Wankel Engine Component Harmonization Techniques

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Evolution and Harmonization Objectives

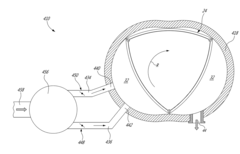

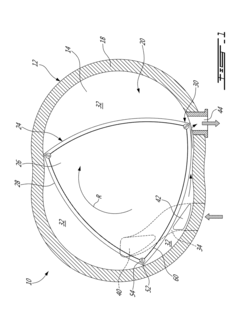

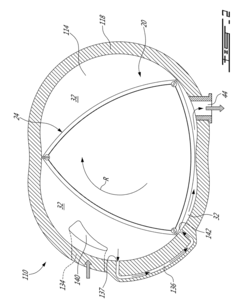

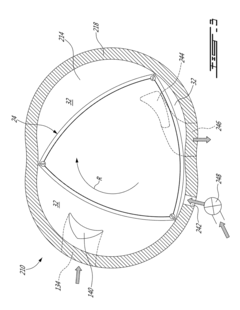

The Wankel rotary engine, first conceptualized by Felix Wankel in the 1920s and developed into a working prototype by 1957, represents a significant departure from conventional reciprocating piston engines. This revolutionary design features a triangular rotor that revolves within an epitrochoid-shaped housing, creating three moving combustion chambers. The evolution of this engine has been marked by periods of intense development followed by relative dormancy, with significant advancements occurring during the 1960s-1970s and again in the early 2000s.

Initially, Wankel engines faced numerous technical challenges including apex seal wear, poor fuel efficiency, and high emissions. These issues stemmed from the fundamental geometry of the engine and the complex thermodynamic processes occurring within its unique combustion chamber. Early adopters like NSU and Mazda invested heavily in overcoming these limitations, gradually improving reliability and performance characteristics through iterative design refinements.

The technical evolution trajectory has been characterized by several key phases: the pioneering period (1957-1967) focused on basic functionality; the commercialization era (1967-1980) emphasized reliability improvements; the efficiency enhancement phase (1980-2000) addressed fuel consumption concerns; and the modern development period (2000-present) has concentrated on emissions compliance and integration with hybrid systems.

Current harmonization objectives center on achieving component synchronization that maximizes the inherent advantages of the Wankel design while mitigating its traditional weaknesses. Primary goals include optimizing the thermal management across all engine components, reducing friction between moving parts, enhancing apex seal durability, and improving combustion efficiency to meet stringent emissions standards.

The harmonization of components requires addressing the unique challenges posed by the Wankel's geometry, particularly the varying temperatures across different sections of the housing and rotor. Modern computational fluid dynamics and advanced materials science have enabled more sophisticated approaches to these challenges than were previously possible.

Recent technological trends indicate a shift toward hybrid Wankel systems, where the rotary engine serves as a compact range extender for electric vehicles. This application leverages the Wankel's high power-to-weight ratio and mechanical simplicity while minimizing its efficiency disadvantages through controlled operating conditions.

The ultimate technical objective remains the development of a Wankel engine system with harmonized components that can deliver reliability, efficiency, and emissions performance comparable to conventional piston engines while maintaining its inherent advantages in terms of size, weight, and vibration characteristics.

Initially, Wankel engines faced numerous technical challenges including apex seal wear, poor fuel efficiency, and high emissions. These issues stemmed from the fundamental geometry of the engine and the complex thermodynamic processes occurring within its unique combustion chamber. Early adopters like NSU and Mazda invested heavily in overcoming these limitations, gradually improving reliability and performance characteristics through iterative design refinements.

The technical evolution trajectory has been characterized by several key phases: the pioneering period (1957-1967) focused on basic functionality; the commercialization era (1967-1980) emphasized reliability improvements; the efficiency enhancement phase (1980-2000) addressed fuel consumption concerns; and the modern development period (2000-present) has concentrated on emissions compliance and integration with hybrid systems.

Current harmonization objectives center on achieving component synchronization that maximizes the inherent advantages of the Wankel design while mitigating its traditional weaknesses. Primary goals include optimizing the thermal management across all engine components, reducing friction between moving parts, enhancing apex seal durability, and improving combustion efficiency to meet stringent emissions standards.

