Wankel Engine In Situ Testing Techniques

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Testing Background and Objectives

The Wankel rotary engine, developed by German engineer Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique design features a triangular rotor that revolves within an epitrochoid-shaped housing, creating three combustion chambers that simultaneously perform intake, compression, combustion, and exhaust functions. This revolutionary approach offers advantages including fewer moving parts, smoother operation, higher power-to-weight ratio, and compact dimensions compared to traditional engines.

The evolution of Wankel engine technology has been marked by both promising advancements and persistent challenges. After initial development at NSU, the technology was licensed to various manufacturers including Mazda, which achieved the most commercial success with rotary engines in vehicles like the RX-7 and RX-8. Despite periods of commercial application, widespread adoption has been hindered by technical limitations including sealing issues, fuel efficiency concerns, and emissions challenges.

In-situ testing techniques for Wankel engines have historically lagged behind those available for conventional engines, creating a significant technological gap. Traditional testing methods often fail to capture the unique thermodynamic and mechanical behaviors of rotary engines during operation, particularly regarding apex seal dynamics, rotor housing deformation, and combustion characteristics under varying conditions.

The primary objective of advancing Wankel engine in-situ testing techniques is to develop comprehensive, real-time monitoring systems capable of accurately measuring and analyzing critical performance parameters during actual operation. This includes developing sensors and methodologies to monitor apex seal behavior, combustion chamber temperatures, rotor dynamics, and emissions formation processes without disrupting normal engine function.

Secondary objectives include establishing standardized testing protocols specifically designed for rotary engines, creating comparative benchmarks against conventional engines, and developing predictive models based on empirical data to accelerate future development. These testing capabilities are essential for addressing the persistent challenges of fuel efficiency and emissions that have limited wider adoption of Wankel technology.

Recent renewed interest in rotary engines for range extenders in electric vehicles and specialized applications has created urgency for advanced testing capabilities. The integration of modern sensor technology, data analytics, and computational modeling presents opportunities to overcome historical limitations in understanding rotary engine behavior under operating conditions, potentially unlocking pathways to improved efficiency and reduced emissions.

The evolution of Wankel engine technology has been marked by both promising advancements and persistent challenges. After initial development at NSU, the technology was licensed to various manufacturers including Mazda, which achieved the most commercial success with rotary engines in vehicles like the RX-7 and RX-8. Despite periods of commercial application, widespread adoption has been hindered by technical limitations including sealing issues, fuel efficiency concerns, and emissions challenges.

In-situ testing techniques for Wankel engines have historically lagged behind those available for conventional engines, creating a significant technological gap. Traditional testing methods often fail to capture the unique thermodynamic and mechanical behaviors of rotary engines during operation, particularly regarding apex seal dynamics, rotor housing deformation, and combustion characteristics under varying conditions.

The primary objective of advancing Wankel engine in-situ testing techniques is to develop comprehensive, real-time monitoring systems capable of accurately measuring and analyzing critical performance parameters during actual operation. This includes developing sensors and methodologies to monitor apex seal behavior, combustion chamber temperatures, rotor dynamics, and emissions formation processes without disrupting normal engine function.

Secondary objectives include establishing standardized testing protocols specifically designed for rotary engines, creating comparative benchmarks against conventional engines, and developing predictive models based on empirical data to accelerate future development. These testing capabilities are essential for addressing the persistent challenges of fuel efficiency and emissions that have limited wider adoption of Wankel technology.

Recent renewed interest in rotary engines for range extenders in electric vehicles and specialized applications has created urgency for advanced testing capabilities. The integration of modern sensor technology, data analytics, and computational modeling presents opportunities to overcome historical limitations in understanding rotary engine behavior under operating conditions, potentially unlocking pathways to improved efficiency and reduced emissions.

Market Demand Analysis for In Situ Testing Solutions

The global market for in situ testing solutions for Wankel engines demonstrates significant growth potential, driven by increasing demands for real-time performance monitoring and efficiency optimization in rotary engine applications. Current market research indicates that the automotive and aerospace sectors represent the primary demand sources, with emerging applications in specialized power generation and marine propulsion systems creating new market opportunities.

