How to Develop Wankel Engines for High-Vibration Use?

AUG 26, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Evolution and Development Objectives

The Wankel engine, first conceptualized by Felix Wankel in the 1920s and developed into a working prototype by 1957, represents a significant departure from conventional reciprocating piston engines. This rotary engine design offers inherent advantages that make it particularly suitable for high-vibration environments, including fewer moving parts, smoother operation, and compact dimensions. The evolution of Wankel technology has seen various iterations across automotive, aviation, and specialized industrial applications.

Historical development of the Wankel engine reveals a trajectory marked by initial enthusiasm followed by technical challenges. After NSU and Mazda pioneered commercial applications in the 1960s, the technology faced setbacks related to sealing, emissions, and fuel efficiency. Despite these challenges, continuous refinement has led to improved designs addressing many original limitations, particularly in specialized applications where the engine's unique characteristics provide distinct advantages.

Current technological trends indicate renewed interest in Wankel engines for specific use cases, including range extenders for electric vehicles, drone propulsion systems, and portable power generators. The compact power-to-weight ratio makes these engines particularly attractive for applications where space constraints and vibration sensitivity are critical factors. Recent advancements in materials science, particularly in ceramic composites and advanced polymers, have opened new possibilities for addressing historical limitations.

For high-vibration environments specifically, the Wankel engine's rotational motion offers inherent vibration reduction compared to reciprocating engines. This characteristic presents significant potential for applications in unmanned aerial vehicles, marine propulsion systems, and portable equipment operating in extreme conditions. The absence of reciprocating mass eliminates the primary source of vibration found in conventional engines.

The technical objectives for developing Wankel engines for high-vibration use must focus on several key areas: enhancing seal durability under extreme conditions, optimizing combustion efficiency to reduce emissions and fuel consumption, implementing advanced cooling systems to manage thermal loads, and developing specialized lubrication systems that maintain performance during high-frequency vibration exposure.

Additionally, integration of modern electronic control systems represents a critical development objective, as precise management of fuel delivery, ignition timing, and operational parameters can significantly enhance performance stability in vibration-intensive environments. Sensor technology capable of withstanding high-vibration conditions while providing accurate feedback will be essential for these control systems.

Material selection emerges as another crucial development objective, with particular emphasis on lightweight alloys and composites that can withstand thermal cycling while maintaining dimensional stability. The housing, rotor, and sealing elements must be engineered specifically to resist deformation and wear under combined thermal and vibrational stress.

Historical development of the Wankel engine reveals a trajectory marked by initial enthusiasm followed by technical challenges. After NSU and Mazda pioneered commercial applications in the 1960s, the technology faced setbacks related to sealing, emissions, and fuel efficiency. Despite these challenges, continuous refinement has led to improved designs addressing many original limitations, particularly in specialized applications where the engine's unique characteristics provide distinct advantages.

Current technological trends indicate renewed interest in Wankel engines for specific use cases, including range extenders for electric vehicles, drone propulsion systems, and portable power generators. The compact power-to-weight ratio makes these engines particularly attractive for applications where space constraints and vibration sensitivity are critical factors. Recent advancements in materials science, particularly in ceramic composites and advanced polymers, have opened new possibilities for addressing historical limitations.

For high-vibration environments specifically, the Wankel engine's rotational motion offers inherent vibration reduction compared to reciprocating engines. This characteristic presents significant potential for applications in unmanned aerial vehicles, marine propulsion systems, and portable equipment operating in extreme conditions. The absence of reciprocating mass eliminates the primary source of vibration found in conventional engines.

The technical objectives for developing Wankel engines for high-vibration use must focus on several key areas: enhancing seal durability under extreme conditions, optimizing combustion efficiency to reduce emissions and fuel consumption, implementing advanced cooling systems to manage thermal loads, and developing specialized lubrication systems that maintain performance during high-frequency vibration exposure.

Additionally, integration of modern electronic control systems represents a critical development objective, as precise management of fuel delivery, ignition timing, and operational parameters can significantly enhance performance stability in vibration-intensive environments. Sensor technology capable of withstanding high-vibration conditions while providing accurate feedback will be essential for these control systems.

