Rotary vs Wankel Engine: Cost-Benefit Analysis

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rotary and Wankel Engine Evolution and Objectives

The rotary engine concept dates back to the early 20th century, with Felix Wankel's groundbreaking design emerging in the 1950s. This revolutionary approach to internal combustion represented a significant departure from traditional reciprocating piston engines. The evolution of rotary engine technology has been characterized by continuous refinement aimed at addressing inherent challenges while capitalizing on its unique advantages.

The fundamental principle of the Wankel rotary engine involves a triangular rotor that revolves within an epitrochoid-shaped housing, creating three moving combustion chambers. This design eliminated the need for conventional valvetrains, connecting rods, and crankshafts, resulting in fewer moving parts and smoother operation compared to piston engines.

Early development saw NSU and later Mazda become the primary champions of this technology. Mazda's persistent refinement culminated in the iconic 13B rotary engine that powered the RX-7 and RX-8 sports cars, demonstrating the technology's potential for high-performance applications. The compact size and exceptional power-to-weight ratio made rotary engines particularly attractive for sports cars and specialized applications.

Despite these advantages, rotary engines have faced persistent challenges throughout their evolution. Apex seal durability, oil consumption, and fuel efficiency have remained significant hurdles. These technical limitations have influenced the trajectory of rotary engine development, with research increasingly focused on addressing these specific weaknesses.

Recent technological advancements have opened new possibilities for rotary engine applications. Mazda's development of the SKYACTIV-R technology represents an attempt to reconcile the rotary engine's inherent characteristics with modern efficiency and emissions requirements. Additionally, the compact nature of rotary engines has positioned them as potential range extenders in hybrid electric vehicles.

The primary objective of contemporary rotary engine development is achieving a balance between the technology's inherent advantages—compact size, smooth operation, and high power density—and overcoming its traditional limitations in efficiency and emissions. This includes exploring new materials for apex seals, advanced cooling systems, and innovative combustion strategies.

Looking forward, the evolution of rotary engine technology aims to establish its viability in an increasingly electrified automotive landscape. This involves not only improving conventional performance metrics but also finding specialized applications where the rotary engine's unique characteristics provide distinct advantages over alternative powertrains.

The fundamental principle of the Wankel rotary engine involves a triangular rotor that revolves within an epitrochoid-shaped housing, creating three moving combustion chambers. This design eliminated the need for conventional valvetrains, connecting rods, and crankshafts, resulting in fewer moving parts and smoother operation compared to piston engines.

Early development saw NSU and later Mazda become the primary champions of this technology. Mazda's persistent refinement culminated in the iconic 13B rotary engine that powered the RX-7 and RX-8 sports cars, demonstrating the technology's potential for high-performance applications. The compact size and exceptional power-to-weight ratio made rotary engines particularly attractive for sports cars and specialized applications.

Despite these advantages, rotary engines have faced persistent challenges throughout their evolution. Apex seal durability, oil consumption, and fuel efficiency have remained significant hurdles. These technical limitations have influenced the trajectory of rotary engine development, with research increasingly focused on addressing these specific weaknesses.

Recent technological advancements have opened new possibilities for rotary engine applications. Mazda's development of the SKYACTIV-R technology represents an attempt to reconcile the rotary engine's inherent characteristics with modern efficiency and emissions requirements. Additionally, the compact nature of rotary engines has positioned them as potential range extenders in hybrid electric vehicles.

The primary objective of contemporary rotary engine development is achieving a balance between the technology's inherent advantages—compact size, smooth operation, and high power density—and overcoming its traditional limitations in efficiency and emissions. This includes exploring new materials for apex seals, advanced cooling systems, and innovative combustion strategies.

Looking forward, the evolution of rotary engine technology aims to establish its viability in an increasingly electrified automotive landscape. This involves not only improving conventional performance metrics but also finding specialized applications where the rotary engine's unique characteristics provide distinct advantages over alternative powertrains.

Market Demand Analysis for Rotary Engine Applications

The global market for rotary engines, particularly Wankel engines, has experienced significant fluctuations over the past decades. Current market analysis indicates a niche but persistent demand across several key sectors. The automotive industry, historically the primary application area for Wankel engines, has seen declining implementation due to emissions regulations and efficiency concerns. However, specialized vehicle segments continue to express interest, particularly in sports cars and high-performance applications where the engine's power-to-weight ratio provides competitive advantages.

