine technology is concentrated among a relatively small community of specialists. Current documentation practices often fail to capture tacit knowledge and experimental insights, creating risks of information loss when experienced researchers retire or change fields. This institutional knowledge gap is particularly problematic for newcomers attempting to interpret historical test data.

Regulatory compliance adds another layer of complexity, as emissions testing documentation for Wankel engines must satisfy requirements designed primarily for conventional powerplants. The unique combustion characteristics of rotary engines often necessitate specialized documentation approaches to accurately represent their environmental impact and performance metrics.

Data volume management presents a formidable obstacle, with modern sensors generating terabytes of information during extended testing periods. This data deluge includes high-frequency measurements of rotor position, combustion chamber pressure, temperature gradients, and emissions data that must be properly organized and stored. Many research facilities rely on outdated documentation systems that were designed for conventional piston engines, creating compatibility issues when applied to Wankel's unique geometry and operating principles.

Visualization challenges are particularly acute when documenting rotary engine performance. The epitrochoidal housing and triangular rotor create complex spatial relationships that are difficult to represent in traditional two-dimensional formats. Current documentation methods often fail to adequately illustrate the dynamic sealing interactions between the rotor apex seals and housing walls—a critical aspect of Wankel engine performance and efficiency.

Temporal correlation of data streams represents another significant documentation hurdle. Engineers must synchronize measurements from multiple sensors with precise rotor position data to accurately analyze combustion events that occur at different locations within the housing. Without proper documentation frameworks, this temporal alignment becomes error-prone and inconsistent across research teams.

Terminology inconsistencies further complicate documentation efforts. Unlike conventional engines with standardized nomenclature, rotary engine components and phenomena often have varying descriptions across different research institutions and manufacturers. This linguistic fragmentation makes it difficult to compare results between studies or build upon previous research findings.

Knowledge preservation poses a long-term challenge, as expertise in rotary engine technology is concentrated among a relatively small community of specialists. Current documentation practices often fail to capture tacit knowledge and experimental insights, creating risks of information loss when experienced researchers retire or change fields. This institutional knowledge gap is particularly problematic for newcomers attempting to interpret historical test data.

Regulatory compliance adds another layer of complexity, as emissions testing documentation for Wankel engines must satisfy requirements designed primarily for conventional powerplants. The unique combustion characteristics of rotary engines often necessitate specialized documentation approaches to accurately represent their environmental impact and performance metrics.

