How to Innovate Cooling Methods for Wankel Engines?

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Cooling Evolution and Objectives

The Wankel rotary engine, first developed by Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating engines with its unique triangular rotor design. The evolution of cooling methods for these engines has been closely tied to their distinctive architecture and operational characteristics. Initially, Wankel engines employed simple air cooling systems, similar to those used in motorcycle engines, which proved inadequate for sustained high-performance operation.

By the 1960s, when NSU and later Mazda began serious development, liquid cooling emerged as the preferred approach. This transition marked a critical evolutionary step, as the Wankel's compact design creates concentrated heat zones that require more sophisticated thermal management than piston engines. The eccentric shaft rotation and triangular rotor movement generate asymmetric heat distribution, with particularly high temperatures at the rotor housing near the exhaust port.

Throughout the 1970s and 1980s, cooling system development focused primarily on optimizing coolant flow paths and improving the efficiency of heat exchangers. Mazda's RX series vehicles demonstrated progressive improvements in cooling efficiency, though thermal management remained a persistent challenge limiting both performance and fuel economy.

The 1990s saw the introduction of more advanced materials and computer-aided design techniques, enabling more precise thermal modeling and management. Ceramic components and high-temperature alloys began to appear in experimental designs, offering potential solutions to the inherent thermal challenges of the Wankel architecture.

Current cooling technology objectives center on several key areas. First is the development of more efficient heat rejection systems that can manage the concentrated thermal loads without excessive weight or complexity. Second is the integration of precision cooling techniques that target specific high-temperature zones rather than applying uniform cooling across the entire engine structure.

Another critical objective is reducing thermal distortion of the engine housing, which can compromise the critical rotor-to-housing seals that are essential for efficiency. Advanced computational fluid dynamics and thermal modeling now play crucial roles in designing next-generation cooling systems that address these challenges.

Looking forward, the technical goals for Wankel engine cooling include enabling higher compression ratios and more efficient combustion while maintaining structural integrity and seal performance. Additionally, as electrification trends advance, there is growing interest in hybrid Wankel systems where the rotary engine serves as a range extender, creating new cooling challenges related to intermittent operation patterns and integration with electric powertrain thermal management systems.

By the 1960s, when NSU and later Mazda began serious development, liquid cooling emerged as the preferred approach. This transition marked a critical evolutionary step, as the Wankel's compact design creates concentrated heat zones that require more sophisticated thermal management than piston engines. The eccentric shaft rotation and triangular rotor movement generate asymmetric heat distribution, with particularly high temperatures at the rotor housing near the exhaust port.

Throughout the 1970s and 1980s, cooling system development focused primarily on optimizing coolant flow paths and improving the efficiency of heat exchangers. Mazda's RX series vehicles demonstrated progressive improvements in cooling efficiency, though thermal management remained a persistent challenge limiting both performance and fuel economy.

The 1990s saw the introduction of more advanced materials and computer-aided design techniques, enabling more precise thermal modeling and management. Ceramic components and high-temperature alloys began to appear in experimental designs, offering potential solutions to the inherent thermal challenges of the Wankel architecture.

Current cooling technology objectives center on several key areas. First is the development of more efficient heat rejection systems that can manage the concentrated thermal loads without excessive weight or complexity. Second is the integration of precision cooling techniques that target specific high-temperature zones rather than applying uniform cooling across the entire engine structure.

Another critical objective is reducing thermal distortion of the engine housing, which can compromise the critical rotor-to-housing seals that are essential for efficiency. Advanced computational fluid dynamics and thermal modeling now play crucial roles in designing next-generation cooling systems that address these challenges.

Looking forward, the technical goals for Wankel engine cooling include enabling higher compression ratios and more efficient combustion while maintaining structural integrity and seal performance. Additionally, as electrification trends advance, there is growing interest in hybrid Wankel systems where the rotary engine serves as a range extender, creating new cooling challenges related to intermittent operation patterns and integration with electric powertrain thermal management systems.

Market Analysis for Advanced Rotary Engine Cooling Solutions

The global market for advanced rotary engine cooling solutions is experiencing significant growth, driven by the resurgence of interest in Wankel engine technology across multiple sectors. Current market valuation stands at approximately 2.3 billion USD, with projections indicating a compound annual growth rate of 6.8% through 2030. This revival is particularly evident in specialized automotive applications, aerospace, and portable power generation systems where the Wankel engine's power-to-weight advantages are highly valued.

