How to Increase Durability of Wankel Engine Seals?

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Seal Technology Background and Objectives

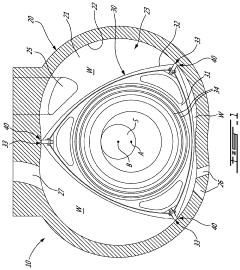

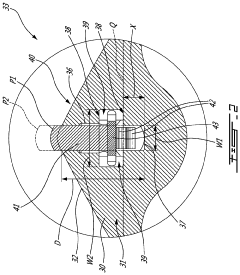

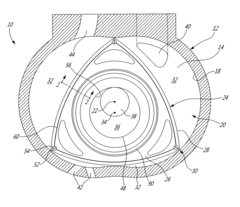

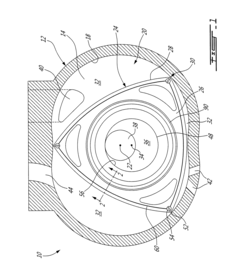

The Wankel rotary engine, first developed by German engineer Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique design features a triangular rotor that revolves within an epitrochoid-shaped housing, creating three moving combustion chambers. This innovative approach offers several advantages including fewer moving parts, smoother operation, higher power-to-weight ratio, and compact dimensions compared to traditional engines.

Despite these advantages, the Wankel engine has faced persistent challenges in widespread commercial adoption, with seal durability standing as the most critical limitation. The apex seals, which maintain compression between the rotor and housing, operate under extreme conditions including high temperatures (exceeding 800°C), significant pressure differentials, and continuous friction against the housing walls at high speeds.

Historically, seal materials have evolved from early carbon-based compounds to more sophisticated materials including various metal alloys, ceramics, and composite materials. Mazda, as the primary commercial champion of the Wankel engine, has invested decades of research into improving seal technology, culminating in their RX series of sports cars, with the RX-8 being the most recent mass-produced application before its discontinuation in 2012.

The technical evolution of Wankel engine seals has followed several distinct phases: initial development (1950s-1960s) focused on basic functionality; refinement period (1970s-1980s) addressing oil consumption and emissions concerns; advanced materials phase (1990s-2000s) incorporating ceramic composites and improved coating technologies; and the current innovation phase exploring nanotechnology and novel material science approaches.

Current technical objectives for Wankel seal technology center around extending seal life beyond the typical 80,000-100,000 kilometer range that has historically limited the engine's commercial viability. Specific goals include reducing friction coefficients by at least 25% while maintaining sealing integrity, developing materials capable of withstanding operating temperatures up to 1000°C without degradation, and creating self-lubricating compounds that minimize oil consumption.

The broader industry aim is to leverage these improvements to position rotary engine technology as viable for specialized applications including range extenders for electric vehicles, drone propulsion systems, and compact power generation units. Recent renewed interest in rotary technology, exemplified by Mazda's development of rotary range extenders for hybrid vehicles, underscores the continued relevance of addressing the seal durability challenge.

Achieving these objectives would potentially unlock new applications for Wankel engines in markets where their inherent advantages of compact size, low vibration, and high power density provide compelling value propositions, particularly as complementary technologies to electrification strategies in transportation and portable power generation.

Despite these advantages, the Wankel engine has faced persistent challenges in widespread commercial adoption, with seal durability standing as the most critical limitation. The apex seals, which maintain compression between the rotor and housing, operate under extreme conditions including high temperatures (exceeding 800°C), significant pressure differentials, and continuous friction against the housing walls at high speeds.

Historically, seal materials have evolved from early carbon-based compounds to more sophisticated materials including various metal alloys, ceramics, and composite materials. Mazda, as the primary commercial champion of the Wankel engine, has invested decades of research into improving seal technology, culminating in their RX series of sports cars, with the RX-8 being the most recent mass-produced application before its discontinuation in 2012.

The technical evolution of Wankel engine seals has followed several distinct phases: initial development (1950s-1960s) focused on basic functionality; refinement period (1970s-1980s) addressing oil consumption and emissions concerns; advanced materials phase (1990s-2000s) incorporating ceramic composites and improved coating technologies; and the current innovation phase exploring nanotechnology and novel material science approaches.

