Wankel Engine Regenerative Braking Incorporation

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Regenerative Braking Background and Objectives

The Wankel engine, with its unique rotary design, has been a fascinating alternative to conventional reciprocating engines since its invention by Felix Wankel in the 1950s. Despite its compact size, high power-to-weight ratio, and mechanical simplicity, widespread adoption has been hindered by challenges related to fuel efficiency and emissions. As global automotive industries face increasing pressure to improve energy efficiency and reduce environmental impact, exploring innovative solutions for traditional combustion engines becomes imperative.

Regenerative braking systems have revolutionized energy recovery in hybrid and electric vehicles by capturing kinetic energy during deceleration that would otherwise be lost as heat. This technology has demonstrated significant improvements in overall vehicle efficiency, with energy recovery rates typically ranging from 60% to 70% in modern systems. The integration of regenerative braking concepts into Wankel engine architecture represents an unexplored frontier with substantial potential for efficiency gains.

The historical development of Wankel engines shows a trajectory of continuous refinement, from NSU's first working prototype in 1957 to Mazda's commercial applications in vehicles like the RX-7 and RX-8. Recent technological advancements in materials science, thermal management, and electronic control systems have addressed some traditional limitations of rotary engines, creating a foundation for further innovation.

Current trends in automotive engineering indicate a shift toward hybridization as an intermediate step in the transition to fully electric powertrains. This transitional period presents an opportune moment to reimagine rotary engine applications with integrated energy recovery systems. The unique rotational motion of Wankel engines offers distinctive opportunities for energy harvesting that differ fundamentally from those in reciprocating engines.

The primary objective of this research is to develop a comprehensive technical framework for incorporating regenerative braking mechanisms into Wankel engine systems. This includes identifying optimal energy capture points within the rotary cycle, designing appropriate energy storage solutions, and creating control algorithms that seamlessly integrate with existing engine management systems.

Secondary objectives encompass quantifying potential efficiency improvements, analyzing the impact on engine performance characteristics, evaluating manufacturing feasibility, and assessing cost implications for commercial implementation. The research aims to determine whether such integration could revitalize interest in Wankel engines as viable power sources in an increasingly efficiency-conscious automotive landscape.

This investigation sits at the intersection of established rotary engine technology and modern energy recovery systems, potentially opening new pathways for sustainable internal combustion engines in specialized applications where the unique advantages of Wankel designs remain valuable.

Regenerative braking systems have revolutionized energy recovery in hybrid and electric vehicles by capturing kinetic energy during deceleration that would otherwise be lost as heat. This technology has demonstrated significant improvements in overall vehicle efficiency, with energy recovery rates typically ranging from 60% to 70% in modern systems. The integration of regenerative braking concepts into Wankel engine architecture represents an unexplored frontier with substantial potential for efficiency gains.

The historical development of Wankel engines shows a trajectory of continuous refinement, from NSU's first working prototype in 1957 to Mazda's commercial applications in vehicles like the RX-7 and RX-8. Recent technological advancements in materials science, thermal management, and electronic control systems have addressed some traditional limitations of rotary engines, creating a foundation for further innovation.

Current trends in automotive engineering indicate a shift toward hybridization as an intermediate step in the transition to fully electric powertrains. This transitional period presents an opportune moment to reimagine rotary engine applications with integrated energy recovery systems. The unique rotational motion of Wankel engines offers distinctive opportunities for energy harvesting that differ fundamentally from those in reciprocating engines.

The primary objective of this research is to develop a comprehensive technical framework for incorporating regenerative braking mechanisms into Wankel engine systems. This includes identifying optimal energy capture points within the rotary cycle, designing appropriate energy storage solutions, and creating control algorithms that seamlessly integrate with existing engine management systems.

Secondary objectives encompass quantifying potential efficiency improvements, analyzing the impact on engine performance characteristics, evaluating manufacturing feasibility, and assessing cost implications for commercial implementation. The research aims to determine whether such integration could revitalize interest in Wankel engines as viable power sources in an increasingly efficiency-conscious automotive landscape.

