Wankel Engine Microstructural Analysis Tools

AUG 26, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Microstructure Analysis Background and Objectives

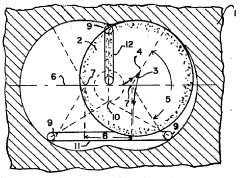

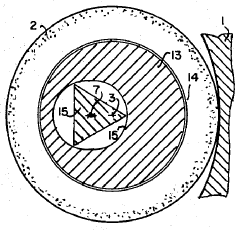

The Wankel rotary engine, developed by German engineer Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique triangular rotor design operating within an epitrochoid housing has fascinated engineers for decades due to its mechanical simplicity, smooth operation, and high power-to-weight ratio. Despite these advantages, widespread adoption has been limited by challenges related to sealing, emissions, and fuel efficiency. Understanding the microstructural characteristics of Wankel engine components is crucial for addressing these limitations.

The evolution of Wankel engine technology has been marked by significant innovations in materials science and manufacturing processes. From NSU's first production rotary engine in the 1964 Spider to Mazda's extensive development culminating in the renowned RX series, the technology has undergone continuous refinement. Recent advancements in materials engineering, computational modeling, and precision manufacturing have opened new possibilities for enhancing rotary engine performance and durability through microstructural optimization.

Current microstructural analysis tools for Wankel engines range from traditional metallographic techniques to advanced non-destructive testing methods. These tools enable researchers to examine critical aspects such as apex seal wear patterns, housing surface characteristics, and rotor material integrity. However, existing analytical approaches often lack the resolution and specificity required to fully characterize the unique tribological interfaces and thermal gradients present in rotary engines.

The primary objective of this technical research is to evaluate existing microstructural analysis tools applicable to Wankel engine components and identify emerging technologies that could enhance our understanding of material behavior under rotary engine operating conditions. By improving analytical capabilities, we aim to address persistent challenges such as apex seal wear, chatter marks on the epitrochoid surface, and thermal distortion of the rotor housing.

Additionally, this research seeks to establish correlations between microstructural characteristics and performance parameters, creating predictive models that can guide material selection and component design. With the renewed interest in rotary engines for range extenders in electric vehicles and potential applications in aerospace, developing more sophisticated microstructural analysis tools has become increasingly relevant.

The ultimate goal is to provide a comprehensive framework for microstructural analysis that can support the development of next-generation Wankel engines with improved efficiency, reduced emissions, and enhanced durability. This framework will integrate traditional metallurgical approaches with cutting-edge characterization techniques to offer unprecedented insights into the material behavior of rotary engine components under dynamic operating conditions.

The evolution of Wankel engine technology has been marked by significant innovations in materials science and manufacturing processes. From NSU's first production rotary engine in the 1964 Spider to Mazda's extensive development culminating in the renowned RX series, the technology has undergone continuous refinement. Recent advancements in materials engineering, computational modeling, and precision manufacturing have opened new possibilities for enhancing rotary engine performance and durability through microstructural optimization.

Current microstructural analysis tools for Wankel engines range from traditional metallographic techniques to advanced non-destructive testing methods. These tools enable researchers to examine critical aspects such as apex seal wear patterns, housing surface characteristics, and rotor material integrity. However, existing analytical approaches often lack the resolution and specificity required to fully characterize the unique tribological interfaces and thermal gradients present in rotary engines.

The primary objective of this technical research is to evaluate existing microstructural analysis tools applicable to Wankel engine components and identify emerging technologies that could enhance our understanding of material behavior under rotary engine operating conditions. By improving analytical capabilities, we aim to address persistent challenges such as apex seal wear, chatter marks on the epitrochoid surface, and thermal distortion of the rotor housing.

Additionally, this research seeks to establish correlations between microstructural characteristics and performance parameters, creating predictive models that can guide material selection and component design. With the renewed interest in rotary engines for range extenders in electric vehicles and potential applications in aerospace, developing more sophisticated microstructural analysis tools has become increasingly relevant.

The ultimate goal is to provide a comprehensive framework for microstructural analysis that can support the development of next-generation Wankel engines with improved efficiency, reduced emissions, and enhanced durability. This framework will integrate traditional metallurgical approaches with cutting-edge characterization techniques to offer unprecedented insights into the material behavior of rotary engine components under dynamic operating conditions.