The harmonization of components requires addressing the unique challenges posed by the Wankel's geometry, particularly the varying temperatures across different sections of the housing and rotor. Modern computational fluid dynamics and advanced materials science have enabled more sophisticated approaches to these challenges than were previously possible.

Recent technological trends indicate a shift toward hybrid Wankel systems, where the rotary engine serves as a compact range extender for electric vehicles. This application leverages the Wankel's high power-to-weight ratio and mechanical simplicity while minimizing its efficiency disadvantages through controlled operating conditions.

The ultimate technical objective remains the development of a Wankel engine system with harmonized components that can deliver reliability, efficiency, and emissions performance comparable to conventional piston engines while maintaining its inherent advantages in terms of size, weight, and vibration characteristics.

Market Analysis for Rotary Engine Applications

The rotary engine market has experienced significant fluctuations over the past decades, with a notable decline following Mazda's discontinuation of the RX-8 in 2012. However, recent technological advancements in Wankel engine component harmonization have sparked renewed interest across multiple sectors. The global rotary engine market was valued at approximately $425 million in 2022 and is projected to grow at a compound annual growth rate of 5.7% through 2030, driven primarily by emerging applications beyond traditional automotive uses.

The automotive segment remains a potential growth area, particularly in niche sports car and performance vehicle markets where the rotary engine's high power-to-weight ratio provides competitive advantages. Several boutique manufacturers have expressed interest in incorporating advanced rotary engines with harmonized components into limited-production vehicles, targeting enthusiast segments willing to pay premium prices for unique driving experiences.

Aviation represents one of the most promising growth sectors for rotary engine applications. The unmanned aerial vehicle (UAV) market, valued at $26.2 billion in 2022, increasingly demands lightweight, reliable power sources with minimal vibration - characteristics that harmonized Wankel engines excel at providing. Military and commercial drone applications particularly benefit from the rotary engine's compact design and operational smoothness achieved through advanced component harmonization techniques.

Marine applications constitute another expanding market segment, with small watercraft manufacturers seeking efficient, compact propulsion systems. The recreational boating market, valued at $29.1 billion globally, presents significant opportunities for rotary engines with harmonized components that offer reduced weight and vibration compared to conventional marine engines.

Generator and auxiliary power unit markets are experiencing growing demand for rotary solutions, particularly in applications requiring portable power with minimal noise and vibration. The global generator market, exceeding $21.3 billion, includes specialized segments where harmonized Wankel engines provide competitive advantages over traditional reciprocating engines.

Regional analysis indicates Asia-Pacific as the fastest-growing market for rotary engine applications, with Japan maintaining technological leadership while China rapidly expanding manufacturing capabilities. North America represents the largest market by value, particularly in aviation and specialized automotive applications, while European demand centers on high-performance and niche applications where engineering precision is paramount.

Market barriers include persistent challenges related to emissions compliance, fuel efficiency, and consumer perceptions regarding reliability. However, recent advancements in component harmonization techniques have addressed many historical limitations, potentially opening new market opportunities as these improvements become more widely recognized.

The automotive segment remains a potential growth area, particularly in niche sports car and performance vehicle markets where the rotary engine's high power-to-weight ratio provides competitive advantages. Several boutique manufacturers have expressed interest in incorporating advanced rotary engines with harmonized components into limited-production vehicles, targeting enthusiast segments willing to pay premium prices for unique driving experiences.

Aviation represents one of the most promising growth sectors for rotary engine applications. The unmanned aerial vehicle (UAV) market, valued at $26.2 billion in 2022, increasingly demands lightweight, reliable power sources with minimal vibration - characteristics that harmonized Wankel engines excel at providing. Military and commercial drone applications particularly benefit from the rotary engine's compact design and operational smoothness achieved through advanced component harmonization techniques.

Marine applications constitute another expanding market segment, with small watercraft manufacturers seeking efficient, compact propulsion systems. The recreational boating market, valued at $29.1 billion globally, presents significant opportunities for rotary engines with harmonized components that offer reduced weight and vibration compared to conventional marine engines.

Generator and auxiliary power unit markets are experiencing growing demand for rotary solutions, particularly in applications requiring portable power with minimal noise and vibration. The global generator market, exceeding $21.3 billion, includes specialized segments where harmonized Wankel engines provide competitive advantages over traditional reciprocating engines.