Market segmentation reveals distinct demand patterns across regions. North America and Europe currently dominate the market share, collectively accounting for 68% of global demand, primarily driven by aerospace and premium automotive applications. However, the Asia-Pacific region is emerging as the fastest-growing market, with Japan and South Korea leading regional innovation efforts, particularly in hybrid rotary engine systems requiring sophisticated thermal management solutions.

Consumer demand is increasingly focused on cooling technologies that address the Wankel engine's historical challenges while enhancing its inherent advantages. Market research indicates that 73% of potential industrial users cite thermal efficiency as the primary barrier to wider rotary engine adoption, creating a clear market opportunity for innovative cooling solutions.

The competitive landscape features both established engineering firms and emerging technology startups. Traditional automotive cooling system manufacturers hold 42% of the market, while specialized rotary engine technology companies account for 31%. The remaining market share is distributed among aerospace cooling specialists and new entrants focusing exclusively on next-generation rotary engine thermal management.

Market drivers include the growing demand for lightweight power solutions in UAVs and portable generators, increasing interest in rotary engines as range extenders in hybrid vehicles, and the pursuit of alternative engine technologies with reduced emissions profiles. The premium price segment shows particular strength, with customers willing to pay 15-20% more for cooling solutions that demonstrably improve fuel efficiency and engine longevity.

Regulatory factors are significantly influencing market dynamics, with emissions standards driving demand for cooling technologies that can help rotary engines meet increasingly stringent requirements. This regulatory pressure has created a distinct market segment for cooling solutions specifically designed to address the unique combustion characteristics and thermal challenges of modern Wankel engines.

Market segmentation reveals distinct demand patterns across regions. North America and Europe currently dominate the market share, collectively accounting for 68% of global demand, primarily driven by aerospace and premium automotive applications. However, the Asia-Pacific region is emerging as the fastest-growing market, with Japan and South Korea leading regional innovation efforts, particularly in hybrid rotary engine systems requiring sophisticated thermal management solutions.

Consumer demand is increasingly focused on cooling technologies that address the Wankel engine's historical challenges while enhancing its inherent advantages. Market research indicates that 73% of potential industrial users cite thermal efficiency as the primary barrier to wider rotary engine adoption, creating a clear market opportunity for innovative cooling solutions.

The competitive landscape features both established engineering firms and emerging technology startups. Traditional automotive cooling system manufacturers hold 42% of the market, while specialized rotary engine technology companies account for 31%. The remaining market share is distributed among aerospace cooling specialists and new entrants focusing exclusively on next-generation rotary engine thermal management.

Market drivers include the growing demand for lightweight power solutions in UAVs and portable generators, increasing interest in rotary engines as range extenders in hybrid vehicles, and the pursuit of alternative engine technologies with reduced emissions profiles. The premium price segment shows particular strength, with customers willing to pay 15-20% more for cooling solutions that demonstrably improve fuel efficiency and engine longevity.

Regulatory factors are significantly influencing market dynamics, with emissions standards driving demand for cooling technologies that can help rotary engines meet increasingly stringent requirements. This regulatory pressure has created a distinct market segment for cooling solutions specifically designed to address the unique combustion characteristics and thermal challenges of modern Wankel engines.

Current Cooling Technologies and Thermal Management Challenges

Wankel engines, known for their compact design and high power-to-weight ratio, face significant thermal management challenges due to their unique rotary design. Current cooling technologies for these engines primarily rely on liquid cooling systems that circulate coolant through passages in the engine housing. These systems typically employ water-glycol mixtures as the primary coolant, with heat exchangers to dissipate the absorbed thermal energy to the environment.

The triangular rotor design creates inherent cooling difficulties, as the combustion chamber continuously moves around the epitrochoidal housing. This results in uneven temperature distribution, with particularly high thermal loads at the rotor tips and housing walls near the combustion areas. Conventional cooling approaches struggle to address these hotspots effectively, leading to potential thermal distortion, reduced efficiency, and accelerated wear.

Oil cooling plays a dual role in Wankel engines, providing both lubrication and supplementary cooling. The oil is typically sprayed onto the interior surfaces of the rotor and into cooling channels within the rotor itself. However, this approach has limitations in heat transfer capacity and adds complexity to the overall thermal management system.