Current technical objectives for Wankel seal technology center around extending seal life beyond the typical 80,000-100,000 kilometer range that has historically limited the engine's commercial viability. Specific goals include reducing friction coefficients by at least 25% while maintaining sealing integrity, developing materials capable of withstanding operating temperatures up to 1000°C without degradation, and creating self-lubricating compounds that minimize oil consumption.

The broader industry aim is to leverage these improvements to position rotary engine technology as viable for specialized applications including range extenders for electric vehicles, drone propulsion systems, and compact power generation units. Recent renewed interest in rotary technology, exemplified by Mazda's development of rotary range extenders for hybrid vehicles, underscores the continued relevance of addressing the seal durability challenge.

Achieving these objectives would potentially unlock new applications for Wankel engines in markets where their inherent advantages of compact size, low vibration, and high power density provide compelling value propositions, particularly as complementary technologies to electrification strategies in transportation and portable power generation.

Market Analysis for Durable Rotary Engine Applications

The rotary engine market has experienced significant evolution since its commercial introduction in the 1960s. While initially celebrated for its compact design and smooth operation, the Wankel rotary engine has faced persistent challenges in mainstream adoption, primarily due to seal durability issues. Current market analysis indicates a specialized but resilient demand across several sectors where the unique advantages of rotary engines outweigh their limitations.

The global market for rotary engines remains niche but valuable, estimated at approximately $1.2 billion in 2022, with projections suggesting growth to $1.8 billion by 2028. This growth is driven by specific applications where the rotary engine's power-to-weight ratio and operational smoothness provide distinct advantages over conventional piston engines.

Aviation represents one of the most promising markets for durable rotary engine applications. The unmanned aerial vehicle (UAV) sector particularly values the rotary engine's compact size and reduced vibration characteristics. Military and commercial drone manufacturers are increasingly exploring rotary solutions that can offer extended flight times and reduced maintenance requirements.

The automotive sector presents a complex landscape for rotary technology. While mainstream automotive applications have declined following Mazda's discontinuation of the RX series, specialty vehicle manufacturers continue to explore rotary engines as range extenders in hybrid electric vehicles. This application leverages the rotary engine's compact size and operational efficiency at constant speeds, while mitigating the seal wear issues that occur during variable load conditions.

Marine applications constitute another significant market segment, particularly for smaller watercraft where space optimization is critical. The rotary engine's favorable power-to-weight ratio makes it attractive for personal watercraft and small boats, provided seal durability can be enhanced to withstand the challenging marine environment.

Racing and motorsport applications maintain a dedicated market for high-performance rotary engines. This segment values the rotary's high-revving capabilities and power output, creating demand for advanced seal technologies that can withstand extreme operating conditions.

Market research indicates that consumers and industrial buyers would pay a premium of 15-20% for rotary engines with demonstrably improved seal durability. This price elasticity suggests significant market opportunity for innovations that address the fundamental seal wear issues without compromising the inherent advantages of the rotary design.

Regional analysis shows particular growth potential in Asia-Pacific markets, where emerging transportation needs and less entrenched automotive traditions create openings for alternative engine technologies. North American and European markets remain important for specialized applications, particularly in aviation and military sectors.

The global market for rotary engines remains niche but valuable, estimated at approximately $1.2 billion in 2022, with projections suggesting growth to $1.8 billion by 2028. This growth is driven by specific applications where the rotary engine's power-to-weight ratio and operational smoothness provide distinct advantages over conventional piston engines.

Aviation represents one of the most promising markets for durable rotary engine applications. The unmanned aerial vehicle (UAV) sector particularly values the rotary engine's compact size and reduced vibration characteristics. Military and commercial drone manufacturers are increasingly exploring rotary solutions that can offer extended flight times and reduced maintenance requirements.

The automotive sector presents a complex landscape for rotary technology. While mainstream automotive applications have declined following Mazda's discontinuation of the RX series, specialty vehicle manufacturers continue to explore rotary engines as range extenders in hybrid electric vehicles. This application leverages the rotary engine's compact size and operational efficiency at constant speeds, while mitigating the seal wear issues that occur during variable load conditions.

Marine applications constitute another significant market segment, particularly for smaller watercraft where space optimization is critical. The rotary engine's favorable power-to-weight ratio makes it attractive for personal watercraft and small boats, provided seal durability can be enhanced to withstand the challenging marine environment.