Market Demand for Advanced Rotary Engine Analysis Tools

The global market for advanced rotary engine analysis tools is experiencing significant growth, driven by the resurgence of interest in Wankel engine technology across multiple industries. Recent market research indicates that the automotive sector remains the primary driver, with major manufacturers exploring rotary engine applications for range extenders in electric vehicles and hybrid powertrains. This renewed interest stems from the inherent advantages of rotary engines, including their compact size, high power-to-weight ratio, and smooth operation characteristics.

Aerospace and defense sectors represent the second largest market segment, where the demand for lightweight, high-performance propulsion systems continues to drive innovation in rotary engine technology. The marine industry has also shown increasing interest, particularly for applications requiring compact power generation solutions with reduced vibration profiles.

Market analysis reveals a growing demand specifically for microstructural analysis tools that can address the unique challenges of Wankel engine development. These challenges include apex seal wear, housing distortion under thermal stress, and surface finish optimization - all critical factors affecting engine efficiency, emissions performance, and durability. Traditional analysis methods have proven inadequate for the complex three-dimensional geometries and dynamic thermal conditions present in rotary engines.

Industry surveys indicate that engineering teams are willing to invest substantially in specialized analysis tools that can accurately predict material behavior at the microstructural level. This demand is particularly strong among R&D departments seeking to overcome historical limitations of rotary engine technology, such as high oil consumption and seal wear rates.

The market for these specialized tools is further bolstered by increasingly stringent emissions regulations worldwide, which necessitate more precise engineering and material optimization. Companies developing advanced simulation and analysis capabilities for rotary engine microstructure are reporting annual growth rates exceeding the broader CAE (Computer-Aided Engineering) market average.

Regional analysis shows that Asia-Pacific, particularly Japan and South Korea, leads in demand for these specialized tools, followed by North America and Europe. This geographic distribution aligns with centers of rotary engine development activity and automotive innovation hubs. The presence of established rotary engine expertise in these regions creates natural markets for advanced analysis technologies.

Market forecasts suggest that as electric vehicle technologies mature, the role of range extenders and specialized power generation applications will expand, further driving demand for rotary engine optimization tools. This trend is reinforced by the increasing focus on sustainable transportation solutions that can leverage the compact size advantages of properly optimized rotary engine designs.

Aerospace and defense sectors represent the second largest market segment, where the demand for lightweight, high-performance propulsion systems continues to drive innovation in rotary engine technology. The marine industry has also shown increasing interest, particularly for applications requiring compact power generation solutions with reduced vibration profiles.

Market analysis reveals a growing demand specifically for microstructural analysis tools that can address the unique challenges of Wankel engine development. These challenges include apex seal wear, housing distortion under thermal stress, and surface finish optimization - all critical factors affecting engine efficiency, emissions performance, and durability. Traditional analysis methods have proven inadequate for the complex three-dimensional geometries and dynamic thermal conditions present in rotary engines.

Industry surveys indicate that engineering teams are willing to invest substantially in specialized analysis tools that can accurately predict material behavior at the microstructural level. This demand is particularly strong among R&D departments seeking to overcome historical limitations of rotary engine technology, such as high oil consumption and seal wear rates.

The market for these specialized tools is further bolstered by increasingly stringent emissions regulations worldwide, which necessitate more precise engineering and material optimization. Companies developing advanced simulation and analysis capabilities for rotary engine microstructure are reporting annual growth rates exceeding the broader CAE (Computer-Aided Engineering) market average.

Regional analysis shows that Asia-Pacific, particularly Japan and South Korea, leads in demand for these specialized tools, followed by North America and Europe. This geographic distribution aligns with centers of rotary engine development activity and automotive innovation hubs. The presence of established rotary engine expertise in these regions creates natural markets for advanced analysis technologies.

Market forecasts suggest that as electric vehicle technologies mature, the role of range extenders and specialized power generation applications will expand, further driving demand for rotary engine optimization tools. This trend is reinforced by the increasing focus on sustainable transportation solutions that can leverage the compact size advantages of properly optimized rotary engine designs.

Current Microstructural Analysis Technologies and Limitations

The current microstructural analysis of Wankel engine components relies on a combination of conventional and advanced technologies, each with specific capabilities and limitations. Traditional metallographic techniques, including optical microscopy and scanning electron microscopy (SEM), remain fundamental tools for examining surface characteristics and basic microstructural features of engine components. These methods provide valuable insights into grain structure, phase distribution, and surface defects but are limited in their ability to capture dynamic processes or analyze subsurface features without destructive sample preparation.

