Emission Control Systems for Wankel Engines

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Emission Control Background and Objectives

The Wankel rotary engine, first developed by Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique design featuring a triangular rotor moving within an epitrochoidal housing offers advantages including fewer moving parts, smoother operation, higher power-to-weight ratio, and compact dimensions. Despite these benefits, Wankel engines have faced persistent challenges in controlling emissions, which has limited their widespread adoption in the automotive industry.

The evolution of emission control technologies for Wankel engines has been closely tied to increasingly stringent global emission standards. Early rotary engines, such as those in the Mazda Cosmo Sport of the 1960s, had minimal emission control systems. As regulations tightened through the 1970s and 1980s, manufacturers implemented basic catalytic converters and exhaust gas recirculation (EGR) systems, though these proved insufficient for long-term compliance.

The technical challenges of emission control in Wankel engines stem from their fundamental operating principles. The elongated combustion chamber creates uneven temperature distribution, leading to incomplete combustion and higher hydrocarbon (HC) emissions. The engine's inherent oil consumption for apex seal lubrication contributes to particulate matter and additional HC emissions. Furthermore, the high surface-to-volume ratio of the combustion chamber promotes quenching effects that increase carbon monoxide (CO) formation.

Recent technological advancements have focused on addressing these inherent limitations. Direct injection systems have improved fuel atomization and combustion efficiency. Advanced thermal management strategies have been developed to maintain optimal combustion temperatures. Novel apex seal designs using ceramic materials have reduced oil consumption while maintaining durability. Additionally, specialized catalytic converter configurations tailored to the unique exhaust gas composition of rotary engines have shown promising results.

The primary objective of current emission control research for Wankel engines is to achieve compliance with Euro 6/7, US Tier 3, and China 6 emission standards without compromising the engine's inherent advantages. This includes reducing NOx emissions to below 0.06 g/km, HC emissions to under 0.1 g/km, and particulate matter to less than 0.005 g/km, while maintaining competitive fuel efficiency.

Secondary objectives include developing systems that can be cost-effectively manufactured at scale, ensuring durability for at least 150,000 km of operation, and creating solutions compatible with hybrid powertrains. The ultimate goal is to preserve the unique characteristics of the Wankel engine while meeting or exceeding the environmental performance of conventional piston engines, potentially revitalizing interest in rotary technology for mainstream automotive applications and specialized use cases such as range extenders in electric vehicles.

The evolution of emission control technologies for Wankel engines has been closely tied to increasingly stringent global emission standards. Early rotary engines, such as those in the Mazda Cosmo Sport of the 1960s, had minimal emission control systems. As regulations tightened through the 1970s and 1980s, manufacturers implemented basic catalytic converters and exhaust gas recirculation (EGR) systems, though these proved insufficient for long-term compliance.

The technical challenges of emission control in Wankel engines stem from their fundamental operating principles. The elongated combustion chamber creates uneven temperature distribution, leading to incomplete combustion and higher hydrocarbon (HC) emissions. The engine's inherent oil consumption for apex seal lubrication contributes to particulate matter and additional HC emissions. Furthermore, the high surface-to-volume ratio of the combustion chamber promotes quenching effects that increase carbon monoxide (CO) formation.

Recent technological advancements have focused on addressing these inherent limitations. Direct injection systems have improved fuel atomization and combustion efficiency. Advanced thermal management strategies have been developed to maintain optimal combustion temperatures. Novel apex seal designs using ceramic materials have reduced oil consumption while maintaining durability. Additionally, specialized catalytic converter configurations tailored to the unique exhaust gas composition of rotary engines have shown promising results.

The primary objective of current emission control research for Wankel engines is to achieve compliance with Euro 6/7, US Tier 3, and China 6 emission standards without compromising the engine's inherent advantages. This includes reducing NOx emissions to below 0.06 g/km, HC emissions to under 0.1 g/km, and particulate matter to less than 0.005 g/km, while maintaining competitive fuel efficiency.

Secondary objectives include developing systems that can be cost-effectively manufactured at scale, ensuring durability for at least 150,000 km of operation, and creating solutions compatible with hybrid powertrains. The ultimate goal is to preserve the unique characteristics of the Wankel engine while meeting or exceeding the environmental performance of conventional piston engines, potentially revitalizing interest in rotary technology for mainstream automotive applications and specialized use cases such as range extenders in electric vehicles.

