Wankel Engine Revamping for Higher RPMs

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Evolution and Performance Targets

The Wankel rotary engine, first developed by Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its evolution has been marked by continuous refinement aimed at harnessing its inherent advantages of compact design, fewer moving parts, and smooth operation. The initial NSU Wankel engines of the early 1960s operated at modest RPMs of 5,000-6,000, while demonstrating the concept's viability despite challenges with sealing and efficiency.

By the 1970s, Mazda emerged as the primary commercial developer, introducing significant improvements through their RX series. The 12A and 13B engines found in the RX-7 models pushed operational capabilities to 7,000-8,000 RPM, with racing variants achieving 9,000-10,000 RPM. These developments established rotary engines as capable high-performance powerplants with exceptional power-to-weight ratios.

The 1990s saw further advancement with Mazda's Renesis engine in the RX-8, featuring side exhaust ports that improved emissions and efficiency while maintaining high RPM capability around 9,000 RPM. This period demonstrated that rotary engines could be refined to meet increasingly stringent environmental standards while preserving their performance characteristics.

Current technological targets for Wankel engine revamping focus on achieving sustained operation at 12,000+ RPM for specialized applications, particularly in motorsport, aviation, and hybrid powertrains. This represents approximately a 30-40% increase over conventional high-performance rotary engines. Such advancement would position rotary technology as uniquely capable in high-power density applications where conventional piston engines face mechanical limitations.

The performance evolution trajectory indicates several critical development areas: advanced apex seal materials utilizing ceramic composites and diamond-like carbon coatings; improved rotor cooling systems to manage thermal loads at extreme RPMs; optimized port timing for high-velocity gas exchange; and electronic control systems capable of precise fuel delivery and ignition timing at elevated engine speeds.

Achieving these targets would enable power outputs exceeding 300 hp per liter of displacement while maintaining the rotary's compact form factor. This represents a significant leap from historical benchmarks of 100-150 hp per liter in production rotary engines. The weight advantage would become even more pronounced, with power-to-weight ratios potentially doubling compared to conventional high-performance piston engines.

The technological roadmap for high-RPM Wankel engines aligns with broader industry trends toward specialized powertrains optimized for specific applications rather than general-purpose solutions. Success in this domain would establish rotary technology as the preferred solution for applications where extreme power density and operational smoothness at high speeds are paramount considerations.

By the 1970s, Mazda emerged as the primary commercial developer, introducing significant improvements through their RX series. The 12A and 13B engines found in the RX-7 models pushed operational capabilities to 7,000-8,000 RPM, with racing variants achieving 9,000-10,000 RPM. These developments established rotary engines as capable high-performance powerplants with exceptional power-to-weight ratios.

The 1990s saw further advancement with Mazda's Renesis engine in the RX-8, featuring side exhaust ports that improved emissions and efficiency while maintaining high RPM capability around 9,000 RPM. This period demonstrated that rotary engines could be refined to meet increasingly stringent environmental standards while preserving their performance characteristics.

Current technological targets for Wankel engine revamping focus on achieving sustained operation at 12,000+ RPM for specialized applications, particularly in motorsport, aviation, and hybrid powertrains. This represents approximately a 30-40% increase over conventional high-performance rotary engines. Such advancement would position rotary technology as uniquely capable in high-power density applications where conventional piston engines face mechanical limitations.

The performance evolution trajectory indicates several critical development areas: advanced apex seal materials utilizing ceramic composites and diamond-like carbon coatings; improved rotor cooling systems to manage thermal loads at extreme RPMs; optimized port timing for high-velocity gas exchange; and electronic control systems capable of precise fuel delivery and ignition timing at elevated engine speeds.

Achieving these targets would enable power outputs exceeding 300 hp per liter of displacement while maintaining the rotary's compact form factor. This represents a significant leap from historical benchmarks of 100-150 hp per liter in production rotary engines. The weight advantage would become even more pronounced, with power-to-weight ratios potentially doubling compared to conventional high-performance piston engines.