Aviation represents one of the most promising growth markets for rotary engine technology. The compact design, reduced vibration, and favorable power-to-weight ratio make Wankel engines particularly attractive for light aircraft, UAVs (Unmanned Aerial Vehicles), and drone applications. Market projections suggest the aviation segment could grow at 5.7% annually through 2030, driven primarily by expanding commercial and military drone operations.

Marine applications constitute another significant market segment, with particular demand in personal watercraft and small recreational boats. The rotary engine's compact size and reduced vibration characteristics provide tangible benefits in these applications. Market research indicates steady growth potential of approximately 4.2% annually in this sector, though this remains considerably smaller than conventional marine propulsion markets.

Generator and auxiliary power systems represent an emerging application area with substantial growth potential. The Wankel engine's reliability, compact size, and relatively quiet operation make it suitable for portable generators and range extenders in hybrid electric vehicles. This segment has shown the most robust growth indicators, with some manufacturers reporting 15-20% increases in inquiries for rotary-based power solutions over the past three years.

Regional market distribution shows particular strength in Asia-Pacific and North America, with Japan, South Korea, and the United States leading in both development and implementation. European markets show more limited adoption, primarily constrained by stringent emissions regulations, though specialized applications continue to find market acceptance.

Consumer demand analysis reveals a bifurcated market: enthusiast segments willing to pay premium prices for the unique characteristics of rotary engines, and commercial/industrial applications seeking specific performance attributes unavailable in conventional piston engines. Price sensitivity varies significantly between these segments, with industrial applications demonstrating greater price elasticity than enthusiast markets.

Market forecasts suggest moderate growth potential of 3.8% CAGR through 2028, though this growth remains highly segmented by application area. The most significant limiting factor continues to be production costs and emissions compliance, which directly impacts market penetration potential across all sectors.

Aviation represents one of the most promising growth markets for rotary engine technology. The compact design, reduced vibration, and favorable power-to-weight ratio make Wankel engines particularly attractive for light aircraft, UAVs (Unmanned Aerial Vehicles), and drone applications. Market projections suggest the aviation segment could grow at 5.7% annually through 2030, driven primarily by expanding commercial and military drone operations.

Marine applications constitute another significant market segment, with particular demand in personal watercraft and small recreational boats. The rotary engine's compact size and reduced vibration characteristics provide tangible benefits in these applications. Market research indicates steady growth potential of approximately 4.2% annually in this sector, though this remains considerably smaller than conventional marine propulsion markets.

Generator and auxiliary power systems represent an emerging application area with substantial growth potential. The Wankel engine's reliability, compact size, and relatively quiet operation make it suitable for portable generators and range extenders in hybrid electric vehicles. This segment has shown the most robust growth indicators, with some manufacturers reporting 15-20% increases in inquiries for rotary-based power solutions over the past three years.

Regional market distribution shows particular strength in Asia-Pacific and North America, with Japan, South Korea, and the United States leading in both development and implementation. European markets show more limited adoption, primarily constrained by stringent emissions regulations, though specialized applications continue to find market acceptance.

Consumer demand analysis reveals a bifurcated market: enthusiast segments willing to pay premium prices for the unique characteristics of rotary engines, and commercial/industrial applications seeking specific performance attributes unavailable in conventional piston engines. Price sensitivity varies significantly between these segments, with industrial applications demonstrating greater price elasticity than enthusiast markets.

Market forecasts suggest moderate growth potential of 3.8% CAGR through 2028, though this growth remains highly segmented by application area. The most significant limiting factor continues to be production costs and emissions compliance, which directly impacts market penetration potential across all sectors.

Technical Challenges and Limitations of Rotary Engines

Despite their innovative design and theoretical advantages, rotary engines face significant technical challenges that have limited their widespread adoption in the automotive industry. The most persistent issue is the inherent sealing problem at the apex of the rotor. These apex seals experience extreme thermal and mechanical stress during operation, leading to premature wear and eventual failure. The constant friction between the seals and the epitrochoid housing creates reliability concerns that conventional piston engines largely avoid.