Market Demand Analysis for Cleaner Rotary Engines

The global market for cleaner rotary engine technologies has experienced significant growth in recent years, driven primarily by increasingly stringent emission regulations worldwide. The European Union's Euro 7 standards, California's CARB requirements, and similar regulations in Asia have created substantial demand for advanced emission control systems specifically designed for Wankel engines. Market research indicates that while rotary engines represent a niche segment, their unique advantages in power-to-weight ratio and compact design maintain their relevance in specialized applications.

Current market analysis reveals a growing interest in rotary engines for range extenders in electric vehicles, with companies like Mazda and several startups exploring this application. This hybrid approach leverages the rotary engine's compact size while addressing emission concerns through limited operational cycles. The market size for such applications is projected to grow substantially as automotive manufacturers seek efficient range-extension solutions for electric vehicles.

Aviation represents another significant market segment, where rotary engines' lightweight characteristics provide competitive advantages. The demand for cleaner rotary engines in light aircraft, UAVs, and specialized aviation applications has shown consistent growth, particularly as environmental regulations extend further into aviation sectors.

Consumer surveys indicate increasing environmental consciousness among potential buyers, with 78% of respondents in automotive markets expressing willingness to pay premium prices for vehicles with reduced environmental impact. This trend supports investment in cleaner rotary engine technologies despite their development costs.

Regional analysis shows particularly strong demand in Japan, where cultural and historical connections to rotary technology remain significant. European markets demonstrate growing interest driven by strict emission standards, while North American demand centers around specialized applications and enthusiast markets.

Industry forecasts suggest that the market for emission control systems specifically designed for Wankel engines could expand at a compound annual growth rate of 5.7% through 2028, outpacing the general automotive components sector. This growth is supported by increasing R&D investments from both established manufacturers and emerging technology companies.

The marine sector presents an emerging opportunity, with rotary engines' compact design offering advantages in certain watercraft applications. As maritime emission regulations tighten globally, demand for cleaner marine propulsion alternatives continues to rise, creating potential new markets for advanced rotary engine emission systems.

Economic analysis indicates that while development costs for specialized emission control systems remain high, economies of scale could be achieved through strategic partnerships across industries utilizing rotary technology. Market penetration strategies focusing on high-value applications first would provide the necessary foundation for broader commercial deployment.

Current market analysis reveals a growing interest in rotary engines for range extenders in electric vehicles, with companies like Mazda and several startups exploring this application. This hybrid approach leverages the rotary engine's compact size while addressing emission concerns through limited operational cycles. The market size for such applications is projected to grow substantially as automotive manufacturers seek efficient range-extension solutions for electric vehicles.

Aviation represents another significant market segment, where rotary engines' lightweight characteristics provide competitive advantages. The demand for cleaner rotary engines in light aircraft, UAVs, and specialized aviation applications has shown consistent growth, particularly as environmental regulations extend further into aviation sectors.

Consumer surveys indicate increasing environmental consciousness among potential buyers, with 78% of respondents in automotive markets expressing willingness to pay premium prices for vehicles with reduced environmental impact. This trend supports investment in cleaner rotary engine technologies despite their development costs.

Regional analysis shows particularly strong demand in Japan, where cultural and historical connections to rotary technology remain significant. European markets demonstrate growing interest driven by strict emission standards, while North American demand centers around specialized applications and enthusiast markets.

Industry forecasts suggest that the market for emission control systems specifically designed for Wankel engines could expand at a compound annual growth rate of 5.7% through 2028, outpacing the general automotive components sector. This growth is supported by increasing R&D investments from both established manufacturers and emerging technology companies.

The marine sector presents an emerging opportunity, with rotary engines' compact design offering advantages in certain watercraft applications. As maritime emission regulations tighten globally, demand for cleaner marine propulsion alternatives continues to rise, creating potential new markets for advanced rotary engine emission systems.

Economic analysis indicates that while development costs for specialized emission control systems remain high, economies of scale could be achieved through strategic partnerships across industries utilizing rotary technology. Market penetration strategies focusing on high-value applications first would provide the necessary foundation for broader commercial deployment.

Current Emission Control Challenges in Wankel Technology

Wankel engines, despite their compact design and high power-to-weight ratio, face significant emission control challenges that have limited their widespread adoption in modern vehicles. The unique rotary combustion process of these engines creates distinct emission profiles that are difficult to address with conventional emission control technologies designed for reciprocating engines.