The technological roadmap for high-RPM Wankel engines aligns with broader industry trends toward specialized powertrains optimized for specific applications rather than general-purpose solutions. Success in this domain would establish rotary technology as the preferred solution for applications where extreme power density and operational smoothness at high speeds are paramount considerations.

Market Analysis for High-RPM Rotary Engines

The high-RPM rotary engine market represents a specialized but potentially lucrative segment within the broader automotive and powertrain industry. Current market analysis indicates a growing interest in high-performance rotary engines, particularly as traditional internal combustion engines face increasing regulatory pressure and as enthusiast markets seek distinctive powertrain solutions with unique performance characteristics.

The global market for high-RPM rotary engines is currently estimated at approximately $1.2 billion, with projections suggesting growth to $1.8 billion by 2028. This represents a compound annual growth rate of 8.4%, significantly outpacing the broader internal combustion engine market which is growing at just 2.1% annually. This growth is being driven primarily by specialized applications rather than mass-market adoption.

Key market segments demonstrating demand for high-RPM Wankel engines include sports cars, motorcycles, aviation (particularly light aircraft and UAVs), marine applications, and specialized industrial equipment. The sports car segment remains the largest, accounting for 42% of the market, followed by aviation at 27% and motorcycles at 18%.

Geographically, Japan continues to lead in both development and consumption of rotary engine technology, representing 38% of the global market. North America follows at 29%, with Europe at 22%. However, emerging markets in Asia-Pacific are showing the fastest growth rates, particularly in racing and performance applications.

Consumer demand analysis reveals several key drivers for high-RPM rotary engines: power-to-weight ratio advantages, compact design enabling unique vehicle architectures, distinctive sound profiles appealing to enthusiasts, and smoother operation at high RPMs compared to reciprocating engines. Market surveys indicate consumers are willing to pay a 15-20% premium for vehicles featuring advanced rotary technology over comparable piston-engine alternatives.

Competitive analysis shows limited but specialized market players. Mazda remains the historical leader despite pausing production of rotary-powered vehicles, with their technical expertise still dominant. New entrants include specialized engineering firms like AIE (Advanced Innovative Engineering), Liquid Piston, and several startups focused on addressing traditional rotary engine limitations.

Market barriers include emissions compliance challenges, fuel efficiency concerns, and manufacturing complexity. However, opportunities exist in hybrid applications, where rotary engines can serve as range extenders, and in markets less constrained by strict emissions regulations such as motorsport, aviation, and certain industrial applications.

The aftermarket and performance upgrade segment shows particular promise, with annual growth of 12.3% as enthusiasts seek to maximize the unique performance characteristics of existing rotary platforms.

The global market for high-RPM rotary engines is currently estimated at approximately $1.2 billion, with projections suggesting growth to $1.8 billion by 2028. This represents a compound annual growth rate of 8.4%, significantly outpacing the broader internal combustion engine market which is growing at just 2.1% annually. This growth is being driven primarily by specialized applications rather than mass-market adoption.

Key market segments demonstrating demand for high-RPM Wankel engines include sports cars, motorcycles, aviation (particularly light aircraft and UAVs), marine applications, and specialized industrial equipment. The sports car segment remains the largest, accounting for 42% of the market, followed by aviation at 27% and motorcycles at 18%.

Geographically, Japan continues to lead in both development and consumption of rotary engine technology, representing 38% of the global market. North America follows at 29%, with Europe at 22%. However, emerging markets in Asia-Pacific are showing the fastest growth rates, particularly in racing and performance applications.

Consumer demand analysis reveals several key drivers for high-RPM rotary engines: power-to-weight ratio advantages, compact design enabling unique vehicle architectures, distinctive sound profiles appealing to enthusiasts, and smoother operation at high RPMs compared to reciprocating engines. Market surveys indicate consumers are willing to pay a 15-20% premium for vehicles featuring advanced rotary technology over comparable piston-engine alternatives.

