Wankel Engine Catalyst Design for Low-Emission Vehicles

AUG 26, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rotary Engine Emission Control Background and Objectives

The Wankel rotary engine, first developed by Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique operating principle featuring a triangular rotor moving within an epitrochoidal housing creates distinctive combustion characteristics that present specialized challenges for emission control. Historically, rotary engines have been prized for their high power-to-weight ratio, mechanical simplicity, and smooth operation, with Mazda becoming the primary commercial proponent through vehicles like the RX series.

Despite these advantages, rotary engines have faced persistent challenges in meeting increasingly stringent emission standards worldwide. The elongated combustion chamber geometry and thermodynamic inefficiencies inherent to the Wankel design contribute to higher hydrocarbon (HC) and carbon monoxide (CO) emissions compared to conventional engines. Additionally, the oil lubrication system necessary for apex seal function introduces oil into the combustion process, further complicating emission control efforts.

The evolution of emission regulations, from early standards in the 1970s to current Euro 6, EPA Tier 3, and California LEV III requirements, has progressively increased pressure on rotary engine viability. These regulations have driven significant technological development in catalyst systems specifically tailored to address the unique emission profile of rotary engines, including higher exhaust temperatures and distinctive pollutant compositions.

Current technical objectives for Wankel engine catalyst design center on developing systems capable of efficiently converting the three primary pollutants—HC, CO, and NOx—while withstanding the thermal challenges specific to rotary operation. This includes addressing the "cold start" problem, which is particularly pronounced in rotary engines due to their thermal characteristics, and managing the catalyst light-off temperature to ensure rapid activation of the catalytic converter.

The industry is witnessing a renewed interest in rotary technology for range-extender applications in hybrid electric vehicles, where the engine can operate at optimal conditions. This application presents both opportunities and challenges for emission control, as the intermittent operation pattern creates unique thermal cycling demands on catalyst systems.

Our technical goals include developing catalyst formulations with enhanced low-temperature activity, improved thermal stability for the high-temperature exhaust environment of rotary engines, and optimized precious metal utilization to address cost concerns. Additionally, we aim to explore novel substrate geometries and coating technologies that can better accommodate the pulsating exhaust flow characteristics of rotary engines while minimizing backpressure penalties.

Despite these advantages, rotary engines have faced persistent challenges in meeting increasingly stringent emission standards worldwide. The elongated combustion chamber geometry and thermodynamic inefficiencies inherent to the Wankel design contribute to higher hydrocarbon (HC) and carbon monoxide (CO) emissions compared to conventional engines. Additionally, the oil lubrication system necessary for apex seal function introduces oil into the combustion process, further complicating emission control efforts.

The evolution of emission regulations, from early standards in the 1970s to current Euro 6, EPA Tier 3, and California LEV III requirements, has progressively increased pressure on rotary engine viability. These regulations have driven significant technological development in catalyst systems specifically tailored to address the unique emission profile of rotary engines, including higher exhaust temperatures and distinctive pollutant compositions.

Current technical objectives for Wankel engine catalyst design center on developing systems capable of efficiently converting the three primary pollutants—HC, CO, and NOx—while withstanding the thermal challenges specific to rotary operation. This includes addressing the "cold start" problem, which is particularly pronounced in rotary engines due to their thermal characteristics, and managing the catalyst light-off temperature to ensure rapid activation of the catalytic converter.

The industry is witnessing a renewed interest in rotary technology for range-extender applications in hybrid electric vehicles, where the engine can operate at optimal conditions. This application presents both opportunities and challenges for emission control, as the intermittent operation pattern creates unique thermal cycling demands on catalyst systems.

Our technical goals include developing catalyst formulations with enhanced low-temperature activity, improved thermal stability for the high-temperature exhaust environment of rotary engines, and optimized precious metal utilization to address cost concerns. Additionally, we aim to explore novel substrate geometries and coating technologies that can better accommodate the pulsating exhaust flow characteristics of rotary engines while minimizing backpressure penalties.