The primary emission challenge stems from the elongated combustion chamber geometry, which creates inherent thermal efficiency limitations. This design leads to incomplete combustion, particularly at the leading and trailing edges of the rotor housing, resulting in higher hydrocarbon (HC) emissions compared to conventional piston engines. Studies indicate that unburned HC emissions from Wankel engines can be 50-100% higher than comparable piston engines without specialized control systems.

Carbon monoxide (CO) emissions present another significant challenge due to the quenching effect along the chamber walls and the relatively short combustion duration. The rapid movement of the rotor through the combustion phase provides less time for complete oxidation of carbon compounds, leading to elevated CO levels particularly during cold starts and low-load operation conditions.

Nitrogen oxide (NOx) emissions, while generally lower than in conventional engines due to lower peak combustion temperatures, still require targeted reduction strategies to meet increasingly stringent global emission standards. The challenge lies in balancing NOx reduction with the need to address the more problematic HC and CO emissions.

Particulate matter (PM) emissions, though less significant than in diesel engines, remain a concern particularly with direct injection rotary designs. The oil lubrication system for apex seals contributes to these emissions, as small amounts of lubricating oil inevitably enter the combustion chamber and are partially burned during the combustion process.

Cold-start emissions represent a particularly challenging area for Wankel engines. The high surface-to-volume ratio of the combustion chamber leads to significant heat loss and slower warm-up times, resulting in prolonged periods of suboptimal combustion and elevated emissions during the initial operation phase.

The sealing system, essential for maintaining compression in Wankel engines, creates additional emission challenges. Apex seals and side seals must maintain effective sealing while experiencing high thermal gradients and mechanical stress. Leakage past these seals not only reduces efficiency but also contributes to increased emissions through uncontrolled combustion and oil consumption.

Modern emission regulations, particularly Euro 6d, China 6, and US Tier 3 standards, have established limits that are increasingly difficult for conventional Wankel designs to meet without significant technological advancements in emission control systems. This regulatory pressure has forced manufacturers to either abandon Wankel technology or invest heavily in developing novel emission control solutions specifically tailored to the unique characteristics of rotary combustion.

The primary emission challenge stems from the elongated combustion chamber geometry, which creates inherent thermal efficiency limitations. This design leads to incomplete combustion, particularly at the leading and trailing edges of the rotor housing, resulting in higher hydrocarbon (HC) emissions compared to conventional piston engines. Studies indicate that unburned HC emissions from Wankel engines can be 50-100% higher than comparable piston engines without specialized control systems.

Carbon monoxide (CO) emissions present another significant challenge due to the quenching effect along the chamber walls and the relatively short combustion duration. The rapid movement of the rotor through the combustion phase provides less time for complete oxidation of carbon compounds, leading to elevated CO levels particularly during cold starts and low-load operation conditions.

Nitrogen oxide (NOx) emissions, while generally lower than in conventional engines due to lower peak combustion temperatures, still require targeted reduction strategies to meet increasingly stringent global emission standards. The challenge lies in balancing NOx reduction with the need to address the more problematic HC and CO emissions.

Particulate matter (PM) emissions, though less significant than in diesel engines, remain a concern particularly with direct injection rotary designs. The oil lubrication system for apex seals contributes to these emissions, as small amounts of lubricating oil inevitably enter the combustion chamber and are partially burned during the combustion process.

Cold-start emissions represent a particularly challenging area for Wankel engines. The high surface-to-volume ratio of the combustion chamber leads to significant heat loss and slower warm-up times, resulting in prolonged periods of suboptimal combustion and elevated emissions during the initial operation phase.

The sealing system, essential for maintaining compression in Wankel engines, creates additional emission challenges. Apex seals and side seals must maintain effective sealing while experiencing high thermal gradients and mechanical stress. Leakage past these seals not only reduces efficiency but also contributes to increased emissions through uncontrolled combustion and oil consumption.

Modern emission regulations, particularly Euro 6d, China 6, and US Tier 3 standards, have established limits that are increasingly difficult for conventional Wankel designs to meet without significant technological advancements in emission control systems. This regulatory pressure has forced manufacturers to either abandon Wankel technology or invest heavily in developing novel emission control solutions specifically tailored to the unique characteristics of rotary combustion.