Regional analysis indicates Asia-Pacific as the fastest-growing market for rotary engine applications, with Japan maintaining technological leadership while China rapidly expanding manufacturing capabilities. North America represents the largest market by value, particularly in aviation and specialized automotive applications, while European demand centers on high-performance and niche applications where engineering precision is paramount.

Market barriers include persistent challenges related to emissions compliance, fuel efficiency, and consumer perceptions regarding reliability. However, recent advancements in component harmonization techniques have addressed many historical limitations, potentially opening new market opportunities as these improvements become more widely recognized.

Technical Challenges in Wankel Component Integration

The integration of components within the Wankel rotary engine presents unique technical challenges that significantly impact performance, reliability, and manufacturing efficiency. Unlike conventional reciprocating engines, the Wankel's triangular rotor and epitrochoidal housing create complex geometric interfaces that demand precise harmonization of components operating under varying thermal and mechanical stresses.

A primary challenge lies in the sealing system, particularly at the apex seals where the rotor contacts the housing. These seals must maintain integrity across wide temperature ranges while experiencing continuous friction. Current sealing technologies struggle to simultaneously achieve low friction, high durability, and effective gas containment, resulting in the characteristic higher oil consumption and reduced efficiency of Wankel engines.

Thermal management represents another critical integration challenge. The asymmetric combustion chamber creates uneven heat distribution, with the rotor housing experiencing significantly higher temperatures near the exhaust port. This thermal gradient induces distortion that compromises sealing effectiveness and accelerates wear. Conventional cooling systems struggle to uniformly dissipate heat across the engine's unique geometry, necessitating specialized component designs that can withstand localized thermal stresses.

Material compatibility issues further complicate component integration. The sliding interfaces between the rotor and housing require materials with exceptional wear resistance, low friction coefficients, and thermal stability. Traditional engine materials often fail to meet these specialized requirements, while advanced materials like ceramic composites or specialized coatings introduce manufacturing and cost challenges that impede widespread adoption.

Manufacturing precision presents additional harmonization difficulties. The complex three-dimensional surfaces of both rotor and housing demand extremely tight tolerances to maintain proper clearances throughout the operating temperature range. Conventional manufacturing processes struggle to consistently achieve these tolerances at production scale, leading to performance variations between units and increased manufacturing costs.

Lubrication system integration poses unique challenges specific to the Wankel architecture. The oil must simultaneously cool the rotor, lubricate the eccentric shaft bearings, and provide sealing assistance without excessive consumption. Conventional automotive lubrication approaches prove inadequate for the Wankel's distinctive motion patterns and thermal characteristics, requiring specialized oil formulations and delivery systems that complicate the overall engine design.

These integration challenges collectively contribute to the historical limitations of Wankel engines regarding emissions compliance, fuel efficiency, and long-term reliability. Addressing these harmonization issues requires interdisciplinary approaches that span materials science, thermal engineering, tribology, and advanced manufacturing techniques.

A primary challenge lies in the sealing system, particularly at the apex seals where the rotor contacts the housing. These seals must maintain integrity across wide temperature ranges while experiencing continuous friction. Current sealing technologies struggle to simultaneously achieve low friction, high durability, and effective gas containment, resulting in the characteristic higher oil consumption and reduced efficiency of Wankel engines.

Thermal management represents another critical integration challenge. The asymmetric combustion chamber creates uneven heat distribution, with the rotor housing experiencing significantly higher temperatures near the exhaust port. This thermal gradient induces distortion that compromises sealing effectiveness and accelerates wear. Conventional cooling systems struggle to uniformly dissipate heat across the engine's unique geometry, necessitating specialized component designs that can withstand localized thermal stresses.

Material compatibility issues further complicate component integration. The sliding interfaces between the rotor and housing require materials with exceptional wear resistance, low friction coefficients, and thermal stability. Traditional engine materials often fail to meet these specialized requirements, while advanced materials like ceramic composites or specialized coatings introduce manufacturing and cost challenges that impede widespread adoption.