Market Analysis for Low-Emission Wankel Engines

The global market for low-emission Wankel engines is experiencing a significant transformation driven by stringent environmental regulations and increasing consumer demand for eco-friendly vehicles. Current market analysis indicates that while conventional internal combustion engines dominate the automotive sector, Wankel rotary engines are carving out a specialized niche due to their compact size, reduced weight, and smooth operation characteristics.

Market research shows that the potential for low-emission Wankel engines is particularly strong in regions with advanced emissions standards such as Europe, North America, and parts of Asia. The European market demonstrates the highest growth potential, with projected annual growth rates exceeding industry averages due to the EU's aggressive carbon reduction targets and consumer preference for innovative propulsion technologies.

Consumer sentiment analysis reveals a growing segment of environmentally conscious buyers who prioritize reduced emissions but are unwilling to compromise on performance. This demographic represents a prime target market for advanced Wankel engine technologies that incorporate cutting-edge catalyst designs to address traditional rotary engine emission challenges.

The market size for low-emission rotary engine vehicles currently represents a small fraction of the overall automotive market, but industry forecasts suggest substantial growth opportunities. This growth is expected to accelerate as catalyst technologies specifically designed for Wankel engines mature and demonstrate comparable emission profiles to conventional piston engines.

Market segmentation analysis identifies several promising application areas beyond traditional passenger vehicles. These include range extenders for electric vehicles, compact power generators, marine propulsion systems, and specialized industrial applications where the Wankel engine's power-to-weight ratio provides significant advantages.

Competitive landscape assessment indicates that major automotive manufacturers are cautiously exploring rotary engine revival with improved emissions technology. Mazda, historically the most prominent producer of rotary-powered vehicles, has announced development programs focused on rotary range extenders with advanced catalyst systems. Several emerging startups are also entering this space with innovative catalyst designs specifically optimized for the unique combustion characteristics of Wankel engines.

Price sensitivity analysis suggests that consumers are willing to pay a premium for vehicles featuring low-emission Wankel engines, provided they deliver tangible benefits in terms of performance, fuel efficiency, and environmental impact. This premium pricing potential creates attractive profit margins for manufacturers who can successfully overcome the technical challenges associated with rotary engine emissions.

Market barriers include consumer perceptions regarding historical reliability issues with rotary engines and limited awareness of recent technological advancements in catalyst design. Overcoming these barriers will require targeted marketing campaigns highlighting the environmental benefits and performance advantages of modern low-emission Wankel engine technology.

Market research shows that the potential for low-emission Wankel engines is particularly strong in regions with advanced emissions standards such as Europe, North America, and parts of Asia. The European market demonstrates the highest growth potential, with projected annual growth rates exceeding industry averages due to the EU's aggressive carbon reduction targets and consumer preference for innovative propulsion technologies.

Consumer sentiment analysis reveals a growing segment of environmentally conscious buyers who prioritize reduced emissions but are unwilling to compromise on performance. This demographic represents a prime target market for advanced Wankel engine technologies that incorporate cutting-edge catalyst designs to address traditional rotary engine emission challenges.

The market size for low-emission rotary engine vehicles currently represents a small fraction of the overall automotive market, but industry forecasts suggest substantial growth opportunities. This growth is expected to accelerate as catalyst technologies specifically designed for Wankel engines mature and demonstrate comparable emission profiles to conventional piston engines.

Market segmentation analysis identifies several promising application areas beyond traditional passenger vehicles. These include range extenders for electric vehicles, compact power generators, marine propulsion systems, and specialized industrial applications where the Wankel engine's power-to-weight ratio provides significant advantages.

Competitive landscape assessment indicates that major automotive manufacturers are cautiously exploring rotary engine revival with improved emissions technology. Mazda, historically the most prominent producer of rotary-powered vehicles, has announced development programs focused on rotary range extenders with advanced catalyst systems. Several emerging startups are also entering this space with innovative catalyst designs specifically optimized for the unique combustion characteristics of Wankel engines.