The Wankel engine market, though niche compared to conventional piston engines, maintains steady demand in specialized applications where its compact design, smooth operation, and high power-to-weight ratio provide distinct advantages. This specialized market creates a corresponding demand for dedicated testing solutions that can address the unique challenges of rotary engine diagnostics.

Industry analysis reveals that maintenance cost reduction serves as a primary market driver, with operators seeking to minimize downtime through predictive maintenance capabilities enabled by advanced in situ testing. Organizations operating Wankel-powered systems report maintenance costs typically 15-30% higher than conventional engines, creating strong economic incentives for improved diagnostic capabilities.

Environmental regulations worldwide are intensifying scrutiny on emissions and efficiency across all engine types, including Wankel designs. This regulatory pressure creates market demand for testing solutions that can monitor combustion efficiency, emissions profiles, and thermal management in real-time operating conditions, rather than relying solely on laboratory testing.

The market demonstrates particular interest in non-invasive testing methodologies that can monitor critical parameters without disrupting engine operation. Vibration analysis, thermal imaging, acoustic monitoring, and exhaust gas composition testing represent the fastest-growing segments within the in situ testing solution market for Wankel applications.

Regional market analysis indicates that North America and Europe currently lead in adoption of advanced testing solutions, driven by stringent regulatory environments and concentration of aerospace applications. However, the Asia-Pacific region shows the highest growth potential, with increasing industrial applications and automotive development programs incorporating Wankel technology.

Market segmentation reveals distinct requirements across different application sectors. Aerospace applications prioritize reliability and precision, automotive applications focus on cost-effectiveness and integration with existing diagnostic systems, while industrial applications emphasize durability and simplified operator interfaces. This segmentation necessitates customized testing solutions tailored to specific operational contexts rather than one-size-fits-all approaches.

The Wankel engine market, though niche compared to conventional piston engines, maintains steady demand in specialized applications where its compact design, smooth operation, and high power-to-weight ratio provide distinct advantages. This specialized market creates a corresponding demand for dedicated testing solutions that can address the unique challenges of rotary engine diagnostics.

Industry analysis reveals that maintenance cost reduction serves as a primary market driver, with operators seeking to minimize downtime through predictive maintenance capabilities enabled by advanced in situ testing. Organizations operating Wankel-powered systems report maintenance costs typically 15-30% higher than conventional engines, creating strong economic incentives for improved diagnostic capabilities.

Environmental regulations worldwide are intensifying scrutiny on emissions and efficiency across all engine types, including Wankel designs. This regulatory pressure creates market demand for testing solutions that can monitor combustion efficiency, emissions profiles, and thermal management in real-time operating conditions, rather than relying solely on laboratory testing.

The market demonstrates particular interest in non-invasive testing methodologies that can monitor critical parameters without disrupting engine operation. Vibration analysis, thermal imaging, acoustic monitoring, and exhaust gas composition testing represent the fastest-growing segments within the in situ testing solution market for Wankel applications.

Regional market analysis indicates that North America and Europe currently lead in adoption of advanced testing solutions, driven by stringent regulatory environments and concentration of aerospace applications. However, the Asia-Pacific region shows the highest growth potential, with increasing industrial applications and automotive development programs incorporating Wankel technology.

Market segmentation reveals distinct requirements across different application sectors. Aerospace applications prioritize reliability and precision, automotive applications focus on cost-effectiveness and integration with existing diagnostic systems, while industrial applications emphasize durability and simplified operator interfaces. This segmentation necessitates customized testing solutions tailored to specific operational contexts rather than one-size-fits-all approaches.

Current Challenges in Rotary Engine Diagnostics

Despite significant advancements in internal combustion engine diagnostics, Wankel rotary engines present unique challenges that conventional testing methods struggle to address effectively. The distinctive triangular rotor design, eccentric shaft movement, and three-phase combustion cycle create complex diagnostic scenarios that traditional piston engine testing equipment cannot adequately evaluate. Current in situ testing techniques for Wankel engines suffer from several critical limitations that impede accurate performance assessment and maintenance.

