Wankel Engine Emissions Reduction Strategies

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Evolution and Emission Reduction Goals

The Wankel rotary engine, first developed by Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its evolution has been marked by periods of both promise and challenge, particularly regarding emissions performance. The rotary engine's compact design, smooth operation, and high power-to-weight ratio initially positioned it as an innovative alternative to traditional internal combustion engines. However, its inherent design characteristics have presented persistent emissions challenges throughout its development history.

Early Wankel engines, most notably commercialized by NSU and later Mazda, demonstrated excellent performance characteristics but struggled with high fuel consumption and emissions. The elongated combustion chamber geometry and moving seals created inherent difficulties in achieving complete combustion, resulting in higher hydrocarbon (HC) and carbon monoxide (CO) emissions compared to conventional engines of similar displacement.

The 1970s and 1980s saw significant advancements in rotary engine technology, with Mazda leading development efforts through its RX series vehicles. The introduction of thermal reactors and later catalytic converters helped address some emissions concerns, though the fundamental challenges remained. By the 1990s, increasingly stringent emissions regulations worldwide began to place substantial pressure on rotary engine development.

The early 2000s marked a critical juncture for Wankel technology with Mazda's RENESIS engine, which incorporated side exhaust ports to reduce overlap between intake and exhaust phases, significantly improving emissions performance. This innovation earned the engine international recognition, including the International Engine of the Year award in 2003, demonstrating the potential for emissions improvements through clever engineering solutions.

Current emissions reduction goals for Wankel engines focus on several key areas: optimizing combustion chamber design to reduce unburned hydrocarbons, improving apex seal technology to minimize oil consumption and associated particulate emissions, implementing advanced fuel injection strategies, and exploring hybrid or hydrogen rotary configurations. The target is to achieve compliance with Euro 6/7, China 6, and US Tier 3 emissions standards while maintaining the rotary engine's characteristic advantages.

Looking forward, the industry aims to reduce CO2 emissions by 30-40% compared to previous generation rotary engines, decrease NOx emissions by over 50%, and virtually eliminate particulate matter through advanced combustion control and aftertreatment systems. These ambitious goals reflect both regulatory pressures and market demands for cleaner propulsion technologies, setting the stage for the next evolution of Wankel engine technology in an increasingly emissions-conscious automotive landscape.

Early Wankel engines, most notably commercialized by NSU and later Mazda, demonstrated excellent performance characteristics but struggled with high fuel consumption and emissions. The elongated combustion chamber geometry and moving seals created inherent difficulties in achieving complete combustion, resulting in higher hydrocarbon (HC) and carbon monoxide (CO) emissions compared to conventional engines of similar displacement.

The 1970s and 1980s saw significant advancements in rotary engine technology, with Mazda leading development efforts through its RX series vehicles. The introduction of thermal reactors and later catalytic converters helped address some emissions concerns, though the fundamental challenges remained. By the 1990s, increasingly stringent emissions regulations worldwide began to place substantial pressure on rotary engine development.

The early 2000s marked a critical juncture for Wankel technology with Mazda's RENESIS engine, which incorporated side exhaust ports to reduce overlap between intake and exhaust phases, significantly improving emissions performance. This innovation earned the engine international recognition, including the International Engine of the Year award in 2003, demonstrating the potential for emissions improvements through clever engineering solutions.

Current emissions reduction goals for Wankel engines focus on several key areas: optimizing combustion chamber design to reduce unburned hydrocarbons, improving apex seal technology to minimize oil consumption and associated particulate emissions, implementing advanced fuel injection strategies, and exploring hybrid or hydrogen rotary configurations. The target is to achieve compliance with Euro 6/7, China 6, and US Tier 3 emissions standards while maintaining the rotary engine's characteristic advantages.