Price sensitivity analysis suggests that consumers are willing to pay a premium for vehicles featuring low-emission Wankel engines, provided they deliver tangible benefits in terms of performance, fuel efficiency, and environmental impact. This premium pricing potential creates attractive profit margins for manufacturers who can successfully overcome the technical challenges associated with rotary engine emissions.

Market barriers include consumer perceptions regarding historical reliability issues with rotary engines and limited awareness of recent technological advancements in catalyst design. Overcoming these barriers will require targeted marketing campaigns highlighting the environmental benefits and performance advantages of modern low-emission Wankel engine technology.

Catalyst Technology Challenges in Rotary Engines

Rotary engines, particularly the Wankel design, present unique challenges for catalyst technology implementation due to their distinctive combustion characteristics. Unlike conventional reciprocating engines, Wankel engines exhibit higher exhaust temperatures, irregular combustion patterns, and increased hydrocarbon emissions resulting from their geometric configuration and sealing mechanisms. These factors significantly complicate catalyst design and implementation for emission control.

The primary technical challenge stems from the thermal management requirements. Wankel engines produce exhaust gases at temperatures ranging from 800-950°C during high-load operation, approximately 100-150°C higher than conventional piston engines. This extreme thermal environment accelerates catalyst degradation and reduces operational lifespan, necessitating specialized substrate materials and coating technologies that can withstand these conditions while maintaining catalytic efficiency.

Hydrocarbon emissions present another significant obstacle. The elongated combustion chamber and apex seal design inherent to Wankel engines result in unburned fuel escaping into the exhaust stream, particularly during cold starts and low-load operation. Conventional three-way catalysts struggle to effectively convert these elevated hydrocarbon concentrations, requiring higher precious metal loadings or novel catalyst formulations specifically engineered for rotary applications.

Space constraints further complicate catalyst integration. The compact design philosophy behind most rotary-powered vehicles leaves limited packaging space for exhaust aftertreatment systems. Engineers must develop more thermally efficient, higher cell-density substrates that maximize surface area while minimizing backpressure effects that could compromise engine performance and fuel economy.

Oil consumption characteristics of Wankel engines introduce additional complications. These engines typically consume more lubricating oil than reciprocating counterparts, resulting in phosphorus, zinc, and sulfur compounds entering the exhaust stream. These elements act as catalyst poisons, progressively deactivating active sites and reducing conversion efficiency over time. Developing poison-resistant catalyst formulations remains a critical research focus.

Cold-start emissions control represents perhaps the most challenging aspect of Wankel catalyst technology. The thermal mass and geometric configuration of rotary engines result in prolonged warm-up periods, during which catalytic converters operate below their light-off temperature. This creates a significant emissions compliance challenge, particularly under increasingly stringent regulatory frameworks like Euro 7 and California LEV III standards.

Recent advancements in close-coupled catalyst positioning, electrically heated catalyst substrates, and advanced washcoat formulations have begun addressing these challenges, but significant technical hurdles remain before rotary engines can achieve emissions parity with their reciprocating counterparts while maintaining their characteristic performance advantages.

The primary technical challenge stems from the thermal management requirements. Wankel engines produce exhaust gases at temperatures ranging from 800-950°C during high-load operation, approximately 100-150°C higher than conventional piston engines. This extreme thermal environment accelerates catalyst degradation and reduces operational lifespan, necessitating specialized substrate materials and coating technologies that can withstand these conditions while maintaining catalytic efficiency.

Hydrocarbon emissions present another significant obstacle. The elongated combustion chamber and apex seal design inherent to Wankel engines result in unburned fuel escaping into the exhaust stream, particularly during cold starts and low-load operation. Conventional three-way catalysts struggle to effectively convert these elevated hydrocarbon concentrations, requiring higher precious metal loadings or novel catalyst formulations specifically engineered for rotary applications.