Access constraints represent a primary challenge, as the compact design of rotary engines offers limited physical entry points for diagnostic equipment. The sealed nature of the epitrochoidal housing makes it particularly difficult to place sensors at optimal locations without compromising the engine's structural integrity. This restricted access significantly hampers real-time monitoring of critical parameters such as apex seal wear, which remains one of the most problematic maintenance issues in Wankel engines.

Temperature measurement presents another substantial obstacle. The unique combustion pattern creates extreme thermal gradients across the rotor housing that are difficult to map accurately with conventional temperature sensors. The leading edge of the rotor experiences significantly different thermal conditions compared to the trailing edge, yet current sensor technologies struggle to capture these variations without disrupting normal engine operation.

Vibration analysis, a cornerstone of modern engine diagnostics, faces interpretation challenges when applied to Wankel engines. The eccentric rotational movement generates vibration signatures fundamentally different from reciprocating engines, rendering standard vibration analysis algorithms largely ineffective. Current accelerometer-based systems lack the specialized algorithms needed to differentiate between normal operational vibrations and those indicating potential failures in rotary-specific components.

Emissions testing methodologies also require significant adaptation for rotary engines. The continuous combustion cycle and unique port design create exhaust gas compositions that differ markedly from conventional engines. Standard lambda sensors and gas analyzers often provide misleading readings when applied to Wankel engines without proper calibration protocols, complicating both performance tuning and emissions compliance verification.

Real-time oil analysis, crucial for early detection of apex seal and rotor bearing wear, remains underdeveloped for rotary applications. The high operating temperatures and specialized oil requirements of Wankel engines create conditions that conventional oil condition monitoring systems are not calibrated to assess accurately. This diagnostic gap often leads to late detection of critical wear patterns that could otherwise be addressed proactively.

Access constraints represent a primary challenge, as the compact design of rotary engines offers limited physical entry points for diagnostic equipment. The sealed nature of the epitrochoidal housing makes it particularly difficult to place sensors at optimal locations without compromising the engine's structural integrity. This restricted access significantly hampers real-time monitoring of critical parameters such as apex seal wear, which remains one of the most problematic maintenance issues in Wankel engines.

Temperature measurement presents another substantial obstacle. The unique combustion pattern creates extreme thermal gradients across the rotor housing that are difficult to map accurately with conventional temperature sensors. The leading edge of the rotor experiences significantly different thermal conditions compared to the trailing edge, yet current sensor technologies struggle to capture these variations without disrupting normal engine operation.

Vibration analysis, a cornerstone of modern engine diagnostics, faces interpretation challenges when applied to Wankel engines. The eccentric rotational movement generates vibration signatures fundamentally different from reciprocating engines, rendering standard vibration analysis algorithms largely ineffective. Current accelerometer-based systems lack the specialized algorithms needed to differentiate between normal operational vibrations and those indicating potential failures in rotary-specific components.

Emissions testing methodologies also require significant adaptation for rotary engines. The continuous combustion cycle and unique port design create exhaust gas compositions that differ markedly from conventional engines. Standard lambda sensors and gas analyzers often provide misleading readings when applied to Wankel engines without proper calibration protocols, complicating both performance tuning and emissions compliance verification.

Real-time oil analysis, crucial for early detection of apex seal and rotor bearing wear, remains underdeveloped for rotary applications. The high operating temperatures and specialized oil requirements of Wankel engines create conditions that conventional oil condition monitoring systems are not calibrated to assess accurately. This diagnostic gap often leads to late detection of critical wear patterns that could otherwise be addressed proactively.

Existing In Situ Testing Technologies for Wankel Engines

01 In-situ testing methods for Wankel engine performance

Various methods have been developed for testing Wankel engine performance while the engine is operating in its normal environment. These methods include monitoring combustion efficiency, power output, and thermal characteristics during operation. In-situ testing allows engineers to evaluate real-world performance without removing the engine from its installation, providing more accurate data on operational parameters under actual working conditions.- In-situ testing methods for Wankel engine performance: Various methods for testing Wankel engine performance while the engine is operating in its normal environment. These methods include real-time monitoring of engine parameters, performance evaluation under different operating conditions, and diagnostic techniques that can be applied without removing the engine from its installation. Such testing approaches allow for accurate assessment of engine efficiency, power output, and operational characteristics during actual running conditions.