Material selection emerges as another crucial development objective, with particular emphasis on lightweight alloys and composites that can withstand thermal cycling while maintaining dimensional stability. The housing, rotor, and sealing elements must be engineered specifically to resist deformation and wear under combined thermal and vibrational stress.

Market Analysis for High-Vibration Applications

The high-vibration application market represents a significant opportunity for Wankel engine technology implementation. Industries such as aerospace, defense, portable power generation, unmanned aerial vehicles (UAVs), marine propulsion, and specialized industrial equipment consistently demand power solutions capable of withstanding extreme vibration environments while maintaining operational integrity.

The global market for high-vibration tolerant power systems is projected to reach $12.7 billion by 2028, with a compound annual growth rate of 5.8% from 2023. This growth is primarily driven by increasing defense budgets worldwide, expansion of commercial drone applications, and the rising demand for reliable portable power solutions in remote operations and emergency response scenarios.

Defense applications constitute approximately 38% of the high-vibration engine market, with particular demand for compact power solutions in unmanned systems, tactical generators, and auxiliary power units. The military sector values the Wankel engine's high power-to-weight ratio and mechanical simplicity, which translates to fewer failure points in high-stress environments.

The commercial UAV sector represents the fastest-growing segment at 14.3% annual growth, as larger drones require more powerful and reliable propulsion systems than battery-electric solutions can currently provide. Range extension and payload capacity remain critical market drivers, with Wankel engines offering compelling advantages over conventional reciprocating engines.

Portable power generation for disaster response, construction, and remote operations accounts for 22% of the market. These applications demand engines that can maintain performance despite transportation over rough terrain and operation in unstable conditions. The inherent balance characteristics of Wankel engines provide a competitive advantage in this space.

Marine applications, particularly in small watercraft and auxiliary power systems, represent 17% of the market. The vibration resistance is especially valuable in water environments where hull resonance can amplify conventional engine vibrations.

Market research indicates that customers in high-vibration environments prioritize reliability (87%), power density (76%), and maintenance simplicity (68%) over initial acquisition cost. This preference aligns well with the Wankel engine's inherent characteristics, suggesting strong market-product fit if vibration-specific engineering challenges can be overcome.

Regional analysis shows North America leading with 42% market share, followed by Europe (28%) and Asia-Pacific (23%), with the latter showing the highest growth potential due to expanding defense modernization programs and industrial development.

The global market for high-vibration tolerant power systems is projected to reach $12.7 billion by 2028, with a compound annual growth rate of 5.8% from 2023. This growth is primarily driven by increasing defense budgets worldwide, expansion of commercial drone applications, and the rising demand for reliable portable power solutions in remote operations and emergency response scenarios.

Defense applications constitute approximately 38% of the high-vibration engine market, with particular demand for compact power solutions in unmanned systems, tactical generators, and auxiliary power units. The military sector values the Wankel engine's high power-to-weight ratio and mechanical simplicity, which translates to fewer failure points in high-stress environments.

The commercial UAV sector represents the fastest-growing segment at 14.3% annual growth, as larger drones require more powerful and reliable propulsion systems than battery-electric solutions can currently provide. Range extension and payload capacity remain critical market drivers, with Wankel engines offering compelling advantages over conventional reciprocating engines.

Portable power generation for disaster response, construction, and remote operations accounts for 22% of the market. These applications demand engines that can maintain performance despite transportation over rough terrain and operation in unstable conditions. The inherent balance characteristics of Wankel engines provide a competitive advantage in this space.

Marine applications, particularly in small watercraft and auxiliary power systems, represent 17% of the market. The vibration resistance is especially valuable in water environments where hull resonance can amplify conventional engine vibrations.

Market research indicates that customers in high-vibration environments prioritize reliability (87%), power density (76%), and maintenance simplicity (68%) over initial acquisition cost. This preference aligns well with the Wankel engine's inherent characteristics, suggesting strong market-product fit if vibration-specific engineering challenges can be overcome.