Looking forward, the industry aims to reduce CO2 emissions by 30-40% compared to previous generation rotary engines, decrease NOx emissions by over 50%, and virtually eliminate particulate matter through advanced combustion control and aftertreatment systems. These ambitious goals reflect both regulatory pressures and market demands for cleaner propulsion technologies, setting the stage for the next evolution of Wankel engine technology in an increasingly emissions-conscious automotive landscape.

Market Demand Analysis for Cleaner Rotary Engines

The global market for cleaner rotary engines is experiencing significant growth driven by increasingly stringent emissions regulations worldwide. The European Union's Euro 7 standards, California's CARB requirements, and similar regulations in Asia have created substantial demand for innovative emission reduction technologies specifically tailored to Wankel engines. Market research indicates that while rotary engines represent a niche segment, their unique advantages in power-to-weight ratio and compact design maintain their relevance in specialized applications.

Consumer demand for environmentally friendly transportation options has expanded beyond traditional piston engines to include all powertrain types. A 2022 industry survey revealed that 67% of specialty vehicle buyers now consider emissions performance as a "very important" factor in purchasing decisions, compared to just 38% a decade ago. This shift in consumer preference has created new market opportunities for cleaner rotary engine technologies.

The automotive sector remains the primary market for Wankel engine applications, particularly in sports cars and specialty vehicles where their compact size and smooth operation provide competitive advantages. Mazda's announcement of the rotary engine's return as a range extender in electric vehicles signals a potential growth area, with market analysts projecting this hybrid application could reach 300,000 units annually by 2028.

Beyond automotive applications, rotary engines maintain significant market share in unmanned aerial vehicles, marine propulsion systems, and portable generators. The UAV segment is particularly promising, with annual growth rates exceeding 15% and increasing demand for low-emission power sources. Military and commercial drone manufacturers have expressed strong interest in cleaner rotary solutions that maintain the power density advantages while meeting stricter environmental standards.

Regional market analysis reveals varying demand patterns. Japan and Germany lead in rotary engine technology development, while emerging markets in Southeast Asia show the fastest growth rates for adoption. North America represents the largest potential market by volume, particularly if emissions challenges can be overcome to meet regional standards.

Economic analysis suggests that successful emissions reduction technologies for Wankel engines could unlock a specialized market valued at approximately $2.5 billion by 2030. However, this potential is contingent upon achieving emissions performance comparable to modern piston engines while maintaining the rotary's inherent advantages. The price sensitivity analysis indicates consumers would accept a 12-18% premium for cleaner rotary technology compared to conventional alternatives.

Industry partnerships between engine manufacturers, emissions control specialists, and materials science companies have increased by 40% in the past three years, demonstrating strong market interest in collaborative approaches to solving the rotary emissions challenge.

Consumer demand for environmentally friendly transportation options has expanded beyond traditional piston engines to include all powertrain types. A 2022 industry survey revealed that 67% of specialty vehicle buyers now consider emissions performance as a "very important" factor in purchasing decisions, compared to just 38% a decade ago. This shift in consumer preference has created new market opportunities for cleaner rotary engine technologies.

The automotive sector remains the primary market for Wankel engine applications, particularly in sports cars and specialty vehicles where their compact size and smooth operation provide competitive advantages. Mazda's announcement of the rotary engine's return as a range extender in electric vehicles signals a potential growth area, with market analysts projecting this hybrid application could reach 300,000 units annually by 2028.

Beyond automotive applications, rotary engines maintain significant market share in unmanned aerial vehicles, marine propulsion systems, and portable generators. The UAV segment is particularly promising, with annual growth rates exceeding 15% and increasing demand for low-emission power sources. Military and commercial drone manufacturers have expressed strong interest in cleaner rotary solutions that maintain the power density advantages while meeting stricter environmental standards.

Regional market analysis reveals varying demand patterns. Japan and Germany lead in rotary engine technology development, while emerging markets in Southeast Asia show the fastest growth rates for adoption. North America represents the largest potential market by volume, particularly if emissions challenges can be overcome to meet regional standards.