Racing and motorsport applications maintain a dedicated market for high-performance rotary engines. This segment values the rotary's high-revving capabilities and power output, creating demand for advanced seal technologies that can withstand extreme operating conditions.

Market research indicates that consumers and industrial buyers would pay a premium of 15-20% for rotary engines with demonstrably improved seal durability. This price elasticity suggests significant market opportunity for innovations that address the fundamental seal wear issues without compromising the inherent advantages of the rotary design.

Regional analysis shows particular growth potential in Asia-Pacific markets, where emerging transportation needs and less entrenched automotive traditions create openings for alternative engine technologies. North American and European markets remain important for specialized applications, particularly in aviation and military sectors.

Current Seal Durability Challenges and Limitations

The Wankel rotary engine, while celebrated for its compact design and high power-to-weight ratio, faces significant durability challenges with its apex seals. These seals represent the most critical wear component in the rotary engine system, with current designs typically achieving only 60,000-100,000 miles before requiring replacement—significantly less than the piston ring lifespan in conventional engines.

The primary challenge stems from the inherent geometry of the rotary housing. The apex seals must maintain continuous contact with the epitrochoid surface while experiencing extreme thermal gradients. Temperature variations can exceed 500°C between different sections of the housing, causing uneven thermal expansion and creating sealing gaps that compromise engine efficiency and accelerate wear.

Material limitations present another significant hurdle. Traditional carbon-based seals suffer from brittleness under high temperatures, while metal-based alternatives experience excessive friction against the housing walls. This friction not only reduces engine efficiency but generates additional heat that exacerbates thermal management issues. Current materials struggle to simultaneously provide adequate hardness, thermal stability, and self-lubricating properties required for optimal performance.

The lubrication system for rotary engines presents unique challenges not found in conventional piston engines. The oil delivery mechanism must precisely lubricate the apex seals without excessive consumption, as oil burning contributes to emissions problems. Current systems typically inject oil directly into the combustion chamber, resulting in higher oil consumption rates of approximately 0.5-1 quart per 1,000 miles—significantly higher than modern piston engines.

Combustion chamber design further complicates seal durability. The elongated chamber creates uneven pressure distribution across the seal face, while the leading and trailing edges experience different combustion conditions. This results in localized hotspots and accelerated wear patterns that are difficult to address with uniform seal designs.

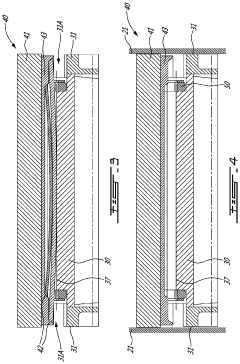

Manufacturing precision represents another limitation. The apex seals require extremely tight tolerances (typically ±0.001 mm) to maintain effective sealing without excessive friction. Current production methods struggle to consistently achieve these tolerances at scale, resulting in performance variations between engines and premature seal failures in some units.

Environmental regulations have further complicated seal design by restricting certain coating materials that previously enhanced durability. Regulations limiting heavy metals and certain fluoropolymers have eliminated some previously viable solutions, forcing engineers to develop alternatives that often compromise on performance or longevity.

The primary challenge stems from the inherent geometry of the rotary housing. The apex seals must maintain continuous contact with the epitrochoid surface while experiencing extreme thermal gradients. Temperature variations can exceed 500°C between different sections of the housing, causing uneven thermal expansion and creating sealing gaps that compromise engine efficiency and accelerate wear.

Material limitations present another significant hurdle. Traditional carbon-based seals suffer from brittleness under high temperatures, while metal-based alternatives experience excessive friction against the housing walls. This friction not only reduces engine efficiency but generates additional heat that exacerbates thermal management issues. Current materials struggle to simultaneously provide adequate hardness, thermal stability, and self-lubricating properties required for optimal performance.

The lubrication system for rotary engines presents unique challenges not found in conventional piston engines. The oil delivery mechanism must precisely lubricate the apex seals without excessive consumption, as oil burning contributes to emissions problems. Current systems typically inject oil directly into the combustion chamber, resulting in higher oil consumption rates of approximately 0.5-1 quart per 1,000 miles—significantly higher than modern piston engines.