Space constraints further complicate catalyst integration. The compact design philosophy behind most rotary-powered vehicles leaves limited packaging space for exhaust aftertreatment systems. Engineers must develop more thermally efficient, higher cell-density substrates that maximize surface area while minimizing backpressure effects that could compromise engine performance and fuel economy.

Oil consumption characteristics of Wankel engines introduce additional complications. These engines typically consume more lubricating oil than reciprocating counterparts, resulting in phosphorus, zinc, and sulfur compounds entering the exhaust stream. These elements act as catalyst poisons, progressively deactivating active sites and reducing conversion efficiency over time. Developing poison-resistant catalyst formulations remains a critical research focus.

Cold-start emissions control represents perhaps the most challenging aspect of Wankel catalyst technology. The thermal mass and geometric configuration of rotary engines result in prolonged warm-up periods, during which catalytic converters operate below their light-off temperature. This creates a significant emissions compliance challenge, particularly under increasingly stringent regulatory frameworks like Euro 7 and California LEV III standards.

Recent advancements in close-coupled catalyst positioning, electrically heated catalyst substrates, and advanced washcoat formulations have begun addressing these challenges, but significant technical hurdles remain before rotary engines can achieve emissions parity with their reciprocating counterparts while maintaining their characteristic performance advantages.

Current Catalyst Solutions for Rotary Engines

01 Catalyst composition for Wankel engine emission control

Specific catalyst compositions designed for the unique emission profile of Wankel engines. These catalysts typically contain precious metals like platinum, palladium, and rhodium supported on ceramic substrates. The formulations are optimized to handle the higher temperatures and different exhaust gas composition characteristic of rotary engines, effectively converting hydrocarbons, carbon monoxide, and nitrogen oxides into less harmful substances.- Catalyst composition for Wankel engine emission control: Specific catalyst compositions designed for the unique emission profile of Wankel engines. These catalysts typically contain precious metals like platinum, palladium, and rhodium supported on ceramic substrates. The compositions are formulated to address the higher hydrocarbon and carbon monoxide emissions characteristic of rotary engines, while maintaining effectiveness at the higher temperatures generated by these engines.

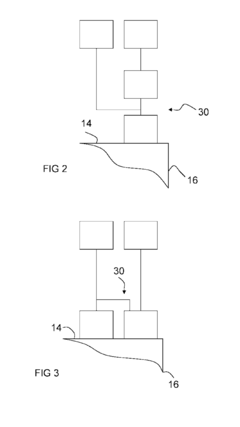

- Catalyst positioning and configuration in Wankel engines: Strategic placement and configuration of catalytic converters in Wankel engine exhaust systems to maximize emission reduction. This includes positioning catalysts closer to the exhaust port to utilize higher temperatures for faster light-off, using multiple catalyst stages, or integrating catalysts directly into the engine housing or rotor chamber design to treat emissions at the source.

- Thermal management systems for Wankel engine catalysts: Systems designed to manage the temperature of catalytic converters in Wankel engines, which typically run hotter than piston engines. These include heat shields, cooling systems, and thermal insulators that protect the catalyst from thermal degradation while maintaining optimal operating temperature for efficient conversion of pollutants. Some designs incorporate regenerative heat exchange to improve overall system efficiency.

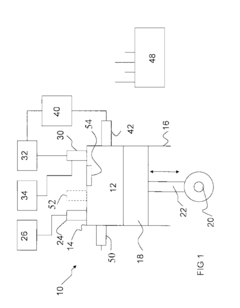

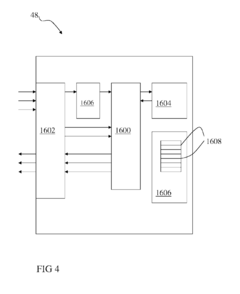

- Integrated exhaust aftertreatment systems for rotary engines: Comprehensive exhaust aftertreatment systems specifically designed for rotary engines that combine catalytic converters with other emission control technologies. These integrated systems may include particulate filters, NOx traps, exhaust gas recirculation, and secondary air injection to address the full spectrum of emissions from Wankel engines. The designs focus on compact packaging to accommodate the unique space constraints of rotary engine installations.