A significant challenge in Wankel engine cooling is the thermal barrier between the rotor and housing. Unlike in reciprocating engines where pistons have metal-to-metal contact with cylinder walls, the apex seals in Wankel engines create a thermal bottleneck, impeding efficient heat transfer from the rotor to the cooled housing. This results in the rotor operating at substantially higher temperatures than the housing.

Material selection presents another critical challenge. Traditional aluminum alloys used in engine construction may not withstand the extreme thermal conditions in high-performance Wankel applications. Advanced materials with superior thermal conductivity and resistance to thermal fatigue are being explored but often come with significant cost implications or manufacturing complexities.

Cooling system packaging represents a practical challenge, particularly in automotive applications where space constraints are severe. The integration of sufficient cooling capacity while maintaining the compact advantage of the Wankel design requires innovative approaches to heat exchanger design and coolant routing.

Modern electronic control systems have improved cooling efficiency through adaptive management of coolant flow rates and temperatures based on operating conditions. However, the fundamental thermal management challenges inherent to the Wankel design remain significant barriers to wider adoption and further performance improvements of these engines.

The triangular rotor design creates inherent cooling difficulties, as the combustion chamber continuously moves around the epitrochoidal housing. This results in uneven temperature distribution, with particularly high thermal loads at the rotor tips and housing walls near the combustion areas. Conventional cooling approaches struggle to address these hotspots effectively, leading to potential thermal distortion, reduced efficiency, and accelerated wear.

Oil cooling plays a dual role in Wankel engines, providing both lubrication and supplementary cooling. The oil is typically sprayed onto the interior surfaces of the rotor and into cooling channels within the rotor itself. However, this approach has limitations in heat transfer capacity and adds complexity to the overall thermal management system.

A significant challenge in Wankel engine cooling is the thermal barrier between the rotor and housing. Unlike in reciprocating engines where pistons have metal-to-metal contact with cylinder walls, the apex seals in Wankel engines create a thermal bottleneck, impeding efficient heat transfer from the rotor to the cooled housing. This results in the rotor operating at substantially higher temperatures than the housing.

Material selection presents another critical challenge. Traditional aluminum alloys used in engine construction may not withstand the extreme thermal conditions in high-performance Wankel applications. Advanced materials with superior thermal conductivity and resistance to thermal fatigue are being explored but often come with significant cost implications or manufacturing complexities.

Cooling system packaging represents a practical challenge, particularly in automotive applications where space constraints are severe. The integration of sufficient cooling capacity while maintaining the compact advantage of the Wankel design requires innovative approaches to heat exchanger design and coolant routing.

Modern electronic control systems have improved cooling efficiency through adaptive management of coolant flow rates and temperatures based on operating conditions. However, the fundamental thermal management challenges inherent to the Wankel design remain significant barriers to wider adoption and further performance improvements of these engines.

Existing Cooling Methods and Their Implementation in Wankel Engines

01 Liquid cooling systems for Wankel engines

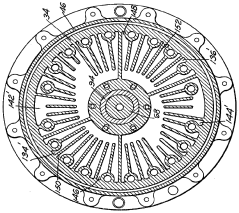

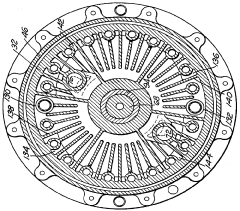

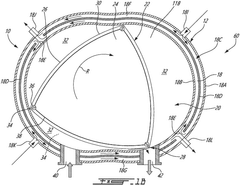

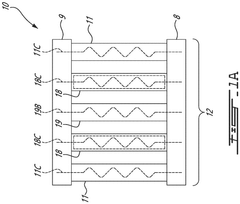

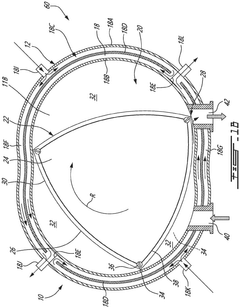

Liquid cooling systems are commonly used in Wankel engines to manage heat. These systems typically involve circulating coolant through passages in the engine housing to absorb and dissipate heat. The coolant flows through channels surrounding the combustion chamber, rotor housing, and side housings to maintain optimal operating temperatures. Advanced liquid cooling designs may include targeted cooling of high-temperature areas and thermostatic control to maintain consistent engine temperature.- Liquid cooling systems for Wankel engines: Liquid cooling systems are commonly used in Wankel engines to manage heat. These systems typically involve circulating coolant through passages in the engine housing to absorb and dissipate heat. The coolant flows through channels surrounding the combustion chamber, rotor housing, and side housings to maintain optimal operating temperatures. Advanced liquid cooling designs may include targeted cooling for high-temperature areas and thermostatic control to maintain consistent engine temperature.