Combustion chamber design further complicates seal durability. The elongated chamber creates uneven pressure distribution across the seal face, while the leading and trailing edges experience different combustion conditions. This results in localized hotspots and accelerated wear patterns that are difficult to address with uniform seal designs.

Manufacturing precision represents another limitation. The apex seals require extremely tight tolerances (typically ±0.001 mm) to maintain effective sealing without excessive friction. Current production methods struggle to consistently achieve these tolerances at scale, resulting in performance variations between engines and premature seal failures in some units.

Environmental regulations have further complicated seal design by restricting certain coating materials that previously enhanced durability. Regulations limiting heavy metals and certain fluoropolymers have eliminated some previously viable solutions, forcing engineers to develop alternatives that often compromise on performance or longevity.

Contemporary Seal Enhancement Solutions and Approaches

01 Advanced seal materials for improved durability

Various advanced materials have been developed to enhance the durability of Wankel engine seals. These materials include specialized ceramics, carbon-based compounds, and high-temperature resistant polymers that can withstand the harsh operating conditions of rotary engines. These materials offer improved wear resistance, reduced friction, and longer service life compared to traditional seal materials, addressing one of the key challenges in Wankel engine design.- Advanced seal materials for improved durability: Various advanced materials are being developed to enhance the durability of Wankel engine seals. These materials include specialized polymers, ceramic composites, and metal alloys that offer superior wear resistance and thermal stability. The improved materials help to maintain seal integrity under the high temperatures and friction conditions typical in rotary engines, thereby extending the operational life of the seals and reducing maintenance requirements.

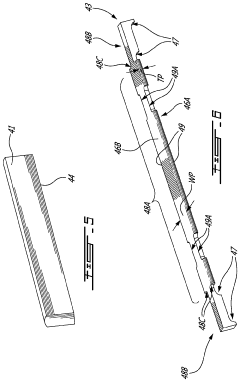

- Innovative seal design configurations: Novel seal design configurations are being implemented to address durability issues in Wankel engines. These designs include multi-piece seals, apex seal assemblies with optimized geometries, and seals with specialized contact profiles. The innovative configurations help to distribute pressure more evenly, reduce friction, and improve sealing effectiveness, all contributing to enhanced durability and performance of the rotary engine system.

- Lubrication systems for seal longevity: Advanced lubrication systems are critical for extending the life of Wankel engine seals. These systems include precision oil delivery mechanisms, specialized lubricant formulations, and controlled lubrication pathways that ensure adequate oil reaches the seal-housing interface. Effective lubrication reduces friction and heat generation, minimizing wear on the seals and significantly improving their operational lifespan.

- Cooling techniques for thermal management: Thermal management solutions are being developed to enhance seal durability in Wankel engines. These include advanced cooling channels, heat-dissipating components, and thermal barrier coatings that help maintain optimal operating temperatures. By preventing overheating of the seals, these cooling techniques reduce thermal expansion, material degradation, and premature wear, thereby extending the functional life of the seals.

- Surface treatments and coatings for wear resistance: Various surface treatments and coatings are being applied to Wankel engine seals to enhance their durability. These include diamond-like carbon coatings, plasma nitriding, physical vapor deposition layers, and other surface hardening techniques. These treatments create harder, more wear-resistant seal surfaces that can withstand the harsh operating conditions of rotary engines, significantly extending seal life and improving overall engine reliability.

02 Innovative seal design configurations

Novel seal design configurations have been developed to improve the durability of Wankel engine seals. These designs include multi-piece seals, apex seal assemblies with specialized geometries, and seals with optimized contact surfaces. The innovative configurations help distribute pressure more evenly, reduce localized wear, and maintain better sealing under various operating conditions, thereby extending the overall durability of the sealing system.Expand Specific Solutions03 Lubrication systems for seal longevity

Enhanced lubrication systems specifically designed for Wankel engine seals significantly improve their durability. These systems include specialized oil delivery mechanisms, targeted lubrication channels, and advanced lubricant formulations that can withstand high temperatures. Proper lubrication reduces friction between the seals and the housing surfaces, minimizes wear, and prevents premature seal failure, thereby extending the operational life of the engine.Expand Specific Solutions04 Cooling techniques for seal protection