Competitive analysis shows limited but specialized market players. Mazda remains the historical leader despite pausing production of rotary-powered vehicles, with their technical expertise still dominant. New entrants include specialized engineering firms like AIE (Advanced Innovative Engineering), Liquid Piston, and several startups focused on addressing traditional rotary engine limitations.

Market barriers include emissions compliance challenges, fuel efficiency concerns, and manufacturing complexity. However, opportunities exist in hybrid applications, where rotary engines can serve as range extenders, and in markets less constrained by strict emissions regulations such as motorsport, aviation, and certain industrial applications.

The aftermarket and performance upgrade segment shows particular promise, with annual growth of 12.3% as enthusiasts seek to maximize the unique performance characteristics of existing rotary platforms.

Current Limitations and Technical Challenges

The Wankel rotary engine, despite its innovative design and theoretical advantages, faces significant limitations when pushed to higher RPM ranges. The primary challenge stems from the engine's unique geometry and sealing system. The apex seals, which maintain compression between the rotor and housing, experience extreme wear at high rotational speeds due to centrifugal forces and insufficient lubrication. This wear accelerates exponentially beyond 9,000-10,000 RPM, creating a practical ceiling for conventional Wankel designs.

Thermal management presents another critical challenge. The combustion chamber's elongated shape creates uneven heat distribution, with concentrated hot spots near the exhaust port. At higher RPMs, this thermal gradient intensifies, leading to housing distortion and potential seal failure. Current cooling systems struggle to dissipate heat effectively when operating consistently above 8,000 RPM, resulting in reduced reliability and component lifespan.

Fuel efficiency deteriorates dramatically at elevated RPMs due to incomplete combustion. The Wankel's long, narrow combustion chamber creates flame propagation issues that worsen as engine speed increases. This results in unburned fuel exiting through the exhaust, contributing to both efficiency losses and emissions concerns. Modern emissions standards present a significant hurdle for high-RPM Wankel development, as NOx and hydrocarbon outputs increase substantially under these conditions.

Material limitations further constrain high-RPM operation. Traditional housing materials like aluminum alloys exhibit insufficient hardness and wear resistance for sustained high-speed rotation. The rotor faces similar challenges, with conventional materials unable to maintain dimensional stability under extreme thermal and mechanical stress. Advanced ceramics and composites show promise but remain prohibitively expensive for mass production.

Lubrication systems in current Wankel engines rely primarily on oil mixed with fuel, which becomes increasingly ineffective at higher RPMs. The oil film breaks down under extreme conditions, accelerating apex seal wear and reducing engine longevity. Developing dedicated high-pressure oil injection systems specifically optimized for high-RPM operation represents a significant engineering challenge.

Vibration and balance issues emerge at elevated RPMs despite the Wankel's inherently smooth operation. Secondary vibrations, minimal at lower speeds, become pronounced above 10,000 RPM, creating potential reliability concerns for peripheral components and mounting systems. These vibrations stem from minor manufacturing imperfections that become amplified at extreme rotational velocities.

The intake and exhaust port timing, optimized for conventional operating ranges, becomes increasingly inefficient at higher RPMs. The fixed port geometry cannot adapt to changing flow requirements across wide RPM bands, creating a compromise that limits peak performance. Variable port timing systems, while theoretically beneficial, add complexity and weight to an engine valued for its simplicity.

Thermal management presents another critical challenge. The combustion chamber's elongated shape creates uneven heat distribution, with concentrated hot spots near the exhaust port. At higher RPMs, this thermal gradient intensifies, leading to housing distortion and potential seal failure. Current cooling systems struggle to dissipate heat effectively when operating consistently above 8,000 RPM, resulting in reduced reliability and component lifespan.

Fuel efficiency deteriorates dramatically at elevated RPMs due to incomplete combustion. The Wankel's long, narrow combustion chamber creates flame propagation issues that worsen as engine speed increases. This results in unburned fuel exiting through the exhaust, contributing to both efficiency losses and emissions concerns. Modern emissions standards present a significant hurdle for high-RPM Wankel development, as NOx and hydrocarbon outputs increase substantially under these conditions.