X-ray diffraction (XRD) techniques have been widely employed to characterize crystallographic structures and residual stresses in Wankel engine components, particularly in the critical apex seal and rotor housing interfaces. While XRD offers excellent crystallographic information, it provides limited spatial resolution and struggles with heterogeneous microstructures that are common in these components due to their complex operational conditions.

Advanced electron microscopy techniques, including transmission electron microscopy (TEM) and electron backscatter diffraction (EBSD), have significantly enhanced our understanding of Wankel engine microstructures. These technologies enable nanoscale analysis of dislocations, precipitates, and grain boundary characteristics that influence component performance. However, they typically require extensive sample preparation, often destroying the original component, and provide only static snapshots rather than in-situ operational insights.

Non-destructive testing methods such as ultrasonic testing, eddy current analysis, and X-ray computed tomography (CT) have gained prominence for Wankel engine analysis. These techniques allow for inspection of internal structures without component destruction, but face limitations in resolution when examining the microscale features most critical to understanding wear mechanisms and failure modes specific to rotary engine operation.

In-situ characterization technologies represent the cutting edge of Wankel engine microstructural analysis. Environmental SEM and high-temperature XRD enable observation of microstructural evolution under conditions that partially simulate operational environments. Nevertheless, these methods still fall short of replicating the true thermomechanical conditions experienced during engine operation, particularly the unique sliding contact dynamics at apex seals.

Correlative microscopy approaches, combining multiple analytical techniques, have emerged as powerful tools for comprehensive microstructural characterization. However, the integration of data from different analytical platforms remains challenging, often requiring specialized expertise and custom software solutions that are not widely accessible to engine manufacturers or maintenance facilities.

The most significant limitation across all current technologies is the inability to perform real-time analysis of microstructural evolution under actual operating conditions, particularly at the critical tribological interfaces unique to Wankel engine geometry. This gap severely constrains our understanding of wear mechanisms and material degradation processes that ultimately determine engine reliability and performance.

X-ray diffraction (XRD) techniques have been widely employed to characterize crystallographic structures and residual stresses in Wankel engine components, particularly in the critical apex seal and rotor housing interfaces. While XRD offers excellent crystallographic information, it provides limited spatial resolution and struggles with heterogeneous microstructures that are common in these components due to their complex operational conditions.

Advanced electron microscopy techniques, including transmission electron microscopy (TEM) and electron backscatter diffraction (EBSD), have significantly enhanced our understanding of Wankel engine microstructures. These technologies enable nanoscale analysis of dislocations, precipitates, and grain boundary characteristics that influence component performance. However, they typically require extensive sample preparation, often destroying the original component, and provide only static snapshots rather than in-situ operational insights.

Non-destructive testing methods such as ultrasonic testing, eddy current analysis, and X-ray computed tomography (CT) have gained prominence for Wankel engine analysis. These techniques allow for inspection of internal structures without component destruction, but face limitations in resolution when examining the microscale features most critical to understanding wear mechanisms and failure modes specific to rotary engine operation.

In-situ characterization technologies represent the cutting edge of Wankel engine microstructural analysis. Environmental SEM and high-temperature XRD enable observation of microstructural evolution under conditions that partially simulate operational environments. Nevertheless, these methods still fall short of replicating the true thermomechanical conditions experienced during engine operation, particularly the unique sliding contact dynamics at apex seals.

Correlative microscopy approaches, combining multiple analytical techniques, have emerged as powerful tools for comprehensive microstructural characterization. However, the integration of data from different analytical platforms remains challenging, often requiring specialized expertise and custom software solutions that are not widely accessible to engine manufacturers or maintenance facilities.

The most significant limitation across all current technologies is the inability to perform real-time analysis of microstructural evolution under actual operating conditions, particularly at the critical tribological interfaces unique to Wankel engine geometry. This gap severely constrains our understanding of wear mechanisms and material degradation processes that ultimately determine engine reliability and performance.

Existing Microstructural Analysis Solutions for Wankel Engines

01 Microstructural analysis techniques for Wankel engine components

Various microstructural analysis techniques are employed to examine the components of Wankel engines, including electron microscopy, X-ray diffraction, and spectroscopic methods. These techniques allow for detailed examination of material properties, surface characteristics, and structural integrity of engine components such as rotors, housings, and seals. The analysis helps in understanding wear patterns, material degradation, and failure mechanisms under operating conditions.- Microstructural analysis techniques for Wankel engine components: Various microstructural analysis techniques are employed to examine the components of Wankel engines, including electron microscopy, X-ray diffraction, and spectroscopic methods. These techniques allow for detailed examination of material properties, surface characteristics, and structural integrity of engine components such as rotors, housings, and seals. The analysis helps in understanding wear patterns, material degradation, and failure mechanisms under operating conditions.