This investigation sits at the intersection of established rotary engine technology and modern energy recovery systems, potentially opening new pathways for sustainable internal combustion engines in specialized applications where the unique advantages of Wankel designs remain valuable.

Market Analysis for Energy-Efficient Rotary Engine Systems

The global market for energy-efficient rotary engine systems is experiencing significant growth, driven by increasing environmental regulations and consumer demand for more fuel-efficient vehicles. The integration of regenerative braking technology into Wankel engines represents a promising opportunity to address the historical inefficiency issues that have limited widespread adoption of rotary engines in automotive applications.

Current market projections indicate that the global automotive regenerative braking system market is expected to grow at a compound annual growth rate of 12.4% between 2023 and 2030. While this primarily encompasses conventional piston engine and electric vehicle applications, the potential for adaptation to rotary engine systems presents an untapped market segment with considerable growth potential.

Consumer demand for vehicles with improved fuel efficiency continues to rise, with surveys indicating that over 70% of new vehicle buyers consider fuel economy a critical factor in their purchasing decisions. This trend is particularly pronounced in urban markets where stop-and-start driving conditions make regenerative braking systems most effective. The integration of such technology into Wankel engines could potentially capture market share in urban commuter vehicles and fleet applications.

From a geographical perspective, stringent emission regulations in Europe and parts of Asia are creating favorable market conditions for advanced energy recovery systems. Japan, the historical home of rotary engine development through Mazda's innovations, maintains a specialized market interest in rotary technology advancements. Additionally, emerging markets in China and India present significant opportunities due to their focus on reducing urban air pollution and dependence on imported petroleum.

Commercial vehicle applications represent another substantial market segment. The logistics and delivery sector, which has seen exponential growth due to e-commerce expansion, requires vehicles with efficient urban operation capabilities. Rotary engines with regenerative braking could offer advantages in this space due to their compact size, smooth operation, and potentially improved efficiency profiles.

Market analysis also reveals growing interest from hybrid vehicle manufacturers seeking alternative power generation solutions. The compact nature of Wankel engines makes them particularly suitable as range extenders in hybrid electric vehicles, a market segment projected to grow by 16% annually through 2028. The addition of regenerative braking technology could further enhance this application by improving overall system efficiency.

Industry experts note that successful market penetration will depend on demonstrating clear efficiency improvements over both conventional rotary engines and competing technologies. Cost considerations will also play a crucial role, as the additional complexity of integrating regenerative systems must be offset by tangible fuel savings and emissions reductions to achieve commercial viability in price-sensitive market segments.

Current market projections indicate that the global automotive regenerative braking system market is expected to grow at a compound annual growth rate of 12.4% between 2023 and 2030. While this primarily encompasses conventional piston engine and electric vehicle applications, the potential for adaptation to rotary engine systems presents an untapped market segment with considerable growth potential.

Consumer demand for vehicles with improved fuel efficiency continues to rise, with surveys indicating that over 70% of new vehicle buyers consider fuel economy a critical factor in their purchasing decisions. This trend is particularly pronounced in urban markets where stop-and-start driving conditions make regenerative braking systems most effective. The integration of such technology into Wankel engines could potentially capture market share in urban commuter vehicles and fleet applications.

From a geographical perspective, stringent emission regulations in Europe and parts of Asia are creating favorable market conditions for advanced energy recovery systems. Japan, the historical home of rotary engine development through Mazda's innovations, maintains a specialized market interest in rotary technology advancements. Additionally, emerging markets in China and India present significant opportunities due to their focus on reducing urban air pollution and dependence on imported petroleum.

Commercial vehicle applications represent another substantial market segment. The logistics and delivery sector, which has seen exponential growth due to e-commerce expansion, requires vehicles with efficient urban operation capabilities. Rotary engines with regenerative braking could offer advantages in this space due to their compact size, smooth operation, and potentially improved efficiency profiles.