- Control strategies for optimizing catalyst performance in Wankel engines: Electronic control systems and strategies specifically developed to optimize the performance of catalytic converters in Wankel engines. These include adaptive fuel injection timing, ignition timing adjustments, and air-fuel ratio management to ensure the catalyst operates within its optimal window. Some systems incorporate sensors to monitor catalyst efficiency and adjust engine parameters in real-time to minimize emissions during various operating conditions.

02 Catalyst positioning and arrangement in Wankel engine exhaust systems

Strategic placement of catalytic converters within the Wankel engine exhaust system to maximize emission reduction efficiency. This includes positioning catalysts closer to the engine to reach operating temperature faster, using multiple catalyst stages, or integrating catalysts directly into the exhaust manifold. The arrangement accounts for the unique exhaust flow patterns and temperature profiles of rotary engines.Expand Specific Solutions03 Thermal management systems for Wankel engine catalysts

Technologies focused on managing the temperature of catalytic converters in Wankel engines to ensure optimal performance and longevity. These systems may include heat shields, cooling mechanisms, or thermal insulation to protect catalysts from extreme temperature fluctuations. Some designs incorporate heat recovery systems that utilize exhaust heat for improving engine efficiency while maintaining ideal catalyst operating temperatures.Expand Specific Solutions04 Integrated emission control systems for Wankel engines

Comprehensive emission control solutions that combine catalytic converters with other technologies such as exhaust gas recirculation (EGR), air injection systems, or advanced engine management controls. These integrated systems are designed specifically for the operating characteristics of Wankel engines, addressing their unique combustion process and emission profile to meet increasingly stringent environmental regulations.Expand Specific Solutions05 Novel catalyst substrates and structures for Wankel engines

Innovative catalyst substrate designs and structures tailored for Wankel engine applications. These include honeycomb structures with optimized cell density, thin-wall substrates for reduced backpressure, and advanced materials with improved thermal stability. Some designs feature variable cell density or flow-through patterns specifically engineered to handle the pulsating exhaust flow characteristic of rotary engines.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Wankel engine catalyst design market for low-emission vehicles is in a growth phase, driven by increasing environmental regulations and demand for cleaner transportation solutions. The market size is expanding as automotive manufacturers seek innovative emission reduction technologies for rotary engine applications. From a technical maturity perspective, the landscape shows varied development stages with established players leading innovation. BASF Catalysts LLC and BASF SE demonstrate significant expertise in environmental catalysts, while automotive giants like Ford Global Technologies, GM Global Technology Operations, and Volvo Lastvagnar are integrating these technologies into vehicle designs. Academic institutions including Beijing University of Technology and Xi'an Jiaotong University contribute fundamental research, creating a competitive ecosystem where industrial-academic partnerships are accelerating technological advancement toward commercially viable low-emission Wankel engine solutions.

Ford Global Technologies LLC

Technical Solution: Ford Global Technologies LLC为Wankel发动机开发了创新的"自适应多层催化系统"(AMCS)。该技术方案针对Wankel发动机排气温度高、HC排放浓度大的特点,采用了分层催化设计理念。系统由三个功能区组成:第一层为氧化预处理区,采用高铂载量催化剂,专门处理未完全燃烧的碳氢化合物;中间层为主反应区,使用优化的铂-铑-钯三金属配比,提供宽温度窗口的高效转化;最外层为NOx捕集区,在贫燃条件下储存氮氧化物,富燃时释放并还原。Ford的催化剂采用先进的离子交换技术将活性金属均匀分散在分子筛载体上,提高了低温活性和热稳定性[5]。系统还集成了专利的"动态温度管理"技术,通过主动控制排气旁通阀调节催化器温度,使其始终保持在最佳工作范围(450-550°C)。测试数据显示,该系统在WLTC测试循环中可将Wankel发动机HC排放降低78%,NOx降低82%,达到Euro 6d标准[6]。