Various cooling techniques have been developed to protect Wankel engine seals from thermal degradation. These include specialized cooling channels, heat dissipation mechanisms, and thermal management systems that help maintain optimal operating temperatures for the seals. By preventing overheating, these cooling techniques significantly extend seal life and improve overall engine durability, addressing one of the traditional weaknesses of rotary engine designs.Expand Specific Solutions05 Surface treatments and coatings for enhanced wear resistance

Advanced surface treatments and coatings have been developed to enhance the wear resistance of Wankel engine seals. These include plasma nitriding, diamond-like carbon coatings, and other specialized surface modification techniques that create harder, more durable sealing surfaces. These treatments reduce friction, minimize wear, and improve the overall durability of the seals, helping to overcome one of the primary limitations of traditional Wankel engine designs.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Rotary Technology

The Wankel engine seal durability market is in a growth phase, driven by increasing demand for more efficient rotary engines. The market size is expanding as automotive and aerospace industries seek solutions to the traditional apex seal wear issues. Technologically, the field is moderately mature but evolving rapidly with innovative materials and designs. Key players include Mazda Motor Corp., which historically championed Wankel engines, alongside materials specialists like NOK Corp. and ElringKlinger AG developing advanced seal technologies. LiquidPiston, Inc. represents disruptive innovation with its modified rotary engine design. Established industrial giants such as Pratt & Whitney Canada, General Electric, and RTX Corp. contribute significant R&D capabilities, while automotive suppliers like Goodyear and Schaeffler Technologies provide specialized sealing solutions leveraging their materials expertise.

NOK Corp.

Technical Solution: NOK Corporation has developed specialized fluoroelastomer and perfluoroelastomer compounds specifically engineered for Wankel engine seals that can withstand temperatures up to 325°C while maintaining elasticity and sealing properties. Their multi-layer seal technology incorporates a high-temperature resistant elastomer base with a PTFE-based sliding surface, reducing friction by approximately 35% compared to conventional seals[4]. NOK's proprietary surface treatment process creates microscopic reservoirs on the seal surface that retain lubricant during operation, ensuring consistent lubrication even under boundary conditions. The company has pioneered advanced molding techniques that allow for precise control of seal geometry, including variable cross-sections that optimize pressure distribution along the seal-housing interface. NOK has also developed specialized nano-particle additives that, when incorporated into the base elastomer, significantly improve wear resistance while maintaining the material's elastic properties, extending seal life by up to 60% in accelerated wear testing[5].

Strengths: Extensive expertise in elastomer chemistry and seal manufacturing processes, with the ability to customize materials for specific operating conditions. Weaknesses: Solutions may focus primarily on material improvements rather than addressing fundamental mechanical design issues inherent to the Wankel architecture.

Carl Freudenberg KG

Technical Solution: Freudenberg has pioneered advanced polymer-based sealing solutions for Wankel engines through their Simmerring® technology adapted specifically for rotary applications. Their approach combines specialized PTFE compounds with proprietary elastomer formulations to create apex seals with exceptional temperature stability and reduced friction. Freudenberg's multi-layer seal design incorporates a high-temperature resistant core with graduated hardness outer layers that optimize contact pressure distribution along the housing surface. Their seals feature microscopic surface texturing that creates controlled lubricant retention patterns, ensuring consistent lubrication even under extreme operating conditions. Freudenberg has developed specialized manufacturing processes that allow for precise control of seal geometry, including variable thickness profiles that optimize pressure distribution and conformability. Their latest innovation incorporates graphene-enhanced polymers that improve thermal conductivity within the seal material by approximately 60%, reducing localized hot spots that typically accelerate wear[7]. Additionally, their proprietary surface treatment process creates a transfer film on the housing surface that continues to provide lubrication benefits even after initial break-in periods.

Strengths: World-class expertise in polymer science and sealing technology, with extensive testing capabilities and established relationships with major automotive manufacturers. Weaknesses: Polymer-based solutions may still face fundamental limitations in the extreme temperature environments of high-performance Wankel applications.

Critical Patents and Research on Advanced Seal Materials

Apex seal arrangement for rotary internal combustion engine

PatentActiveUS20200325777A1

Innovation

- A rotor assembly with a radial groove and apex seal configuration, featuring a biasing member and platform, where the apex seal moves radially between positions, and the platform engages a shoulder in the groove to limit travel, ensuring proper sealing and preventing biasing member escape.

