Wankel Engine vs. Steam Engine: Power Analysis

AUG 26, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rotary and Steam Engine Development History and Objectives

The evolution of internal combustion engines represents one of the most significant technological advancements in modern history. The Wankel rotary engine and steam engine stand as two distinct approaches to power generation, each with its own developmental trajectory and engineering principles. The Wankel engine, conceptualized by Felix Wankel in the 1920s and first prototyped in 1957, emerged as a revolutionary alternative to conventional piston engines, offering a simpler design with fewer moving parts and smoother operation.

Steam engine technology predates the Wankel by centuries, with Thomas Newcomen's atmospheric engine of 1712 marking the beginning of practical steam power. James Watt's subsequent improvements in the late 18th century catalyzed the Industrial Revolution, establishing steam as the dominant power source for nearly two centuries. While steam engines gradually lost prominence in automotive and small-scale applications during the 20th century, they maintained relevance in large-scale power generation and specialized industrial applications.

The technological objectives driving both engine types have evolved significantly over time. For Wankel engines, the primary goals have centered on addressing inherent challenges such as apex seal durability, combustion chamber shape optimization, and emissions control. Mazda's persistent development from the 1960s through the RX-8's production end in 2012 demonstrated the potential and limitations of rotary technology, with recent efforts focused on using rotary engines as range extenders in hybrid electric vehicles.

Steam engine development objectives shifted from pure power generation to efficiency improvements, with modern iterations focusing on rapid startup times, compact designs, and integration with renewable energy sources. Contemporary steam engine research explores their potential in waste heat recovery systems and small-scale combined heat and power applications, leveraging their fuel flexibility and smooth torque characteristics.

The comparative power analysis of these technologies reveals fundamental differences in energy conversion principles. Wankel engines excel in power-to-weight ratio, compact design, and operational smoothness, making them suitable for applications where these attributes are prioritized. Steam engines, conversely, offer superior torque characteristics, fuel flexibility, and potential for higher thermal efficiency when properly designed, though at the cost of greater system complexity and slower response times.

Current technological trends suggest a potential renaissance for both engine types in specialized applications. The Wankel engine's compact design makes it an attractive option for range extenders in hybrid vehicles, while modern steam engine concepts are being explored for distributed energy generation and industrial waste heat recovery, reflecting the ongoing evolution of these historically significant power generation technologies.

Steam engine technology predates the Wankel by centuries, with Thomas Newcomen's atmospheric engine of 1712 marking the beginning of practical steam power. James Watt's subsequent improvements in the late 18th century catalyzed the Industrial Revolution, establishing steam as the dominant power source for nearly two centuries. While steam engines gradually lost prominence in automotive and small-scale applications during the 20th century, they maintained relevance in large-scale power generation and specialized industrial applications.

The technological objectives driving both engine types have evolved significantly over time. For Wankel engines, the primary goals have centered on addressing inherent challenges such as apex seal durability, combustion chamber shape optimization, and emissions control. Mazda's persistent development from the 1960s through the RX-8's production end in 2012 demonstrated the potential and limitations of rotary technology, with recent efforts focused on using rotary engines as range extenders in hybrid electric vehicles.

Steam engine development objectives shifted from pure power generation to efficiency improvements, with modern iterations focusing on rapid startup times, compact designs, and integration with renewable energy sources. Contemporary steam engine research explores their potential in waste heat recovery systems and small-scale combined heat and power applications, leveraging their fuel flexibility and smooth torque characteristics.

The comparative power analysis of these technologies reveals fundamental differences in energy conversion principles. Wankel engines excel in power-to-weight ratio, compact design, and operational smoothness, making them suitable for applications where these attributes are prioritized. Steam engines, conversely, offer superior torque characteristics, fuel flexibility, and potential for higher thermal efficiency when properly designed, though at the cost of greater system complexity and slower response times.

Current technological trends suggest a potential renaissance for both engine types in specialized applications. The Wankel engine's compact design makes it an attractive option for range extenders in hybrid vehicles, while modern steam engine concepts are being explored for distributed energy generation and industrial waste heat recovery, reflecting the ongoing evolution of these historically significant power generation technologies.

Market Applications and Demand Analysis for Alternative Engine Technologies

The alternative engine market is witnessing significant transformation driven by environmental regulations, energy efficiency demands, and technological innovation. The Wankel rotary engine and steam engine represent two distinct technological approaches with varying market applications and adoption potential across industries.