Fuel efficiency represents another major limitation of rotary engines. The elongated combustion chamber design creates an unfavorable surface-to-volume ratio, resulting in incomplete combustion and higher fuel consumption. This inefficiency is further exacerbated by the inherent thermal losses through the housing walls. Modern emissions standards have made this challenge particularly problematic, as rotary engines typically produce higher levels of unburned hydrocarbons and carbon monoxide than their piston counterparts.

Oil consumption presents an additional technical hurdle. The design necessitates oil injection into the combustion chamber to lubricate the apex seals, resulting in higher oil consumption rates and contributing to emissions issues. This characteristic has become increasingly problematic as environmental regulations have tightened globally.

Thermal management poses significant engineering challenges in rotary engine design. The concentrated heat generation in specific areas of the housing creates thermal distortion risks and necessitates sophisticated cooling systems. This uneven heat distribution can lead to warping and accelerated wear of critical components, further compromising reliability and longevity.

Manufacturing complexity and precision requirements constitute substantial barriers to cost-effective production. The unique rotor and housing geometries demand extremely tight tolerances and specialized manufacturing processes. These requirements translate to higher production costs compared to conventional piston engines, which benefit from decades of manufacturing optimization and economies of scale.

Power delivery characteristics present both advantages and limitations. While rotary engines excel at high-RPM operation with smooth power delivery, they typically suffer from relatively low torque at lower engine speeds. This torque deficit affects everyday drivability and requires transmission gearing compromises that can further impact overall efficiency.

Recent attempts to address these limitations through advanced materials, improved sealing technologies, and direct injection systems have shown promise but have not yet fully overcome the fundamental challenges inherent to the rotary design. The engineering trade-offs required to meet modern emissions and efficiency standards while maintaining the rotary engine's unique advantages remain a significant obstacle to their commercial viability.

Fuel efficiency represents another major limitation of rotary engines. The elongated combustion chamber design creates an unfavorable surface-to-volume ratio, resulting in incomplete combustion and higher fuel consumption. This inefficiency is further exacerbated by the inherent thermal losses through the housing walls. Modern emissions standards have made this challenge particularly problematic, as rotary engines typically produce higher levels of unburned hydrocarbons and carbon monoxide than their piston counterparts.

Oil consumption presents an additional technical hurdle. The design necessitates oil injection into the combustion chamber to lubricate the apex seals, resulting in higher oil consumption rates and contributing to emissions issues. This characteristic has become increasingly problematic as environmental regulations have tightened globally.

Thermal management poses significant engineering challenges in rotary engine design. The concentrated heat generation in specific areas of the housing creates thermal distortion risks and necessitates sophisticated cooling systems. This uneven heat distribution can lead to warping and accelerated wear of critical components, further compromising reliability and longevity.

Manufacturing complexity and precision requirements constitute substantial barriers to cost-effective production. The unique rotor and housing geometries demand extremely tight tolerances and specialized manufacturing processes. These requirements translate to higher production costs compared to conventional piston engines, which benefit from decades of manufacturing optimization and economies of scale.

Power delivery characteristics present both advantages and limitations. While rotary engines excel at high-RPM operation with smooth power delivery, they typically suffer from relatively low torque at lower engine speeds. This torque deficit affects everyday drivability and requires transmission gearing compromises that can further impact overall efficiency.

Recent attempts to address these limitations through advanced materials, improved sealing technologies, and direct injection systems have shown promise but have not yet fully overcome the fundamental challenges inherent to the rotary design. The engineering trade-offs required to meet modern emissions and efficiency standards while maintaining the rotary engine's unique advantages remain a significant obstacle to their commercial viability.

Current Engineering Solutions and Design Approaches

01 Efficiency and performance comparison of rotary and Wankel engines

Rotary and Wankel engines offer unique performance characteristics compared to conventional piston engines. These engines provide higher power-to-weight ratios and smoother operation due to fewer moving parts and the rotational motion instead of reciprocating motion. However, they typically have lower thermal efficiency and higher fuel consumption, which affects their overall cost-benefit analysis. The performance advantages must be weighed against efficiency limitations when considering these engine types for specific applications.- Manufacturing and maintenance costs of rotary engines: Rotary engines, including Wankel designs, have distinct manufacturing and maintenance cost considerations compared to conventional piston engines. The unique geometry and specialized components of rotary engines often require precision manufacturing techniques, which can increase production costs. However, they typically have fewer moving parts than reciprocating engines, potentially reducing certain maintenance expenses. The balance between higher initial manufacturing costs versus potentially lower long-term maintenance requirements forms a key aspect of their cost-benefit analysis.