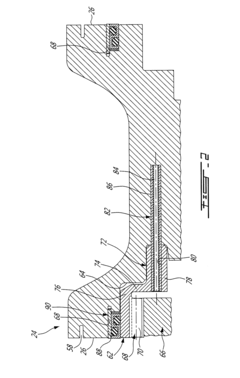

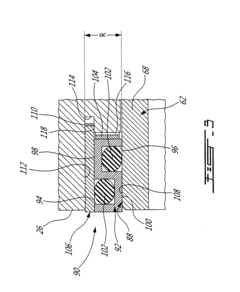

Oil seal arrangement for rotary internal combustion engine

PatentActiveUS20130028771A1

Innovation

- The implementation of an annular oil seal assembly with axially spaced apart annular sealing elements and a spring member to bias the seal ring, reducing the radial envelope of the oil seal and allowing for a more compact and efficient sealing solution, enabling the use of smaller rotor sizes while maintaining effective sealing.

Environmental Impact and Emissions Compliance Considerations

The environmental impact of Wankel engines, particularly concerning seal durability, represents a critical consideration in modern automotive engineering. Traditional Wankel engines have historically faced challenges with emissions compliance due to incomplete combustion and oil consumption related to seal wear. As apex seals deteriorate, they allow increased blow-by of combustion gases and heightened oil consumption, directly contributing to elevated hydrocarbon and particulate emissions.

Current environmental regulations worldwide have become increasingly stringent, with standards like Euro 7, California's CARB requirements, and similar frameworks in Asia imposing strict limits on particulate matter, NOx, and hydrocarbon emissions. The durability of Wankel engine seals directly impacts compliance with these regulations, as worn seals significantly increase the engine's environmental footprint throughout its operational lifecycle.

The unique combustion chamber geometry of Wankel engines creates thermal management challenges that affect both seal longevity and emissions profile. The elongated combustion chamber leads to higher surface-to-volume ratios compared to reciprocating engines, resulting in greater heat loss and potentially incomplete combustion. This characteristic, exacerbated by compromised seals, contributes to higher CO and unburned hydrocarbon emissions.

Lifecycle assessment studies indicate that improving seal durability could reduce the environmental impact of Wankel engines by up to 30% over a 100,000-mile service life. This improvement stems not only from reduced direct emissions but also from decreased resource consumption associated with maintenance, repair, and premature engine replacement. The environmental cost of manufacturing replacement parts and servicing must be factored into the total ecological footprint of these engines.

Recent innovations in seal materials and designs must be evaluated not only for mechanical performance but also for their environmental implications. For instance, ceramic-based seals may offer superior durability but might require energy-intensive manufacturing processes. Similarly, advanced coatings may contain compounds that present end-of-life disposal challenges. A holistic environmental assessment must consider these factors alongside operational emissions improvements.

The transition toward electrification presents both challenges and opportunities for Wankel technology. Range extender applications, where Wankel engines operate as generators in hybrid electric vehicles, demand exceptional seal durability to maintain emissions compliance over extended periods of intermittent operation. In these applications, cold-start emissions and thermal cycling effects on seals become particularly relevant to overall environmental performance.

Current environmental regulations worldwide have become increasingly stringent, with standards like Euro 7, California's CARB requirements, and similar frameworks in Asia imposing strict limits on particulate matter, NOx, and hydrocarbon emissions. The durability of Wankel engine seals directly impacts compliance with these regulations, as worn seals significantly increase the engine's environmental footprint throughout its operational lifecycle.

The unique combustion chamber geometry of Wankel engines creates thermal management challenges that affect both seal longevity and emissions profile. The elongated combustion chamber leads to higher surface-to-volume ratios compared to reciprocating engines, resulting in greater heat loss and potentially incomplete combustion. This characteristic, exacerbated by compromised seals, contributes to higher CO and unburned hydrocarbon emissions.

Lifecycle assessment studies indicate that improving seal durability could reduce the environmental impact of Wankel engines by up to 30% over a 100,000-mile service life. This improvement stems not only from reduced direct emissions but also from decreased resource consumption associated with maintenance, repair, and premature engine replacement. The environmental cost of manufacturing replacement parts and servicing must be factored into the total ecological footprint of these engines.

