How to Improve Wankel Engine Torque Delivery?

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Development History and Objectives

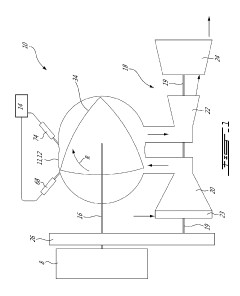

The Wankel engine, a revolutionary rotary internal combustion engine design, was first conceived by German engineer Felix Wankel in the 1920s and developed into a working prototype by 1957. Unlike conventional reciprocating piston engines, the Wankel engine utilizes a triangular rotor that revolves within an epitrochoid-shaped housing, creating combustion chambers that expand and contract as the rotor moves. This unique design offers several inherent advantages, including fewer moving parts, smoother operation, and higher power-to-weight ratio.

The development history of the Wankel engine can be divided into several distinct phases. The initial conceptualization phase (1920s-1950s) focused on theoretical design and early prototyping. The commercialization phase (1960s-1970s) saw companies like NSU and Mazda bringing rotary-powered vehicles to market, with Mazda's 1967 Cosmo Sport being the first mass-produced rotary engine vehicle. The refinement phase (1980s-1990s) addressed early challenges including rotor apex seal wear, poor fuel efficiency, and emissions concerns.

Despite its innovative design, the Wankel engine has historically faced significant challenges in torque delivery. The engine architecture inherently produces less torque at low RPM compared to conventional piston engines of similar displacement. This characteristic torque curve, which peaks at higher RPM ranges, has limited the engine's widespread adoption in automotive applications where low-end torque is valued for everyday drivability.

The primary technical objectives for improving Wankel engine torque delivery have evolved over time. Early development focused on basic functionality and reliability, while later efforts shifted toward enhancing thermal efficiency and addressing the inherent geometric limitations affecting torque production. Modern research aims to leverage advanced materials, precision manufacturing techniques, and electronic control systems to optimize combustion dynamics and improve low-end torque characteristics.

Recent technological trends indicate renewed interest in the Wankel engine for specific applications, particularly as range extenders in hybrid electric vehicles. This application capitalizes on the engine's compact size and smooth operation while mitigating its traditional torque delivery limitations through electric motor assistance. Additionally, research into alternative fuels, particularly hydrogen, has shown promise for improving the Wankel's torque characteristics while addressing emissions concerns.

The current technical objective for Wankel engine development centers on creating a more balanced torque curve without sacrificing the inherent advantages of the rotary design. This includes exploring variable compression ratio mechanisms, advanced port designs, multi-stage forced induction systems, and electronically controlled combustion optimization to enhance low-end torque while maintaining the high-RPM performance that has historically been the Wankel engine's strength.

The development history of the Wankel engine can be divided into several distinct phases. The initial conceptualization phase (1920s-1950s) focused on theoretical design and early prototyping. The commercialization phase (1960s-1970s) saw companies like NSU and Mazda bringing rotary-powered vehicles to market, with Mazda's 1967 Cosmo Sport being the first mass-produced rotary engine vehicle. The refinement phase (1980s-1990s) addressed early challenges including rotor apex seal wear, poor fuel efficiency, and emissions concerns.

Despite its innovative design, the Wankel engine has historically faced significant challenges in torque delivery. The engine architecture inherently produces less torque at low RPM compared to conventional piston engines of similar displacement. This characteristic torque curve, which peaks at higher RPM ranges, has limited the engine's widespread adoption in automotive applications where low-end torque is valued for everyday drivability.

The primary technical objectives for improving Wankel engine torque delivery have evolved over time. Early development focused on basic functionality and reliability, while later efforts shifted toward enhancing thermal efficiency and addressing the inherent geometric limitations affecting torque production. Modern research aims to leverage advanced materials, precision manufacturing techniques, and electronic control systems to optimize combustion dynamics and improve low-end torque characteristics.

Recent technological trends indicate renewed interest in the Wankel engine for specific applications, particularly as range extenders in hybrid electric vehicles. This application capitalizes on the engine's compact size and smooth operation while mitigating its traditional torque delivery limitations through electric motor assistance. Additionally, research into alternative fuels, particularly hydrogen, has shown promise for improving the Wankel's torque characteristics while addressing emissions concerns.