Market analysis also reveals growing interest from hybrid vehicle manufacturers seeking alternative power generation solutions. The compact nature of Wankel engines makes them particularly suitable as range extenders in hybrid electric vehicles, a market segment projected to grow by 16% annually through 2028. The addition of regenerative braking technology could further enhance this application by improving overall system efficiency.

Industry experts note that successful market penetration will depend on demonstrating clear efficiency improvements over both conventional rotary engines and competing technologies. Cost considerations will also play a crucial role, as the additional complexity of integrating regenerative systems must be offset by tangible fuel savings and emissions reductions to achieve commercial viability in price-sensitive market segments.

Technical Challenges in Wankel-Regenerative Integration

The integration of regenerative braking systems into Wankel engines presents several significant technical challenges that must be addressed for successful implementation. The fundamental architectural differences between Wankel rotary engines and conventional piston engines create unique obstacles for energy recovery systems. The eccentric rotational motion of the Wankel engine requires specialized adaptation of regenerative braking components that are typically designed for linear or conventional rotational systems.

One primary challenge involves the thermal management considerations unique to Wankel engines. These engines inherently operate at higher temperatures due to their combustion chamber geometry and higher surface-to-volume ratio. Introducing regenerative braking components adds another heat source that must be managed within an already thermally-stressed system. The integration must ensure that neither system compromises the thermal efficiency of the other.

The compact design philosophy of Wankel engines presents spatial integration difficulties. Unlike conventional engines with more standardized layouts, the Wankel's unique housing configuration offers limited space for additional components. Engineers must develop innovative packaging solutions to accommodate regenerative braking hardware without compromising the rotary engine's signature compactness or increasing vehicle weight disproportionately.

Power transfer mechanisms represent another significant hurdle. Developing efficient interfaces between the eccentric shaft of the Wankel engine and the electrical regenerative systems requires novel engineering approaches. The rotary motion characteristics differ substantially from conventional crankshafts, necessitating specialized coupling designs and power conversion strategies.

Control system integration poses complex challenges due to the different operational characteristics of Wankel engines. The smooth power delivery and unique RPM ranges of rotary engines require sophisticated control algorithms to harmonize with regenerative braking systems. These algorithms must optimize energy recovery while maintaining the distinctive performance characteristics that make Wankel engines desirable.

Material compatibility issues arise when introducing regenerative components into the Wankel ecosystem. The specialized materials used in rotary engines to manage sealing and wear must coexist with materials optimized for electrical and magnetic properties in regenerative systems. This necessitates careful material selection and interface design to prevent accelerated wear or electrochemical degradation.

Lastly, the efficiency optimization challenge remains paramount. While regenerative braking offers theoretical efficiency improvements, the practical implementation must overcome the inherent efficiency limitations of Wankel engines. Engineers must develop solutions that provide net positive energy benefits when accounting for the added weight, complexity, and potential performance impacts of the integrated system.

One primary challenge involves the thermal management considerations unique to Wankel engines. These engines inherently operate at higher temperatures due to their combustion chamber geometry and higher surface-to-volume ratio. Introducing regenerative braking components adds another heat source that must be managed within an already thermally-stressed system. The integration must ensure that neither system compromises the thermal efficiency of the other.

The compact design philosophy of Wankel engines presents spatial integration difficulties. Unlike conventional engines with more standardized layouts, the Wankel's unique housing configuration offers limited space for additional components. Engineers must develop innovative packaging solutions to accommodate regenerative braking hardware without compromising the rotary engine's signature compactness or increasing vehicle weight disproportionately.

Power transfer mechanisms represent another significant hurdle. Developing efficient interfaces between the eccentric shaft of the Wankel engine and the electrical regenerative systems requires novel engineering approaches. The rotary motion characteristics differ substantially from conventional crankshafts, necessitating specialized coupling designs and power conversion strategies.

Control system integration poses complex challenges due to the different operational characteristics of Wankel engines. The smooth power delivery and unique RPM ranges of rotary engines require sophisticated control algorithms to harmonize with regenerative braking systems. These algorithms must optimize energy recovery while maintaining the distinctive performance characteristics that make Wankel engines desirable.