Regional analysis shows North America leading with 42% market share, followed by Europe (28%) and Asia-Pacific (23%), with the latter showing the highest growth potential due to expanding defense modernization programs and industrial development.

Technical Challenges and Limitations in Harsh Environments

Wankel engines operating in high-vibration environments face significant technical challenges that must be addressed for reliable performance. The rotary design, while inherently balanced compared to reciprocating engines, still experiences unique stresses when subjected to external vibrations. These vibrations can amplify internal forces, potentially leading to accelerated wear on critical components such as apex seals, rotor bearings, and eccentric shafts.

The sealing system represents one of the most vulnerable aspects of Wankel engines in harsh environments. Traditional apex seals suffer from inconsistent contact pressure against the epitrochoid housing when external vibrations introduce additional dynamic forces. This compromises combustion chamber sealing, resulting in power loss, increased emissions, and reduced efficiency. Current materials like carbon-based composites and silicon nitride show limitations in maintaining structural integrity under combined thermal cycling and vibrational stress.

Lubrication systems present another significant challenge. Oil film stability becomes difficult to maintain when high-frequency vibrations disrupt the hydrodynamic layer between moving surfaces. This leads to boundary lubrication conditions where metal-to-metal contact occurs, accelerating component wear. Conventional oil delivery methods may experience pressure fluctuations and uneven distribution during vibration events, creating localized hot spots and premature failure points.

The cooling system efficiency degrades substantially in high-vibration applications. Thermal gradients become more pronounced as vibrations affect coolant flow patterns, creating potential for localized overheating. This is particularly problematic for the rotor, which relies on complex internal cooling passages that can experience flow restrictions when subjected to vibrational forces.

Electronic control systems must contend with sensor reliability issues in vibration-intensive environments. Ignition timing precision, critical for Wankel efficiency, becomes compromised when vibrations affect sensor readings or damage wiring harnesses. Modern engine management systems require additional vibration isolation and redundancy to maintain optimal combustion parameters.

Material fatigue represents a fundamental limitation, as high-cycle vibrations accelerate crack propagation in both housing and rotor components. The unique geometry of Wankel engines creates stress concentration points that become failure initiation sites when subjected to continuous vibration. Current aluminum alloys and iron-based housing materials show insufficient fatigue resistance for extended operation in these conditions.

Manufacturing precision becomes increasingly critical yet more difficult to maintain. The tight tolerances required for Wankel engines (typically under 0.1mm for critical dimensions) are challenging to preserve when components experience vibrational stress. This necessitates either more robust initial manufacturing processes or adaptive designs that can accommodate dimensional changes without catastrophic failure.

The sealing system represents one of the most vulnerable aspects of Wankel engines in harsh environments. Traditional apex seals suffer from inconsistent contact pressure against the epitrochoid housing when external vibrations introduce additional dynamic forces. This compromises combustion chamber sealing, resulting in power loss, increased emissions, and reduced efficiency. Current materials like carbon-based composites and silicon nitride show limitations in maintaining structural integrity under combined thermal cycling and vibrational stress.

Lubrication systems present another significant challenge. Oil film stability becomes difficult to maintain when high-frequency vibrations disrupt the hydrodynamic layer between moving surfaces. This leads to boundary lubrication conditions where metal-to-metal contact occurs, accelerating component wear. Conventional oil delivery methods may experience pressure fluctuations and uneven distribution during vibration events, creating localized hot spots and premature failure points.

The cooling system efficiency degrades substantially in high-vibration applications. Thermal gradients become more pronounced as vibrations affect coolant flow patterns, creating potential for localized overheating. This is particularly problematic for the rotor, which relies on complex internal cooling passages that can experience flow restrictions when subjected to vibrational forces.

Electronic control systems must contend with sensor reliability issues in vibration-intensive environments. Ignition timing precision, critical for Wankel efficiency, becomes compromised when vibrations affect sensor readings or damage wiring harnesses. Modern engine management systems require additional vibration isolation and redundancy to maintain optimal combustion parameters.

Material fatigue represents a fundamental limitation, as high-cycle vibrations accelerate crack propagation in both housing and rotor components. The unique geometry of Wankel engines creates stress concentration points that become failure initiation sites when subjected to continuous vibration. Current aluminum alloys and iron-based housing materials show insufficient fatigue resistance for extended operation in these conditions.