Economic analysis suggests that successful emissions reduction technologies for Wankel engines could unlock a specialized market valued at approximately $2.5 billion by 2030. However, this potential is contingent upon achieving emissions performance comparable to modern piston engines while maintaining the rotary's inherent advantages. The price sensitivity analysis indicates consumers would accept a 12-18% premium for cleaner rotary technology compared to conventional alternatives.

Industry partnerships between engine manufacturers, emissions control specialists, and materials science companies have increased by 40% in the past three years, demonstrating strong market interest in collaborative approaches to solving the rotary emissions challenge.

Current Emission Challenges in Wankel Technology

Wankel engines, despite their compact design and high power-to-weight ratio, face significant emission challenges that have limited their widespread adoption in modern automotive applications. The rotary engine's inherent design characteristics contribute to higher emissions compared to conventional reciprocating engines, particularly in terms of unburned hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx).

The triangular rotor design creates elongated combustion chambers with high surface-to-volume ratios, resulting in quenching effects near chamber walls that lead to incomplete combustion. This fundamental issue causes elevated hydrocarbon emissions, estimated to be 30-50% higher than comparable piston engines under similar operating conditions. The problem is exacerbated by the engine's inherent oil consumption mechanism, where lubricating oil intentionally introduced into the combustion chamber contributes to both particulate matter and hydrocarbon emissions.

Thermal efficiency challenges represent another critical emission-related concern. Wankel engines typically operate at 15-25% lower thermal efficiency than modern piston engines, necessitating greater fuel consumption to achieve equivalent power output. This efficiency deficit directly translates to increased carbon dioxide (CO2) emissions per unit of work performed, a significant disadvantage in an era of stringent greenhouse gas regulations.

The unique apex seal design, while essential to the rotary operation, creates additional emission challenges. These seals experience variable pressure and temperature conditions as they traverse the epitrochoidal housing, resulting in inconsistent sealing that allows unburned fuel to escape into the exhaust. Studies indicate apex seal leakage can account for up to 15% of total hydrocarbon emissions under certain operating conditions.

Cold-start emissions present a particularly difficult challenge for Wankel engines. The extended surface area and thermal characteristics of the rotary housing result in prolonged warm-up periods, during which combustion efficiency remains suboptimal. Emissions during these cold-start phases can be 2-3 times higher than steady-state operation, significantly impacting overall emission profiles in real-world driving scenarios.

Current regulatory frameworks pose existential challenges for Wankel technology. Euro 6d, China 6, and US Tier 3 emission standards have established limits that are increasingly difficult for rotary engines to meet without extensive aftertreatment systems. The cost and complexity of these systems often negate the inherent advantages of the Wankel's compact design and mechanical simplicity, creating a significant barrier to market viability.

Recent testing data from major research institutions indicates that even modern Wankel designs struggle to meet particulate number (PN) limits without extensive filtration systems, while NOx control requires sophisticated catalytic converters specifically calibrated for the unique exhaust gas composition of rotary engines.

The triangular rotor design creates elongated combustion chambers with high surface-to-volume ratios, resulting in quenching effects near chamber walls that lead to incomplete combustion. This fundamental issue causes elevated hydrocarbon emissions, estimated to be 30-50% higher than comparable piston engines under similar operating conditions. The problem is exacerbated by the engine's inherent oil consumption mechanism, where lubricating oil intentionally introduced into the combustion chamber contributes to both particulate matter and hydrocarbon emissions.

Thermal efficiency challenges represent another critical emission-related concern. Wankel engines typically operate at 15-25% lower thermal efficiency than modern piston engines, necessitating greater fuel consumption to achieve equivalent power output. This efficiency deficit directly translates to increased carbon dioxide (CO2) emissions per unit of work performed, a significant disadvantage in an era of stringent greenhouse gas regulations.