- Specialized instrumentation for Wankel engine testing: Development of specialized instruments and sensors designed specifically for monitoring and testing Wankel rotary engines. These include custom pressure sensors, temperature monitoring devices, vibration analyzers, and emission testing equipment adapted to the unique geometry and operating principles of rotary engines. The instrumentation enables precise measurement of critical parameters such as rotor position, combustion chamber conditions, and seal performance during operation.

- Combustion analysis and optimization in Wankel engines: Methods for analyzing and optimizing the combustion process within Wankel engines during operation. These techniques focus on monitoring flame propagation, fuel-air mixture distribution, and combustion efficiency in the unique geometry of the rotary engine. By analyzing combustion characteristics in situ, engineers can optimize fuel injection timing, ignition parameters, and chamber design to improve performance, reduce emissions, and enhance fuel efficiency.

- Seal and wear monitoring systems for rotary engines: Technologies for monitoring the condition and performance of seals and other wear components in Wankel engines during operation. These systems track the degradation of apex seals, side seals, and housing surfaces over time, providing early warning of potential failures. In-situ monitoring allows for predictive maintenance scheduling and can help identify design improvements to extend component life and maintain optimal engine performance.

- Thermal management testing in operational Wankel engines: Methods for evaluating and optimizing thermal management systems in Wankel rotary engines during actual operation. These approaches focus on monitoring temperature distribution, cooling system effectiveness, and heat transfer characteristics throughout the engine. In-situ thermal testing helps identify hotspots, thermal stress points, and cooling inefficiencies, allowing engineers to develop improved cooling strategies and materials to enhance engine durability and performance.

02 Diagnostic systems for Wankel engine monitoring

Specialized diagnostic systems have been developed for real-time monitoring of Wankel engines. These systems incorporate sensors to detect abnormalities in rotor movement, seal integrity, and combustion chamber conditions. The diagnostic tools can identify potential failures before they occur, allowing for preventive maintenance and reducing downtime. Some systems include data logging capabilities for long-term performance analysis and trend identification.Expand Specific Solutions03 Seal testing and evaluation in operational Wankel engines

Methods for evaluating the performance and integrity of seals in operational Wankel engines have been developed. These techniques focus on measuring seal wear, leakage, and effectiveness while the engine is running. Since seal performance is critical to Wankel engine efficiency, in-situ testing of these components provides valuable data on their durability and functionality under various operating conditions, including different speeds, loads, and temperatures.Expand Specific Solutions04 Thermal and combustion analysis during Wankel engine operation

Techniques for analyzing thermal characteristics and combustion efficiency in operating Wankel engines have been developed. These methods include temperature mapping of the epitrochoidal housing, monitoring heat distribution across the rotor faces, and analyzing exhaust gas composition. Such in-situ testing helps optimize fuel mixture, ignition timing, and cooling systems by providing real-time data on combustion quality and thermal stress points during actual operation.Expand Specific Solutions05 Vibration and acoustic testing for Wankel engine condition assessment

Vibration and acoustic analysis methods have been developed for assessing Wankel engine condition during operation. These non-invasive testing techniques use accelerometers and acoustic sensors to detect abnormal vibration patterns or sound signatures that may indicate mechanical issues. By analyzing the frequency spectrum and amplitude of vibrations, technicians can identify specific problems such as rotor imbalance, bearing wear, or housing deformation without engine disassembly.Expand Specific Solutions

Key Industry Players in Rotary Engine Testing

The Wankel engine in situ testing market is currently in a growth phase, with increasing demand for more efficient and reliable rotary engine diagnostics. The market size is estimated to be expanding at a moderate rate as automotive and aerospace industries seek advanced testing solutions. From a technological maturity perspective, established players like BMW, Toyota, and Robert Bosch lead with sophisticated diagnostic systems, while RTX Corp. and Pratt & Whitney contribute aerospace-grade testing innovations. Chinese entities including Shandong University and AVIC Shenyang Liming are rapidly advancing their capabilities, particularly in non-invasive testing methods. European manufacturers such as Renault and IFP Energies Nouvelles focus on emissions and performance optimization testing technologies, creating a competitive landscape where regional strengths are emerging in this specialized field.