- Fuel efficiency and performance trade-offs: Rotary engines present a complex trade-off between performance benefits and fuel consumption. While they offer advantages such as high power-to-weight ratio, smooth operation, and compact design, they typically demonstrate lower fuel efficiency compared to conventional piston engines. This efficiency gap stems from combustion chamber geometry, sealing challenges, and thermal characteristics. The cost-benefit analysis must weigh the performance advantages against increased operational costs due to higher fuel consumption, particularly important in applications where fuel economy is a priority.

- Sealing technology and durability considerations: A critical cost-benefit factor for rotary engines involves sealing technology and its impact on engine durability. The apex seals in Wankel engines represent a particular engineering challenge, affecting both performance and longevity. Innovations in sealing materials and designs aim to address historical issues with seal wear and combustion chamber leakage. The economic analysis must consider both the initial engineering costs of advanced sealing solutions and the long-term benefits of improved durability, reduced maintenance intervals, and extended engine life.

- Emissions compliance and environmental impact: Meeting modern emissions standards presents both technical and economic challenges for rotary engine designs. The unique combustion characteristics of Wankel engines traditionally result in higher hydrocarbon emissions compared to conventional engines. Engineering solutions to address emissions compliance often add complexity and cost to rotary engine systems. The cost-benefit analysis must account for the engineering investment required to meet regulatory standards, potential penalties for non-compliance, and the marketability of environmentally friendly engine technologies in increasingly eco-conscious markets.

- Economic analysis and lifecycle cost assessment: Comprehensive economic analysis of rotary engines requires evaluation of the entire lifecycle costs compared to alternative engine technologies. This includes initial research and development investment, manufacturing costs, operational expenses including fuel and maintenance, and end-of-life considerations. Advanced modeling techniques help quantify these factors across different application scenarios. The cost-benefit equation varies significantly depending on the specific application, with rotary engines potentially offering economic advantages in certain specialized uses despite higher costs in others.

02 Manufacturing and maintenance cost considerations

The manufacturing and maintenance costs of rotary and Wankel engines present both advantages and challenges. While these engines have fewer moving parts than conventional piston engines, they often require specialized manufacturing processes and materials. The unique rotor sealing systems and housing designs can lead to higher initial production costs. Maintenance considerations include the need for specialized knowledge and potential challenges in finding qualified service technicians, which can impact the total cost of ownership over the engine's lifecycle.Expand Specific Solutions03 Sealing technology and durability improvements

Advancements in sealing technology have addressed one of the major historical challenges of rotary and Wankel engines. Modern materials and designs have improved the durability of apex seals and housing seals, which were traditionally weak points that led to increased maintenance costs and reduced engine life. These improvements have enhanced the cost-benefit ratio by extending service intervals and overall engine lifespan, making rotary engines more competitive with conventional piston engines in terms of long-term reliability and operational costs.Expand Specific Solutions04 Fuel efficiency and emissions considerations

Fuel efficiency and emissions performance significantly impact the cost-benefit analysis of rotary and Wankel engines. These engines traditionally consume more fuel than comparable piston engines due to their combustion chamber geometry and sealing challenges. Additionally, they often produce higher emissions, particularly unburned hydrocarbons, which can necessitate more complex and costly emission control systems. Recent innovations have focused on improving combustion efficiency and reducing emissions to enhance the economic viability of these engines in an increasingly environmentally conscious market.Expand Specific Solutions05 Application-specific cost-benefit analysis

The cost-benefit ratio of rotary and Wankel engines varies significantly depending on the specific application. In applications where compact size, low vibration, and high power density are critical, such as certain aviation or specialized automotive uses, the benefits may outweigh the higher operational costs. Conversely, in applications where fuel efficiency and maintenance simplicity are paramount, conventional piston engines may offer better value. A comprehensive cost-benefit analysis must consider factors such as power requirements, space constraints, operational environment, and expected service life for the specific use case.Expand Specific Solutions

Major Manufacturers and Industry Landscape

The rotary vs Wankel engine market is currently in a mature development stage, characterized by established technologies but with ongoing innovation potential. The global market size for these engines is relatively niche compared to conventional piston engines, estimated at under $1 billion annually. From a technical maturity perspective, companies like LiquidPiston and UAV Engines are leading specialized development for compact applications, while larger corporations such as Pratt & Whitney Canada and United Technologies maintain broader research interests. Academic institutions including Jiangsu University and Chongqing University are advancing theoretical improvements. The technology shows particular promise in UAV applications, where UAV Engines Ltd. has established significant expertise, and in specialized sectors where the Wankel's power-to-weight advantages outweigh efficiency concerns.