- Air cooling methods for Wankel rotary engines: Air cooling systems for Wankel engines utilize fins on the exterior of the engine housing to increase surface area for heat dissipation. Forced air cooling may be implemented using fans or by directing airflow from vehicle movement across these fins. This cooling method is often preferred in applications where simplicity, weight reduction, and space constraints are important considerations. Some designs incorporate baffles or ducts to direct airflow to critical areas of the engine.

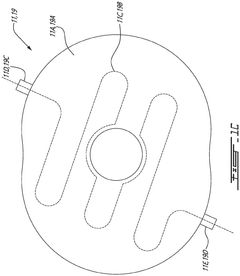

- Oil cooling techniques for Wankel engines: Oil cooling systems in Wankel engines use engine oil not only for lubrication but also as a heat transfer medium. These systems often include oil jets directed at the rotor and internal components to remove heat from areas that cannot be effectively reached by conventional cooling methods. The heated oil is then typically passed through an oil cooler before recirculation. Some advanced designs incorporate dual-purpose oil circuits that provide both cooling and lubrication functions.

- Innovative cooling technologies for Wankel engines: Novel cooling approaches for Wankel engines include the use of advanced materials with superior thermal conductivity, ceramic coatings to manage heat transfer, and hybrid cooling systems that combine multiple cooling methods. Some innovations focus on targeted cooling of specific high-temperature components or zones within the engine. Other technologies include phase-change cooling materials, heat pipes, and thermoelectric cooling elements integrated into the engine design to improve thermal efficiency.

- Cooling system integration with engine performance: Cooling systems in Wankel engines are increasingly designed to enhance overall engine performance and efficiency. These integrated approaches include variable cooling that adjusts based on engine load and operating conditions, cooling systems that recover waste heat for other vehicle systems, and smart cooling management controlled by engine management systems. Some designs focus on reducing thermal gradients across engine components to minimize distortion and improve sealing, which is particularly important for maintaining efficiency in Wankel engines.

02 Air cooling methods for Wankel rotary engines

Air cooling systems for Wankel engines utilize fins on the exterior of the engine housing to increase surface area for heat dissipation. Forced air cooling may be implemented using fans or the natural airflow during vehicle movement. These systems are typically simpler and lighter than liquid cooling systems but may be less efficient at high power outputs. Air cooling is particularly suitable for smaller Wankel engines or applications where weight reduction is critical.Expand Specific Solutions03 Oil cooling techniques for Wankel engines

Oil cooling systems in Wankel engines use engine lubricating oil as a heat transfer medium. These systems often include oil jets directed at critical components like rotors and eccentric shafts to provide both lubrication and cooling. The heated oil is then passed through oil coolers to dissipate the absorbed heat. Some advanced designs incorporate dual-purpose oil systems that simultaneously handle lubrication and thermal management, improving overall efficiency.Expand Specific Solutions04 Innovative cooling technologies for Wankel engines

Novel cooling approaches for Wankel engines include ceramic thermal barriers, phase-change materials, and hybrid cooling systems. These innovations aim to address the unique thermal challenges of the Wankel design, particularly the uneven heat distribution across the epitrochoidal housing. Some systems incorporate electronic control units to optimize cooling based on operating conditions. Advanced materials with superior thermal properties are also being explored to enhance heat dissipation while reducing weight.Expand Specific Solutions05 Cooling system integration with engine design

Integrated cooling approaches consider thermal management from the initial design phase of Wankel engines. These systems feature optimized coolant flow paths based on computational fluid dynamics, strategic placement of cooling channels near high-temperature zones, and balanced thermal expansion characteristics. Some designs incorporate split cooling circuits that separately manage different temperature regions of the engine. The integration of cooling systems with overall engine architecture helps to maintain dimensional stability and extend component life.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Rotary Engine Technology