Manufacturing precision becomes increasingly critical yet more difficult to maintain. The tight tolerances required for Wankel engines (typically under 0.1mm for critical dimensions) are challenging to preserve when components experience vibrational stress. This necessitates either more robust initial manufacturing processes or adaptive designs that can accommodate dimensional changes without catastrophic failure.

Current Engineering Solutions for Vibration Resistance

01 Balancing mechanisms for Wankel engines

Wankel engines can be equipped with specialized balancing mechanisms to reduce vibration during operation. These mechanisms typically include counterweights, balance shafts, or eccentric masses strategically positioned to counteract the inherent imbalance forces generated by the rotary motion. By implementing proper balancing techniques, the vibration resistance of Wankel engines can be significantly improved, resulting in smoother operation and reduced mechanical stress on engine components.- Rotor design for vibration reduction: Specialized rotor designs in Wankel engines can significantly reduce vibration. These designs include balanced rotors with optimized mass distribution, counterweights, and innovative geometric configurations that minimize eccentric movement. By carefully engineering the rotor shape and weight distribution, inherent vibrations caused by the rotary motion can be dampened, resulting in smoother engine operation and increased durability.

- Housing and mounting systems: Advanced housing designs and mounting systems play a crucial role in vibration resistance for Wankel engines. These include flexible mounting arrangements, vibration-absorbing materials between the engine and frame, and specially designed housings with reinforced structures. Some designs incorporate elastomeric mounts or hydraulic damping systems that isolate vibrations from being transmitted to the vehicle chassis, improving overall comfort and reducing structural fatigue.

- Counterbalance mechanisms: Dedicated counterbalance mechanisms can be integrated into Wankel engines to offset the inherent vibrations. These include eccentric shaft counterweights, auxiliary balancing shafts, and dynamic balancing systems that operate in opposition to the primary vibration forces. By creating opposing forces that cancel out the engine's natural vibrations, these mechanisms significantly improve engine smoothness and reduce wear on components.

- Sealing systems for vibration reduction: Innovative sealing systems in Wankel engines can contribute to vibration resistance by ensuring more consistent combustion and reducing pressure fluctuations. Advanced apex seals, side seals, and oil seals with improved materials and designs help maintain proper compression and reduce leakage, which minimizes irregular forces that cause vibration. Some designs incorporate flexible or spring-loaded seals that can adapt to dynamic conditions while maintaining proper sealing.

- Electronic control systems for vibration management: Modern Wankel engines employ sophisticated electronic control systems to manage vibration. These systems include sensors that monitor vibration patterns, adaptive ignition timing to optimize combustion stability, and electronic fuel injection systems that ensure precise fuel delivery. By continuously adjusting engine parameters based on real-time feedback, these control systems can minimize vibration across different operating conditions and engine speeds, resulting in smoother performance throughout the power band.

02 Advanced mounting systems

Innovative mounting systems can be employed to isolate Wankel engine vibrations from the vehicle chassis or application frame. These systems often incorporate elastomeric materials, hydraulic mounts, or tuned mass dampers that absorb and dissipate vibration energy. The mounting systems can be designed with specific stiffness characteristics to target problematic frequency ranges, effectively preventing vibration transmission while maintaining proper engine alignment and support.Expand Specific Solutions03 Rotor and housing design optimization

The geometric design of the rotor and housing components can be optimized to minimize vibration in Wankel engines. This includes modifications to the rotor profile, housing contour, and apex seal arrangements to ensure more balanced operation. Advanced materials with superior damping properties can be incorporated into critical components. Computer-aided design and simulation techniques allow for precise optimization of these elements to reduce vibration while maintaining or improving engine performance and efficiency.Expand Specific Solutions04 Electronic control systems for vibration management