Contemporary Documentation Methodologies for Engine Testing

01 Wankel Engine Design and Structure

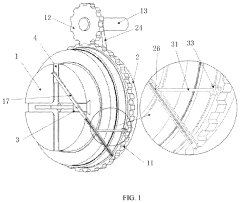

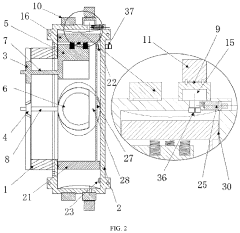

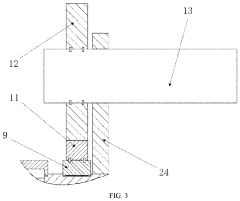

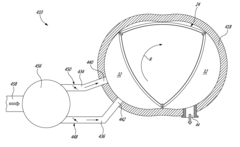

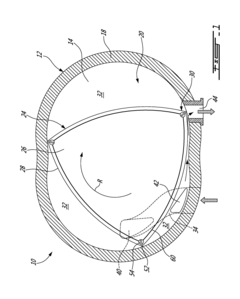

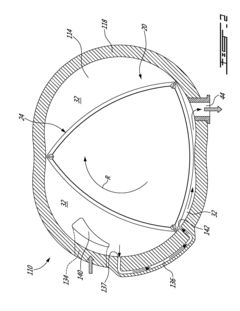

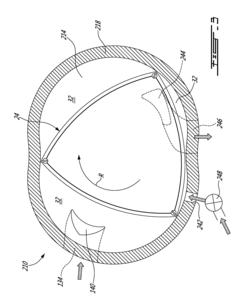

The Wankel engine has a unique rotary design that differs from conventional piston engines. It features a triangular rotor that rotates within an epitrochoidal housing, creating combustion chambers of varying volumes. This design allows for smoother operation with fewer moving parts compared to reciprocating engines. Documentation in this category covers the fundamental structure, components, and mechanical principles of Wankel engines.- Wankel Engine Design and Structure: The Wankel engine has a unique rotary design that differs from conventional piston engines. It features a triangular rotor that rotates within an epitrochoid-shaped housing, creating combustion chambers of varying volumes. This design allows for a smoother operation with fewer moving parts compared to traditional engines. The structure includes specific components such as rotor housings, eccentric shafts, and apex seals that are critical to its functioning.

- Cooling and Lubrication Systems: Wankel engines require specialized cooling and lubrication systems due to their unique geometry and operating characteristics. The cooling system must address the uneven heat distribution across the housing, particularly at the rotor housing where combustion occurs. Lubrication systems are designed to properly oil the apex seals, side seals, and bearings while minimizing oil consumption and emissions. These systems are crucial for maintaining engine efficiency and longevity.

- Performance Optimization and Efficiency Improvements: Various innovations focus on improving the efficiency and performance of Wankel engines. These include modifications to the combustion chamber geometry, advanced fuel injection systems, and optimized ignition timing. Techniques for reducing friction losses, improving sealing, and enhancing thermal efficiency are documented. Some developments address the traditional challenges of Wankel engines such as fuel consumption and emissions control.

- Electronic Control Systems and Documentation: Modern Wankel engines incorporate sophisticated electronic control systems for optimizing performance under various operating conditions. These systems manage fuel injection, ignition timing, emissions control, and other parameters. Documentation includes software architectures, control algorithms, and diagnostic procedures specific to rotary engines. Electronic documentation systems provide technical specifications, maintenance procedures, and troubleshooting guides for service technicians.

- Applications and Specialized Implementations: Wankel engines find applications in various fields beyond automotive use. Documentation covers specialized implementations in aircraft, marine vessels, generators, and other applications where the rotary engine's power-to-weight ratio and smooth operation provide advantages. These specialized applications often require modifications to the basic engine design to meet specific requirements such as altitude operation, continuous duty cycles, or integration with hybrid power systems.

02 Wankel Engine Performance Optimization

Documentation related to improving the performance of Wankel engines, including modifications to enhance power output, fuel efficiency, and operational stability. This includes innovations in rotor design, housing geometry, and combustion chamber optimization. These improvements address some of the traditional limitations of Wankel engines while maximizing their inherent advantages of high power-to-weight ratio and smooth operation.Expand Specific Solutions03 Wankel Engine Control Systems

Documentation covering electronic and mechanical control systems specifically designed for Wankel engines. This includes engine management systems, fuel injection control, ignition timing optimization, and monitoring systems. These control systems are tailored to address the unique operational characteristics of rotary engines, such as their different combustion dynamics and sealing challenges compared to conventional engines.Expand Specific Solutions04 Wankel Engine Manufacturing and Assembly

Documentation related to the manufacturing processes, assembly techniques, and production methods specific to Wankel engines. This includes precision machining of the epitrochoidal housing, rotor fabrication, apex seal installation, and quality control procedures. These documents detail the specialized manufacturing requirements needed to ensure proper operation of the critical components that affect engine performance and longevity.Expand Specific Solutions05 Wankel Engine Documentation Software and Systems

Documentation covering software tools, digital systems, and computational methods used for designing, analyzing, and documenting Wankel engines. This includes computer-aided design software, simulation tools for rotary engine performance, documentation management systems, and digital repositories for Wankel engine specifications. These tools help engineers and designers optimize rotary engine designs and maintain comprehensive technical documentation.Expand Specific Solutions