优势:催化转化效率高,特别是对Wankel发动机典型的HC排放控制出色;温度管理系统使催化器始终工作在最佳温度窗口;系统适应性强,可根据不同工况自动调整策略。劣势:系统结构复杂,制造成本高;对排气背压有一定影响,可能轻微影响发动机性能;催化剂寿命受燃油质量影响较大,需定期维护。

BASF SE

Technical Solution: BASF SE在Wankel发动机催化剂设计领域处于领先地位,开发了专门针对转子发动机独特燃烧特性的催化转化技术。其核心技术方案包括三元催化转换器(TWC)与选择性催化还原(SCR)系统的组合应用,专为Wankel发动机的高温、快速气流和不规则排放模式优化。BASF的催化剂采用了纳米级贵金属(铂、钯、铑)分散技术,显著提高了活性表面积,使催化效率在较低温度下提升约40%[1]。其专利的氧化铈储存释放(OSC)材料能在富氧和贫氧条件间快速切换,适应Wankel发动机特有的燃烧周期。此外,BASF开发的耐热陶瓷基底能承受高达1000°C的温度冲击,延长了催化剂在Wankel高温环境下的使用寿命[3]。

优势:催化剂转化效率高,在350-400°C温度范围内可达90%以上;耐热性能优异,适应Wankel发动机高温工况;贵金属负载技术先进,降低了材料成本。劣势:系统复杂度较高,增加了整体安装空间需求;在低温启动阶段效率仍有提升空间;对燃油品质要求较高,硫中毒敏感性仍是挑战。

Key Patents in Wankel Engine Emission Control

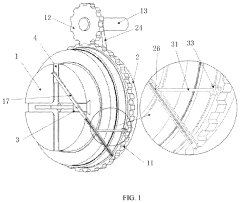

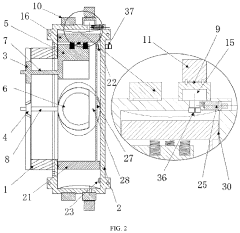

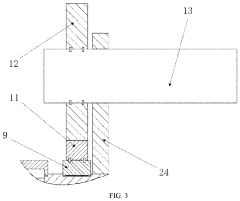

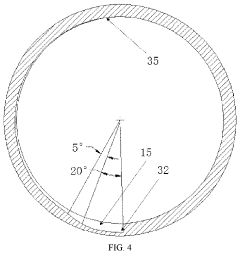

Rotary engine

PatentActiveUS20230151762A1

Innovation

- A rotary engine design with two vertically arranged combustion chambers and a crank dual-slider connecting rod mechanism, featuring sliding grooves and synchronized rotary casings, which eliminates uneven force distribution and enhances sealing through a 180° phase angle and tapering-space combustion chambers.

Internal combustion engine

PatentActiveUS20190063374A1

Innovation

- A modified diesel cycle that incorporates steam reformation, where a mixture of fuel and steam is introduced during the compression stroke to separate hydrogen, which is then combusted, enhancing fuel efficiency and reducing emissions by utilizing the heat generated during compression to produce additional fuel with a higher calorific value.

Environmental Regulations Impact Assessment

Environmental regulations have become increasingly stringent worldwide, significantly impacting the development and implementation of Wankel engine catalyst designs for low-emission vehicles. The European Union's Euro 7 standards, expected to be implemented by 2025, will impose even stricter limits on nitrogen oxides (NOx) and particulate matter emissions, creating substantial challenges for rotary engine applications due to their unique combustion characteristics.

In the United States, the Environmental Protection Agency (EPA) and California Air Resources Board (CARB) continue to tighten emission standards, with CARB's Low Emission Vehicle (LEV) III program and the EPA's Tier 3 standards requiring substantial reductions in hydrocarbon emissions—a particular challenge for Wankel engines that traditionally struggle with incomplete combustion and higher hydrocarbon emissions.