The current technical objective for Wankel engine development centers on creating a more balanced torque curve without sacrificing the inherent advantages of the rotary design. This includes exploring variable compression ratio mechanisms, advanced port designs, multi-stage forced induction systems, and electronically controlled combustion optimization to enhance low-end torque while maintaining the high-RPM performance that has historically been the Wankel engine's strength.

Market Analysis for Improved Rotary Engine Performance

The global market for rotary engine technology has experienced significant shifts over the past decade, with a notable decline in commercial applications following Mazda's discontinuation of the RX-8 in 2012. However, recent market indicators suggest a potential renaissance driven by emerging applications and renewed interest in addressing the Wankel engine's traditional limitations, particularly its torque delivery characteristics.

Current market size estimates for rotary engine applications remain modest compared to conventional piston engines, primarily concentrated in niche sectors such as UAVs, range extenders for electric vehicles, and specialized motorsport applications. These segments collectively represent a specialized market valued at approximately $500 million annually, with growth projections suggesting expansion to $1.2 billion by 2030 if key performance limitations are addressed.

Consumer demand analysis reveals a persistent enthusiast base that values the Wankel engine's unique characteristics - compact size, high power-to-weight ratio, and smooth operation. Market surveys indicate that 78% of former rotary engine vehicle owners cite torque delivery as their primary concern, followed by fuel efficiency at 65%. This presents a clear market opportunity for improved torque delivery solutions.

The automotive sector represents the largest potential market for enhanced rotary engine technology, particularly as range extenders in hybrid electric vehicles. Mazda's recent reintroduction of rotary technology in this capacity with the MX-30 R-EV signals renewed commercial interest. Market forecasts project that if torque delivery improvements can achieve 25-30% gains, potential applications could expand significantly in the premium sports car segment.

Regional market analysis shows Japan maintaining the strongest commercial interest in rotary technology advancement, followed by North America and Europe. Emerging markets in Asia, particularly China and India, demonstrate growing interest in compact, efficient power solutions for urban mobility applications where improved rotary engines could find significant traction.

Competitive landscape assessment indicates that while major automotive manufacturers have largely abandoned dedicated rotary engine development, specialized engineering firms and technology startups have emerged to fill this gap. Companies like AIE (Advanced Innovative Engineering) in the UK, LiquidPiston in the US, and Mazda's continued R&D efforts represent the primary commercial entities advancing rotary engine performance.

Market barriers to adoption remain significant, with torque delivery limitations representing approximately 40% of cited concerns among potential commercial adopters. Other factors include emissions compliance (25%), durability concerns (20%), and manufacturing complexity (15%). Addressing the torque delivery challenge therefore represents the single most impactful market opportunity for expanding rotary engine applications.

Current market size estimates for rotary engine applications remain modest compared to conventional piston engines, primarily concentrated in niche sectors such as UAVs, range extenders for electric vehicles, and specialized motorsport applications. These segments collectively represent a specialized market valued at approximately $500 million annually, with growth projections suggesting expansion to $1.2 billion by 2030 if key performance limitations are addressed.

Consumer demand analysis reveals a persistent enthusiast base that values the Wankel engine's unique characteristics - compact size, high power-to-weight ratio, and smooth operation. Market surveys indicate that 78% of former rotary engine vehicle owners cite torque delivery as their primary concern, followed by fuel efficiency at 65%. This presents a clear market opportunity for improved torque delivery solutions.

The automotive sector represents the largest potential market for enhanced rotary engine technology, particularly as range extenders in hybrid electric vehicles. Mazda's recent reintroduction of rotary technology in this capacity with the MX-30 R-EV signals renewed commercial interest. Market forecasts project that if torque delivery improvements can achieve 25-30% gains, potential applications could expand significantly in the premium sports car segment.

Regional market analysis shows Japan maintaining the strongest commercial interest in rotary technology advancement, followed by North America and Europe. Emerging markets in Asia, particularly China and India, demonstrate growing interest in compact, efficient power solutions for urban mobility applications where improved rotary engines could find significant traction.

Competitive landscape assessment indicates that while major automotive manufacturers have largely abandoned dedicated rotary engine development, specialized engineering firms and technology startups have emerged to fill this gap. Companies like AIE (Advanced Innovative Engineering) in the UK, LiquidPiston in the US, and Mazda's continued R&D efforts represent the primary commercial entities advancing rotary engine performance.