Bayerische Motoren Werke AG

Technical Solution: BMW has developed sophisticated in situ testing techniques specifically for Wankel engines, building on their experience with rotary technology. Their approach centers on a comprehensive thermal mapping system that utilizes infrared sensors embedded at critical points within the epitrochoidal housing. This allows for real-time monitoring of temperature distribution across the combustion chamber, rotor faces, and apex seals during operation. BMW's system incorporates high-frequency vibration analysis sensors calibrated to detect the unique rotational characteristics of Wankel engines, enabling early identification of rotor imbalance and bearing wear. Their technology includes specialized oil film thickness sensors that monitor the critical lubrication layer between rotor apex seals and the housing surface, providing insights into seal dynamics and wear patterns. Additionally, BMW has implemented exhaust gas composition analysis with millisecond response times, correlating combustion efficiency with rotor position throughout the eccentric rotation cycle. The system integrates all sensor data through a proprietary algorithm that accounts for the three-dimensional movement patterns unique to rotary engines.

Strengths: Exceptional thermal mapping capabilities providing insights into the complex heat distribution patterns in Wankel engines; highly sensitive vibration analysis tuned specifically for rotary dynamics; comprehensive integration of multiple data streams for holistic engine health assessment. Weaknesses: System complexity requires specialized training for proper interpretation; higher implementation cost compared to conventional engine testing; some sensors require periodic recalibration to maintain accuracy in the unique operating environment of rotary engines.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered non-invasive in situ testing techniques for Wankel engines through their advanced piezoelectric sensor arrays that can be retrofitted to existing engine designs. Their system features miniaturized sensors positioned at strategic points along the epitrochoidal housing to capture comprehensive data on combustion dynamics. The technology incorporates proprietary algorithms that compensate for the unique thermal expansion characteristics of rotary engines during operation, ensuring measurement accuracy across varying operating conditions. Bosch's approach includes specialized oil analysis sensors that continuously monitor lubricant condition in real-time, addressing the critical lubrication challenges inherent to Wankel designs. Their system integrates with engine control units to provide adaptive feedback, allowing for immediate adjustment of fuel delivery and timing based on in situ measurements. Additionally, Bosch has developed acoustic emission sensors calibrated specifically for the frequency patterns of Wankel engines, enabling early detection of apex seal wear and housing surface degradation before they manifest as performance issues.

Strengths: Highly adaptable system compatible with various Wankel engine designs; excellent integration with existing ECU systems; provides actionable data for real-time engine management adjustments. Weaknesses: Requires initial calibration specific to each engine variant; some sensors have difficulty distinguishing between normal operational variations and actual fault conditions; higher complexity compared to conventional engine testing systems.

Critical Patents in Rotary Engine Diagnostic Systems

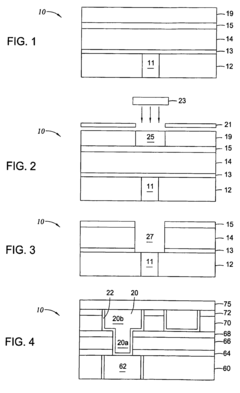

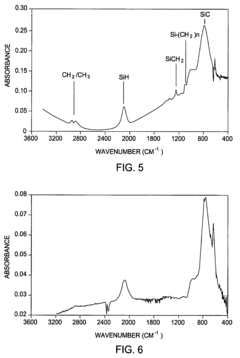

In situ deposition of a low & K dielectric layer, barrier layer, etch stop, and anti-reflective coating for damascene application

PatentInactiveUS7670945B2

Innovation

- A process using organosilane precursors to form SiC with a dielectric constant less than 7.0, allowing for in situ deposition as a barrier layer, etch stop, and anti-reflective coating, utilizing a plasma with a reducing agent like ammonia to reduce oxides, and employing a dual damascene structure with counterbore or self-aligning contact schemes for precise layer formation.