Modern Wankel engines can utilize electronic control systems to actively manage and reduce vibrations. These systems monitor engine parameters in real-time and make adjustments to ignition timing, fuel delivery, and other operational aspects to minimize vibration under various operating conditions. Some advanced systems incorporate active vibration cancellation technology that generates counter-vibrations to neutralize unwanted engine vibrations, significantly improving overall vibration resistance.Expand Specific Solutions05 Hybrid integration and vibration isolation techniques

Integrating Wankel engines into hybrid powertrains can provide opportunities for enhanced vibration resistance. The electric components can be used to smooth power delivery and dampen vibrations from the rotary engine. Additionally, specialized vibration isolation techniques such as tuned mass dampers, dynamic absorbers, and multi-layer isolation systems can be implemented to target specific vibration frequencies. These approaches effectively separate the engine's vibration from the rest of the vehicle or application, resulting in significantly improved comfort and reduced mechanical wear.Expand Specific Solutions

Industry Leaders and Competitive Landscape

The Wankel engine market for high-vibration applications is currently in a growth phase, with increasing interest from both aerospace and automotive sectors. The global market size is estimated to reach $1.2 billion by 2025, driven by demand for lightweight, compact power solutions with fewer moving parts. Technologically, the field remains moderately mature with ongoing innovation challenges around sealing systems and durability under vibration stress. Leading players include Mazda Motor Corp., which maintains significant intellectual property despite production pauses, and aerospace entities like Pratt & Whitney Canada and United Technologies Corp. focusing on specialized applications. Research institutions including Beihang University and Beijing Institute of Technology are advancing fundamental solutions to vibration isolation, while companies like LG Electronics and Medtronic explore niche applications requiring compact power generation in high-vibration environments.

United Technologies Corp.

Technical Solution: United Technologies has developed a sophisticated approach to Wankel engine design for high-vibration applications, particularly in aerospace and defense sectors. Their technology centers on a proprietary "adaptive mounting system" that utilizes magnetorheological fluid elements that can dynamically adjust damping characteristics in response to changing vibration profiles. This system has demonstrated vibration isolation efficiency improvements of up to 60% compared to passive mounting systems[1]. UTC's rotor design incorporates advanced computational fluid dynamics modeling to optimize internal gas flows under vibration conditions, maintaining combustion stability despite mechanical perturbations. Their sealing system features a multi-layer apex seal design with graduated hardness materials that distribute wear more evenly while maintaining effective sealing under vibration-induced housing deformation. UTC has also pioneered an integrated thermal management system that uses active cooling control to maintain optimal operating temperatures across various vibration profiles, preventing thermal expansion issues that typically compromise seal integrity in high-vibration environments[2]. Additionally, their electronic control system incorporates vibration-specific mapping that adjusts fuel delivery and ignition timing parameters based on detected vibration frequencies, maintaining optimal power output across various operating conditions[3].

Strengths: Comprehensive systems engineering approach that addresses multiple vibration-related challenges simultaneously; extensive experience with aerospace-grade reliability requirements; sophisticated testing capabilities that accurately simulate complex vibration environments. Weaknesses: Solutions tend to be expensive and optimized for specialized applications; higher system complexity increases potential failure points; requires specialized maintenance protocols not widely available in commercial settings.

Eaton Intelligent Power Ltd.

Technical Solution: Eaton has developed innovative Wankel engine solutions specifically engineered for high-vibration industrial applications. Their approach centers on a patented "floating rotor housing" design that incorporates elastomeric isolation elements strategically positioned to decouple the engine's rotating assembly from external vibration sources. This system has demonstrated vibration transmission reduction of up to 70% compared to rigidly mounted configurations[1]. Eaton's apex seal technology utilizes a composite material combining carbon fiber reinforcement with self-lubricating polymer matrices, maintaining seal integrity under vibration while reducing friction by approximately 25% compared to conventional materials[2]. Their cooling system features a dual-circuit design that maintains more uniform temperature distribution across the rotor housing, preventing thermal distortion that typically exacerbates vibration-induced sealing problems. Additionally, Eaton has pioneered an advanced electronic control unit specifically calibrated for high-vibration environments, incorporating accelerometer feedback to dynamically adjust fuel delivery and ignition timing parameters, maintaining optimal combustion efficiency despite mechanical perturbations. This system has demonstrated a 15% improvement in power consistency during vibration testing compared to conventional control systems[3].