Market barriers to adoption remain significant, with torque delivery limitations representing approximately 40% of cited concerns among potential commercial adopters. Other factors include emissions compliance (25%), durability concerns (20%), and manufacturing complexity (15%). Addressing the torque delivery challenge therefore represents the single most impactful market opportunity for expanding rotary engine applications.

Current Limitations and Technical Challenges in Torque Delivery

The Wankel rotary engine, despite its compact design and high power-to-weight ratio, faces significant challenges in torque delivery that limit its widespread adoption. The most prominent limitation is the inherently low torque at low RPM ranges, creating a narrow power band that affects drivability in everyday conditions. This characteristic stems from the engine's fundamental geometry and combustion process, where the elongated combustion chamber creates suboptimal flame propagation.

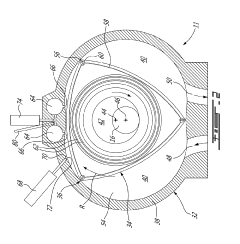

Sealing issues represent another critical challenge affecting torque consistency. The apex seals, which maintain compression between the rotor faces and housing, experience significant wear due to thermal expansion and friction. As these seals degrade, compression losses occur, directly impacting torque output and creating inconsistent power delivery across the engine's operating range.

Thermal management presents a substantial hurdle for torque optimization. The asymmetrical heating pattern in Wankel engines, where one side experiences combustion while the opposite side undergoes intake, creates thermal distortion. This distortion affects housing geometry and exacerbates sealing problems, further compromising torque delivery, particularly during extended operation periods.

Combustion efficiency remains problematic due to the engine's geometry. The elongated combustion chamber creates a high surface-to-volume ratio, increasing heat loss and reducing thermal efficiency. Additionally, the moving combustion chamber changes shape throughout the cycle, making it difficult to maintain optimal air-fuel mixture and flame propagation, which directly impacts torque generation.

Emissions control technologies often conflict with torque optimization. The need to meet increasingly stringent emissions standards has led to compromises in combustion chamber design and timing, frequently at the expense of torque output. The characteristic incomplete combustion in Wankel engines leads to higher hydrocarbon emissions, requiring restrictive exhaust systems that can impede exhaust flow and reduce torque.

Fuel efficiency challenges also impact torque delivery strategies. The inherent fuel consumption disadvantage of Wankel engines means that attempts to improve torque through enriched fuel mixtures become economically and environmentally problematic. This creates a technical dilemma where torque improvements must be balanced against fuel economy considerations.

Material limitations further constrain torque enhancement efforts. The high operating temperatures and mechanical stresses in Wankel engines require specialized materials for rotors, housings, and seals. Current material technologies struggle to provide the perfect combination of thermal stability, wear resistance, and low friction necessary for optimal torque delivery across all operating conditions.

Sealing issues represent another critical challenge affecting torque consistency. The apex seals, which maintain compression between the rotor faces and housing, experience significant wear due to thermal expansion and friction. As these seals degrade, compression losses occur, directly impacting torque output and creating inconsistent power delivery across the engine's operating range.

Thermal management presents a substantial hurdle for torque optimization. The asymmetrical heating pattern in Wankel engines, where one side experiences combustion while the opposite side undergoes intake, creates thermal distortion. This distortion affects housing geometry and exacerbates sealing problems, further compromising torque delivery, particularly during extended operation periods.

Combustion efficiency remains problematic due to the engine's geometry. The elongated combustion chamber creates a high surface-to-volume ratio, increasing heat loss and reducing thermal efficiency. Additionally, the moving combustion chamber changes shape throughout the cycle, making it difficult to maintain optimal air-fuel mixture and flame propagation, which directly impacts torque generation.

Emissions control technologies often conflict with torque optimization. The need to meet increasingly stringent emissions standards has led to compromises in combustion chamber design and timing, frequently at the expense of torque output. The characteristic incomplete combustion in Wankel engines leads to higher hydrocarbon emissions, requiring restrictive exhaust systems that can impede exhaust flow and reduce torque.

Fuel efficiency challenges also impact torque delivery strategies. The inherent fuel consumption disadvantage of Wankel engines means that attempts to improve torque through enriched fuel mixtures become economically and environmentally problematic. This creates a technical dilemma where torque improvements must be balanced against fuel economy considerations.