The unique apex seal design, while essential to the rotary operation, creates additional emission challenges. These seals experience variable pressure and temperature conditions as they traverse the epitrochoidal housing, resulting in inconsistent sealing that allows unburned fuel to escape into the exhaust. Studies indicate apex seal leakage can account for up to 15% of total hydrocarbon emissions under certain operating conditions.

Cold-start emissions present a particularly difficult challenge for Wankel engines. The extended surface area and thermal characteristics of the rotary housing result in prolonged warm-up periods, during which combustion efficiency remains suboptimal. Emissions during these cold-start phases can be 2-3 times higher than steady-state operation, significantly impacting overall emission profiles in real-world driving scenarios.

Current regulatory frameworks pose existential challenges for Wankel technology. Euro 6d, China 6, and US Tier 3 emission standards have established limits that are increasingly difficult for rotary engines to meet without extensive aftertreatment systems. The cost and complexity of these systems often negate the inherent advantages of the Wankel's compact design and mechanical simplicity, creating a significant barrier to market viability.

Recent testing data from major research institutions indicates that even modern Wankel designs struggle to meet particulate number (PN) limits without extensive filtration systems, while NOx control requires sophisticated catalytic converters specifically calibrated for the unique exhaust gas composition of rotary engines.

Current Emission Reduction Solutions for Wankel Engines

01 Emission control systems for Wankel engines

Various emission control systems have been developed specifically for Wankel engines to reduce harmful exhaust emissions. These systems include catalytic converters, exhaust gas recirculation (EGR) systems, and specialized aftertreatment devices designed to address the unique combustion characteristics of rotary engines. These technologies help Wankel engines meet increasingly stringent emission standards by treating exhaust gases before they are released into the atmosphere.- Emission control systems for Wankel engines: Various emission control systems have been developed specifically for Wankel engines to reduce harmful exhaust emissions. These systems include catalytic converters, exhaust gas recirculation (EGR) systems, and specialized aftertreatment devices designed to address the unique combustion characteristics of rotary engines. These technologies help Wankel engines meet increasingly stringent emission standards by treating exhaust gases before they are released into the atmosphere.

- Combustion chamber design improvements: Innovations in the combustion chamber design of Wankel engines have been developed to improve combustion efficiency and reduce emissions. These include modified rotor geometry, optimized apex seal configurations, and enhanced port designs. By improving the combustion process within the chamber, these designs help achieve more complete fuel burning, resulting in lower hydrocarbon and carbon monoxide emissions while maintaining or improving engine performance.

- Fuel injection and mixture formation technologies: Advanced fuel injection systems and mixture formation technologies have been developed for Wankel engines to optimize the air-fuel ratio and improve combustion efficiency. These include direct injection systems, stratified charge configurations, and electronic fuel management systems. By delivering precisely controlled amounts of fuel at optimal timing, these technologies help reduce emissions while improving fuel economy and engine performance.

- Thermal management solutions: Thermal management solutions address the unique cooling challenges of Wankel engines and their impact on emissions. These include advanced cooling systems, heat recovery mechanisms, and thermal barrier coatings. By maintaining optimal operating temperatures throughout the engine, especially at the combustion chamber walls, these solutions help reduce hydrocarbon emissions that typically result from incomplete combustion due to temperature variations within the engine.

- Hybrid and alternative fuel adaptations: Wankel engines have been adapted to work with hybrid powertrains and alternative fuels to reduce emissions. These adaptations include integration with electric motors in hybrid configurations, modifications for hydrogen fuel operation, and compatibility with biofuels. By leveraging the compact size and smooth operation of Wankel engines while addressing their traditional emission challenges through alternative power sources or cleaner fuels, these innovations help achieve significant reductions in greenhouse gas and pollutant emissions.