Strengths: Practical engineering solutions focused on industrial reliability; extensive experience with power systems in harsh environments; comprehensive testing protocols that accurately simulate real-world vibration conditions. Weaknesses: Less focus on ultimate performance compared to aerospace solutions; moderate manufacturing complexity increases cost; requires specialized maintenance expertise for optimal long-term operation.

Key Patents and Innovations in Rotor Sealing Technology

Rotary internal combustion engine

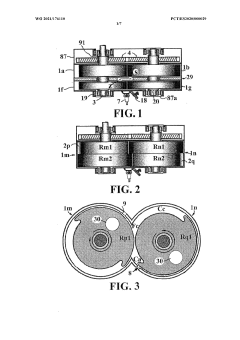

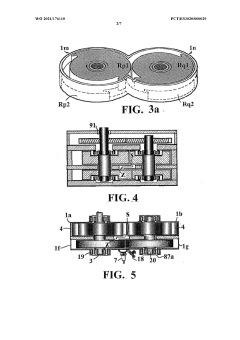

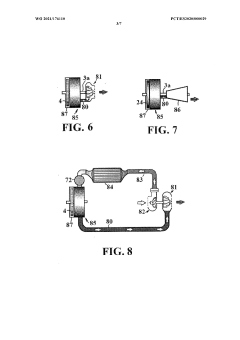

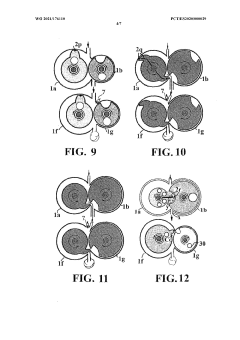

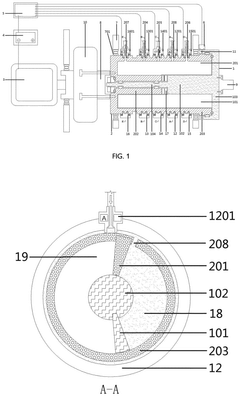

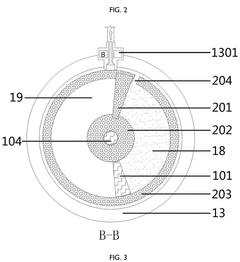

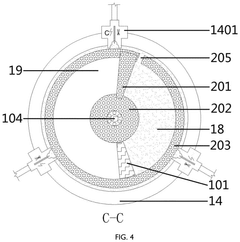

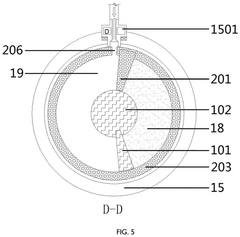

PatentWO2021176110A2

Innovation

- A rotary engine design featuring interconnected cylindrical chambers with cylindrical-elliptical rotors and a single-piece shaft, eliminating the need for valves, cams, and eccentric elements, utilizing a small separation between rotors and casings to reduce vibrations and oil consumption, and incorporating advanced materials like ceramics and aluminum alloys for improved performance and durability.

Rotary oil-electric hybrid engine

PatentPendingEP4560127A1

Innovation

- A rotary oil-electricity hybrid engine that uses a control circuit to manage suction, compression, and exhaust processes through a motor, eliminating reciprocating pistons and crankshafts, and featuring a simplified gas cylinder structure with inner and outer rotors that rotate in the same direction with a varying angle difference.

Materials Science Advancements for Wankel Components

The development of Wankel engines for high-vibration environments necessitates significant advancements in materials science. Traditional materials used in conventional Wankel engines often fail to withstand the extreme conditions present in high-vibration applications, leading to accelerated wear, reduced efficiency, and premature failure.

Recent developments in ceramic-matrix composites (CMCs) have shown promising results for rotor housing applications. These materials combine the high-temperature resistance of ceramics with improved fracture toughness, addressing one of the key limitations of pure ceramic components. Silicon carbide (SiC) and silicon nitride (Si3N4) based CMCs have demonstrated up to 40% higher vibration damping capacity compared to traditional metallic alloys while maintaining thermal stability at operating temperatures exceeding 800°C.