Leading Organizations in Rotary Engine Research

The Wankel engine experimental documentation landscape is currently in a growth phase, with increasing market interest driven by renewed focus on rotary engine efficiency and emissions. The technology maturity varies significantly among key players, with Toyota Motor Corp., Mazda (not listed), and BMW Brilliance Automotive leading commercial applications, while research institutions like Northwestern University and Jiangsu University focus on fundamental improvements. Companies like Pratt & Whitney Canada and AVIC Shenyang Liming are exploring aerospace applications, while Castrol and Sinopec develop specialized lubricants. Documentation standards are evolving from traditional methods toward digital platforms integrating real-time analytics, with automotive OEMs like GM Global Technology and Ford Global Technologies establishing proprietary protocols for experimental data collection and analysis.

GM Global Technology Operations LLC

Technical Solution: General Motors has established a comprehensive documentation protocol for Wankel engine experimentation that emphasizes practical application and production feasibility. Their approach integrates traditional dynamometer testing with advanced computational fluid dynamics (CFD) validation, creating a feedback loop between physical testing and simulation. GM's documentation system features specialized instrumentation for measuring the unique tribological interactions between apex seals and the epitrochoidal housing, capturing wear patterns and friction coefficients across various operating conditions. Their methodology incorporates a standardized test matrix that systematically explores the multidimensional parameter space of rotary engine operation, including variations in rotor geometry, port timing, and combustion chamber design[4]. GM has developed custom data visualization tools that represent the three-dimensional combustion process in an intuitive format, allowing engineers to identify optimization opportunities more effectively. Their documentation process includes detailed uncertainty analysis for each measurement channel, providing confidence intervals that help researchers distinguish between genuine performance trends and measurement artifacts.

Strengths: GM's documentation approach excels at bridging the gap between experimental results and production feasibility, making it particularly valuable for applied research and development. Their systematic test matrices ensure comprehensive coverage of the parameter space, reducing the risk of missing optimal configurations. Weaknesses: The system's focus on production feasibility sometimes comes at the expense of exploring more radical or theoretical concepts that might yield breakthrough innovations. The extensive test matrices required by their approach can significantly increase the time and resources needed to complete a research program.

Pratt & Whitney Canada Corp.

Technical Solution: Pratt & Whitney Canada has developed a specialized documentation framework for Wankel engine experimentation that draws on their extensive experience with high-performance rotary aircraft engines. Their approach emphasizes reliability assessment and durability testing, with particular attention to the unique challenges of aviation applications. P&WC's documentation system incorporates long-duration endurance testing protocols that capture performance degradation over time, with automated data collection continuing uninterrupted for thousands of operating hours. Their methodology features specialized instrumentation for monitoring oil consumption and contamination patterns specific to rotary engines, providing insights into sealing effectiveness and lubrication requirements. The company utilizes a hierarchical data structure that organizes experimental results across multiple timescales, from microsecond combustion events to thousand-hour durability trends[5]. P&WC's documentation process includes comprehensive thermal mapping of the entire engine assembly, with particular attention to the critical interfaces between stationary and rotating components. Their system also incorporates standardized reporting templates that ensure consistent presentation of results across different test cells and research facilities.

Strengths: Pratt & Whitney's documentation system excels at capturing long-term performance trends and reliability metrics that are crucial for aviation applications. Their comprehensive thermal mapping provides unique insights into heat management challenges that are particularly relevant for high-performance Wankel applications. Weaknesses: The system's aviation focus sometimes emphasizes parameters that may be less relevant for automotive or other applications of Wankel technology. The extensive durability testing protocols significantly increase the time required to complete a full experimental program compared to more focused approaches.

Critical Patents and Literature on Wankel Engine Measurement

Rotary engine

PatentActiveUS20230151762A1

Innovation

- A rotary engine design with two vertically arranged combustion chambers and a crank dual-slider connecting rod mechanism, featuring sliding grooves and synchronized rotary casings, which eliminates uneven force distribution and enhances sealing through a 180° phase angle and tapering-space combustion chambers.