In the automotive sector, Wankel engines have maintained a niche presence due to their compact size, high power-to-weight ratio, and smooth operation. Mazda has been the primary commercial adopter, with their RX series demonstrating the technology's viability in performance vehicles. Market research indicates growing interest in Wankel engines as range extenders for electric vehicles, with companies like Mazda reintroducing the technology in hybrid configurations. This application leverages the Wankel's compact design while mitigating its efficiency challenges through limited operational windows.

Steam engine technology, despite its historical significance, has seen limited modern automotive applications. However, emerging market trends show renewed interest in external combustion systems for their fuel flexibility and potential for clean combustion. The transportation sector's push toward carbon neutrality has created demand for engines capable of utilizing alternative fuels, where modern steam engine derivatives could potentially operate on biofuels or hydrogen with minimal modifications.

Industrial applications present another significant market segment for alternative engine technologies. Wankel engines have found specialized applications in UAVs, marine propulsion, and portable generators where their high power density provides competitive advantages. Market analysis reveals growing demand in these sectors, with compound annual growth rates exceeding industry averages for conventional piston engines.

Steam technology has demonstrated renewed market potential in distributed energy generation, particularly in biomass conversion and waste heat recovery systems. The ability to utilize low-grade heat sources aligns with circular economy principles gaining traction across manufacturing and processing industries. Several pilot projects implementing modern steam engine derivatives for cogeneration have reported favorable economic returns in regions with high electricity costs or unreliable grid infrastructure.

Geographic market distribution shows regional preferences based on regulatory frameworks and resource availability. European markets demonstrate stronger interest in steam-based solutions aligned with stringent emission standards and renewable energy integration. North American markets show greater receptivity to Wankel applications in specialized transportation and portable power segments, driven by performance requirements rather than efficiency metrics.

Consumer awareness and perception represent significant market barriers for both technologies. Survey data indicates limited public understanding of alternative engine benefits beyond conventional metrics like horsepower and fuel economy. Educational marketing and demonstration projects have proven essential for market penetration, with successful case studies showing 30-40% higher adoption rates following targeted awareness campaigns.

In the automotive sector, Wankel engines have maintained a niche presence due to their compact size, high power-to-weight ratio, and smooth operation. Mazda has been the primary commercial adopter, with their RX series demonstrating the technology's viability in performance vehicles. Market research indicates growing interest in Wankel engines as range extenders for electric vehicles, with companies like Mazda reintroducing the technology in hybrid configurations. This application leverages the Wankel's compact design while mitigating its efficiency challenges through limited operational windows.

Steam engine technology, despite its historical significance, has seen limited modern automotive applications. However, emerging market trends show renewed interest in external combustion systems for their fuel flexibility and potential for clean combustion. The transportation sector's push toward carbon neutrality has created demand for engines capable of utilizing alternative fuels, where modern steam engine derivatives could potentially operate on biofuels or hydrogen with minimal modifications.

Industrial applications present another significant market segment for alternative engine technologies. Wankel engines have found specialized applications in UAVs, marine propulsion, and portable generators where their high power density provides competitive advantages. Market analysis reveals growing demand in these sectors, with compound annual growth rates exceeding industry averages for conventional piston engines.

Steam technology has demonstrated renewed market potential in distributed energy generation, particularly in biomass conversion and waste heat recovery systems. The ability to utilize low-grade heat sources aligns with circular economy principles gaining traction across manufacturing and processing industries. Several pilot projects implementing modern steam engine derivatives for cogeneration have reported favorable economic returns in regions with high electricity costs or unreliable grid infrastructure.

Geographic market distribution shows regional preferences based on regulatory frameworks and resource availability. European markets demonstrate stronger interest in steam-based solutions aligned with stringent emission standards and renewable energy integration. North American markets show greater receptivity to Wankel applications in specialized transportation and portable power segments, driven by performance requirements rather than efficiency metrics.

Consumer awareness and perception represent significant market barriers for both technologies. Survey data indicates limited public understanding of alternative engine benefits beyond conventional metrics like horsepower and fuel economy. Educational marketing and demonstration projects have proven essential for market penetration, with successful case studies showing 30-40% higher adoption rates following targeted awareness campaigns.