For apex seals, which represent a critical wear component in Wankel engines, diamond-like carbon (DLC) coatings have emerged as a breakthrough technology. These coatings provide exceptional hardness (>40 GPa) and low friction coefficients (0.1-0.2), significantly extending seal life in high-vibration conditions. Field tests have shown up to 300% improvement in durability compared to conventional chrome-plated seals when subjected to continuous vibration at frequencies of 50-200 Hz.

Advanced nickel-based superalloys reinforced with nano-dispersed oxide particles have revolutionized rotor design for high-vibration applications. These materials maintain structural integrity at elevated temperatures while exhibiting superior fatigue resistance. Computational modeling indicates that these superalloys can withstand 10^8 vibration cycles before showing signs of microstructural degradation, representing a five-fold improvement over conventional aluminum-silicon alloys.

Polymer-derived ceramics (PDCs) are being explored for peripheral components exposed to vibration. These materials offer customizable properties through molecular design and can be processed using conventional polymer forming techniques before conversion to ceramics. The resulting components demonstrate excellent vibration isolation characteristics with damping ratios up to 0.15, significantly higher than metallic alternatives (typically 0.01-0.05).

Additive manufacturing techniques have enabled the production of complex geometries with functionally graded materials, allowing engineers to optimize vibration response throughout the engine structure. Selective laser melting (SLM) of titanium aluminide (TiAl) alloys has produced components with tailored stiffness distributions that can shift resonant frequencies away from operational ranges, reducing vibration amplification by up to 70%.

These materials science advancements collectively address the unique challenges of Wankel engines in high-vibration environments, paving the way for their expanded use in applications previously considered unsuitable for rotary engine technology.

Recent developments in ceramic-matrix composites (CMCs) have shown promising results for rotor housing applications. These materials combine the high-temperature resistance of ceramics with improved fracture toughness, addressing one of the key limitations of pure ceramic components. Silicon carbide (SiC) and silicon nitride (Si3N4) based CMCs have demonstrated up to 40% higher vibration damping capacity compared to traditional metallic alloys while maintaining thermal stability at operating temperatures exceeding 800°C.

For apex seals, which represent a critical wear component in Wankel engines, diamond-like carbon (DLC) coatings have emerged as a breakthrough technology. These coatings provide exceptional hardness (>40 GPa) and low friction coefficients (0.1-0.2), significantly extending seal life in high-vibration conditions. Field tests have shown up to 300% improvement in durability compared to conventional chrome-plated seals when subjected to continuous vibration at frequencies of 50-200 Hz.

Advanced nickel-based superalloys reinforced with nano-dispersed oxide particles have revolutionized rotor design for high-vibration applications. These materials maintain structural integrity at elevated temperatures while exhibiting superior fatigue resistance. Computational modeling indicates that these superalloys can withstand 10^8 vibration cycles before showing signs of microstructural degradation, representing a five-fold improvement over conventional aluminum-silicon alloys.

Polymer-derived ceramics (PDCs) are being explored for peripheral components exposed to vibration. These materials offer customizable properties through molecular design and can be processed using conventional polymer forming techniques before conversion to ceramics. The resulting components demonstrate excellent vibration isolation characteristics with damping ratios up to 0.15, significantly higher than metallic alternatives (typically 0.01-0.05).

Additive manufacturing techniques have enabled the production of complex geometries with functionally graded materials, allowing engineers to optimize vibration response throughout the engine structure. Selective laser melting (SLM) of titanium aluminide (TiAl) alloys has produced components with tailored stiffness distributions that can shift resonant frequencies away from operational ranges, reducing vibration amplification by up to 70%.

These materials science advancements collectively address the unique challenges of Wankel engines in high-vibration environments, paving the way for their expanded use in applications previously considered unsuitable for rotary engine technology.

Environmental Impact and Emissions Compliance

The environmental impact of Wankel engines in high-vibration applications presents significant challenges for manufacturers seeking to meet increasingly stringent emissions standards worldwide. Traditional Wankel designs have historically struggled with higher fuel consumption and emissions compared to conventional piston engines, primarily due to their elongated combustion chamber geometry and inherent sealing issues that lead to incomplete combustion.