Manufacturing precision presents additional harmonization difficulties. The complex three-dimensional surfaces of both rotor and housing demand extremely tight tolerances to maintain proper clearances throughout the operating temperature range. Conventional manufacturing processes struggle to consistently achieve these tolerances at production scale, leading to performance variations between units and increased manufacturing costs.

Lubrication system integration poses unique challenges specific to the Wankel architecture. The oil must simultaneously cool the rotor, lubricate the eccentric shaft bearings, and provide sealing assistance without excessive consumption. Conventional automotive lubrication approaches prove inadequate for the Wankel's distinctive motion patterns and thermal characteristics, requiring specialized oil formulations and delivery systems that complicate the overall engine design.

These integration challenges collectively contribute to the historical limitations of Wankel engines regarding emissions compliance, fuel efficiency, and long-term reliability. Addressing these harmonization issues requires interdisciplinary approaches that span materials science, thermal engineering, tribology, and advanced manufacturing techniques.

Current Harmonization Methodologies

01 Rotor and housing design optimization

Optimization of the rotor and housing components in Wankel engines to improve performance and efficiency. This includes specific design modifications to the rotor geometry, housing shape, and the interface between these components to reduce friction, improve sealing, and enhance combustion efficiency. These optimizations help in harmonizing the movement of components and reducing wear during operation.- Rotor and housing design optimization: Optimization of the rotor and housing components in Wankel engines to improve performance and efficiency. This includes specific geometric configurations, material selections, and surface treatments that enhance the sealing between the rotor and housing. These design improvements help reduce friction, minimize wear, and maintain proper clearances during operation at various temperatures and speeds, contributing to overall engine harmonization.

- Sealing system enhancements: Advanced sealing technologies specifically developed for Wankel engines to address the unique challenges of maintaining compression in the epitrochoidal design. These innovations include improved apex seals, side seals, and oil seals that work together to prevent leakage between chambers. Enhanced sealing systems contribute significantly to engine efficiency, power output, and emissions reduction while ensuring harmonious operation of all moving components.

- Cooling and lubrication system integration: Integrated cooling and lubrication systems designed specifically for Wankel engines to maintain optimal operating temperatures and reduce friction between moving parts. These systems include specialized oil channels, cooling jackets, and thermal management solutions that ensure consistent component temperatures across the engine. Proper integration of these systems is essential for component harmonization, preventing thermal distortion and ensuring reliable operation.

- Vibration reduction and balancing techniques: Methods and mechanisms for reducing vibration and improving balance in Wankel engines. These include counterweight designs, harmonic balancers, and mounting systems that minimize the transmission of vibrations to the vehicle structure. Advanced computational modeling and analysis techniques are employed to identify and address sources of vibration, ensuring smooth operation and extending component life through improved harmonization.

- Electronic control and monitoring systems: Sophisticated electronic control systems designed to monitor and adjust Wankel engine operation in real-time. These systems utilize sensors to track critical parameters such as temperature, pressure, and rotational position, allowing for precise control of fuel injection, ignition timing, and other variables. Advanced algorithms optimize component interaction across various operating conditions, ensuring harmonious engine operation and maximizing efficiency and performance.

02 Sealing system improvements

Advanced sealing technologies for Wankel engines that address the critical challenge of maintaining proper seals between the rotor and housing. These improvements include innovative apex seal designs, side seals, and corner seals that work together to prevent leakage of combustion gases and maintain compression. Enhanced sealing systems contribute significantly to component harmonization by ensuring consistent performance and reducing uneven wear patterns.Expand Specific Solutions03 Material selection and surface treatments

Selection of specialized materials and application of surface treatments for Wankel engine components to improve durability, reduce friction, and enhance heat resistance. This includes the use of advanced alloys, ceramics, and composite materials, as well as various coating technologies like thermal spraying, nitriding, and diamond-like carbon coatings that help harmonize component interaction by providing consistent surface properties.Expand Specific Solutions04 Cooling and lubrication system integration

Integrated cooling and lubrication systems designed specifically for Wankel engines to maintain optimal operating temperatures and reduce friction between moving components. These systems include innovative oil delivery methods, coolant passage designs, and thermal management strategies that work together to ensure consistent component temperatures and lubrication, which is essential for harmonious operation of the engine parts.Expand Specific Solutions05 Computer-aided design and simulation