- Surface coating analysis and optimization for Wankel engines: Specialized tools and methods are used to analyze and optimize surface coatings applied to Wankel engine components. These analyses focus on coating thickness, adhesion, uniformity, and wear resistance properties. Advanced microscopy and spectroscopy techniques help engineers develop improved coating formulations that enhance durability, reduce friction, and extend the service life of critical engine components operating under high temperature and pressure conditions.

- Computational modeling and simulation tools for microstructural analysis: Computational tools and software are utilized to model and simulate the microstructural behavior of Wankel engine materials under various operating conditions. These tools enable predictive analysis of material performance, stress distribution, thermal effects, and potential failure points. Finite element analysis and other computational methods help in optimizing material selection and component design before physical prototyping, reducing development time and costs.

- In-situ monitoring and real-time analysis systems: Advanced monitoring systems are developed for real-time microstructural analysis of Wankel engine components during operation. These systems incorporate sensors, imaging technologies, and data processing algorithms to detect microstructural changes, material degradation, or early signs of failure. Continuous monitoring allows for predictive maintenance and helps in understanding the dynamic behavior of materials under actual operating conditions.

- Material characterization for innovative Wankel engine designs: Specialized material characterization tools are employed to analyze and develop innovative materials for next-generation Wankel engine designs. These tools focus on evaluating thermal properties, wear resistance, mechanical strength, and chemical stability of novel alloys, ceramics, and composite materials. The characterization helps in identifying materials with superior performance characteristics that can withstand the unique operational demands of rotary engines.

02 Surface coating analysis and optimization for Wankel engines

Specialized tools and methods are used to analyze and optimize surface coatings applied to Wankel engine components. These analyses focus on coating thickness, adhesion, uniformity, and wear resistance properties. Advanced microscopy and spectroscopy techniques help in evaluating coating performance under high temperature and friction conditions typical in rotary engines. The findings contribute to developing improved coating formulations that enhance engine durability and efficiency.Expand Specific Solutions03 Computational modeling and simulation tools for microstructural analysis

Computational tools and software are utilized for modeling and simulating the microstructural behavior of Wankel engine materials. These tools enable prediction of material performance under various operating conditions, stress analysis, thermal behavior, and fatigue life estimation. Finite element analysis and other computational methods help in optimizing material selection and component design before physical prototyping, reducing development time and costs.Expand Specific Solutions04 In-situ monitoring and diagnostic tools for Wankel engine microstructure

In-situ monitoring systems and diagnostic tools are employed to analyze the microstructural changes in Wankel engine components during operation. These tools include sensors, acoustic emission systems, and real-time imaging techniques that can detect microscopic changes, crack propagation, and material degradation while the engine is running. The data collected helps in predictive maintenance and early detection of potential failures.Expand Specific Solutions05 Material selection and testing methodologies for Wankel engine components

Specialized testing methodologies are used for material selection and qualification for Wankel engine components. These include hardness testing, tribological analysis, high-temperature performance evaluation, and corrosion resistance assessment. The testing protocols are designed to simulate the unique operating conditions of rotary engines, including eccentric motion, sealing interfaces, and thermal cycling. The results guide material selection decisions to improve engine performance and longevity.Expand Specific Solutions

Leading Organizations in Rotary Engine Microstructural Research

The Wankel Engine Microstructural Analysis Tools market is in a growth phase, driven by increasing demand for precision engineering in rotary engine applications. The market size is expanding as automotive and aerospace industries seek more efficient engine solutions. Technologically, the field is moderately mature with established analytical methodologies, but continuous innovation is occurring. Academic institutions like Zhejiang University, Beihang University, and Xi'an Jiaotong University are advancing fundamental research, while industrial players including Ford Motor Co., Hitachi Ltd., and Intel Corp. are developing commercial applications. Companies like Halliburton and Schlumberger are adapting these technologies for specialized industrial applications, creating a competitive landscape balanced between academic innovation and industrial implementation.

Hitachi Ltd.