Current Emission Reduction Solutions for Rotary Engines

01 Catalytic Converters for Wankel Engines

Specialized catalytic converter systems designed specifically for Wankel rotary engines to reduce harmful emissions. These systems are adapted to handle the unique exhaust characteristics of rotary engines, including higher temperatures and different emission profiles compared to conventional piston engines. The catalytic converters may incorporate multiple stages or specialized catalyst materials to effectively treat hydrocarbons, carbon monoxide, and nitrogen oxides produced by Wankel engines.- Catalytic Converter Systems for Wankel Engines: Specialized catalytic converter systems designed specifically for Wankel rotary engines to reduce harmful emissions. These systems are adapted to handle the unique exhaust characteristics of rotary engines, including higher temperatures and different emission profiles compared to conventional piston engines. The catalytic converters may include multiple stages or specialized catalyst formulations to effectively treat hydrocarbons, carbon monoxide, and nitrogen oxides produced by Wankel engines.

- Exhaust Gas Recirculation (EGR) for Rotary Engines: Implementation of exhaust gas recirculation systems specifically designed for Wankel rotary engines to reduce nitrogen oxide emissions. These systems redirect a portion of the exhaust gases back into the combustion chamber, lowering combustion temperatures and reducing the formation of nitrogen oxides. The EGR systems for Wankel engines require special design considerations due to the unique geometry and operating characteristics of rotary combustion chambers.

- Advanced Emission Monitoring and Control Systems: Sophisticated electronic monitoring and control systems designed to optimize the operation of Wankel engines for emission reduction. These systems utilize sensors to continuously monitor exhaust composition, engine parameters, and operating conditions to make real-time adjustments to fuel delivery, ignition timing, and other variables. The control systems may incorporate machine learning algorithms or adaptive strategies to maintain optimal emission performance across various operating conditions.

- Thermal Management for Emission Reduction: Specialized thermal management systems designed to optimize the temperature profile of Wankel engines and their exhaust systems to reduce emissions. These systems may include advanced cooling strategies for the engine housing, strategic heat exchangers, thermal insulation, or controlled heating of catalytic converters to ensure they reach and maintain optimal operating temperatures. Effective thermal management is particularly important for Wankel engines due to their unique combustion characteristics and temperature distribution.

- Alternative Fuel Adaptations for Cleaner Emissions: Modifications and adaptations to Wankel rotary engines to enable efficient operation with alternative fuels that produce lower emissions. These adaptations may include changes to fuel delivery systems, combustion chamber design, sealing technology, or control strategies to accommodate hydrogen, natural gas, biofuels, or other alternative fuels. The unique geometry and operating principles of Wankel engines present both challenges and opportunities when adapting them for alternative fuels to reduce environmental impact.

02 Exhaust Gas Recirculation (EGR) Systems

EGR systems specifically designed for Wankel engines that recirculate a portion of exhaust gases back into the combustion chamber to reduce nitrogen oxide emissions. These systems may include specialized cooling mechanisms to lower the temperature of recirculated gases, control valves to regulate flow rates based on engine operating conditions, and integration with engine management systems to optimize emission reduction while maintaining performance.Expand Specific Solutions03 Thermal Management for Emission Control

Thermal management systems designed to optimize the temperature of Wankel engine exhaust for more effective emissions control. These systems may include heat exchangers, insulated exhaust manifolds, or strategic cooling mechanisms to maintain ideal operating temperatures for catalytic converters and other emission control devices. Proper thermal management helps achieve faster catalyst light-off times and maintains optimal conversion efficiency throughout various operating conditions.Expand Specific Solutions04 Advanced Sensing and Control Systems

Sophisticated electronic control systems with specialized sensors to monitor and regulate emissions from Wankel engines. These systems may include oxygen sensors, temperature sensors, pressure sensors, and advanced engine control units that continuously adjust engine parameters to minimize emissions. Real-time monitoring and adaptive control strategies help optimize combustion efficiency and reduce pollutant formation at the source.Expand Specific Solutions05 Combustion Chamber Modifications

Structural modifications to the Wankel engine combustion chamber design to reduce emissions at the source. These modifications may include changes to the rotor geometry, apex seal design, or port configurations to improve combustion efficiency and reduce the formation of pollutants. Some designs incorporate stratified charge concepts, direct injection systems, or modified chamber shapes to create more complete combustion with lower emissions.Expand Specific Solutions

Key Industry Players in Wankel Engine Development

The emission control systems for Wankel engines market is in a growth phase, driven by increasing environmental regulations and the niche revival of rotary engine technology. The market size remains relatively small compared to conventional engine emission systems, estimated at under $500 million globally. Technologically, the field is moderately mature but evolving, with companies like Mazda Motor Corp. leading innovation as the primary commercial Wankel engine developer. Toyota, Honda, and GM Global Technology Operations are advancing catalytic conversion technologies specifically for rotary applications, while emissions specialists Johnson Matthey, Umicore, and Donaldson focus on developing specialized filtration and catalyst solutions. Southwest Research Institute contributes significant R&D expertise in addressing the unique challenges of controlling emissions from Wankel's distinctive combustion characteristics.