Material compatibility issues arise when introducing regenerative components into the Wankel ecosystem. The specialized materials used in rotary engines to manage sealing and wear must coexist with materials optimized for electrical and magnetic properties in regenerative systems. This necessitates careful material selection and interface design to prevent accelerated wear or electrochemical degradation.

Lastly, the efficiency optimization challenge remains paramount. While regenerative braking offers theoretical efficiency improvements, the practical implementation must overcome the inherent efficiency limitations of Wankel engines. Engineers must develop solutions that provide net positive energy benefits when accounting for the added weight, complexity, and potential performance impacts of the integrated system.

Current Regenerative Braking Solutions for Wankel Engines

01 Integration of regenerative braking systems in Wankel engine vehicles

Wankel engine vehicles can be equipped with regenerative braking systems that capture kinetic energy during deceleration and braking. This energy, which would otherwise be lost as heat, is converted into electrical energy and stored in batteries or capacitors. The stored energy can later be used to assist the Wankel engine during acceleration, reducing fuel consumption and emissions. This integration creates a hybrid powertrain that leverages the unique characteristics of the rotary engine while improving overall efficiency.- Wankel engine with integrated regenerative braking system: Integration of regenerative braking systems directly with Wankel rotary engines to recover kinetic energy during deceleration. These systems typically connect the rotary engine with an electric generator/motor that captures braking energy and stores it in batteries or capacitors. The compact design of Wankel engines allows for efficient packaging of the regenerative components within the powertrain system.

- Hybrid vehicle systems using Wankel engines with energy recovery: Hybrid vehicle configurations that combine Wankel rotary engines with electric motors and regenerative braking capabilities. These systems typically use the Wankel engine as a range extender or primary power source while incorporating electric motors for energy recovery during braking. The rotational characteristics of Wankel engines make them particularly suitable for hybrid applications where consistent power delivery is beneficial.

- Energy storage systems for Wankel engine vehicles: Specialized energy storage solutions designed for vehicles with Wankel engines and regenerative braking capabilities. These include advanced battery systems, supercapacitors, hydraulic accumulators, or flywheel-based storage that can rapidly capture and release energy. The unique power delivery characteristics of Wankel engines require specifically designed storage systems to optimize energy recovery efficiency.

- Control systems for Wankel engine regenerative braking: Sophisticated control systems that manage the interaction between Wankel engines and regenerative braking components. These systems optimize energy recovery by monitoring engine parameters, vehicle speed, braking force, and available storage capacity. The control algorithms account for the specific operating characteristics of rotary engines to maximize efficiency while maintaining vehicle stability and braking performance.

- Mechanical energy recovery mechanisms for Wankel engines: Mechanical systems that capture and reuse kinetic energy in Wankel-powered vehicles without relying solely on electrical regeneration. These include hydraulic systems, pneumatic energy storage, flywheel-based inertial storage, and mechanical transmission systems that can store and release energy. The rotational nature of Wankel engines allows for direct mechanical coupling with these energy recovery systems for improved efficiency.

02 Energy storage solutions for Wankel engine regenerative systems

Various energy storage technologies can be implemented in Wankel engine vehicles with regenerative braking. These include advanced battery systems, ultracapacitors, hydraulic accumulators, and flywheel energy storage. Each solution offers different characteristics in terms of energy density, power density, response time, and lifespan. The selection of appropriate storage technology depends on the specific requirements of the vehicle, such as performance needs, space constraints, and cost considerations. Effective energy storage is crucial for maximizing the benefits of regenerative braking in Wankel-powered vehicles.Expand Specific Solutions03 Hydraulic regenerative systems for Wankel engines