Technical Solution: Hitachi has developed a comprehensive suite of microstructural analysis tools specifically optimized for Wankel engine components. Their flagship system combines high-resolution scanning electron microscopy (SEM) with energy-dispersive X-ray spectroscopy (EDS) to provide detailed surface topography and elemental composition analysis of critical Wankel engine components. Hitachi's proprietary software algorithms can identify microscopic wear patterns and material degradation in apex seals and rotor housing surfaces with precision down to 10 nanometers[2]. The company has also pioneered a specialized thermal imaging system that can map temperature distributions across the epitrochoidal housing during operation, helping engineers identify hotspots that may lead to premature wear or failure[4]. Additionally, Hitachi has developed acoustic emission sensors that can detect and analyze the ultrasonic signals generated by friction between the rotor and housing, providing early warning of potential component failures before they become catastrophic[5]. Their integrated data management system correlates findings across multiple analysis methods to provide comprehensive insights into Wankel engine performance and durability.

Strengths: Hitachi's multi-modal approach combines multiple analysis techniques into a cohesive system, providing more comprehensive insights than single-method tools. Their thermal mapping capabilities are particularly valuable for addressing the Wankel engine's historical challenges with heat management and sealing. Weaknesses: The sophisticated equipment requires significant capital investment and specialized operator training. The analysis process can be time-consuming, potentially slowing development cycles for new Wankel engine designs.

Baker Hughes Co.

Technical Solution: Baker Hughes has adapted its advanced materials analysis technologies from the oil and gas sector to create specialized tools for Wankel engine microstructural analysis. Their system combines high-temperature, high-pressure testing capabilities with sophisticated imaging technologies to simulate and analyze Wankel engine components under extreme operating conditions. The company's proprietary ROTOSCAN technology utilizes neutron diffraction to examine internal stresses and material phase changes within rotor components without destructive testing, providing insights into how these components respond to thermal cycling and mechanical stress[3]. Baker Hughes has also developed specialized coating analysis tools that can evaluate the performance of various surface treatments designed to improve wear resistance in apex seals and rotor housing surfaces. Their system incorporates tribological testing equipment specifically calibrated for the unique sliding contact conditions found in Wankel engines, measuring friction coefficients and wear rates under controlled temperature and pressure conditions[5]. Additionally, Baker Hughes offers advanced fluid dynamics analysis tools that can visualize and quantify oil film thickness and distribution patterns within operating engine models, helping engineers optimize lubrication strategies for the challenging sealing requirements of Wankel designs[7]. The company's integrated data management platform correlates findings across multiple test methodologies to provide comprehensive insights into material performance and failure mechanisms.

Strengths: Baker Hughes' tools excel at simulating extreme operating conditions, providing valuable data on how materials perform under the high temperatures and pressures found in high-performance Wankel engines. Their expertise in tribology and surface coatings addresses key challenges in Wankel engine durability. Weaknesses: The specialized equipment requires significant capital investment and technical expertise to operate effectively. The analysis process can be time-consuming and resource-intensive, potentially limiting throughput for large-scale testing programs.

Key Innovations in Rotary Engine Material Characterization

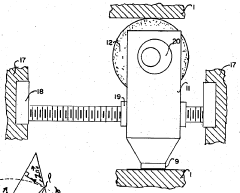

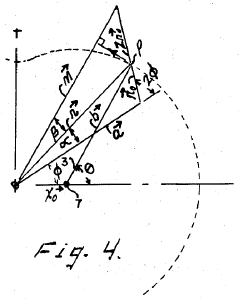

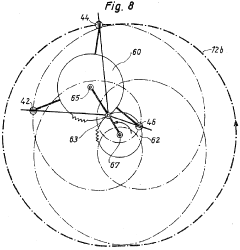

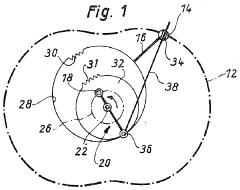

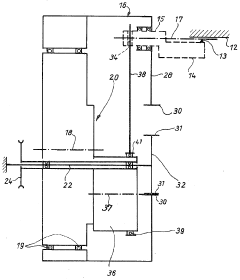

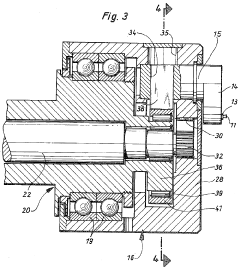

Wankel engine cylinder generating machine

PatentInactiveUS3824746A

Innovation

- A generating machine comprising a lobe generator and neck generator with cutting tools, utilizing a third harmonic cosine function to accurately trace the cylinder curve, and a hydrostatic bearing system for precise torque generation, allowing for parallel setup and efficient reboring or regrinding of Wankel engine cylinders.