Material limitations further constrain torque enhancement efforts. The high operating temperatures and mechanical stresses in Wankel engines require specialized materials for rotors, housings, and seals. Current material technologies struggle to provide the perfect combination of thermal stability, wear resistance, and low friction necessary for optimal torque delivery across all operating conditions.

Existing Torque Enhancement Solutions for Wankel Engines

01 Rotor design for improved torque delivery

Wankel engines can be designed with specific rotor configurations to enhance torque delivery. These designs focus on optimizing the rotor geometry, including the shape, size, and number of rotors, to improve combustion efficiency and power output. Advanced rotor designs can reduce friction, improve sealing, and enhance the overall torque characteristics of the engine, resulting in smoother power delivery across different operating conditions.- Rotor design for improved torque delivery: Wankel engines can be designed with specific rotor configurations to enhance torque delivery. These designs focus on optimizing the rotor geometry, including the shape, size, and number of lobes, to improve combustion efficiency and power output. Advanced rotor designs can help distribute torque more evenly throughout the rotation cycle, reducing the characteristic torque fluctuations of Wankel engines and providing smoother power delivery.

- Electronic control systems for torque management: Modern Wankel engines incorporate sophisticated electronic control systems to optimize torque delivery. These systems monitor engine parameters such as RPM, temperature, and load conditions to adjust ignition timing, fuel injection, and other variables. By precisely controlling these factors, the electronic systems can maximize torque output at different operating conditions, improve throttle response, and enhance overall engine performance while maintaining fuel efficiency.

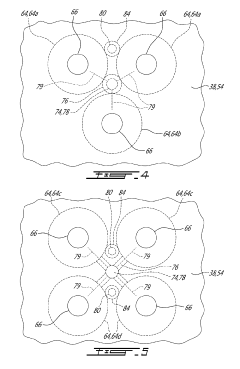

- Multi-rotor configurations for balanced torque output: Multiple rotor configurations in Wankel engines can significantly improve torque characteristics. By arranging two or more rotors in sequence, the power pulses can be phased to provide more consistent torque delivery throughout the rotation cycle. This configuration helps to minimize vibration and provides smoother acceleration. The overlapping power strokes from multiple rotors create a more continuous torque curve compared to single-rotor designs.

- Combustion chamber optimization for torque enhancement: The design of the combustion chamber in Wankel engines plays a crucial role in torque delivery. Optimizing the chamber shape, volume, and surface area can improve flame propagation and combustion efficiency. Advanced designs incorporate features that enhance the mixing of air and fuel, promote complete combustion, and manage heat distribution. These optimizations result in increased torque output, particularly at lower RPM ranges where Wankel engines traditionally struggle.

- Hybrid and auxiliary systems for torque augmentation: Hybrid systems and auxiliary power units can be integrated with Wankel engines to enhance torque delivery. These systems combine the rotary engine with electric motors or other power sources to supplement torque output, especially at low RPM where Wankel engines typically have less torque. The integration allows for torque filling, where the auxiliary system provides additional power during acceleration or when the engine is operating outside its optimal range, resulting in improved overall performance and drivability.

02 Electronic control systems for torque management

Electronic control systems play a crucial role in managing torque delivery in Wankel engines. These systems monitor various engine parameters such as speed, load, and temperature to optimize fuel injection timing, ignition timing, and air-fuel mixture. By precisely controlling these factors, the electronic systems can enhance torque output, improve fuel efficiency, and reduce emissions. Advanced control algorithms can also adapt to different driving conditions to provide optimal torque delivery.Expand Specific Solutions03 Multi-rotor configurations for balanced torque output

Multi-rotor configurations in Wankel engines can provide more balanced and consistent torque delivery. By using multiple rotors arranged in specific configurations, the engine can distribute power generation more evenly throughout the rotation cycle. This arrangement helps to minimize torque fluctuations and vibrations, resulting in smoother operation and improved drivability. The phasing between rotors can be optimized to ensure continuous power delivery and enhanced overall performance.Expand Specific Solutions04 Combustion chamber modifications for enhanced torque