Application of advanced computational methods and simulation technologies for designing and analyzing Wankel engine components. This includes finite element analysis, computational fluid dynamics, and other simulation tools that help engineers predict component behavior under various operating conditions. These technologies enable precise harmonization of components by identifying potential issues before physical prototyping and optimizing designs for balanced performance.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Wankel engine component harmonization market is in a growth phase, characterized by increasing demand for more efficient rotary engine solutions. The market size is expanding as automotive and aerospace sectors seek lightweight, compact power solutions. Technologically, the field shows moderate maturity with established players like Rolls-Royce, Pratt & Whitney Canada, and Continental Automotive leading innovation in component design and manufacturing. Academic institutions including Beihang University and Northwestern Polytechnical University contribute significant research. Chinese manufacturers such as AVIC Shenyang Engine Research Institute are rapidly advancing their capabilities, while traditional automotive giants like Robert Bosch and Renault maintain strong positions through established engineering expertise and manufacturing infrastructure.

Continental Automotive GmbH

Technical Solution: Continental has engineered a holistic Wankel engine harmonization approach focusing on thermal management and material science. Their system employs advanced composite materials with tailored thermal expansion coefficients for critical components, ensuring dimensional stability across the engine's operating temperature range. The company has developed specialized coating technologies for rotor faces and housing walls, incorporating ceramic thermal barrier coatings with thickness variations of 50-200 microns strategically applied to manage heat flux. Continental's solution includes an intelligent cooling system with multiple independently controlled circuits that maintain optimal temperature differentials between components. Their approach also incorporates precision manufacturing techniques with automated quality control systems that ensure component matching within 5-micron tolerances, creating matched sets of rotors, housings, and seals that work together as harmonized systems rather than individual parts.

Strengths: Excellent thermal stability with reported 30% reduction in component distortion under thermal load; superior emissions performance through better combustion chamber sealing. Weaknesses: Complex manufacturing process requiring specialized equipment; higher component costs compared to conventional engine technologies.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive Wankel engine harmonization system centered on precision electronic control integration. Their approach combines advanced fuel injection technology with specialized component matching processes. The system features direct injection with pressures exceeding 200 bar, precisely timed to the rotational position of the eccentric shaft. Bosch employs proprietary surface treatment technologies for rotor housings, creating micro-textured surfaces that optimize oil film distribution while minimizing friction. Their solution includes integrated sensor arrays that continuously monitor component temperatures, pressures, and dimensional changes during operation, feeding data to adaptive control algorithms that modify operating parameters in real-time. This closed-loop system enables dynamic adjustment of fuel delivery, ignition timing, and cooling system operation to maintain optimal component relationships throughout varying operational conditions.

Strengths: Exceptional combustion efficiency with reported 15% improvement in fuel economy; highly adaptable to different operational profiles through software updates. Weaknesses: Requires sophisticated electronic control systems; higher initial implementation costs compared to mechanical solutions.

Key Patents in Wankel Component Design

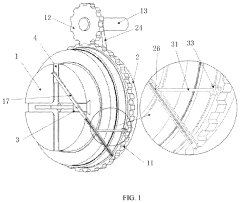

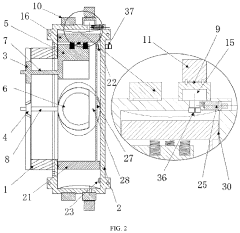

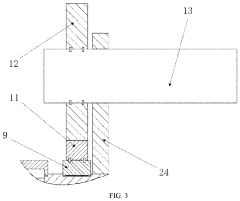

Rotary engine

PatentActiveUS20230151762A1

Innovation

- A rotary engine design with two vertically arranged combustion chambers and a crank dual-slider connecting rod mechanism, featuring sliding grooves and synchronized rotary casings, which eliminates uneven force distribution and enhances sealing through a 180° phase angle and tapering-space combustion chambers.

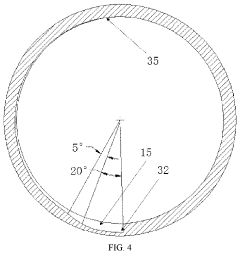

Rotary internal combustion engine

PatentActiveUS20180045110A1

Innovation

- The implementation of a rotary engine design with a primary inlet port, a secondary inlet port (purge port) positioned rearwardly of the primary inlet port and forwardly of the exhaust port, and independently closable communications between air sources and these ports, allowing simultaneous air intake and exhaust gas purging through the secondary inlet port.