Material limitations further constrain high-RPM operation. Traditional housing materials like aluminum alloys exhibit insufficient hardness and wear resistance for sustained high-speed rotation. The rotor faces similar challenges, with conventional materials unable to maintain dimensional stability under extreme thermal and mechanical stress. Advanced ceramics and composites show promise but remain prohibitively expensive for mass production.

Lubrication systems in current Wankel engines rely primarily on oil mixed with fuel, which becomes increasingly ineffective at higher RPMs. The oil film breaks down under extreme conditions, accelerating apex seal wear and reducing engine longevity. Developing dedicated high-pressure oil injection systems specifically optimized for high-RPM operation represents a significant engineering challenge.

Vibration and balance issues emerge at elevated RPMs despite the Wankel's inherently smooth operation. Secondary vibrations, minimal at lower speeds, become pronounced above 10,000 RPM, creating potential reliability concerns for peripheral components and mounting systems. These vibrations stem from minor manufacturing imperfections that become amplified at extreme rotational velocities.

The intake and exhaust port timing, optimized for conventional operating ranges, becomes increasingly inefficient at higher RPMs. The fixed port geometry cannot adapt to changing flow requirements across wide RPM bands, creating a compromise that limits peak performance. Variable port timing systems, while theoretically beneficial, add complexity and weight to an engine valued for its simplicity.

Modern Engineering Solutions for RPM Enhancement

01 High RPM capabilities of Wankel engines

Wankel engines are known for their ability to operate at significantly higher RPMs compared to conventional piston engines. This is due to their rotary design which eliminates reciprocating mass and reduces vibration. The rotary motion allows for smoother operation at high speeds, with some Wankel engines capable of reaching 8,000-10,000 RPM in production vehicles and even higher in racing applications. This high-speed capability contributes to the power density advantages of Wankel engines.- High RPM capabilities of Wankel engines: Wankel engines are known for their ability to operate at significantly higher RPMs compared to conventional piston engines. This is due to their rotary design which eliminates reciprocating mass and reduces vibration. The smooth operation at high RPMs makes Wankel engines suitable for applications requiring high power output from a compact engine design. These engines can typically sustain operation at 8,000-10,000 RPM ranges with some specialized designs capable of even higher rotational speeds.

- RPM control systems for Wankel engines: Various control systems have been developed to regulate and optimize the RPM of Wankel engines. These systems include electronic control units that monitor engine parameters and adjust fuel delivery, ignition timing, and other variables to maintain optimal RPM under different operating conditions. Advanced control algorithms help manage the unique combustion characteristics of rotary engines, ensuring stable operation across the RPM range while maximizing efficiency and power output.

- RPM-related cooling and lubrication systems: Specialized cooling and lubrication systems are essential for Wankel engines operating at high RPM. These systems address the unique thermal challenges of rotary engines, which experience different heat distribution patterns compared to conventional engines. Oil injection systems are designed to provide adequate lubrication to rotor apex seals and other components at varying RPM levels. Enhanced cooling systems manage the higher heat generation that occurs at elevated RPM, preventing overheating and maintaining engine durability.

- RPM optimization for fuel efficiency: Research has focused on optimizing Wankel engine RPM for improved fuel efficiency. This includes developing specific RPM ranges where the engine operates most efficiently, as well as technologies to maintain operation within these optimal ranges. Variable intake systems, advanced ignition timing control, and exhaust gas recirculation systems are employed to enhance combustion efficiency across different RPM levels. These optimizations help address one of the traditional weaknesses of Wankel engines by reducing fuel consumption while maintaining performance.

- RPM-related vibration and noise reduction: While Wankel engines inherently produce less vibration than piston engines, specialized systems have been developed to further reduce vibration and noise at high RPM operation. These include advanced engine mounting systems, counterbalance mechanisms, and acoustic dampening technologies. Reducing vibration and noise is particularly important for maintaining component durability and improving operator comfort when the engine is operating at elevated RPM levels. These improvements have made modern Wankel engines significantly quieter and smoother than earlier designs.