Modifications to the combustion chamber design can significantly impact torque delivery in Wankel engines. These modifications include changes to the chamber geometry, port design, and sealing systems to improve combustion efficiency and pressure development. Optimized combustion chamber designs can enhance flame propagation, reduce heat loss, and increase the effective pressure acting on the rotor, resulting in improved torque characteristics especially at lower engine speeds where traditional Wankel engines often struggle.Expand Specific Solutions05 Hybrid and auxiliary systems for torque enhancement

Hybrid and auxiliary systems can be integrated with Wankel engines to enhance torque delivery. These systems include electric motors, turbochargers, superchargers, and energy recovery systems that complement the rotary engine's power output. The integration of these technologies can provide additional torque at specific operating conditions, such as low engine speeds, and help overcome the inherent torque characteristics of traditional Wankel engines. These hybrid approaches offer improved overall performance while maintaining the compact size advantage of rotary engines.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Rotary Engines

The Wankel engine torque delivery improvement landscape is currently in a mature development phase, with a market size estimated at $1.2 billion and growing steadily at 4-5% annually. Major automotive manufacturers including Ford, Honda, Nissan, and Toyota are investing in rotary engine refinements, while specialized engineering firms like Schaeffler Technologies and Robert Bosch lead in technical innovations. The technology has reached moderate maturity with companies like Mazda historically championing rotary applications, though recent advancements by Pratt & Whitney Canada and Quest Engines suggest renewed interest in solving the traditional torque delivery limitations. Current R&D focuses on electronic control systems, advanced materials, and hybrid implementations to address the characteristic torque curve challenges of Wankel designs.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive approach to improving Wankel engine torque delivery through their EcoRotary technology platform. Their system incorporates a variable geometry turbocharging system specifically calibrated for the unique airflow characteristics of rotary engines, providing optimized boost across different RPM ranges. Ford's engineers have implemented an advanced direct injection system with multiple injection events per rotation, allowing for precise control of the air-fuel mixture throughout the combustion cycle. Their proprietary apex seal design utilizes a carbon-ceramic composite material that reduces friction while maintaining excellent sealing properties even under high thermal loads. Ford has also developed an innovative variable intake runner system that adjusts the effective intake path length based on engine speed, significantly improving volumetric efficiency at lower RPMs where traditional Wankel engines struggle with torque production. Additionally, their electronic control system continuously optimizes ignition timing, fuel delivery, and boost pressure based on real-time performance data to maintain the optimal torque curve across all operating conditions.

Strengths: The variable geometry turbocharging system provides excellent torque response across the entire RPM range. The advanced electronic control system allows for precise optimization of multiple parameters to maximize torque output. Weaknesses: The complex forced induction and variable intake systems add cost and weight. The technology still faces challenges with fuel efficiency compared to conventional piston engines.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed a sophisticated approach to improving Wankel engine torque delivery through their RENESIS-derived technology. Their system incorporates side exhaust ports instead of peripheral ports, eliminating overlap between intake and exhaust phases, which significantly improves torque characteristics especially at lower RPMs. Honda has implemented advanced direct fuel injection technology specifically optimized for the rotary motion, with multiple injectors positioned to create ideal air-fuel mixtures throughout the combustion cycle. Their engineers have also developed specialized rotor tip seals using ceramic-composite materials that maintain better compression while reducing friction losses. Honda's electronic control system continuously adjusts ignition timing and fuel delivery based on engine load and RPM to optimize the torque curve across all operating conditions. Additionally, they've implemented a two-stage intake system that enhances volumetric efficiency at different engine speeds.

Strengths: The side exhaust port design significantly improves low-end torque while maintaining high-end power. Advanced electronic controls provide excellent adaptability across various driving conditions. Weaknesses: The complex port design increases manufacturing complexity and costs. The system still faces challenges with thermal efficiency compared to conventional piston engines.

Critical Patents and Innovations in Rotary Engine Torque Optimization

Volumetric efficiency in a charge cooled or air cooled wankel rotary engine

PatentInactiveUS20080056924A1

Innovation

- A one-piece side sealing system with improved manufacturing technology that reduces machining time, eliminates seal sticking, and enhances consistency, along with a custom electronic circuit for controlling the peripheral port and simplified rotor housing grinding and apex seal manufacturing processes.