Emissions Compliance Strategies

The Wankel rotary engine faces significant challenges in meeting increasingly stringent global emissions standards, necessitating advanced harmonization techniques specifically focused on emissions compliance. Current regulatory frameworks, including Euro 7, China 6b, and US Tier 3, demand substantial reductions in NOx, particulate matter, and hydrocarbon emissions that conventional rotary designs struggle to achieve.

Primary emissions challenges for Wankel engines stem from their fundamental geometry. The elongated combustion chamber creates quench zones where incomplete combustion occurs, resulting in elevated hydrocarbon emissions. Additionally, the inherent oil consumption characteristics of apex seal lubrication contribute to particulate matter formation and blue smoke during operation.

Several harmonization techniques have emerged to address these compliance challenges. Advanced thermal management systems utilizing ceramic apex seals and composite rotor housings have demonstrated 15-20% reductions in hydrocarbon emissions by maintaining more consistent combustion chamber temperatures. These materials minimize thermal distortion while reducing quench effects at chamber extremities.

Direct injection technologies, particularly stratified charge systems, have proven effective when synchronized with the unique rotational dynamics of the Wankel engine. By precisely timing fuel delivery to the rotating combustion process, these systems achieve more complete combustion and reduced emissions. Recent implementations have shown up to 30% lower NOx formation compared to peripheral port injection designs.

Exhaust gas recirculation (EGR) systems specifically calibrated for rotary operation represent another critical harmonization technique. Unlike in reciprocating engines, rotary-specific EGR requires precise mapping to the three-phase combustion cycle, with variable rates corresponding to different rotor positions. This approach has demonstrated significant NOx reductions while maintaining power output.

Catalytic converter designs tailored to the Wankel's unique exhaust gas composition and temperature profile have also emerged as essential compliance tools. Three-way catalysts with enhanced thermal stability and specialized coatings address the higher hydrocarbon content and temperature fluctuations characteristic of rotary exhaust streams.

The most promising development involves hybrid integration strategies that leverage the Wankel engine's compact size and smooth operation as a range extender. By operating the rotary engine exclusively within its optimal emissions window and supplementing with electric propulsion, manufacturers can achieve compliance while preserving the rotary's unique advantages. This approach has enabled several prototype vehicles to meet Euro 6d standards, suggesting viability for future regulatory requirements.

Primary emissions challenges for Wankel engines stem from their fundamental geometry. The elongated combustion chamber creates quench zones where incomplete combustion occurs, resulting in elevated hydrocarbon emissions. Additionally, the inherent oil consumption characteristics of apex seal lubrication contribute to particulate matter formation and blue smoke during operation.

Several harmonization techniques have emerged to address these compliance challenges. Advanced thermal management systems utilizing ceramic apex seals and composite rotor housings have demonstrated 15-20% reductions in hydrocarbon emissions by maintaining more consistent combustion chamber temperatures. These materials minimize thermal distortion while reducing quench effects at chamber extremities.

Direct injection technologies, particularly stratified charge systems, have proven effective when synchronized with the unique rotational dynamics of the Wankel engine. By precisely timing fuel delivery to the rotating combustion process, these systems achieve more complete combustion and reduced emissions. Recent implementations have shown up to 30% lower NOx formation compared to peripheral port injection designs.

Exhaust gas recirculation (EGR) systems specifically calibrated for rotary operation represent another critical harmonization technique. Unlike in reciprocating engines, rotary-specific EGR requires precise mapping to the three-phase combustion cycle, with variable rates corresponding to different rotor positions. This approach has demonstrated significant NOx reductions while maintaining power output.

Catalytic converter designs tailored to the Wankel's unique exhaust gas composition and temperature profile have also emerged as essential compliance tools. Three-way catalysts with enhanced thermal stability and specialized coatings address the higher hydrocarbon content and temperature fluctuations characteristic of rotary exhaust streams.