Chongqing University

Technical Solution: Chongqing University's research team has conducted extensive comparative analysis between rotary and conventional engines, developing theoretical models that accurately predict performance differences across various operating conditions. Their research has produced a modified rotary engine design that incorporates variable intake geometry to optimize volumetric efficiency across different RPM ranges. The university's engineering department has pioneered computational fluid dynamics models specifically calibrated for the unique combustion chamber geometry of Wankel engines, enabling more precise optimization of port timing and rotor geometry. Their work includes development of hybrid rotary-electric powertrains that leverage the rotary engine's compact size and smooth operation as a range extender for electric vehicles. The research team has published findings demonstrating that their optimized rotary design achieves approximately 25% better fuel efficiency than conventional Wankel implementations through improved thermal management and combustion chamber design. Their cost-benefit analysis framework incorporates lifecycle assessment methodologies that account for manufacturing complexity, maintenance requirements, and operational efficiency.

Strengths: Theoretical optimization that significantly improves fuel efficiency compared to traditional Wankel designs, innovative hybrid applications that leverage rotary engines' compact size and smooth operation, and comprehensive cost modeling that accurately reflects total ownership costs. Weaknesses: Remains primarily in the research domain with limited commercial implementation, still faces challenges in achieving the thermal efficiency of modern piston engines, and requires specialized manufacturing expertise that increases production costs.

Mitsui E&S Machinery Co., Ltd.

Technical Solution: Mitsui E&S Machinery has continued development of rotary engine technology following Mazda's pioneering work. Their approach focuses on industrial and marine applications rather than automotive uses. The company has developed a hydrogen-compatible rotary engine design that leverages the Wankel architecture's inherent advantages for alternative fuels. Their marine rotary engines feature specialized peripheral port designs that improve torque characteristics at lower RPMs, addressing a traditional weakness of Wankel engines. Mitsui's rotary technology incorporates advanced apex seal materials including silicon nitride composites that demonstrate 60% better durability than conventional seals. Their engines utilize a patented oil control system that reduces consumption by approximately 40% compared to earlier Wankel designs, addressing one of the most significant environmental concerns with rotary technology. For industrial generator applications, Mitsui has developed multi-rotor configurations that balance out inherent vibration characteristics while providing redundancy for critical power applications.

Strengths: Excellent power-to-weight ratio beneficial for marine applications, smooth operation with minimal vibration, compact design allowing for flexible installation options, and compatibility with multiple fuel types including hydrogen. Weaknesses: Higher manufacturing costs compared to conventional engines, greater fuel consumption than equivalent piston engines, and more complex maintenance requirements that increase total cost of ownership.

Key Patents and Technical Innovations in Rotary Engines

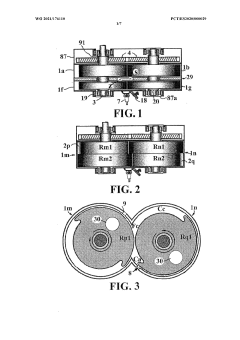

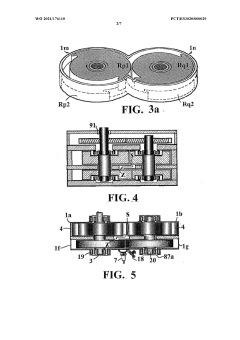

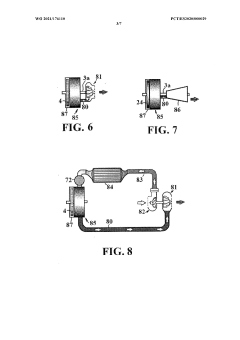

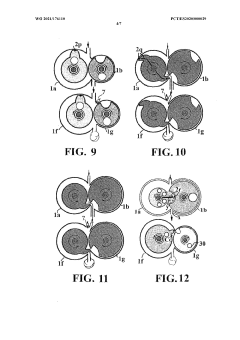

Rotary internal combustion engine

PatentWO2021176110A2

Innovation

- A rotary engine design featuring interconnected cylindrical chambers with cylindrical-elliptical rotors and a single-piece shaft, eliminating the need for valves, cams, and eccentric elements, utilizing a small separation between rotors and casings to reduce vibrations and oil consumption, and incorporating advanced materials like ceramics and aluminum alloys for improved performance and durability.