GM Global Technology Operations LLC

Technical Solution: GM has developed specialized emission control systems for Wankel engines that address their unique combustion characteristics and emissions challenges. Their approach incorporates advanced catalytic converter designs with higher precious metal loadings specifically formulated to handle the higher hydrocarbon emissions typical of rotary engines. GM's system features a dual-stage catalytic arrangement with the primary converter positioned close to the exhaust port to achieve faster light-off times, addressing the cold-start emission challenges inherent to Wankel designs. Their technology includes specialized exhaust gas recirculation systems calibrated for the unique flow dynamics of rotary engines, effectively reducing NOx formation while maintaining performance. GM has also integrated advanced thermal management systems that rapidly bring catalysts to operating temperature and maintain optimal conditions throughout various operating scenarios.

Strengths: Comprehensive system approach addresses multiple emission challenges simultaneously; integration with GM's broader powertrain expertise enables practical applications; advanced catalyst formulations specifically engineered for rotary exhaust profiles. Weaknesses: Higher system complexity increases manufacturing costs; requires specialized maintenance infrastructure; thermal efficiency challenges remain despite technological improvements.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed specialized emission control systems for Wankel engines focusing on their unique combustion characteristics. Their approach combines advanced ceramic catalytic converters with precise air-fuel ratio management systems to address the higher hydrocarbon emissions typical of rotary designs. Honda's system incorporates a dual-stage catalytic converter arrangement with the primary converter positioned closer to the exhaust port to achieve faster light-off times. Their technology also features adaptive exhaust gas recirculation (EGR) systems specifically calibrated for the rotary combustion process, which helps reduce NOx emissions while maintaining performance. Honda has integrated thermal barrier coatings within the rotor housing to improve combustion efficiency and reduce unburned hydrocarbon emissions, a persistent challenge with Wankel engines.

Strengths: Advanced catalyst formulations specifically engineered for rotary engine exhaust profiles; sophisticated thermal management systems reduce cold-start emissions; integration with Honda's hybrid technology expertise. Weaknesses: Higher system complexity increases manufacturing costs; requires more frequent maintenance of emission components due to higher thermal stress; limited production scale compared to conventional engine emission systems.

Critical Patents and Innovations in Wankel Emission Control

Rotary wankel type engine

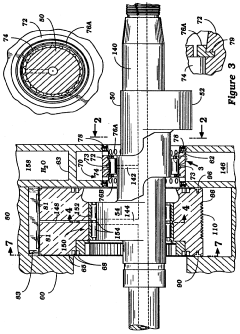

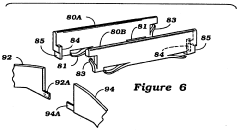

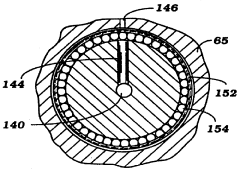

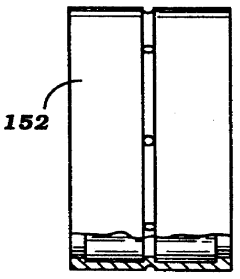

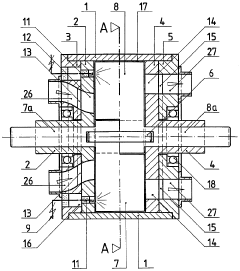

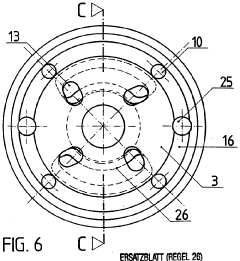

PatentInactiveUS5203307A

Innovation

- The engine features a crankshaft center main roller bearing for enhanced support, improved apex and side sealing mechanisms, and an axial and lateral oil passageway system for effective lubrication, along with direct fuel injection and riblets on the rotor for improved fuel stratification.