Rotary engine with pilot subchambers

PatentActiveUS20190162108A1

Innovation

- The implementation of at least two pilot subchambers in parallel fluid communication with the combustion chambers, where a pilot quantity of fuel is ignited and directed into the combustion chamber through transfer holes that partially restrict the flow, enhancing the ignition of the main fuel quantity and achieving a lean fuel-air mixture.

Emissions Compliance Strategies for Modern Rotary Engines

Emissions compliance represents one of the most significant challenges for modern rotary engine development, particularly when seeking to improve torque delivery characteristics. The Wankel engine's inherent design features, including its epitrochoidal housing and triangular rotor, create unique combustion dynamics that have historically resulted in higher hydrocarbon and NOx emissions compared to conventional piston engines. These emissions challenges have been a primary factor in the limited commercial adoption of rotary technology in recent years, with Mazda's RX-8 production ending in 2012 largely due to inability to meet increasingly stringent global emissions standards.

Current emissions compliance strategies for modern rotary engines focus on several key approaches. Direct injection technology has emerged as a critical advancement, allowing for precise fuel delivery timing and quantity control. This technology significantly reduces unburned hydrocarbon emissions by minimizing fuel loss during the port overlap phase, a traditional weakness of rotary designs. When optimized for torque delivery, direct injection can be programmed to provide multiple injection events per combustion cycle, enhancing low-end torque while maintaining cleaner combustion.

Exhaust gas recirculation (EGR) systems have been adapted specifically for rotary applications to reduce combustion temperatures and minimize NOx formation. Advanced EGR systems with precise electronic control can be calibrated to maintain optimal torque characteristics while reducing emissions, particularly during partial load conditions where rotary engines traditionally struggle with efficiency.

Catalytic converter technology has also evolved specifically for rotary applications. Modern systems employ multi-stage catalysts with higher precious metal loadings and specialized formulations to address the higher exhaust temperatures and unique emission composition of rotary engines. These systems are particularly effective at reducing hydrocarbon emissions during cold-start conditions, which has been a persistent challenge for torque-optimized rotary calibrations.

Hybrid integration represents perhaps the most promising pathway for emissions-compliant rotary engines. By utilizing the rotary engine as a range extender or generator in a hybrid powertrain, the engine can be operated consistently at its optimal efficiency point, maximizing torque production while minimizing emissions. Mazda's e-Skyactiv R-EV system demonstrates this approach, using a small-displacement rotary engine operating at steady state to generate electricity while electric motors provide primary propulsion.

Advanced combustion control strategies, including variable rotor timing and multi-stage ignition systems, allow for more precise combustion phasing across the operating range. These technologies enable engineers to optimize the torque curve while maintaining emissions compliance through adaptive control algorithms that continuously adjust combustion parameters based on operating conditions.

Current emissions compliance strategies for modern rotary engines focus on several key approaches. Direct injection technology has emerged as a critical advancement, allowing for precise fuel delivery timing and quantity control. This technology significantly reduces unburned hydrocarbon emissions by minimizing fuel loss during the port overlap phase, a traditional weakness of rotary designs. When optimized for torque delivery, direct injection can be programmed to provide multiple injection events per combustion cycle, enhancing low-end torque while maintaining cleaner combustion.

Exhaust gas recirculation (EGR) systems have been adapted specifically for rotary applications to reduce combustion temperatures and minimize NOx formation. Advanced EGR systems with precise electronic control can be calibrated to maintain optimal torque characteristics while reducing emissions, particularly during partial load conditions where rotary engines traditionally struggle with efficiency.

Catalytic converter technology has also evolved specifically for rotary applications. Modern systems employ multi-stage catalysts with higher precious metal loadings and specialized formulations to address the higher exhaust temperatures and unique emission composition of rotary engines. These systems are particularly effective at reducing hydrocarbon emissions during cold-start conditions, which has been a persistent challenge for torque-optimized rotary calibrations.

Hybrid integration represents perhaps the most promising pathway for emissions-compliant rotary engines. By utilizing the rotary engine as a range extender or generator in a hybrid powertrain, the engine can be operated consistently at its optimal efficiency point, maximizing torque production while minimizing emissions. Mazda's e-Skyactiv R-EV system demonstrates this approach, using a small-displacement rotary engine operating at steady state to generate electricity while electric motors provide primary propulsion.