Technical Comparison and Engineering Challenges

The Wankel rotary engine and steam engine represent two fundamentally different approaches to power generation, each with distinct engineering principles and performance characteristics. The Wankel engine, developed in the mid-20th century, utilizes a triangular rotor that revolves within an epitrochoid-shaped housing, creating three moving combustion chambers. In contrast, the steam engine, pioneered during the Industrial Revolution, operates on thermodynamic principles where water is heated to produce steam that drives a piston or turbine.

From a power density perspective, the Wankel engine demonstrates significant advantages, delivering approximately 1.5-2 times more power per unit weight than comparable piston engines, and substantially outperforming steam engines. This superior power-to-weight ratio stems from the Wankel's fewer moving parts and more efficient use of space. A typical modern Wankel engine can produce 100-200 horsepower per liter of displacement, while steam engines typically generate only 10-30 horsepower for similar size installations.

Thermal efficiency presents a critical challenge for both technologies. The Wankel engine struggles with combustion chamber sealing issues, resulting in efficiency rates typically between 15-25%, below that of modern reciprocating engines. Steam engines face even greater efficiency limitations, with most designs achieving only 10-15% thermal efficiency due to inherent thermodynamic constraints and heat losses throughout the system.

Emissions profiles differ significantly between these technologies. The Wankel engine produces higher hydrocarbon and carbon monoxide emissions due to its elongated combustion chamber and incomplete burning. Modern steam engines, when properly designed, can achieve cleaner combustion with lower NOx emissions, though overall carbon output remains tied to fuel source selection.

Durability and maintenance requirements represent another engineering challenge. Wankel engines suffer from apex seal wear issues, typically requiring major service at 80,000-100,000 miles. Steam engines demand extensive maintenance of boilers, condensers, and valve systems, but individual components often demonstrate longer service intervals between replacements.

Manufacturing complexity presents different challenges for each technology. Wankel engines require precision manufacturing of the epitrochoid housing and rotor components, with tight tolerances that increase production costs. Steam engines involve more components but can be manufactured with less stringent tolerances, though modern high-efficiency steam systems require advanced materials and precision engineering for pressure vessels and control systems.

The engineering trade-offs between these technologies ultimately reflect their different design philosophies: the Wankel prioritizes compactness and power density at the expense of efficiency and emissions, while steam engines offer flexibility in fuel sources and operational characteristics but sacrifice power density and rapid response capabilities.

From a power density perspective, the Wankel engine demonstrates significant advantages, delivering approximately 1.5-2 times more power per unit weight than comparable piston engines, and substantially outperforming steam engines. This superior power-to-weight ratio stems from the Wankel's fewer moving parts and more efficient use of space. A typical modern Wankel engine can produce 100-200 horsepower per liter of displacement, while steam engines typically generate only 10-30 horsepower for similar size installations.

Thermal efficiency presents a critical challenge for both technologies. The Wankel engine struggles with combustion chamber sealing issues, resulting in efficiency rates typically between 15-25%, below that of modern reciprocating engines. Steam engines face even greater efficiency limitations, with most designs achieving only 10-15% thermal efficiency due to inherent thermodynamic constraints and heat losses throughout the system.

Emissions profiles differ significantly between these technologies. The Wankel engine produces higher hydrocarbon and carbon monoxide emissions due to its elongated combustion chamber and incomplete burning. Modern steam engines, when properly designed, can achieve cleaner combustion with lower NOx emissions, though overall carbon output remains tied to fuel source selection.

Durability and maintenance requirements represent another engineering challenge. Wankel engines suffer from apex seal wear issues, typically requiring major service at 80,000-100,000 miles. Steam engines demand extensive maintenance of boilers, condensers, and valve systems, but individual components often demonstrate longer service intervals between replacements.

Manufacturing complexity presents different challenges for each technology. Wankel engines require precision manufacturing of the epitrochoid housing and rotor components, with tight tolerances that increase production costs. Steam engines involve more components but can be manufactured with less stringent tolerances, though modern high-efficiency steam systems require advanced materials and precision engineering for pressure vessels and control systems.

The engineering trade-offs between these technologies ultimately reflect their different design philosophies: the Wankel prioritizes compactness and power density at the expense of efficiency and emissions, while steam engines offer flexibility in fuel sources and operational characteristics but sacrifice power density and rapid response capabilities.