Environmental Impact and Emissions Testing Compliance

The environmental impact of Wankel rotary engines presents unique challenges for emissions testing compliance, particularly in the context of in situ testing techniques. Unlike conventional reciprocating engines, Wankel engines exhibit distinctive combustion characteristics that result in specific emission profiles requiring specialized monitoring approaches.

Current in situ emissions testing for Wankel engines focuses on addressing their inherent challenges, including higher hydrocarbon (HC) emissions resulting from the elongated combustion chamber geometry and seal dynamics. The characteristic "chatter marks" on the epitrochoid surface can create micro-pockets where unburned fuel accumulates, contributing to elevated HC levels that must be accurately measured during real-time operation.

Advanced portable emissions measurement systems (PEMS) have been adapted specifically for Wankel applications, incorporating faster sampling rates to capture the unique emission pulses generated by the rotary motion. These systems enable comprehensive monitoring of carbon monoxide, nitrogen oxides, particulate matter, and unburned hydrocarbons under actual operating conditions, providing more representative data than laboratory testing alone.

Regulatory compliance frameworks across major markets have evolved to incorporate specific provisions for rotary engine emissions. The European Union's Euro 6d standards and the EPA's Tier 3 regulations include specific testing protocols for Wankel engines that account for their unique combustion characteristics. In-situ testing techniques must therefore be calibrated to meet these regulatory requirements while providing accurate emissions profiles.

Thermal management during emissions testing represents another critical consideration. The Wankel's distinctive cooling requirements and temperature distribution patterns significantly influence emission formation. Modern in situ testing incorporates thermal imaging and multiple temperature sensors to correlate emissions data with thermal conditions throughout the engine housing and rotor faces.

Recent innovations in emissions reduction technologies for Wankel engines include advanced catalytic converters designed specifically for the temperature and exhaust flow characteristics of rotary engines. In situ testing techniques now incorporate real-time catalyst efficiency monitoring to verify the performance of these specialized aftertreatment systems under various operating conditions.

The development of hydrogen-fueled Wankel variants has introduced new emissions testing requirements focused on potential NOx formation and trace hydrocarbon emissions from lubricants. These applications demand ultra-sensitive detection methods capable of measuring near-zero conventional emissions while monitoring for unique compounds associated with hydrogen combustion in the rotary platform.

Current in situ emissions testing for Wankel engines focuses on addressing their inherent challenges, including higher hydrocarbon (HC) emissions resulting from the elongated combustion chamber geometry and seal dynamics. The characteristic "chatter marks" on the epitrochoid surface can create micro-pockets where unburned fuel accumulates, contributing to elevated HC levels that must be accurately measured during real-time operation.

Advanced portable emissions measurement systems (PEMS) have been adapted specifically for Wankel applications, incorporating faster sampling rates to capture the unique emission pulses generated by the rotary motion. These systems enable comprehensive monitoring of carbon monoxide, nitrogen oxides, particulate matter, and unburned hydrocarbons under actual operating conditions, providing more representative data than laboratory testing alone.

Regulatory compliance frameworks across major markets have evolved to incorporate specific provisions for rotary engine emissions. The European Union's Euro 6d standards and the EPA's Tier 3 regulations include specific testing protocols for Wankel engines that account for their unique combustion characteristics. In-situ testing techniques must therefore be calibrated to meet these regulatory requirements while providing accurate emissions profiles.

Thermal management during emissions testing represents another critical consideration. The Wankel's distinctive cooling requirements and temperature distribution patterns significantly influence emission formation. Modern in situ testing incorporates thermal imaging and multiple temperature sensors to correlate emissions data with thermal conditions throughout the engine housing and rotor faces.

Recent innovations in emissions reduction technologies for Wankel engines include advanced catalytic converters designed specifically for the temperature and exhaust flow characteristics of rotary engines. In situ testing techniques now incorporate real-time catalyst efficiency monitoring to verify the performance of these specialized aftertreatment systems under various operating conditions.