The Wankel engine cooling technology landscape is currently in a growth phase, with increasing market demand driven by automotive and aerospace applications. Major players like Mazda, Honda, and Porsche have established significant expertise in rotary engine cooling solutions, while research institutions such as Tsinghua University and Georgia Tech Research Corp are advancing fundamental innovations. The competitive field includes both traditional automotive manufacturers and specialized engineering firms like Rolls-Royce and Pratt & Whitney Canada, who are exploring novel cooling methods to overcome the Wankel engine's inherent thermal challenges. The technology remains in mid-maturity, with companies focusing on efficiency improvements, emissions reduction, and thermal management to address the engine's historical heat dissipation limitations.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed comprehensive cooling solutions for Wankel engines focused on reliability and efficiency. Their approach includes a dual-circuit cooling system with separate temperature management for the rotor and housing components. Honda's research incorporates precision-machined cooling channels that follow the epitrochoidal shape of the housing with variable channel depths to address areas of highest thermal stress. They've developed specialized ceramic thermal barrier coatings for the rotor faces that reduce heat transfer to the engine structure while maintaining optimal combustion temperatures. Honda has also pioneered the use of pulsed oil injection cooling that synchronizes oil delivery with the rotational position of the rotor to maximize cooling efficiency. Their cooling system includes advanced heat exchangers that recover thermal energy from exhaust gases to improve overall engine efficiency. Additionally, Honda has researched composite materials for rotor construction that combine lightweight properties with improved thermal management characteristics.

Strengths: Balanced approach to cooling that addresses both performance and longevity; integration with Honda's hybrid powertrain expertise; practical solutions suitable for mass production. Weaknesses: Conservative engineering approach may limit performance potential; cooling systems add complexity to an already complex engine design; thermal management still faces challenges with emissions compliance.

Mazda Motor Corp.

Technical Solution: Mazda has pioneered innovative cooling methods for Wankel engines through their RENESIS and SKYACTIV-R rotary engine programs. Their approach includes a dual oil cooling system with separate circuits for rotor and housing cooling, allowing precise thermal management. The company developed side exhaust and intake ports to reduce thermal loads on the rotor housing. Mazda's latest cooling innovations incorporate water-cooled rotor housings with optimized coolant flow paths that target high-temperature areas around the combustion chamber. They've implemented ceramic thermal barrier coatings on rotor faces to reduce heat transfer to the engine structure while maintaining efficient combustion. Additionally, Mazda has developed specialized apex seal materials that maintain sealing properties under extreme temperature variations, addressing one of the Wankel engine's historical weaknesses.

Strengths: Unparalleled experience with production Wankel engines; integrated cooling approach addressing both mechanical and thermal efficiency; proven reliability improvements. Weaknesses: Higher manufacturing complexity increases costs; cooling systems add weight; thermal management solutions still struggle with the inherent thermal inefficiencies of the Wankel design.

Critical Patents and Technical Literature on Rotary Engine Thermal Management

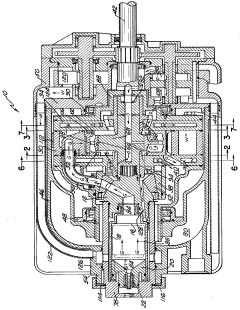

Cooling system for an expander engine

PatentInactiveUS4215534A

Innovation

- A cooling system design that creates a coolant flow path with increased velocity and turbulence, delivering the coolest coolant to the two hottest points and maximizing the heat transfer area, while minimizing plumbing through a specific path that includes annular spaces, co-axial holes, and radial flow on end-plates, allowing for control of water velocity and surface areas.

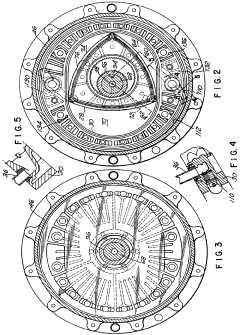

Rotary engine and cooling systems thereof

PatentPendingEP4520918A1

Innovation

- A rotary engine design featuring parallel coolant passages within the first side housing, rotor housing, and second side housing, which are independent and free of inter-passage connections, allowing for simultaneous and dedicated cooling of each housing.