Advanced combustion control strategies, including variable rotor timing and multi-stage ignition systems, allow for more precise combustion phasing across the operating range. These technologies enable engineers to optimize the torque curve while maintaining emissions compliance through adaptive control algorithms that continuously adjust combustion parameters based on operating conditions.

Materials Science Advancements for Rotor Seal Technology

Recent advancements in materials science have opened new frontiers for addressing one of the Wankel engine's most persistent challenges: apex seal wear and friction that directly impact torque delivery. Traditional apex seals made from carbon-based materials suffer from rapid wear and inconsistent sealing properties, resulting in compression loss and reduced torque output, particularly at lower RPMs.

Ceramic composite materials represent a significant breakthrough in this domain. Silicon nitride and silicon carbide composites demonstrate superior hardness and thermal stability compared to conventional materials, maintaining their structural integrity under the extreme temperature conditions experienced in the combustion chamber. These advanced ceramics exhibit wear rates approximately 60% lower than traditional carbon seals while maintaining effective sealing properties across a broader temperature range.

Self-lubricating composite materials incorporating molybdenum disulfide and tungsten disulfide have shown promising results in reducing friction between the rotor and housing. Laboratory tests indicate friction coefficient reductions of up to 40% compared to standard seals, directly translating to improved mechanical efficiency and more consistent torque delivery throughout the RPM range.

Plasma-sprayed thermal barrier coatings represent another innovative approach, creating microscopically engineered surfaces that optimize the balance between sealing effectiveness and friction reduction. These coatings can be precisely tailored to specific engine designs and operating conditions, offering customized solutions for different performance requirements.

Diamond-like carbon (DLC) coatings applied through physical vapor deposition techniques have demonstrated exceptional wear resistance while maintaining low friction characteristics. When applied to both the apex seals and the epitrochoidal housing surface, these coatings create a synergistic effect that significantly extends service intervals while improving combustion chamber sealing efficiency.

Nano-engineered surface treatments that create precisely controlled surface textures at the microscopic level are showing promise in laboratory testing. These treatments create optimized contact patterns between the seal and housing surface, reducing friction without compromising sealing effectiveness. Early prototypes have demonstrated torque improvements of 7-12% across the operating range.

The integration of these advanced materials into production engines presents manufacturing challenges that researchers are actively addressing. Techniques such as spark plasma sintering and advanced ceramic injection molding are being refined to enable cost-effective mass production of these complex components while maintaining the precise tolerances required for optimal performance.

Ceramic composite materials represent a significant breakthrough in this domain. Silicon nitride and silicon carbide composites demonstrate superior hardness and thermal stability compared to conventional materials, maintaining their structural integrity under the extreme temperature conditions experienced in the combustion chamber. These advanced ceramics exhibit wear rates approximately 60% lower than traditional carbon seals while maintaining effective sealing properties across a broader temperature range.

Self-lubricating composite materials incorporating molybdenum disulfide and tungsten disulfide have shown promising results in reducing friction between the rotor and housing. Laboratory tests indicate friction coefficient reductions of up to 40% compared to standard seals, directly translating to improved mechanical efficiency and more consistent torque delivery throughout the RPM range.

Plasma-sprayed thermal barrier coatings represent another innovative approach, creating microscopically engineered surfaces that optimize the balance between sealing effectiveness and friction reduction. These coatings can be precisely tailored to specific engine designs and operating conditions, offering customized solutions for different performance requirements.

Diamond-like carbon (DLC) coatings applied through physical vapor deposition techniques have demonstrated exceptional wear resistance while maintaining low friction characteristics. When applied to both the apex seals and the epitrochoidal housing surface, these coatings create a synergistic effect that significantly extends service intervals while improving combustion chamber sealing efficiency.

Nano-engineered surface treatments that create precisely controlled surface textures at the microscopic level are showing promise in laboratory testing. These treatments create optimized contact patterns between the seal and housing surface, reducing friction without compromising sealing effectiveness. Early prototypes have demonstrated torque improvements of 7-12% across the operating range.

The integration of these advanced materials into production engines presents manufacturing challenges that researchers are actively addressing. Techniques such as spark plasma sintering and advanced ceramic injection molding are being refined to enable cost-effective mass production of these complex components while maintaining the precise tolerances required for optimal performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!