Rotary internal combustion engine with exhaust purge

PatentActiveUS20150075483A1

Innovation

- The design incorporates a rotary engine with a stator body and rotor body that create variable volume chambers, featuring an inlet port, an exhaust port, and a purge port positioned relative to each other to achieve a lower volumetric compression ratio compared to the expansion ratio, with the purge port momentarily communicating with the exhaust port during specific rotor positions to effectively purge combustion gases.

Data Visualization Techniques for Complex Engine Parameters

Visualizing complex Wankel engine parameters requires specialized approaches due to the unique rotary design and operational characteristics. Traditional visualization methods often fail to capture the three-dimensional movement patterns and thermal distributions that are critical for understanding rotary engine performance. Advanced 3D rendering techniques have emerged as essential tools, allowing researchers to create dynamic visualizations of the rotor movement, combustion chamber geometry changes, and apex seal interactions throughout the operating cycle.

Heat map visualizations prove particularly valuable for documenting temperature distributions across the epitrochoidal housing and rotor faces. These visualizations can be enhanced with temporal elements to show how thermal patterns evolve during different operational phases, providing insights into potential cooling system optimizations. For Wankel engine experimental results, multi-parameter correlation displays are crucial, as they allow researchers to observe relationships between variables such as rotor eccentricity, compression ratio, and combustion efficiency simultaneously.

Interactive dashboards have revolutionized how Wankel engine data is presented, enabling stakeholders to manipulate variables and observe real-time changes in performance metrics. These platforms typically incorporate slider controls for adjusting parameters like RPM, fuel mixture, and timing advance, with corresponding outputs displayed as performance curves or efficiency maps. Such interactive tools significantly enhance the communication of complex relationships between operational variables.

Time-series animations represent another powerful visualization technique, particularly for documenting cycle-to-cycle variations in combustion characteristics. These animations can synchronize multiple data streams, showing pressure waves, flame front propagation, and emissions formation concurrently with rotor position. This temporal alignment helps identify critical events in the combustion process that might be missed in static representations.

Comparative visualization frameworks enable researchers to juxtapose experimental results against theoretical models or previous iterations. Split-screen approaches and overlay techniques allow for direct visual comparison of parameters like volumetric efficiency, power output, and emissions across different engine configurations or operating conditions. These comparative visualizations are essential for validating design improvements and identifying areas where actual performance deviates from predicted behavior.

Statistical visualization methods, including box plots and violin plots, provide valuable insights into data distribution and variability across repeated Wankel engine experiments. These representations help researchers assess the reliability of their findings and identify outliers that may indicate interesting phenomena or experimental errors requiring further investigation.

Heat map visualizations prove particularly valuable for documenting temperature distributions across the epitrochoidal housing and rotor faces. These visualizations can be enhanced with temporal elements to show how thermal patterns evolve during different operational phases, providing insights into potential cooling system optimizations. For Wankel engine experimental results, multi-parameter correlation displays are crucial, as they allow researchers to observe relationships between variables such as rotor eccentricity, compression ratio, and combustion efficiency simultaneously.

Interactive dashboards have revolutionized how Wankel engine data is presented, enabling stakeholders to manipulate variables and observe real-time changes in performance metrics. These platforms typically incorporate slider controls for adjusting parameters like RPM, fuel mixture, and timing advance, with corresponding outputs displayed as performance curves or efficiency maps. Such interactive tools significantly enhance the communication of complex relationships between operational variables.

Time-series animations represent another powerful visualization technique, particularly for documenting cycle-to-cycle variations in combustion characteristics. These animations can synchronize multiple data streams, showing pressure waves, flame front propagation, and emissions formation concurrently with rotor position. This temporal alignment helps identify critical events in the combustion process that might be missed in static representations.

Comparative visualization frameworks enable researchers to juxtapose experimental results against theoretical models or previous iterations. Split-screen approaches and overlay techniques allow for direct visual comparison of parameters like volumetric efficiency, power output, and emissions across different engine configurations or operating conditions. These comparative visualizations are essential for validating design improvements and identifying areas where actual performance deviates from predicted behavior.