The development of hydrogen-fueled Wankel variants has introduced new emissions testing requirements focused on potential NOx formation and trace hydrocarbon emissions from lubricants. These applications demand ultra-sensitive detection methods capable of measuring near-zero conventional emissions while monitoring for unique compounds associated with hydrogen combustion in the rotary platform.

Cost-Benefit Analysis of Advanced Testing Techniques

The implementation of advanced in situ testing techniques for Wankel engines represents a significant investment that must be carefully evaluated against potential returns. Traditional testing methods typically involve engine disassembly, which increases maintenance downtime and labor costs. In contrast, advanced in situ testing techniques offer real-time monitoring capabilities without extensive disassembly, potentially reducing these operational disruptions.

When analyzing the cost structure of advanced testing techniques, initial capital expenditure emerges as the primary consideration. High-resolution thermal imaging systems for rotor chamber analysis typically range from $15,000 to $45,000, while specialized acoustic emission sensors for apex seal monitoring may cost between $8,000 and $20,000 per unit. Additionally, integration of these systems with existing engine management platforms requires specialized software development, estimated at $30,000 to $75,000 depending on complexity.

Operational expenses must also be factored into the analysis. Training technicians to properly utilize advanced testing equipment represents a recurring cost of approximately $2,000 to $5,000 per technician annually. System calibration and maintenance add another $3,000 to $7,000 yearly to ensure testing accuracy and reliability.

The benefits side of the equation presents compelling advantages. Studies from automotive research institutions indicate that in situ testing can reduce diagnostic time by 60-75% compared to conventional methods. This translates to approximately 4-6 fewer labor hours per diagnostic session. More significantly, early detection of rotor housing wear patterns and apex seal degradation can prevent catastrophic engine failures, with potential savings of $10,000 to $30,000 per avoided major repair event.

Long-term data collection through continuous monitoring enables predictive maintenance strategies, which industry analyses suggest can reduce overall maintenance costs by 15-25% over a five-year period. Furthermore, the enhanced understanding of Wankel engine performance under various operating conditions contributes to improved design iterations and operational efficiency gains of 3-7%.

Return on investment calculations indicate that most advanced in situ testing implementations achieve break-even within 18-24 months for fleet operations and 24-36 months for individual maintenance facilities. Organizations with larger Wankel engine deployments realize economies of scale that significantly improve these metrics, potentially reducing payback periods to 12-18 months.

When analyzing the cost structure of advanced testing techniques, initial capital expenditure emerges as the primary consideration. High-resolution thermal imaging systems for rotor chamber analysis typically range from $15,000 to $45,000, while specialized acoustic emission sensors for apex seal monitoring may cost between $8,000 and $20,000 per unit. Additionally, integration of these systems with existing engine management platforms requires specialized software development, estimated at $30,000 to $75,000 depending on complexity.

Operational expenses must also be factored into the analysis. Training technicians to properly utilize advanced testing equipment represents a recurring cost of approximately $2,000 to $5,000 per technician annually. System calibration and maintenance add another $3,000 to $7,000 yearly to ensure testing accuracy and reliability.

The benefits side of the equation presents compelling advantages. Studies from automotive research institutions indicate that in situ testing can reduce diagnostic time by 60-75% compared to conventional methods. This translates to approximately 4-6 fewer labor hours per diagnostic session. More significantly, early detection of rotor housing wear patterns and apex seal degradation can prevent catastrophic engine failures, with potential savings of $10,000 to $30,000 per avoided major repair event.

Long-term data collection through continuous monitoring enables predictive maintenance strategies, which industry analyses suggest can reduce overall maintenance costs by 15-25% over a five-year period. Furthermore, the enhanced understanding of Wankel engine performance under various operating conditions contributes to improved design iterations and operational efficiency gains of 3-7%.

Return on investment calculations indicate that most advanced in situ testing implementations achieve break-even within 18-24 months for fleet operations and 24-36 months for individual maintenance facilities. Organizations with larger Wankel engine deployments realize economies of scale that significantly improve these metrics, potentially reducing payback periods to 12-18 months.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!