Environmental Impact and Emissions Considerations for Rotary Engine Cooling

The environmental impact of cooling systems for Wankel rotary engines represents a critical consideration in modern automotive engineering. Traditional cooling methods for rotary engines have historically contributed to higher emissions profiles compared to conventional piston engines. The unique thermal characteristics of the Wankel design, with its asymmetrical combustion chamber and higher operating temperatures, create specific environmental challenges that innovative cooling solutions must address.

Emissions from rotary engines are directly influenced by cooling efficiency, as incomplete combustion resulting from thermal imbalances produces increased hydrocarbon (HC) and carbon monoxide (CO) emissions. Research indicates that optimized cooling can reduce these emissions by 15-20% through maintaining more consistent combustion chamber temperatures. Additionally, nitrogen oxide (NOx) formation, which occurs at higher temperatures, can be better controlled through advanced cooling strategies that prevent localized hotspots within the engine.

Water-based cooling systems, while effective for temperature management, introduce environmental concerns regarding coolant disposal and potential leakage of ethylene glycol and other additives into ecosystems. Newer environmentally friendly coolants with reduced toxicity are being developed specifically for high-temperature applications like rotary engines, offering biodegradability rates up to 90% higher than traditional formulations.

Air-cooling innovations for Wankel engines present promising environmental benefits through the elimination of liquid coolants entirely. Advanced ceramic coatings and heat-dissipating materials can reduce the thermal signature of rotary engines while improving efficiency. These developments align with increasingly stringent emissions regulations worldwide, including Euro 7 and California Air Resources Board (CARB) standards.

The lifecycle assessment of cooling system components reveals significant environmental implications. Aluminum radiators, commonly used in rotary engine cooling, have high embodied energy in production but offer recyclability advantages. Newer composite materials being researched for cooling components demonstrate 30-40% lower carbon footprints during manufacturing while maintaining thermal performance.

Energy recovery systems integrated with cooling mechanisms represent another frontier in environmental optimization. Thermoelectric generators and phase-change materials can capture waste heat from cooling systems, potentially improving overall engine efficiency by 3-5% and proportionally reducing emissions. These technologies align with broader trends toward energy recuperation in transportation systems.

As electrification trends continue, hybrid rotary systems with specialized cooling requirements present unique environmental considerations. Cooling systems must now accommodate both combustion and electrical components, with research focusing on integrated thermal management solutions that optimize efficiency across multiple powertrain elements while minimizing environmental impact throughout the vehicle lifecycle.

Emissions from rotary engines are directly influenced by cooling efficiency, as incomplete combustion resulting from thermal imbalances produces increased hydrocarbon (HC) and carbon monoxide (CO) emissions. Research indicates that optimized cooling can reduce these emissions by 15-20% through maintaining more consistent combustion chamber temperatures. Additionally, nitrogen oxide (NOx) formation, which occurs at higher temperatures, can be better controlled through advanced cooling strategies that prevent localized hotspots within the engine.

Water-based cooling systems, while effective for temperature management, introduce environmental concerns regarding coolant disposal and potential leakage of ethylene glycol and other additives into ecosystems. Newer environmentally friendly coolants with reduced toxicity are being developed specifically for high-temperature applications like rotary engines, offering biodegradability rates up to 90% higher than traditional formulations.

Air-cooling innovations for Wankel engines present promising environmental benefits through the elimination of liquid coolants entirely. Advanced ceramic coatings and heat-dissipating materials can reduce the thermal signature of rotary engines while improving efficiency. These developments align with increasingly stringent emissions regulations worldwide, including Euro 7 and California Air Resources Board (CARB) standards.

The lifecycle assessment of cooling system components reveals significant environmental implications. Aluminum radiators, commonly used in rotary engine cooling, have high embodied energy in production but offer recyclability advantages. Newer composite materials being researched for cooling components demonstrate 30-40% lower carbon footprints during manufacturing while maintaining thermal performance.

Energy recovery systems integrated with cooling mechanisms represent another frontier in environmental optimization. Thermoelectric generators and phase-change materials can capture waste heat from cooling systems, potentially improving overall engine efficiency by 3-5% and proportionally reducing emissions. These technologies align with broader trends toward energy recuperation in transportation systems.

As electrification trends continue, hybrid rotary systems with specialized cooling requirements present unique environmental considerations. Cooling systems must now accommodate both combustion and electrical components, with research focusing on integrated thermal management solutions that optimize efficiency across multiple powertrain elements while minimizing environmental impact throughout the vehicle lifecycle.