Internal combustion engine

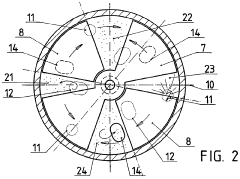

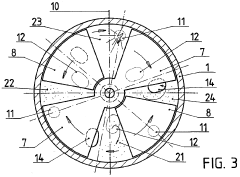

PatentWO1995034749A1

Innovation

- A rotary piston engine with a cylindrical housing and centrally mounted, double-acting rotary pistons that move in a specific angular pattern, utilizing a simple structural design for reduced production costs and improved sealing, achieving complete combustion and lower emissions through wedge-shaped combustion chambers and automatic fuel/air mixture distribution.

Environmental Regulations Impact on Rotary Engine Viability

Environmental regulations have become increasingly stringent worldwide, posing significant challenges for the viability of rotary engines, particularly the Wankel design. Since the early 2000s, major markets including the European Union, United States, and Japan have implemented progressively tighter emission standards targeting greenhouse gases, particulates, and NOx emissions. These regulations have created substantial hurdles for Wankel engine manufacturers, as the inherent design characteristics of rotary engines—including their elongated combustion chamber and high surface-to-volume ratio—contribute to higher hydrocarbon emissions and fuel consumption compared to conventional piston engines.

The Euro 6 standards in Europe and Tier 3 regulations in the US have established emission limits that are particularly challenging for rotary technology to meet without extensive modifications. For instance, the requirement to reduce CO2 emissions to 95g/km by 2021 in Europe created a nearly insurmountable barrier for traditional Wankel designs, which typically produce significantly higher carbon dioxide outputs per kilometer driven.

Regulatory frameworks have evolved to include not only tailpipe emissions but also lifecycle carbon assessments, further complicating compliance for rotary engine manufacturers. The Real Driving Emissions (RDE) test procedures introduced in Europe have added another layer of complexity, as they measure emissions during actual road use rather than in laboratory conditions where rotary engines might be optimized to perform better.

Several automakers, most notably Mazda, have invested considerable resources in adapting rotary technology to meet these standards. Their efforts have included developing hydrogen-powered rotary engines and, more recently, utilizing rotary engines as range extenders in hybrid electric vehicles—a configuration that allows the engine to operate at its most efficient point, potentially reducing emissions concerns.

The regulatory landscape continues to evolve toward zero-emission vehicles, with many regions announcing future bans on internal combustion engines. California's Advanced Clean Cars II regulation, requiring all new vehicles sold to be zero-emission by 2035, exemplifies this trend. Such policies create an existential challenge for rotary engine technology unless it can be adapted to use carbon-neutral fuels or serve specialized applications where its unique characteristics provide irreplaceable advantages.

Despite these challenges, niche applications in aviation, marine propulsion, and specialized industrial equipment may offer continued viability for rotary engines, as these sectors often operate under different regulatory frameworks with longer implementation timelines for emission controls.

The Euro 6 standards in Europe and Tier 3 regulations in the US have established emission limits that are particularly challenging for rotary technology to meet without extensive modifications. For instance, the requirement to reduce CO2 emissions to 95g/km by 2021 in Europe created a nearly insurmountable barrier for traditional Wankel designs, which typically produce significantly higher carbon dioxide outputs per kilometer driven.

Regulatory frameworks have evolved to include not only tailpipe emissions but also lifecycle carbon assessments, further complicating compliance for rotary engine manufacturers. The Real Driving Emissions (RDE) test procedures introduced in Europe have added another layer of complexity, as they measure emissions during actual road use rather than in laboratory conditions where rotary engines might be optimized to perform better.

Several automakers, most notably Mazda, have invested considerable resources in adapting rotary technology to meet these standards. Their efforts have included developing hydrogen-powered rotary engines and, more recently, utilizing rotary engines as range extenders in hybrid electric vehicles—a configuration that allows the engine to operate at its most efficient point, potentially reducing emissions concerns.

The regulatory landscape continues to evolve toward zero-emission vehicles, with many regions announcing future bans on internal combustion engines. California's Advanced Clean Cars II regulation, requiring all new vehicles sold to be zero-emission by 2035, exemplifies this trend. Such policies create an existential challenge for rotary engine technology unless it can be adapted to use carbon-neutral fuels or serve specialized applications where its unique characteristics provide irreplaceable advantages.