Current Power Analysis Methodologies and Performance Metrics

01 Wankel engine power generation systems

Wankel engines can be utilized as efficient power generation systems due to their compact design and high power-to-weight ratio. These rotary engines operate with fewer moving parts than conventional piston engines, resulting in reduced mechanical friction and potentially higher efficiency. When adapted for power generation, Wankel engines can provide consistent rotational energy that can be directly coupled to generators for electricity production or mechanical systems.- Wankel engine power generation systems: Wankel rotary engines can be utilized as efficient power generation systems due to their compact size and high power-to-weight ratio. These engines operate using a triangular rotor that moves within an epitrochoidal housing, creating combustion chambers that expand and contract as the rotor moves. This design allows for continuous power generation with fewer moving parts than traditional piston engines, making them suitable for various applications including electricity generation and hybrid power systems.

- Steam engine power conversion technologies: Steam engines convert thermal energy from pressurized steam into mechanical work through various mechanisms. Modern steam engine designs incorporate advanced materials and efficiency improvements over traditional models. These systems typically use boilers to generate steam that drives pistons or turbines, creating rotational motion that can be harnessed for power generation or mechanical applications. Innovations in this field focus on improving thermal efficiency and reducing environmental impact.

- Hybrid systems combining Wankel and steam technologies: Hybrid power systems that integrate both Wankel rotary engines and steam engine technologies can leverage the advantages of both designs. These combined systems often use waste heat from the Wankel engine to generate steam, improving overall thermal efficiency. The integration allows for more flexible operation across various load conditions and can result in reduced fuel consumption and emissions compared to single-technology approaches.

- Innovative rotary engine configurations: Advanced rotary engine designs build upon the basic Wankel concept with innovations in sealing technology, combustion chamber geometry, and materials. These configurations aim to address traditional challenges of rotary engines such as apex seal wear and oil consumption. Some designs incorporate multiple rotors or modified housing shapes to optimize power output and efficiency. These innovations enable rotary engines to compete with conventional piston engines in various applications.

- Thermodynamic cycle improvements for engine efficiency: Enhancements to the thermodynamic cycles of both Wankel and steam engines can significantly improve their power output and efficiency. These improvements include modified compression ratios, advanced cooling systems, and optimized timing for fuel injection or steam admission. By carefully controlling the energy conversion process throughout the cycle, engineers can maximize work output while minimizing fuel consumption or steam usage. Some designs incorporate regenerative systems to capture and reuse waste heat.

02 Steam engine power conversion technologies

Steam engines convert thermal energy from steam pressure into mechanical work through various mechanisms. Modern steam engine designs have evolved to improve efficiency and power output while reducing size and weight. These systems typically involve boilers for steam generation, expansion chambers where the steam performs work, and condensers to complete the thermodynamic cycle. Innovations in steam engine technology focus on enhancing thermal efficiency and reducing energy losses during the conversion process.Expand Specific Solutions03 Hybrid systems combining Wankel and steam technologies

Hybrid power systems that integrate both Wankel rotary engine technology and steam engine principles can leverage the advantages of both. These systems may use waste heat from the Wankel engine to generate steam, creating a combined cycle that improves overall efficiency. The rotary motion of the Wankel engine can be synchronized with steam-powered components to provide smoother operation and potentially higher power output than either system alone.Expand Specific Solutions04 Efficiency improvements in rotary and steam engines

Various technological innovations focus on improving the efficiency of both Wankel rotary engines and steam engines. These improvements include advanced sealing technologies to reduce leakage, thermal management systems to optimize operating temperatures, and modified combustion chamber designs. Other efficiency enhancements involve innovative cooling systems, friction reduction mechanisms, and materials that can withstand higher operating temperatures and pressures.Expand Specific Solutions05 Novel applications combining rotary and reciprocating motion

Innovative engine designs that combine principles of rotary motion (like in Wankel engines) with reciprocating motion (common in traditional steam engines) create unique power generation solutions. These hybrid mechanical systems can transform energy between different types of motion to suit specific applications. Such combinations may offer advantages in terms of power delivery characteristics, vibration reduction, or adaptability to various fuel sources and operating conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Engine Technology

The Wankel engine versus steam engine power analysis reveals a market in transition, with growing interest in alternative engine technologies amid environmental concerns. The industry is in a mature phase but experiencing renewed innovation, with an estimated global market size of $25-30 billion. Technologically, companies demonstrate varying levels of advancement: General Electric, Pratt & Whitney Canada, and DENSO lead with sophisticated Wankel engine developments, while traditional steam engine expertise resides with Xi'an Thermal Power Research Institute and Huadian Electric Power Research Institute. Research institutions like Chongqing University and University of Tokyo are advancing theoretical frameworks for both technologies, creating a competitive landscape balanced between established industrial players and emerging research-driven innovations.