02 Combustion chamber design improvements

Modifications to the combustion chamber design of Wankel engines can significantly reduce emissions. These improvements include optimized rotor geometry, modified epitrochoidal housing profiles, and enhanced apex seal designs that improve combustion efficiency and reduce unburned hydrocarbon emissions. By creating more complete combustion and reducing crevice volumes where unburned fuel can escape, these design improvements directly address one of the primary sources of emissions in rotary engines.Expand Specific Solutions03 Fuel injection and ignition system enhancements

Advanced fuel injection and ignition systems have been developed to optimize the combustion process in Wankel engines. These include direct injection systems, stratified charge configurations, and multiple spark plug arrangements that ensure more complete fuel burning. By precisely controlling fuel delivery timing and ignition patterns, these systems reduce the formation of pollutants at their source and improve overall combustion efficiency, resulting in lower emissions.Expand Specific Solutions04 Thermal management solutions

Effective thermal management is crucial for controlling emissions in Wankel engines, which traditionally suffer from high operating temperatures. Innovations include advanced cooling systems, heat-resistant materials, and thermal barrier coatings that maintain optimal operating temperatures. By preventing overheating and ensuring consistent combustion chamber temperatures, these solutions help reduce the formation of nitrogen oxides (NOx) and improve overall emission performance.Expand Specific Solutions05 Alternative fuel adaptations

Wankel engines have been adapted to operate on alternative fuels such as hydrogen, natural gas, and biofuels to reduce emissions. These adaptations include modified fuel delivery systems, combustion chamber designs optimized for specific alternative fuels, and specialized sealing technologies. By utilizing cleaner-burning fuels, these adaptations can significantly reduce carbon dioxide, particulate matter, and other harmful emissions while maintaining the compact size and smooth operation characteristic of rotary engines.Expand Specific Solutions

Key Manufacturers and Research Institutions in Rotary Engine Space

The Wankel engine emissions reduction market is in a growth phase, with increasing focus on sustainable transportation solutions. The market is expanding due to stringent global emissions regulations, though still smaller than conventional engine technologies. Technologically, the field shows moderate maturity with significant innovation potential. Key players include Ford Global Technologies and GM Global Technology Operations leading automotive applications, while specialized companies like Tula Technology focus on software-based efficiency solutions. Continental Automotive and Johnson Matthey contribute emissions control technologies, with research institutions like Tianjin University advancing fundamental innovations. Oil companies including Phillips 66 and Chevron Oronite are developing compatible fuel formulations to further reduce Wankel engine emissions.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive emissions reduction strategy for Wankel engines focusing on advanced direct injection systems combined with stratified charge combustion. Their approach utilizes a dual-injection system that precisely controls fuel delivery at different engine operating conditions. The system incorporates low-pressure port injection for homogeneous mixture formation during cold starts and high-pressure direct injection for stratified charge operation during normal running conditions. Ford has also implemented variable exhaust gas recirculation (EGR) rates controlled by their proprietary PowerShift electronic control unit that dynamically adjusts based on engine load and temperature. Their latest patents show integration of ceramic apex seals with thermal barrier coatings that reduce heat rejection to cooling systems, improving thermal efficiency while reducing hydrocarbon emissions from quench zones. Additionally, Ford has developed specialized catalytic converter designs specifically shaped to accommodate the unique exhaust pulse characteristics of Wankel engines.

Strengths: Ford's dual-injection system provides excellent flexibility across operating conditions, significantly reducing cold-start emissions which are traditionally problematic for rotary engines. Their specialized catalytic converter designs show superior conversion efficiency for the unique exhaust composition of Wankel engines. Weaknesses: The complex electronic control systems add cost and potential reliability concerns, while the specialized apex seal materials may have durability limitations under certain operating conditions.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered a multi-faceted approach to Wankel engine emissions reduction centered around their patented HCCI-Rotary hybrid combustion system. This technology enables the engine to operate in homogeneous charge compression ignition mode during part-load conditions, dramatically reducing NOx formation while maintaining the Wankel's characteristic high power density during full-load operation. Their system incorporates variable rotor chamber geometry through electronically controlled side ports that modify the effective compression ratio based on operating conditions. GM has also developed specialized oil control systems that minimize oil consumption—a traditional weakness of Wankel designs that contributes significantly to particulate and hydrocarbon emissions. Their "TriSeal" technology uses a three-stage oil control mechanism with primary and secondary scraper seals followed by a specialized oil recovery channel that captures and returns oil to the sump before it can enter the combustion chamber. Additionally, GM has implemented advanced thermal management systems that maintain optimal rotor housing temperatures to prevent fuel condensation on chamber walls, reducing unburned hydrocarbon emissions.