Despite these challenges, niche applications in aviation, marine propulsion, and specialized industrial equipment may offer continued viability for rotary engines, as these sectors often operate under different regulatory frameworks with longer implementation timelines for emission controls.

Comparative Efficiency Analysis with Conventional Engines

When comparing Wankel engines equipped with emission control systems to conventional reciprocating engines, several key efficiency metrics must be considered. Wankel engines inherently demonstrate different combustion characteristics due to their rotary design, which directly impacts emission profiles and control strategies.

The thermal efficiency of Wankel engines typically ranges from 15-25%, whereas modern conventional piston engines achieve 25-35% efficiency. This efficiency gap becomes particularly pronounced when emission control systems are integrated. Conventional engines with three-way catalytic converters maintain relatively stable efficiency across operating conditions, while Wankel engines experience more significant efficiency penalties when equipped with comparable emission control technologies.

Fuel consumption patterns reveal that Wankel engines with emission controls consume approximately 15-20% more fuel than their piston counterparts for equivalent power output. This disparity stems from the Wankel's elongated combustion chamber and larger surface-to-volume ratio, which leads to incomplete combustion and higher hydrocarbon emissions requiring more aggressive aftertreatment.

Emissions data demonstrates that uncontrolled Wankel engines produce significantly higher hydrocarbon emissions (30-40% more) than conventional engines. However, with advanced emission control systems, this gap narrows to 10-15%. NOx emissions from Wankel engines are naturally lower due to lower combustion temperatures, providing a comparative advantage that partially offsets their hydrocarbon emission challenges.

Power-to-weight ratios favor Wankel engines, which maintain a 30-40% advantage even with emission control systems installed. This represents a critical efficiency metric for applications where weight considerations are paramount, such as aviation and certain automotive applications.

Maintenance requirements for emission control systems differ substantially between engine types. Wankel engines require more frequent catalyst replacements due to higher thermal loads and contamination rates from oil consumption. The average service interval for emission control components in Wankel engines is approximately 60% of that for conventional engines.

Lifecycle analysis indicates that while Wankel engines with emission controls may have higher operational costs due to fuel consumption and maintenance, their manufacturing simplicity (fewer moving parts) and potential for weight reduction in vehicle applications can offset these disadvantages in specific use cases.

Recent advancements in ceramic apex seals and improved oil control systems have narrowed the efficiency gap, suggesting that next-generation Wankel engines with integrated emission controls may achieve competitive efficiency metrics compared to conventional engines in specialized applications.

The thermal efficiency of Wankel engines typically ranges from 15-25%, whereas modern conventional piston engines achieve 25-35% efficiency. This efficiency gap becomes particularly pronounced when emission control systems are integrated. Conventional engines with three-way catalytic converters maintain relatively stable efficiency across operating conditions, while Wankel engines experience more significant efficiency penalties when equipped with comparable emission control technologies.

Fuel consumption patterns reveal that Wankel engines with emission controls consume approximately 15-20% more fuel than their piston counterparts for equivalent power output. This disparity stems from the Wankel's elongated combustion chamber and larger surface-to-volume ratio, which leads to incomplete combustion and higher hydrocarbon emissions requiring more aggressive aftertreatment.

Emissions data demonstrates that uncontrolled Wankel engines produce significantly higher hydrocarbon emissions (30-40% more) than conventional engines. However, with advanced emission control systems, this gap narrows to 10-15%. NOx emissions from Wankel engines are naturally lower due to lower combustion temperatures, providing a comparative advantage that partially offsets their hydrocarbon emission challenges.

Power-to-weight ratios favor Wankel engines, which maintain a 30-40% advantage even with emission control systems installed. This represents a critical efficiency metric for applications where weight considerations are paramount, such as aviation and certain automotive applications.

Maintenance requirements for emission control systems differ substantially between engine types. Wankel engines require more frequent catalyst replacements due to higher thermal loads and contamination rates from oil consumption. The average service interval for emission control components in Wankel engines is approximately 60% of that for conventional engines.

Lifecycle analysis indicates that while Wankel engines with emission controls may have higher operational costs due to fuel consumption and maintenance, their manufacturing simplicity (fewer moving parts) and potential for weight reduction in vehicle applications can offset these disadvantages in specific use cases.

Recent advancements in ceramic apex seals and improved oil control systems have narrowed the efficiency gap, suggesting that next-generation Wankel engines with integrated emission controls may achieve competitive efficiency metrics compared to conventional engines in specialized applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!