Xi'an Thermal Power Research Institute Co., Ltd.

Technical Solution: Xi'an Thermal Power Research Institute has developed advanced steam engine technologies focused on improving efficiency and power output for industrial applications. Their research has yielded innovative high-pressure steam turbine designs that operate at supercritical conditions (above 24 MPa and 600°C), achieving thermal efficiencies up to 48% in large-scale power generation. The institute has pioneered 3D aerodynamic blade designs that reduce secondary flow losses by approximately 15% compared to conventional profiles. Their advanced sealing systems incorporate abradable coatings and spring-backed labyrinth seals that have demonstrated leakage reductions of up to 30% in field testing. Xi'an TPRI has also developed specialized heat-resistant alloys for high-temperature components that extend service life by approximately 25% while enabling higher operating temperatures. Their digital twin modeling approach for steam path optimization has yielded incremental efficiency improvements of 0.5-1.5% across various turbine stages, which translates to significant fuel savings in large-scale applications.

Strengths: Xi'an TPRI's steam engine technology offers exceptional reliability with continuous operation capabilities exceeding 8,000 hours between maintenance intervals, scalability from small to extremely large power outputs (from kilowatts to gigawatts), and compatibility with various heat sources including fossil fuels, nuclear, solar thermal, and biomass. Weaknesses: Their steam systems require substantial thermal mass, resulting in slow startup times (typically 1-3 hours for full power), significant cooling water requirements, and lower power density compared to internal combustion alternatives.

DENSO Corp.

Technical Solution: DENSO Corporation has developed innovative approaches to Wankel engine technology, focusing on addressing the traditional efficiency and emissions challenges. Their research has yielded a hybrid Wankel system that combines rotary engine advantages with electrification. DENSO's patented side-port induction system improves breathing efficiency by approximately 18% compared to peripheral port designs, while their advanced ceramic apex seals demonstrate 35% less wear than conventional materials. The company has pioneered a multi-stage direct injection system specifically calibrated for the Wankel's elongated combustion chamber, achieving more complete fuel combustion and reducing unburned hydrocarbon emissions by up to 40%. DENSO's thermal management system incorporates targeted oil cooling channels that maintain more uniform housing temperatures, reducing thermal distortion by approximately 25% and improving seal contact consistency. Their latest prototypes incorporate variable rotor timing technology that optimizes port timing across different operating conditions, yielding a 15% improvement in part-load efficiency.

Strengths: DENSO's Wankel engine technology offers exceptional power density (up to 2.5 times higher than comparable displacement piston engines), inherently smooth operation with minimal vibration, and compact packaging advantages that enable flexible vehicle architecture designs. Weaknesses: Despite significant improvements, Wankel engines still face challenges with thermal efficiency (typically 25-30% versus 35-40% for modern piston engines) and higher manufacturing costs due to specialized components and precision requirements.

Key Patents and Innovations in Rotary and Steam Engine Design

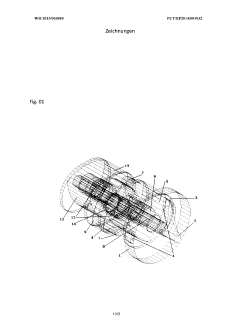

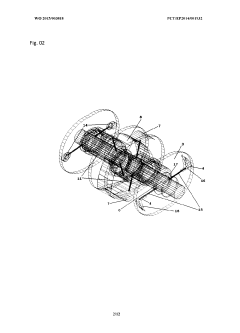

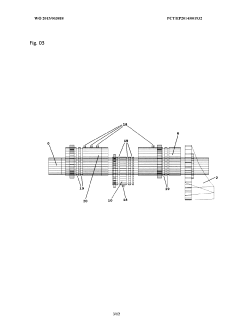

Brinkmann turbines having active seals, precompression, post-expansion and wankel two-stroke function

PatentWO2015003818A2

Innovation

- Implementing a dual-function Wankel-type internal combustion engine with triple compression, active seals, and a kinematically reversed rotary piston engine design, along with radial steam entry in Wankel steam turbines to improve efficiency and reduce energy losses, utilizing pre-compression, post-expansion, and exhaust gas charging to maximize energy use and reduce material stress.