Strengths: GM's HCCI-Rotary hybrid combustion system achieves near-diesel efficiency levels during cruise conditions while maintaining the Wankel's high power density capabilities. Their oil control technology effectively addresses one of the Wankel's most persistent emissions challenges. Weaknesses: The variable geometry components add mechanical complexity and potential reliability concerns, and the system requires sophisticated electronic controls that increase cost and development complexity.

Critical Patents and Innovations in Rotary Engine Emissions

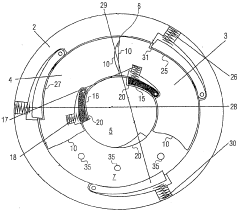

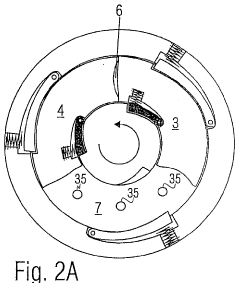

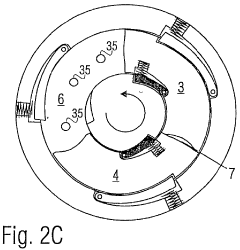

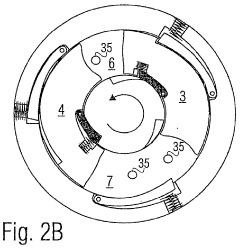

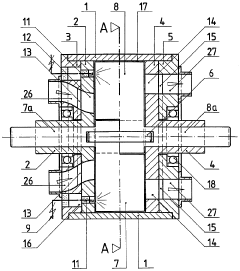

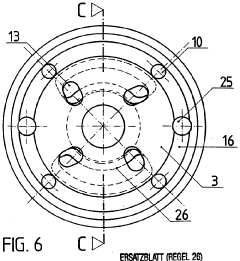

Rotary internal combustion engine

PatentWO2007028487A1

Innovation

- A rotary internal combustion engine with rotationally symmetrical, ring-shaped combustion chambers and circular segment pistons arranged in a circular pattern, improving sealing and combustion efficiency by using a section of the pistons to seal the chambers, similar to reciprocating engines, and connecting pistons to a torsionally rigid output shaft for power transmission.

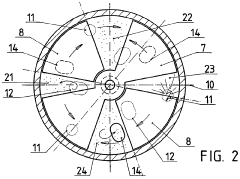

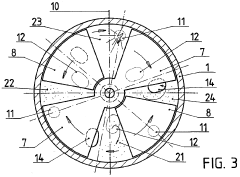

Internal combustion engine

PatentWO1995034749A1

Innovation

- A rotary piston engine with a cylindrical housing and centrally mounted, double-acting rotary pistons that move in a specific angular pattern, utilizing a simple structural design for reduced production costs and improved sealing, achieving complete combustion and lower emissions through wedge-shaped combustion chambers and automatic fuel/air mixture distribution.

Regulatory Framework and Emission Standards Impact

The regulatory landscape governing emissions from internal combustion engines has evolved significantly over the past decades, creating both challenges and opportunities for Wankel engine development. Emissions regulations worldwide have progressively tightened, with major jurisdictions including the European Union (Euro standards), United States (EPA/CARB), and Japan (Japanese Emission Standards) implementing increasingly stringent limits on pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM).