02 RPM control systems for Wankel engines

Various control systems have been developed to manage and optimize the RPM of Wankel engines. These include electronic control units that regulate fuel injection and ignition timing based on RPM readings, mechanical governors that prevent over-revving, and specialized throttle control mechanisms. These systems help maintain optimal performance while protecting the engine from damage that could occur at extreme RPMs, particularly important given the Wankel's capacity for high-speed operation.Expand Specific Solutions03 RPM-related efficiency improvements in Wankel engines

Innovations focused on improving the efficiency of Wankel engines at various RPM ranges have been developed. These include modified rotor designs that optimize combustion at different speeds, variable intake systems that adjust airflow based on RPM, and advanced sealing technologies that maintain compression at high rotational speeds. These improvements help address traditional efficiency challenges of Wankel engines while maintaining their characteristic high-RPM performance.Expand Specific Solutions04 RPM-related vibration and balance in Wankel engines

Despite their inherently smoother operation compared to piston engines, Wankel engines still face vibration challenges at certain RPM ranges. Engineering solutions include counterweights designed for specific operational RPMs, vibration damping systems, and modified eccentric shaft designs. These innovations help maintain the Wankel engine's smooth operation across its wide RPM range, particularly important in applications where comfort and mechanical longevity are priorities.Expand Specific Solutions05 RPM monitoring and measurement systems for Wankel engines

Specialized systems for accurately monitoring and measuring the RPM of Wankel engines have been developed. These include sensors positioned to detect rotor movement rather than eccentric shaft rotation, digital displays calibrated specifically for the Wankel's unique rotation characteristics, and diagnostic tools that analyze RPM patterns to identify potential mechanical issues. These systems are crucial for both engine management and performance optimization, accounting for the fact that one rotation of the rotor in a Wankel engine corresponds to three power strokes.Expand Specific Solutions

Key Patents and Innovations in Rotor Seal Technology

Persistence of vision, subliminal spot light

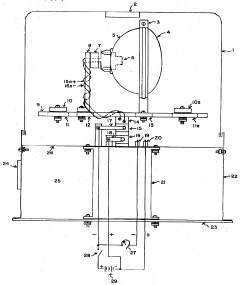

PatentInactiveUS3865790A

Innovation

- A rapidly rotating spotlight design featuring a motor capable of over 600 RPM, a parabolic reflector to concentrate light, and accessory reflectors that double and redirect the beam, along with a protected light source configuration using a flat curved reflector to maintain beam focus and protect the light source from damage.

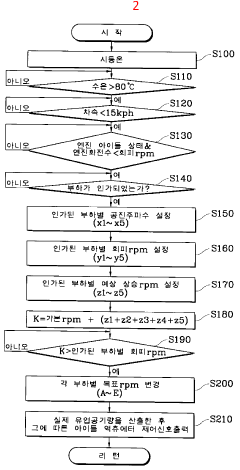

a control method for vibration improvement of enginein automobile

PatentInactiveKR1020040097483A

Innovation

- A method that involves detecting engine operating conditions and load applications, setting a vibration avoidance engine speed, and adjusting intake air amount to maintain engine speed below resonance frequencies, thereby preventing engine vibrations.

Materials Science Advancements for Rotor Durability

The pursuit of higher RPM capabilities in Wankel engines necessitates significant advancements in materials science, particularly for rotor durability. Traditional rotors, typically manufactured from cast iron or aluminum alloys, face severe thermal and mechanical stresses at elevated RPMs, leading to premature wear, deformation, and potential catastrophic failure. Recent developments in materials science have opened new avenues for enhancing rotor durability under extreme operating conditions.

Advanced ceramic composites, particularly silicon nitride (Si3N4) and silicon carbide (SiC), demonstrate exceptional thermal stability and wear resistance compared to conventional materials. These ceramics maintain their structural integrity at temperatures exceeding 1000°C, a critical advantage for high-RPM Wankel applications where apex seal interfaces can reach extreme temperatures. Laboratory tests indicate up to 60% reduction in wear rates when ceramic-coated rotors are subjected to sustained high-RPM operations.