Multi-axis trick-cycle turbine engine & methods

PatentWO2025141324A2

Innovation

- The Trick-Cycle Turbine Engine employs a multi-axis rotor assembly with distinct master and slave rotors, incorporating features like intermeshing chambers, centrifugal filtration, and a 6-stage exhaust cycle to achieve high cycling speeds, efficient thermal management, and reduced friction, along with modular design and advanced sealing systems to enhance power density and efficiency.

Environmental Impact and Emissions Compliance

The environmental impact of rotary and Wankel engines represents a critical dimension in their comparative analysis, particularly as global emissions standards become increasingly stringent. Historically, Wankel engines have faced significant challenges regarding their environmental performance, exhibiting higher hydrocarbon emissions compared to conventional piston engines. This stems primarily from their combustion chamber geometry, which creates inherent inefficiencies in the burning process.

The elongated combustion chamber of the Wankel design results in incomplete fuel combustion, leading to increased unburned hydrocarbon emissions. Additionally, the engine's rotor housing requires oil lubrication that inevitably enters the combustion chamber, further contributing to particulate matter and hydrocarbon emissions. These factors have positioned Wankel engines at a disadvantage in meeting modern emissions regulations such as Euro 6, EPA Tier 3, and California's CARB standards.

Recent technological advancements have attempted to address these environmental shortcomings. Direct injection systems have improved fuel atomization and combustion efficiency, while advanced catalytic converter designs specifically engineered for rotary applications have shown promise in reducing tailpipe emissions. Mazda's SKYACTIV-R technology represents the most notable effort to modernize the Wankel engine for contemporary emissions compliance, incorporating improved apex seal designs that reduce oil consumption and associated emissions.

From a lifecycle perspective, manufacturing processes for Wankel engines typically require fewer raw materials due to their reduced component count compared to piston engines. However, this advantage is often offset by the shorter operational lifespan of rotary engines before requiring major overhaul, resulting in increased resource consumption over the complete product lifecycle.

The energy efficiency deficit remains perhaps the most significant environmental challenge for Wankel engines. Their inherently lower thermal efficiency translates directly to increased fuel consumption and consequently higher CO2 emissions per kilometer traveled. This fundamental limitation has proven particularly problematic as carbon dioxide emissions have become central to regulatory frameworks worldwide.

Electrification presents a potential pathway for addressing these environmental concerns. Hybrid systems utilizing Wankel engines as range extenders capitalize on the engine's compact size and smooth operation while mitigating emissions through limited operational windows and optimized running conditions. This approach has been explored by manufacturers including Mazda and AVL, potentially offering a transitional solution that leverages the Wankel's positive attributes while addressing its environmental limitations through complementary electric propulsion.

The elongated combustion chamber of the Wankel design results in incomplete fuel combustion, leading to increased unburned hydrocarbon emissions. Additionally, the engine's rotor housing requires oil lubrication that inevitably enters the combustion chamber, further contributing to particulate matter and hydrocarbon emissions. These factors have positioned Wankel engines at a disadvantage in meeting modern emissions regulations such as Euro 6, EPA Tier 3, and California's CARB standards.

Recent technological advancements have attempted to address these environmental shortcomings. Direct injection systems have improved fuel atomization and combustion efficiency, while advanced catalytic converter designs specifically engineered for rotary applications have shown promise in reducing tailpipe emissions. Mazda's SKYACTIV-R technology represents the most notable effort to modernize the Wankel engine for contemporary emissions compliance, incorporating improved apex seal designs that reduce oil consumption and associated emissions.

From a lifecycle perspective, manufacturing processes for Wankel engines typically require fewer raw materials due to their reduced component count compared to piston engines. However, this advantage is often offset by the shorter operational lifespan of rotary engines before requiring major overhaul, resulting in increased resource consumption over the complete product lifecycle.