Apparatus for machining and/or treatment of trochoidal surfaces

PatentInactiveUS3916738A

Innovation

- An apparatus with a control member, rotatable carrier, and tool holders that maintain constant tool orientation along a trochoidal path using an eccentric mechanism and gear system, ensuring consistent tool angles and speed variation to track true trochoidal paths accurately.

Environmental Impact Assessment of Rotary Engine Technologies

The environmental impact of Wankel rotary engine technologies presents a complex profile that differs significantly from conventional reciprocating engines. Rotary engines typically demonstrate higher fuel consumption rates, resulting in increased carbon dioxide emissions per unit of power output. This efficiency challenge stems from the inherent geometric design of the combustion chamber, which creates elongated combustion spaces with unfavorable surface-to-volume ratios, leading to incomplete combustion and higher hydrocarbon emissions.

Microstructural analysis tools have revealed critical insights into the environmental performance of rotary engines. Advanced electron microscopy and spectroscopic techniques have identified that the apex seal interfaces experience unique wear patterns that contribute to oil consumption and subsequent particulate emissions. These emissions contain higher concentrations of unburned hydrocarbons and carbon monoxide compared to modern piston engines equipped with similar emission control systems.

The thermal efficiency limitations of Wankel engines further compound their environmental impact. Thermal imaging analysis has demonstrated uneven temperature distribution across the rotor housing, creating hot spots that accelerate NOx formation during combustion. This thermal behavior, coupled with the inherent challenges in maintaining consistent sealing across the moving interfaces, results in a distinctive emissions profile that requires specialized catalytic conversion strategies.

Recent advancements in materials science have introduced ceramic-coated apex seals and rotor surfaces that show promise in reducing friction and improving thermal management. Environmental lifecycle assessments of these advanced materials indicate potential reductions in operational emissions, though manufacturing processes for specialized ceramics may carry higher embodied carbon footprints than conventional materials.

From a noise pollution perspective, rotary engines generally produce lower vibration levels and different acoustic signatures compared to reciprocating engines. Acoustic analysis tools have measured reduced low-frequency noise but identified distinctive high-frequency components that present different challenges for noise abatement strategies in urban environments.

Water consumption represents another environmental consideration, as rotary engines typically operate at higher temperatures and may require more robust cooling systems. Computational fluid dynamics models have demonstrated that cooling system requirements can increase water consumption in manufacturing processes and during the operational lifecycle of rotary-powered vehicles.

As emissions regulations continue to tighten globally, the environmental viability of rotary engine technologies increasingly depends on innovations in microstructural design and materials. The integration of hydrogen as an alternative fuel shows particular promise, as rotary engines demonstrate favorable combustion characteristics with hydrogen that could potentially mitigate many of their traditional environmental limitations.

Microstructural analysis tools have revealed critical insights into the environmental performance of rotary engines. Advanced electron microscopy and spectroscopic techniques have identified that the apex seal interfaces experience unique wear patterns that contribute to oil consumption and subsequent particulate emissions. These emissions contain higher concentrations of unburned hydrocarbons and carbon monoxide compared to modern piston engines equipped with similar emission control systems.

The thermal efficiency limitations of Wankel engines further compound their environmental impact. Thermal imaging analysis has demonstrated uneven temperature distribution across the rotor housing, creating hot spots that accelerate NOx formation during combustion. This thermal behavior, coupled with the inherent challenges in maintaining consistent sealing across the moving interfaces, results in a distinctive emissions profile that requires specialized catalytic conversion strategies.

Recent advancements in materials science have introduced ceramic-coated apex seals and rotor surfaces that show promise in reducing friction and improving thermal management. Environmental lifecycle assessments of these advanced materials indicate potential reductions in operational emissions, though manufacturing processes for specialized ceramics may carry higher embodied carbon footprints than conventional materials.

From a noise pollution perspective, rotary engines generally produce lower vibration levels and different acoustic signatures compared to reciprocating engines. Acoustic analysis tools have measured reduced low-frequency noise but identified distinctive high-frequency components that present different challenges for noise abatement strategies in urban environments.