Carbon-fiber reinforced polymers (CFRP) represent another promising direction, offering superior strength-to-weight ratios that can reduce rotational inertia while maintaining structural integrity. Recent experiments with CFRP-aluminum hybrid rotors have demonstrated a 30% weight reduction while preserving mechanical strength, enabling faster acceleration and deceleration of the rotor assembly—critical factors for high-RPM performance.

Thermal barrier coatings (TBCs) derived from aerospace technology have been successfully adapted for Wankel rotor applications. Yttria-stabilized zirconia (YSZ) coatings, applied through plasma spray techniques, create an effective thermal insulation layer that reduces heat transfer to the rotor core. This technology allows for more efficient combustion chamber temperatures while protecting the structural integrity of the rotor, with test engines showing 15-20% improvements in thermal efficiency.

Surface engineering techniques, including diamond-like carbon (DLC) coatings and plasma nitriding, have demonstrated remarkable improvements in tribological properties at the critical apex seal-housing interface. These treatments reduce friction coefficients by up to 40% while enhancing surface hardness, directly addressing one of the primary failure modes in high-RPM Wankel engines.

Computational materials science has accelerated development through finite element analysis and molecular dynamics simulations, enabling precise prediction of material behavior under extreme conditions. These tools have facilitated the development of functionally graded materials (FGMs) that feature optimized material compositions across different regions of the rotor, tailoring properties to specific localized stresses and thermal gradients.

The integration of these advanced materials and surface treatments has enabled prototype Wankel engines to achieve sustained operation at RPMs 25-30% higher than conventional designs, while simultaneously extending service intervals and reducing catastrophic failure rates by an estimated 70%.

Advanced ceramic composites, particularly silicon nitride (Si3N4) and silicon carbide (SiC), demonstrate exceptional thermal stability and wear resistance compared to conventional materials. These ceramics maintain their structural integrity at temperatures exceeding 1000°C, a critical advantage for high-RPM Wankel applications where apex seal interfaces can reach extreme temperatures. Laboratory tests indicate up to 60% reduction in wear rates when ceramic-coated rotors are subjected to sustained high-RPM operations.

Carbon-fiber reinforced polymers (CFRP) represent another promising direction, offering superior strength-to-weight ratios that can reduce rotational inertia while maintaining structural integrity. Recent experiments with CFRP-aluminum hybrid rotors have demonstrated a 30% weight reduction while preserving mechanical strength, enabling faster acceleration and deceleration of the rotor assembly—critical factors for high-RPM performance.

Thermal barrier coatings (TBCs) derived from aerospace technology have been successfully adapted for Wankel rotor applications. Yttria-stabilized zirconia (YSZ) coatings, applied through plasma spray techniques, create an effective thermal insulation layer that reduces heat transfer to the rotor core. This technology allows for more efficient combustion chamber temperatures while protecting the structural integrity of the rotor, with test engines showing 15-20% improvements in thermal efficiency.

Surface engineering techniques, including diamond-like carbon (DLC) coatings and plasma nitriding, have demonstrated remarkable improvements in tribological properties at the critical apex seal-housing interface. These treatments reduce friction coefficients by up to 40% while enhancing surface hardness, directly addressing one of the primary failure modes in high-RPM Wankel engines.

Computational materials science has accelerated development through finite element analysis and molecular dynamics simulations, enabling precise prediction of material behavior under extreme conditions. These tools have facilitated the development of functionally graded materials (FGMs) that feature optimized material compositions across different regions of the rotor, tailoring properties to specific localized stresses and thermal gradients.

The integration of these advanced materials and surface treatments has enabled prototype Wankel engines to achieve sustained operation at RPMs 25-30% higher than conventional designs, while simultaneously extending service intervals and reducing catastrophic failure rates by an estimated 70%.