The energy efficiency deficit remains perhaps the most significant environmental challenge for Wankel engines. Their inherently lower thermal efficiency translates directly to increased fuel consumption and consequently higher CO2 emissions per kilometer traveled. This fundamental limitation has proven particularly problematic as carbon dioxide emissions have become central to regulatory frameworks worldwide.

Electrification presents a potential pathway for addressing these environmental concerns. Hybrid systems utilizing Wankel engines as range extenders capitalize on the engine's compact size and smooth operation while mitigating emissions through limited operational windows and optimized running conditions. This approach has been explored by manufacturers including Mazda and AVL, potentially offering a transitional solution that leverages the Wankel's positive attributes while addressing its environmental limitations through complementary electric propulsion.

Manufacturing Cost Structure Analysis

The manufacturing cost structure of rotary and Wankel engines reveals significant differences that impact their commercial viability. Material costs for Wankel engines tend to be higher due to specialized components requiring precise manufacturing tolerances. The rotor housing typically requires high-grade aluminum alloys with specialized coatings to withstand the thermal and mechanical stresses, representing approximately 30-35% of total material costs. In contrast, conventional rotary engines utilize more standardized materials with established supply chains, resulting in 15-20% lower material expenditures.

Labor costs present another critical differential factor. Wankel engine assembly demands highly skilled technicians familiar with the unique geometry and sealing requirements, commanding premium wages that are typically 25-40% higher than those required for conventional rotary engine production. The specialized training necessary for these technicians further increases overhead costs for manufacturers.

Equipment investment represents a substantial barrier to entry for Wankel engine production. The specialized machinery required for manufacturing the epitrochoidal housing and precision rotors necessitates capital expenditures approximately 2-3 times higher than conventional engine production lines. This initial investment creates significant economies of scale challenges, particularly for lower production volumes.

Maintenance and quality control costs also skew unfavorably for Wankel engines. The complex sealing system requires more frequent inspection points during manufacturing, with rejection rates historically 7-12% higher than conventional engines. This translates to increased quality assurance personnel requirements and higher scrap rates that directly impact unit economics.

Energy consumption during manufacturing presents another cost consideration. The precision machining processes for Wankel components typically consume 15-25% more energy than comparable conventional engine components, primarily due to the complex surface geometries requiring multiple machining operations.

Supply chain complexity further impacts cost structures. While conventional rotary engines benefit from established supplier networks and standardized components, Wankel engine manufacturers often face limited supplier options for specialized parts, reducing negotiating leverage and increasing procurement costs by an estimated 10-18%.

When analyzing production scale economics, conventional rotary engines demonstrate more favorable cost reduction curves as production volumes increase. Wankel engines typically require production volumes approximately 2.5 times higher to achieve comparable unit cost reductions, creating significant challenges for market entry and competitive pricing strategies.

Labor costs present another critical differential factor. Wankel engine assembly demands highly skilled technicians familiar with the unique geometry and sealing requirements, commanding premium wages that are typically 25-40% higher than those required for conventional rotary engine production. The specialized training necessary for these technicians further increases overhead costs for manufacturers.

Equipment investment represents a substantial barrier to entry for Wankel engine production. The specialized machinery required for manufacturing the epitrochoidal housing and precision rotors necessitates capital expenditures approximately 2-3 times higher than conventional engine production lines. This initial investment creates significant economies of scale challenges, particularly for lower production volumes.

Maintenance and quality control costs also skew unfavorably for Wankel engines. The complex sealing system requires more frequent inspection points during manufacturing, with rejection rates historically 7-12% higher than conventional engines. This translates to increased quality assurance personnel requirements and higher scrap rates that directly impact unit economics.

Energy consumption during manufacturing presents another cost consideration. The precision machining processes for Wankel components typically consume 15-25% more energy than comparable conventional engine components, primarily due to the complex surface geometries requiring multiple machining operations.

Supply chain complexity further impacts cost structures. While conventional rotary engines benefit from established supplier networks and standardized components, Wankel engine manufacturers often face limited supplier options for specialized parts, reducing negotiating leverage and increasing procurement costs by an estimated 10-18%.

When analyzing production scale economics, conventional rotary engines demonstrate more favorable cost reduction curves as production volumes increase. Wankel engines typically require production volumes approximately 2.5 times higher to achieve comparable unit cost reductions, creating significant challenges for market entry and competitive pricing strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!