Water consumption represents another environmental consideration, as rotary engines typically operate at higher temperatures and may require more robust cooling systems. Computational fluid dynamics models have demonstrated that cooling system requirements can increase water consumption in manufacturing processes and during the operational lifecycle of rotary-powered vehicles.

As emissions regulations continue to tighten globally, the environmental viability of rotary engine technologies increasingly depends on innovations in microstructural design and materials. The integration of hydrogen as an alternative fuel shows particular promise, as rotary engines demonstrate favorable combustion characteristics with hydrogen that could potentially mitigate many of their traditional environmental limitations.

Standardization Requirements for Microstructural Analysis Tools

The standardization of microstructural analysis tools for Wankel engines represents a critical need in the rotary engine industry. Current analysis methodologies vary significantly across research institutions, manufacturers, and maintenance facilities, creating inconsistencies in data interpretation and limiting cross-organizational collaboration. Establishing unified standards would enable more reliable comparison of research findings and engineering solutions across the global Wankel engine community.

Primary standardization requirements should address sample preparation protocols, which currently lack consistency in sectioning techniques, polishing procedures, and etching methods specific to the unique geometries and material compositions of Wankel engine components. The triangular rotor's apex seals and epitrochoidal housing surfaces require specialized preparation approaches that must be standardized to ensure comparable microstructural evaluations.

Imaging parameters constitute another critical area requiring standardization. Magnification levels, contrast settings, and resolution requirements should be established for different component analyses, with particular attention to the characteristic wear patterns at rotor apex seals and housing surfaces. Standard reference images for common microstructural features would provide valuable benchmarks for analysts across different facilities.

Quantitative analysis metrics need formalization to enable objective comparison of microstructural characteristics. This includes standardized methods for measuring coating thickness uniformity, apex seal wear patterns, surface roughness parameters, and epitrochoidal surface degradation. Statistical analysis approaches should be harmonized to ensure consistency in data interpretation and reporting.

Data reporting formats represent a significant standardization challenge, as current practices range from proprietary formats to inconsistent documentation methods. A unified reporting structure would facilitate knowledge sharing and collaborative problem-solving across organizational boundaries. This should include standardized terminology for Wankel-specific microstructural features and defect classifications.

Calibration procedures for analysis equipment must be standardized to ensure measurement accuracy across different facilities. Reference materials specific to Wankel engine alloys and coatings should be developed and certified for calibration purposes, with established verification protocols to maintain measurement integrity over time.

Interlaboratory testing programs would strengthen standardization efforts by validating methodology consistency across different facilities. Regular round-robin testing using identical reference samples would help identify procedural variations and refine standardization requirements, ultimately leading to more reliable and comparable microstructural analyses throughout the Wankel engine industry.

Primary standardization requirements should address sample preparation protocols, which currently lack consistency in sectioning techniques, polishing procedures, and etching methods specific to the unique geometries and material compositions of Wankel engine components. The triangular rotor's apex seals and epitrochoidal housing surfaces require specialized preparation approaches that must be standardized to ensure comparable microstructural evaluations.

Imaging parameters constitute another critical area requiring standardization. Magnification levels, contrast settings, and resolution requirements should be established for different component analyses, with particular attention to the characteristic wear patterns at rotor apex seals and housing surfaces. Standard reference images for common microstructural features would provide valuable benchmarks for analysts across different facilities.

Quantitative analysis metrics need formalization to enable objective comparison of microstructural characteristics. This includes standardized methods for measuring coating thickness uniformity, apex seal wear patterns, surface roughness parameters, and epitrochoidal surface degradation. Statistical analysis approaches should be harmonized to ensure consistency in data interpretation and reporting.

Data reporting formats represent a significant standardization challenge, as current practices range from proprietary formats to inconsistent documentation methods. A unified reporting structure would facilitate knowledge sharing and collaborative problem-solving across organizational boundaries. This should include standardized terminology for Wankel-specific microstructural features and defect classifications.

Calibration procedures for analysis equipment must be standardized to ensure measurement accuracy across different facilities. Reference materials specific to Wankel engine alloys and coatings should be developed and certified for calibration purposes, with established verification protocols to maintain measurement integrity over time.

Interlaboratory testing programs would strengthen standardization efforts by validating methodology consistency across different facilities. Regular round-robin testing using identical reference samples would help identify procedural variations and refine standardization requirements, ultimately leading to more reliable and comparable microstructural analyses throughout the Wankel engine industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!