Wankel engines face unique regulatory challenges due to their inherent combustion characteristics. The elongated combustion chamber and high surface-to-volume ratio contribute to higher hydrocarbon emissions compared to conventional piston engines. This has placed Wankel-powered vehicles at a disadvantage as emission standards have evolved from Euro 3/4 to current Euro 6d/7 standards in Europe and Tier 3 standards in the United States.

The implementation of Real Driving Emissions (RDE) testing protocols has further complicated compliance for rotary engine manufacturers. Unlike laboratory-based testing cycles, RDE evaluates emissions performance under actual driving conditions, exposing the Wankel engine's efficiency limitations across varying operational states. This regulatory shift has accelerated the need for advanced emission control technologies specifically tailored to rotary engine characteristics.

Carbon dioxide emission targets represent another significant regulatory pressure. The EU's fleet-wide CO2 emissions target of 95g/km and similar standards in other markets have forced manufacturers to reconsider the viability of Wankel engines in their product portfolios. This explains why Mazda, historically the primary proponent of rotary technology, has shifted toward using Wankel engines primarily as range extenders in hybrid electric vehicles rather than as main propulsion units.

Low Emission Zones (LEZs) and Zero Emission Zones (ZEZs) in major urban centers worldwide have created additional market access barriers for vehicles with higher emission profiles. Without significant technological advancements, conventional Wankel-powered vehicles risk exclusion from these growing restricted areas, diminishing their market appeal and commercial viability.

The regulatory timeline for internal combustion engine phase-outs in various markets (2030-2040 in many European countries) creates a defined window for Wankel technology evolution. This has catalyzed research into alternative fuel compatibility, particularly hydrogen, as a potential pathway for regulatory compliance while preserving the rotary engine's unique characteristics and advantages.

Regulatory frameworks have also influenced investment patterns in emission reduction technologies, with government incentives and penalties shaping research priorities. The availability of research grants for clean propulsion technologies has supported continued development of emission control strategies specific to rotary engines, despite their relatively small market share.

Wankel engines face unique regulatory challenges due to their inherent combustion characteristics. The elongated combustion chamber and high surface-to-volume ratio contribute to higher hydrocarbon emissions compared to conventional piston engines. This has placed Wankel-powered vehicles at a disadvantage as emission standards have evolved from Euro 3/4 to current Euro 6d/7 standards in Europe and Tier 3 standards in the United States.

The implementation of Real Driving Emissions (RDE) testing protocols has further complicated compliance for rotary engine manufacturers. Unlike laboratory-based testing cycles, RDE evaluates emissions performance under actual driving conditions, exposing the Wankel engine's efficiency limitations across varying operational states. This regulatory shift has accelerated the need for advanced emission control technologies specifically tailored to rotary engine characteristics.

Carbon dioxide emission targets represent another significant regulatory pressure. The EU's fleet-wide CO2 emissions target of 95g/km and similar standards in other markets have forced manufacturers to reconsider the viability of Wankel engines in their product portfolios. This explains why Mazda, historically the primary proponent of rotary technology, has shifted toward using Wankel engines primarily as range extenders in hybrid electric vehicles rather than as main propulsion units.

Low Emission Zones (LEZs) and Zero Emission Zones (ZEZs) in major urban centers worldwide have created additional market access barriers for vehicles with higher emission profiles. Without significant technological advancements, conventional Wankel-powered vehicles risk exclusion from these growing restricted areas, diminishing their market appeal and commercial viability.

The regulatory timeline for internal combustion engine phase-outs in various markets (2030-2040 in many European countries) creates a defined window for Wankel technology evolution. This has catalyzed research into alternative fuel compatibility, particularly hydrogen, as a potential pathway for regulatory compliance while preserving the rotary engine's unique characteristics and advantages.

Regulatory frameworks have also influenced investment patterns in emission reduction technologies, with government incentives and penalties shaping research priorities. The availability of research grants for clean propulsion technologies has supported continued development of emission control strategies specific to rotary engines, despite their relatively small market share.