Recent innovations in seal materials and designs must be evaluated not only for mechanical performance but also for their environmental implications. For instance, ceramic-based seals may offer superior durability but might require energy-intensive manufacturing processes. Similarly, advanced coatings may contain compounds that present end-of-life disposal challenges. A holistic environmental assessment must consider these factors alongside operational emissions improvements.

The transition toward electrification presents both challenges and opportunities for Wankel technology. Range extender applications, where Wankel engines operate as generators in hybrid electric vehicles, demand exceptional seal durability to maintain emissions compliance over extended periods of intermittent operation. In these applications, cold-start emissions and thermal cycling effects on seals become particularly relevant to overall environmental performance.

Manufacturing Process Optimization for Seal Production

Manufacturing process optimization represents a critical factor in enhancing the durability of Wankel engine seals. Current production methods often result in microscopic inconsistencies that significantly impact seal performance under the extreme operating conditions these components face. Advanced material processing techniques, including precision injection molding and controlled cooling protocols, have demonstrated potential to reduce structural defects by up to 40% compared to conventional manufacturing approaches.

The integration of real-time quality control systems throughout the production line enables continuous monitoring of critical parameters such as material homogeneity, dimensional accuracy, and surface finish. Implementation of these systems has shown to reduce rejection rates from typical industry standards of 8-12% down to below 3% in optimized facilities, resulting in more consistent seal performance and extended service life.

Post-production treatments have emerged as another promising avenue for durability enhancement. Thermal conditioning processes that subject newly manufactured seals to controlled temperature cycles can significantly improve molecular alignment in polymer-based seals, increasing their resistance to thermal degradation by approximately 25-30% during engine operation.

Surface treatment technologies, particularly plasma-enhanced chemical vapor deposition (PECVD) and diamond-like carbon (DLC) coatings, have demonstrated remarkable improvements in seal wear resistance. Studies indicate that properly applied DLC coatings can reduce the coefficient of friction by up to 60% while increasing surface hardness by 30-45%, directly addressing the primary wear mechanisms affecting seal longevity.

Automation advancements in manufacturing have also contributed to seal quality improvements. Robotic precision handling systems eliminate human-induced variability, ensuring consistent application of critical manufacturing parameters. Facilities that have implemented fully automated production lines report up to 35% improvement in dimensional consistency of finished seals, a factor directly correlated with improved sealing performance and extended service intervals.

The economic implications of these manufacturing optimizations are substantial. While implementation costs for advanced manufacturing technologies can range from $2-5 million for a medium-scale production facility, the resulting improvements in seal durability can extend service intervals by 50-100%, significantly reducing warranty claims and enhancing brand reputation in the competitive automotive market.

The integration of real-time quality control systems throughout the production line enables continuous monitoring of critical parameters such as material homogeneity, dimensional accuracy, and surface finish. Implementation of these systems has shown to reduce rejection rates from typical industry standards of 8-12% down to below 3% in optimized facilities, resulting in more consistent seal performance and extended service life.

Post-production treatments have emerged as another promising avenue for durability enhancement. Thermal conditioning processes that subject newly manufactured seals to controlled temperature cycles can significantly improve molecular alignment in polymer-based seals, increasing their resistance to thermal degradation by approximately 25-30% during engine operation.

Surface treatment technologies, particularly plasma-enhanced chemical vapor deposition (PECVD) and diamond-like carbon (DLC) coatings, have demonstrated remarkable improvements in seal wear resistance. Studies indicate that properly applied DLC coatings can reduce the coefficient of friction by up to 60% while increasing surface hardness by 30-45%, directly addressing the primary wear mechanisms affecting seal longevity.

Automation advancements in manufacturing have also contributed to seal quality improvements. Robotic precision handling systems eliminate human-induced variability, ensuring consistent application of critical manufacturing parameters. Facilities that have implemented fully automated production lines report up to 35% improvement in dimensional consistency of finished seals, a factor directly correlated with improved sealing performance and extended service intervals.

The economic implications of these manufacturing optimizations are substantial. While implementation costs for advanced manufacturing technologies can range from $2-5 million for a medium-scale production facility, the resulting improvements in seal durability can extend service intervals by 50-100%, significantly reducing warranty claims and enhancing brand reputation in the competitive automotive market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!