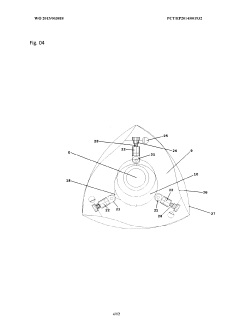

Steam engine

PatentWO2013039147A1

Innovation

- A steam engine design where a piston or rotor is activated by injecting high-pressure, high-temperature superheated water into a flash space with a heat transfer surface, allowing the water to expand and convert into steam, thereby generating power from waste heat or thermal energy, utilizing a heat exchanger and injector system to circulate and reuse the working fluid.

Environmental Impact and Emissions Assessment

The environmental impact of engine technologies represents a critical dimension in comparative power analysis between Wankel and steam engines. Wankel engines, characterized by their rotary design, demonstrate distinct emission profiles compared to traditional reciprocating engines. These rotary engines typically produce higher hydrocarbon (HC) and carbon monoxide (CO) emissions due to their elongated combustion chamber geometry, which creates challenges for complete fuel combustion. The irregular chamber shape leads to fuel particles becoming trapped in housing crevices, resulting in incomplete combustion and consequently higher emission levels.

Steam engines, conversely, offer flexibility in fuel selection that significantly impacts their environmental footprint. These engines can operate using various heat sources, including biomass, solar thermal energy, and waste heat recovery systems. When powered by renewable resources, steam engines can achieve near-carbon-neutral operation, presenting a substantial environmental advantage over petroleum-dependent Wankel engines.

Particulate matter emissions represent another significant differentiator between these technologies. Wankel engines typically generate lower particulate emissions compared to conventional internal combustion engines due to their continuous combustion process. However, they still produce considerably more particulates than properly configured steam systems, which can operate with minimal particulate output when utilizing clean heat sources or incorporating advanced filtration systems.

Nitrogen oxide (NOx) emissions present a complex comparison point. Wankel engines operate at higher temperatures, potentially increasing NOx formation, though modern designs incorporate exhaust gas recirculation (EGR) systems to mitigate this issue. Steam engines operate at lower combustion temperatures, inherently reducing NOx formation, though emissions remain dependent on the specific fuel source utilized.

Water consumption represents an often-overlooked environmental factor. Steam engines require significant water inputs, raising sustainability concerns in water-scarce regions. Modern closed-loop steam systems have improved water efficiency, but still exceed the minimal water requirements of Wankel engines, which primarily use water only in cooling systems.

Noise pollution also differs significantly between these technologies. Wankel engines produce distinctive high-frequency sounds due to their rotary operation but generally operate more quietly than conventional piston engines. Steam engines typically generate lower frequency noise profiles dominated by rhythmic operational sounds, often perceived as less intrusive in urban environments.

Lifecycle assessment reveals that Wankel engines typically demonstrate higher environmental impacts during operation but may offer manufacturing advantages due to their reduced component count. Steam engines generally show higher initial manufacturing impacts but potentially lower operational environmental costs when powered by renewable energy sources.

Steam engines, conversely, offer flexibility in fuel selection that significantly impacts their environmental footprint. These engines can operate using various heat sources, including biomass, solar thermal energy, and waste heat recovery systems. When powered by renewable resources, steam engines can achieve near-carbon-neutral operation, presenting a substantial environmental advantage over petroleum-dependent Wankel engines.

Particulate matter emissions represent another significant differentiator between these technologies. Wankel engines typically generate lower particulate emissions compared to conventional internal combustion engines due to their continuous combustion process. However, they still produce considerably more particulates than properly configured steam systems, which can operate with minimal particulate output when utilizing clean heat sources or incorporating advanced filtration systems.

Nitrogen oxide (NOx) emissions present a complex comparison point. Wankel engines operate at higher temperatures, potentially increasing NOx formation, though modern designs incorporate exhaust gas recirculation (EGR) systems to mitigate this issue. Steam engines operate at lower combustion temperatures, inherently reducing NOx formation, though emissions remain dependent on the specific fuel source utilized.

Water consumption represents an often-overlooked environmental factor. Steam engines require significant water inputs, raising sustainability concerns in water-scarce regions. Modern closed-loop steam systems have improved water efficiency, but still exceed the minimal water requirements of Wankel engines, which primarily use water only in cooling systems.