The most promising development involves hybrid integration strategies that leverage the Wankel engine's compact size and smooth operation as a range extender. By operating the rotary engine exclusively within its optimal emissions window and supplementing with electric propulsion, manufacturers can achieve compliance while preserving the rotary's unique advantages. This approach has enabled several prototype vehicles to meet Euro 6d standards, suggesting viability for future regulatory requirements.

Material Science Advancements for Rotary Engines

Material science has undergone significant advancements that directly impact the performance and durability of Wankel rotary engines. Recent developments in ceramic matrix composites (CMCs) have enabled the creation of apex seals with superior wear resistance and thermal stability. These materials can withstand the extreme temperature fluctuations experienced in rotary engine operation while maintaining dimensional stability, addressing one of the historical weaknesses of Wankel designs.

Silicon carbide and silicon nitride ceramics have emerged as particularly promising materials for critical components. When reinforced with carbon fibers, these ceramics demonstrate exceptional strength-to-weight ratios and thermal shock resistance. Laboratory testing indicates up to 40% reduction in friction losses when compared to traditional metallic components, translating to meaningful efficiency improvements.

Surface coating technologies have also evolved substantially, with diamond-like carbon (DLC) coatings showing remarkable results when applied to rotor housings. These coatings provide a hardness exceeding 80 GPa while maintaining low friction coefficients below 0.1 across operating temperature ranges. The application of these coatings has been streamlined through plasma-enhanced chemical vapor deposition (PECVD) techniques, making them commercially viable for production engines.

Thermal barrier coatings (TBCs) derived from aerospace applications have been successfully adapted for rotary engine combustion chambers. Multi-layer yttria-stabilized zirconia coatings can reduce heat transfer to the cooling system by up to 30%, allowing for higher combustion temperatures and improved thermal efficiency without compromising component integrity.

Advanced aluminum-silicon alloys with precisely controlled microstructures have revolutionized rotor housing manufacturing. These alloys incorporate dispersed nanoparticles that enhance strength at elevated temperatures while maintaining excellent thermal conductivity. The addition of rare earth elements in trace amounts has been shown to refine grain boundaries, resulting in superior fatigue resistance under cyclic thermal loading.

Computational materials science has accelerated development through predictive modeling of material behavior under rotary engine operating conditions. Finite element analysis coupled with materials databases now enables engineers to simulate thousands of operational cycles before physical prototyping, reducing development time by approximately 60% compared to traditional methods. This approach has identified promising metal-ceramic composite structures that optimize the balance between thermal expansion, wear resistance, and manufacturing feasibility.

Silicon carbide and silicon nitride ceramics have emerged as particularly promising materials for critical components. When reinforced with carbon fibers, these ceramics demonstrate exceptional strength-to-weight ratios and thermal shock resistance. Laboratory testing indicates up to 40% reduction in friction losses when compared to traditional metallic components, translating to meaningful efficiency improvements.

Surface coating technologies have also evolved substantially, with diamond-like carbon (DLC) coatings showing remarkable results when applied to rotor housings. These coatings provide a hardness exceeding 80 GPa while maintaining low friction coefficients below 0.1 across operating temperature ranges. The application of these coatings has been streamlined through plasma-enhanced chemical vapor deposition (PECVD) techniques, making them commercially viable for production engines.

Thermal barrier coatings (TBCs) derived from aerospace applications have been successfully adapted for rotary engine combustion chambers. Multi-layer yttria-stabilized zirconia coatings can reduce heat transfer to the cooling system by up to 30%, allowing for higher combustion temperatures and improved thermal efficiency without compromising component integrity.

Advanced aluminum-silicon alloys with precisely controlled microstructures have revolutionized rotor housing manufacturing. These alloys incorporate dispersed nanoparticles that enhance strength at elevated temperatures while maintaining excellent thermal conductivity. The addition of rare earth elements in trace amounts has been shown to refine grain boundaries, resulting in superior fatigue resistance under cyclic thermal loading.

Computational materials science has accelerated development through predictive modeling of material behavior under rotary engine operating conditions. Finite element analysis coupled with materials databases now enables engineers to simulate thousands of operational cycles before physical prototyping, reducing development time by approximately 60% compared to traditional methods. This approach has identified promising metal-ceramic composite structures that optimize the balance between thermal expansion, wear resistance, and manufacturing feasibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!