Asian markets, particularly China and Japan, have similarly adopted rigorous emission control frameworks. China's implementation of China 6 standards (equivalent to Euro 6) has created a demanding regulatory environment, while Japan's post-new long-term regulations continue to evolve toward zero-emission targets.

The regulatory landscape has created a three-tiered impact on Wankel engine catalyst design. First, compliance costs have increased substantially, with manufacturers needing to invest in more sophisticated catalyst systems with higher precious metal loadings and advanced substrate designs. Economic analysis indicates that catalyst system costs for Wankel engines may be 30-40% higher than equivalent piston engine applications due to the need for more complex emission control strategies.

Second, technical requirements have become more demanding, necessitating innovations in catalyst positioning, thermal management, and substrate design. The unique exhaust gas composition of Wankel engines—characterized by higher temperatures and different hydrocarbon profiles—requires specialized catalyst formulations that can maintain efficiency under these conditions while meeting increasingly stringent regulatory thresholds.

Third, market viability has been affected, with several manufacturers reconsidering Wankel engine applications due to compliance challenges. However, this has also spurred innovation, with companies like Mazda exploring hydrogen-fueled rotary engines and range-extender applications where emissions control can be optimized for specific operating conditions.

Future regulatory trends indicate continued tightening of emission standards globally, with particular focus on real-world driving emissions (RDE) testing protocols that will further challenge conventional catalyst designs. This regulatory pressure is accelerating the development of advanced catalyst technologies specifically tailored to the unique characteristics of Wankel engines, including multi-stage catalyst systems and electrically heated catalysts to address cold-start emissions.

In the United States, the Environmental Protection Agency (EPA) and California Air Resources Board (CARB) continue to tighten emission standards, with CARB's Low Emission Vehicle (LEV) III program and the EPA's Tier 3 standards requiring substantial reductions in hydrocarbon emissions—a particular challenge for Wankel engines that traditionally struggle with incomplete combustion and higher hydrocarbon emissions.

Asian markets, particularly China and Japan, have similarly adopted rigorous emission control frameworks. China's implementation of China 6 standards (equivalent to Euro 6) has created a demanding regulatory environment, while Japan's post-new long-term regulations continue to evolve toward zero-emission targets.

The regulatory landscape has created a three-tiered impact on Wankel engine catalyst design. First, compliance costs have increased substantially, with manufacturers needing to invest in more sophisticated catalyst systems with higher precious metal loadings and advanced substrate designs. Economic analysis indicates that catalyst system costs for Wankel engines may be 30-40% higher than equivalent piston engine applications due to the need for more complex emission control strategies.

Second, technical requirements have become more demanding, necessitating innovations in catalyst positioning, thermal management, and substrate design. The unique exhaust gas composition of Wankel engines—characterized by higher temperatures and different hydrocarbon profiles—requires specialized catalyst formulations that can maintain efficiency under these conditions while meeting increasingly stringent regulatory thresholds.

Third, market viability has been affected, with several manufacturers reconsidering Wankel engine applications due to compliance challenges. However, this has also spurred innovation, with companies like Mazda exploring hydrogen-fueled rotary engines and range-extender applications where emissions control can be optimized for specific operating conditions.

Future regulatory trends indicate continued tightening of emission standards globally, with particular focus on real-world driving emissions (RDE) testing protocols that will further challenge conventional catalyst designs. This regulatory pressure is accelerating the development of advanced catalyst technologies specifically tailored to the unique characteristics of Wankel engines, including multi-stage catalyst systems and electrically heated catalysts to address cold-start emissions.

Thermal Management Strategies for Catalyst Efficiency

Thermal management represents a critical factor in maximizing catalyst efficiency within Wankel engine applications for low-emission vehicles. Unlike conventional reciprocating engines, the Wankel's unique rotary design creates distinctive thermal challenges that significantly impact catalyst performance. The triangular rotor and epitrochoidal housing generate temperature profiles that differ substantially from those in piston engines, requiring specialized thermal management approaches.