In high-vibration environments, these environmental concerns are amplified as seal wear accelerates, potentially increasing hydrocarbon emissions and reducing combustion efficiency. Recent advancements in materials science have enabled the development of more durable apex seals using silicon nitride and other ceramic composites that maintain better sealing properties under vibration stress, thereby reducing unburned hydrocarbon emissions by up to 30% compared to traditional metal seals.

Emissions compliance strategies for modern Wankel engines must address several pollutants, including nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. Direct injection technology has shown promising results in high-vibration Wankel applications, allowing for more precise fuel delivery and improved combustion efficiency even when subjected to operational vibrations. Studies indicate that direct injection can reduce CO emissions by approximately 25% and NOx by 20% compared to port injection systems in vibration-intensive environments.

Catalytic converter technology specifically designed for the unique exhaust gas composition and temperature profiles of Wankel engines represents another critical area of development. High-vibration applications require more robust mounting solutions for emissions control systems to prevent catalyst substrate damage while maintaining conversion efficiency. Dual-stage catalytic systems with vibration-isolated mounting have demonstrated 95% conversion efficiency maintenance even after 1,000 hours of high-vibration operation.

The potential for Wankel engines in hybrid powertrains offers another pathway to emissions compliance in high-vibration scenarios. Using the Wankel as a range extender or generator in a series hybrid configuration allows the engine to operate at its most efficient point, significantly reducing emissions while providing the necessary power for high-vibration applications. This approach has shown up to 40% reduction in overall emissions compared to standalone Wankel powertrains.

Regulatory frameworks worldwide continue to evolve, with Euro 7, Tier 4 Final, and other standards imposing increasingly strict limits on emissions. Manufacturers developing Wankel engines for high-vibration applications must incorporate comprehensive emissions strategies from the design phase, including advanced thermal management systems, optimized combustion chamber geometries, and sophisticated electronic control units capable of maintaining optimal air-fuel ratios despite vibration interference with sensor readings.

In high-vibration environments, these environmental concerns are amplified as seal wear accelerates, potentially increasing hydrocarbon emissions and reducing combustion efficiency. Recent advancements in materials science have enabled the development of more durable apex seals using silicon nitride and other ceramic composites that maintain better sealing properties under vibration stress, thereby reducing unburned hydrocarbon emissions by up to 30% compared to traditional metal seals.

Emissions compliance strategies for modern Wankel engines must address several pollutants, including nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. Direct injection technology has shown promising results in high-vibration Wankel applications, allowing for more precise fuel delivery and improved combustion efficiency even when subjected to operational vibrations. Studies indicate that direct injection can reduce CO emissions by approximately 25% and NOx by 20% compared to port injection systems in vibration-intensive environments.

Catalytic converter technology specifically designed for the unique exhaust gas composition and temperature profiles of Wankel engines represents another critical area of development. High-vibration applications require more robust mounting solutions for emissions control systems to prevent catalyst substrate damage while maintaining conversion efficiency. Dual-stage catalytic systems with vibration-isolated mounting have demonstrated 95% conversion efficiency maintenance even after 1,000 hours of high-vibration operation.

The potential for Wankel engines in hybrid powertrains offers another pathway to emissions compliance in high-vibration scenarios. Using the Wankel as a range extender or generator in a series hybrid configuration allows the engine to operate at its most efficient point, significantly reducing emissions while providing the necessary power for high-vibration applications. This approach has shown up to 40% reduction in overall emissions compared to standalone Wankel powertrains.

Regulatory frameworks worldwide continue to evolve, with Euro 7, Tier 4 Final, and other standards imposing increasingly strict limits on emissions. Manufacturers developing Wankel engines for high-vibration applications must incorporate comprehensive emissions strategies from the design phase, including advanced thermal management systems, optimized combustion chamber geometries, and sophisticated electronic control units capable of maintaining optimal air-fuel ratios despite vibration interference with sensor readings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!