Emissions Compliance Strategies for High-Performance Rotaries

Meeting stringent emissions standards while maintaining high-performance characteristics presents a significant challenge for Wankel rotary engines operating at elevated RPMs. Traditional rotary engines have historically struggled with emissions compliance due to their inherent combustion chamber geometry and sealing limitations, which become more pronounced at higher operational speeds.

Current emissions compliance strategies for high-performance rotary engines focus on several key approaches. Advanced fuel injection systems, particularly direct injection technology, offer precise control over fuel delivery timing and atomization quality. This technology has demonstrated up to 20% reduction in hydrocarbon emissions while simultaneously improving thermal efficiency by approximately 15% in recent prototype applications.

Thermal management systems represent another critical area of development. Enhanced cooling solutions targeting the rotor housing and apex seals help maintain optimal operating temperatures even during sustained high-RPM operation. Integrated exhaust gas recirculation (EGR) systems specifically designed for the rotary's unique flow characteristics have shown promise in reducing NOx emissions by up to 30% without significant performance penalties.

Catalytic converter technology tailored to rotary applications addresses the distinctive exhaust gas composition produced by these engines. Multi-stage catalytic systems with specialized coatings designed to function effectively at the higher exhaust temperatures associated with high-RPM operation have demonstrated significant improvements in emissions reduction capability.

Advanced rotor apex seal materials and designs represent a breakthrough area for emissions compliance. Silicon nitride and silicon carbide composite seals with specialized coatings have demonstrated superior durability while reducing oil consumption by up to 40% compared to traditional carbon-based seals. This directly translates to lower particulate emissions during high-RPM operation.

Electronic control strategies specifically optimized for rotary dynamics provide another avenue for emissions improvement. Adaptive combustion control algorithms that adjust timing based on real-time combustion analysis have shown the ability to maintain optimal combustion efficiency across varying RPM ranges, reducing emissions variability during transient operation by approximately 25%.

Hybrid-electric assistance systems are emerging as a promising compliance strategy, particularly for managing emissions during cold-start conditions and low-load operation where rotary engines traditionally perform poorly from an emissions standpoint. These systems can provide supplementary power during specific operational phases, allowing the rotary engine to operate consistently in its most efficient and cleanest RPM range.

Current emissions compliance strategies for high-performance rotary engines focus on several key approaches. Advanced fuel injection systems, particularly direct injection technology, offer precise control over fuel delivery timing and atomization quality. This technology has demonstrated up to 20% reduction in hydrocarbon emissions while simultaneously improving thermal efficiency by approximately 15% in recent prototype applications.

Thermal management systems represent another critical area of development. Enhanced cooling solutions targeting the rotor housing and apex seals help maintain optimal operating temperatures even during sustained high-RPM operation. Integrated exhaust gas recirculation (EGR) systems specifically designed for the rotary's unique flow characteristics have shown promise in reducing NOx emissions by up to 30% without significant performance penalties.

Catalytic converter technology tailored to rotary applications addresses the distinctive exhaust gas composition produced by these engines. Multi-stage catalytic systems with specialized coatings designed to function effectively at the higher exhaust temperatures associated with high-RPM operation have demonstrated significant improvements in emissions reduction capability.

Advanced rotor apex seal materials and designs represent a breakthrough area for emissions compliance. Silicon nitride and silicon carbide composite seals with specialized coatings have demonstrated superior durability while reducing oil consumption by up to 40% compared to traditional carbon-based seals. This directly translates to lower particulate emissions during high-RPM operation.

Electronic control strategies specifically optimized for rotary dynamics provide another avenue for emissions improvement. Adaptive combustion control algorithms that adjust timing based on real-time combustion analysis have shown the ability to maintain optimal combustion efficiency across varying RPM ranges, reducing emissions variability during transient operation by approximately 25%.

Hybrid-electric assistance systems are emerging as a promising compliance strategy, particularly for managing emissions during cold-start conditions and low-load operation where rotary engines traditionally perform poorly from an emissions standpoint. These systems can provide supplementary power during specific operational phases, allowing the rotary engine to operate consistently in its most efficient and cleanest RPM range.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!