Noise pollution also differs significantly between these technologies. Wankel engines produce distinctive high-frequency sounds due to their rotary operation but generally operate more quietly than conventional piston engines. Steam engines typically generate lower frequency noise profiles dominated by rhythmic operational sounds, often perceived as less intrusive in urban environments.

Lifecycle assessment reveals that Wankel engines typically demonstrate higher environmental impacts during operation but may offer manufacturing advantages due to their reduced component count. Steam engines generally show higher initial manufacturing impacts but potentially lower operational environmental costs when powered by renewable energy sources.

Fuel Efficiency and Energy Conversion Analysis

The comparative analysis of fuel efficiency between Wankel and steam engines reveals significant differences in their energy conversion principles and practical performance. Wankel engines typically achieve thermal efficiency rates of 15-25%, with modern optimized designs approaching 30% under ideal conditions. This efficiency stems from their compact design, reduced moving parts, and higher power-to-weight ratio compared to conventional piston engines. However, Wankel engines face persistent challenges with apex seal wear and incomplete combustion that negatively impact their fuel economy in practical applications.

Steam engines, conversely, demonstrate thermal efficiency rates typically between 10-20%, with advanced compound steam systems potentially reaching 25%. Their efficiency is fundamentally limited by the Rankine cycle thermodynamics and heat transfer losses inherent in the steam generation process. Despite lower peak efficiency, steam engines offer remarkable fuel flexibility, capable of utilizing virtually any heat source including coal, wood, biomass, and even concentrated solar energy.

The energy conversion pathways differ substantially between these technologies. Wankel engines directly convert chemical energy to mechanical energy through controlled combustion in a rotating chamber, with minimal intermediate steps. This direct conversion pathway reduces certain transmission losses but introduces unique combustion chamber geometry challenges that affect complete fuel utilization.

Steam engines employ a more complex energy conversion chain, transforming chemical energy to thermal energy in an external combustion process, then converting thermal energy to mechanical energy via steam pressure acting on pistons or turbines. This indirect approach introduces additional conversion losses but provides greater fuel flexibility and smoother torque delivery.

From an environmental perspective, Wankel engines typically produce higher hydrocarbon and carbon monoxide emissions per unit of power output compared to modern reciprocating engines, primarily due to their elongated combustion chamber geometry. Steam engines, while potentially carbon-neutral when using renewable biomass fuels, generally exhibit lower combustion efficiency and higher particulate emissions unless equipped with modern emission control systems.

Recent advancements in materials science have improved both technologies. For Wankel engines, ceramic apex seals and advanced coating technologies have enhanced durability and reduced friction losses. In steam engine development, high-temperature alloys and improved boiler designs have increased operating pressures and temperatures, yielding modest efficiency improvements while maintaining their inherent operational flexibility.

Steam engines, conversely, demonstrate thermal efficiency rates typically between 10-20%, with advanced compound steam systems potentially reaching 25%. Their efficiency is fundamentally limited by the Rankine cycle thermodynamics and heat transfer losses inherent in the steam generation process. Despite lower peak efficiency, steam engines offer remarkable fuel flexibility, capable of utilizing virtually any heat source including coal, wood, biomass, and even concentrated solar energy.

The energy conversion pathways differ substantially between these technologies. Wankel engines directly convert chemical energy to mechanical energy through controlled combustion in a rotating chamber, with minimal intermediate steps. This direct conversion pathway reduces certain transmission losses but introduces unique combustion chamber geometry challenges that affect complete fuel utilization.

Steam engines employ a more complex energy conversion chain, transforming chemical energy to thermal energy in an external combustion process, then converting thermal energy to mechanical energy via steam pressure acting on pistons or turbines. This indirect approach introduces additional conversion losses but provides greater fuel flexibility and smoother torque delivery.

From an environmental perspective, Wankel engines typically produce higher hydrocarbon and carbon monoxide emissions per unit of power output compared to modern reciprocating engines, primarily due to their elongated combustion chamber geometry. Steam engines, while potentially carbon-neutral when using renewable biomass fuels, generally exhibit lower combustion efficiency and higher particulate emissions unless equipped with modern emission control systems.

Recent advancements in materials science have improved both technologies. For Wankel engines, ceramic apex seals and advanced coating technologies have enhanced durability and reduced friction losses. In steam engine development, high-temperature alloys and improved boiler designs have increased operating pressures and temperatures, yielding modest efficiency improvements while maintaining their inherent operational flexibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!