Statistical visualization methods, including box plots and violin plots, provide valuable insights into data distribution and variability across repeated Wankel engine experiments. These representations help researchers assess the reliability of their findings and identify outliers that may indicate interesting phenomena or experimental errors requiring further investigation.

Standardization Requirements for Experimental Reproducibility

Standardization of experimental procedures and documentation for Wankel engine testing is critical to ensure reproducibility across different research institutions and industrial settings. The current landscape reveals significant inconsistencies in how rotary engine experimental results are documented, leading to challenges in comparative analysis and knowledge transfer. To address this issue, a comprehensive standardization framework must be established.

Primary documentation parameters should include precise specifications of the engine geometry, with particular emphasis on the epitrochoid housing shape, rotor dimensions, and eccentricity measurements. These geometric factors significantly influence combustion dynamics and must be documented with tolerances not exceeding ±0.01mm. Additionally, standardized measurement points for temperature distribution across the rotor faces and housing walls should be established, with a minimum of 12 measurement points recommended for adequate thermal mapping.

Operational parameters require equally rigorous standardization, including detailed documentation of apex seal dynamics under various RPM conditions. High-speed imaging protocols should specify frame rates of at least 10,000 fps to adequately capture seal movement during operation. Fuel delivery characteristics, particularly for peripheral port injection systems, must document injection timing relative to rotor position with precision of ±0.5 degrees.

Emissions measurement protocols present unique challenges for Wankel engines due to their distinctive combustion characteristics. Standardized sampling positions should be established at 150mm from the exhaust port, with temperature-controlled sampling lines maintained at 190°C ±5°C to prevent hydrocarbon condensation. Sampling frequency should correlate with engine speed, with a minimum of 4 samples per revolution at operational speeds.

Data reporting formats require standardization to facilitate cross-study comparison. Time-series data should be provided in both raw and processed formats, with processing algorithms explicitly documented. Statistical analysis methods must be standardized, with confidence intervals of 95% as the minimum reporting requirement for all performance metrics.

Calibration procedures for all measurement equipment must be documented in detail, including traceability to national or international standards. Inter-laboratory validation studies are recommended, with at least three independent facilities verifying critical performance metrics before publication of significant findings. This approach would substantially improve the reliability and reproducibility of Wankel engine experimental results across the research community.

Primary documentation parameters should include precise specifications of the engine geometry, with particular emphasis on the epitrochoid housing shape, rotor dimensions, and eccentricity measurements. These geometric factors significantly influence combustion dynamics and must be documented with tolerances not exceeding ±0.01mm. Additionally, standardized measurement points for temperature distribution across the rotor faces and housing walls should be established, with a minimum of 12 measurement points recommended for adequate thermal mapping.

Operational parameters require equally rigorous standardization, including detailed documentation of apex seal dynamics under various RPM conditions. High-speed imaging protocols should specify frame rates of at least 10,000 fps to adequately capture seal movement during operation. Fuel delivery characteristics, particularly for peripheral port injection systems, must document injection timing relative to rotor position with precision of ±0.5 degrees.

Emissions measurement protocols present unique challenges for Wankel engines due to their distinctive combustion characteristics. Standardized sampling positions should be established at 150mm from the exhaust port, with temperature-controlled sampling lines maintained at 190°C ±5°C to prevent hydrocarbon condensation. Sampling frequency should correlate with engine speed, with a minimum of 4 samples per revolution at operational speeds.

Data reporting formats require standardization to facilitate cross-study comparison. Time-series data should be provided in both raw and processed formats, with processing algorithms explicitly documented. Statistical analysis methods must be standardized, with confidence intervals of 95% as the minimum reporting requirement for all performance metrics.

Calibration procedures for all measurement equipment must be documented in detail, including traceability to national or international standards. Inter-laboratory validation studies are recommended, with at least three independent facilities verifying critical performance metrics before publication of significant findings. This approach would substantially improve the reliability and reproducibility of Wankel engine experimental results across the research community.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!