Comparative Analysis with Alternative Powertrain Technologies

When evaluating Wankel engine emissions reduction strategies, it is essential to compare this rotary engine technology with other powertrain solutions in today's rapidly evolving automotive landscape. Battery Electric Vehicles (BEVs) offer zero tailpipe emissions and higher energy efficiency (85-90%) compared to Wankel engines (15-25%), but face challenges in charging infrastructure, range limitations, and battery production environmental impacts. The total lifecycle emissions of BEVs depend heavily on electricity generation sources, potentially offsetting their environmental advantages in regions reliant on fossil fuels.

Hydrogen Fuel Cell Electric Vehicles (FCEVs) present another alternative with zero tailpipe emissions except for water vapor. While offering quick refueling and longer ranges than BEVs, FCEVs struggle with hydrogen production efficiency, storage challenges, and limited refueling infrastructure. The well-to-wheel efficiency of FCEVs (around 30-35%) surpasses traditional Wankel engines but remains lower than BEVs.

Conventional internal combustion engines (ICEs) with advanced emissions control systems have significantly reduced their environmental impact through technologies like direct injection, variable valve timing, and three-way catalytic converters. Modern gasoline engines achieve 25-30% efficiency, outperforming typical Wankel engines while producing fewer emissions per unit of power.

Hybrid powertrains represent a middle-ground solution, combining ICEs with electric motors to optimize efficiency. Particularly relevant for Wankel applications are range-extender configurations, where a small rotary engine serves as an onboard generator for an electric drivetrain. Mazda has explored this approach with their rotary range extender technology, leveraging the Wankel engine's compact size and smooth operation while mitigating its emissions challenges through controlled, steady-state operation.

From a regulatory perspective, Wankel engines face increasingly stringent emissions standards worldwide that favor electrified solutions. The technology gap between optimized Wankel engines and alternative powertrains continues to widen as investment in electric mobility accelerates. However, niche applications remain where the Wankel's power-to-weight ratio and mechanical simplicity provide unique advantages.

Cost considerations also impact competitiveness, with Wankel engines requiring specialized manufacturing processes and materials to address sealing and durability issues. Meanwhile, battery costs continue to decline (approximately 13% annually over the past decade), gradually eroding the price advantage of combustion technologies.

Hydrogen Fuel Cell Electric Vehicles (FCEVs) present another alternative with zero tailpipe emissions except for water vapor. While offering quick refueling and longer ranges than BEVs, FCEVs struggle with hydrogen production efficiency, storage challenges, and limited refueling infrastructure. The well-to-wheel efficiency of FCEVs (around 30-35%) surpasses traditional Wankel engines but remains lower than BEVs.

Conventional internal combustion engines (ICEs) with advanced emissions control systems have significantly reduced their environmental impact through technologies like direct injection, variable valve timing, and three-way catalytic converters. Modern gasoline engines achieve 25-30% efficiency, outperforming typical Wankel engines while producing fewer emissions per unit of power.

Hybrid powertrains represent a middle-ground solution, combining ICEs with electric motors to optimize efficiency. Particularly relevant for Wankel applications are range-extender configurations, where a small rotary engine serves as an onboard generator for an electric drivetrain. Mazda has explored this approach with their rotary range extender technology, leveraging the Wankel engine's compact size and smooth operation while mitigating its emissions challenges through controlled, steady-state operation.

From a regulatory perspective, Wankel engines face increasingly stringent emissions standards worldwide that favor electrified solutions. The technology gap between optimized Wankel engines and alternative powertrains continues to widen as investment in electric mobility accelerates. However, niche applications remain where the Wankel's power-to-weight ratio and mechanical simplicity provide unique advantages.

Cost considerations also impact competitiveness, with Wankel engines requiring specialized manufacturing processes and materials to address sealing and durability issues. Meanwhile, battery costs continue to decline (approximately 13% annually over the past decade), gradually eroding the price advantage of combustion technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!