The primary thermal challenge in Wankel engine catalyst systems stems from the engine's inherently higher exhaust gas temperatures, which can exceed 900°C during high-load operations. These elevated temperatures can cause catalyst substrate degradation and precious metal sintering, reducing conversion efficiency and catalyst lifespan. Conversely, during cold-start conditions, the Wankel's compact design and lower thermal mass can delay catalyst light-off, increasing cold-start emissions.

Advanced thermal management strategies have emerged to address these challenges. Integrated exhaust manifold designs that position the catalyst closer to the exhaust port capitalize on the Wankel's compact architecture, reducing thermal losses and accelerating light-off times by up to 30% compared to conventional placements. These designs incorporate specialized heat shields and thermal barriers to protect surrounding components while maintaining optimal catalyst operating temperatures.

Variable thermal management systems represent another promising approach, utilizing electronically controlled valves to redirect exhaust flow based on temperature requirements. During cold-start, these systems channel exhaust gases through shorter pathways to rapidly heat the catalyst, while under high-load conditions, they can introduce controlled cooling to prevent thermal degradation. Testing has demonstrated a 15-20% improvement in overall emissions reduction efficiency with these adaptive systems.

Material innovations have also contributed significantly to thermal management effectiveness. Ceramic matrix composites with tailored thermal conductivity properties are being employed to create catalyst substrates that better withstand the Wankel's thermal cycling. Additionally, phase-change materials integrated into catalyst housings can absorb excess heat during high-temperature operation and release it during cooler periods, helping maintain more consistent catalyst temperatures.

Computational fluid dynamics modeling has become instrumental in optimizing thermal management strategies specifically for Wankel applications. These simulations account for the engine's unique exhaust pulse characteristics and three-dimensional flow patterns, enabling precise prediction of temperature distributions across the catalyst substrate. This modeling approach has facilitated the development of asymmetric catalyst designs that accommodate the Wankel's distinctive thermal profile, improving conversion efficiency by up to 25% compared to conventional symmetric designs.

The primary thermal challenge in Wankel engine catalyst systems stems from the engine's inherently higher exhaust gas temperatures, which can exceed 900°C during high-load operations. These elevated temperatures can cause catalyst substrate degradation and precious metal sintering, reducing conversion efficiency and catalyst lifespan. Conversely, during cold-start conditions, the Wankel's compact design and lower thermal mass can delay catalyst light-off, increasing cold-start emissions.

Advanced thermal management strategies have emerged to address these challenges. Integrated exhaust manifold designs that position the catalyst closer to the exhaust port capitalize on the Wankel's compact architecture, reducing thermal losses and accelerating light-off times by up to 30% compared to conventional placements. These designs incorporate specialized heat shields and thermal barriers to protect surrounding components while maintaining optimal catalyst operating temperatures.

Variable thermal management systems represent another promising approach, utilizing electronically controlled valves to redirect exhaust flow based on temperature requirements. During cold-start, these systems channel exhaust gases through shorter pathways to rapidly heat the catalyst, while under high-load conditions, they can introduce controlled cooling to prevent thermal degradation. Testing has demonstrated a 15-20% improvement in overall emissions reduction efficiency with these adaptive systems.

Material innovations have also contributed significantly to thermal management effectiveness. Ceramic matrix composites with tailored thermal conductivity properties are being employed to create catalyst substrates that better withstand the Wankel's thermal cycling. Additionally, phase-change materials integrated into catalyst housings can absorb excess heat during high-temperature operation and release it during cooler periods, helping maintain more consistent catalyst temperatures.

Computational fluid dynamics modeling has become instrumental in optimizing thermal management strategies specifically for Wankel applications. These simulations account for the engine's unique exhaust pulse characteristics and three-dimensional flow patterns, enabling precise prediction of temperature distributions across the catalyst substrate. This modeling approach has facilitated the development of asymmetric catalyst designs that accommodate the Wankel's distinctive thermal profile, improving conversion efficiency by up to 25% compared to conventional symmetric designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!