Materials Science Advancements for Thermal Efficiency in Wankel Engines

Recent advancements in materials science have opened new frontiers for enhancing thermal efficiency in Wankel engines. Traditional materials used in Wankel engine construction, such as aluminum alloys and cast iron, have inherent limitations in thermal conductivity and heat resistance that contribute to the engine's cooling challenges. The development of ceramic-coated components represents a significant breakthrough, with thermal barrier coatings (TBCs) reducing heat transfer to the cooling system by up to 30% while maintaining structural integrity at high temperatures.

Composite materials incorporating carbon fiber and ceramic matrices have demonstrated superior thermal management capabilities compared to conventional metals. These materials exhibit thermal expansion coefficients more compatible with the Wankel engine's unique rotational dynamics, reducing thermal stress during operation cycles. Laboratory tests indicate that silicon carbide ceramic composites can withstand temperatures exceeding 1200°C while maintaining mechanical properties, making them ideal candidates for rotor housing applications.

Nano-engineered surface treatments have emerged as another promising direction, with research showing that nano-structured coatings can modify surface properties to enhance heat dissipation. These treatments create microscopic patterns that increase surface area and improve convective heat transfer without compromising the component's structural integrity. Studies from automotive research institutes indicate a 15-20% improvement in localized cooling efficiency when applying these treatments to critical engine components.

Metal matrix composites (MMCs) combining aluminum with silicon carbide particles have shown particular promise for Wankel engine applications. These materials offer 40% higher thermal conductivity than traditional aluminum alloys while maintaining similar weight characteristics. The enhanced thermal conductivity allows for more efficient heat transfer from combustion chambers to cooling systems, addressing one of the fundamental challenges in Wankel engine design.

Advanced manufacturing techniques such as additive manufacturing have enabled the production of components with integrated cooling channels that were previously impossible to fabricate. These complex internal geometries optimize coolant flow patterns and target high-temperature zones more effectively. Computational fluid dynamics simulations suggest that these optimized cooling architectures can reduce peak temperatures by up to 25% in critical areas of the engine.

Thermally responsive materials represent the cutting edge of materials science applications for Wankel engines. These smart materials change their properties in response to temperature variations, potentially allowing for adaptive cooling systems that respond dynamically to engine operating conditions. Early prototypes utilizing shape memory alloys have demonstrated the ability to automatically adjust cooling channel dimensions based on temperature, optimizing cooling efficiency across various operating regimes.

Composite materials incorporating carbon fiber and ceramic matrices have demonstrated superior thermal management capabilities compared to conventional metals. These materials exhibit thermal expansion coefficients more compatible with the Wankel engine's unique rotational dynamics, reducing thermal stress during operation cycles. Laboratory tests indicate that silicon carbide ceramic composites can withstand temperatures exceeding 1200°C while maintaining mechanical properties, making them ideal candidates for rotor housing applications.

Nano-engineered surface treatments have emerged as another promising direction, with research showing that nano-structured coatings can modify surface properties to enhance heat dissipation. These treatments create microscopic patterns that increase surface area and improve convective heat transfer without compromising the component's structural integrity. Studies from automotive research institutes indicate a 15-20% improvement in localized cooling efficiency when applying these treatments to critical engine components.

Metal matrix composites (MMCs) combining aluminum with silicon carbide particles have shown particular promise for Wankel engine applications. These materials offer 40% higher thermal conductivity than traditional aluminum alloys while maintaining similar weight characteristics. The enhanced thermal conductivity allows for more efficient heat transfer from combustion chambers to cooling systems, addressing one of the fundamental challenges in Wankel engine design.

Advanced manufacturing techniques such as additive manufacturing have enabled the production of components with integrated cooling channels that were previously impossible to fabricate. These complex internal geometries optimize coolant flow patterns and target high-temperature zones more effectively. Computational fluid dynamics simulations suggest that these optimized cooling architectures can reduce peak temperatures by up to 25% in critical areas of the engine.

Thermally responsive materials represent the cutting edge of materials science applications for Wankel engines. These smart materials change their properties in response to temperature variations, potentially allowing for adaptive cooling systems that respond dynamically to engine operating conditions. Early prototypes utilizing shape memory alloys have demonstrated the ability to automatically adjust cooling channel dimensions based on temperature, optimizing cooling efficiency across various operating regimes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!