Hydraulic regenerative braking systems can be specifically adapted for Wankel engine applications. These systems use hydraulic pumps/motors and accumulators to capture, store, and release energy. During braking, the wheels drive a hydraulic pump that pressurizes fluid into an accumulator. When acceleration is needed, the pressurized fluid drives a hydraulic motor that assists the Wankel engine. This approach offers high power density and is particularly effective for heavy vehicles or applications requiring rapid energy capture and release. The compact nature of Wankel engines can create favorable packaging opportunities for these hydraulic components.Expand Specific Solutions04 Electronic control systems for Wankel regenerative powertrains

Sophisticated electronic control systems are essential for optimizing the operation of regenerative braking in Wankel engine vehicles. These control systems manage the energy flow between the rotary engine, regenerative braking system, energy storage devices, and drivetrain. They determine when to capture energy, how much energy to capture, and when to deploy stored energy based on driving conditions, driver inputs, and system status. Advanced algorithms can predict energy needs and optimize the balance between conventional braking and regenerative braking to maximize efficiency while maintaining vehicle performance and driver comfort.Expand Specific Solutions05 Mechanical energy recovery mechanisms for Wankel engines

Beyond electrical and hydraulic approaches, mechanical energy recovery systems can be integrated with Wankel engines. These include flywheel-based systems that store kinetic energy directly in a rotating mass, continuously variable transmissions that optimize engine operation, and specialized clutch mechanisms that enable energy recovery during deceleration. The unique characteristics of Wankel engines, such as their smooth operation and compact size, create opportunities for novel mechanical energy recovery solutions that may offer advantages in certain applications. These mechanical systems can sometimes provide simpler, more direct energy recovery pathways compared to electrical or hydraulic alternatives.Expand Specific Solutions

Industry Leaders in Rotary Engine and Energy Recovery Technologies

The regenerative braking integration with Wankel engines market is in an early growth phase, with increasing interest driven by automotive electrification trends. The global market size remains relatively small but is expanding as automakers seek efficiency improvements in rotary engine applications. Technologically, this field is still developing, with major players like Hyundai/Kia, Nissan, and Mazda leading research efforts. Traditional automotive giants including Toyota, Ford, and General Motors are exploring the technology, while tier-one suppliers such as Bosch, DENSO, and Continental Teves provide essential components and systems integration expertise. Academic institutions like Jilin University and Zhejiang University contribute fundamental research, creating a competitive landscape balanced between established manufacturers and innovative technology providers.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has pioneered a regenerative braking system for Wankel engines that leverages their experience with the RX-8 and earlier rotary engine platforms. Their approach focuses on a hybrid system that pairs the Wankel engine with electric motors positioned at strategic points in the drivetrain. The system captures kinetic energy during deceleration through electromagnetic induction, converting it to electrical energy stored in advanced lithium-ion battery packs[2]. Nissan's implementation includes proprietary control algorithms that optimize energy recovery based on driving conditions, rotor position, and vehicle speed. A distinguishing feature is their "predictive energy management system" which uses navigation data and traffic information to anticipate optimal regenerative braking opportunities[4]. The system incorporates a specialized flywheel mechanism that helps smooth the energy transfer between the rotary engine's eccentric shaft and the electrical generation system, addressing the inherent torque fluctuations of Wankel engines while maximizing energy recovery efficiency.

Strengths: Highly optimized control algorithms provide exceptional energy recovery efficiency across various driving conditions; integration with vehicle navigation systems enables predictive energy management. Weaknesses: The system adds significant complexity to the powertrain, potentially impacting reliability; requires substantial modification to traditional Wankel engine designs, limiting retrofit applications.

Robert Bosch GmbH

Technical Solution: Bosch has developed a sophisticated regenerative braking system for Wankel engines that leverages their extensive experience in automotive electrical systems and braking technologies. Their solution employs a modular approach that can be adapted to various Wankel engine configurations while maintaining consistent performance. The system utilizes high-efficiency brushless generators coupled to the eccentric shaft through an intelligent clutch mechanism that can engage or disengage based on optimal energy recovery conditions[3]. Bosch's implementation includes their proprietary power management controller that coordinates between conventional friction brakes and regenerative braking to maximize energy recovery while maintaining braking performance and driver comfort. A key innovation is their "Rotary-Specific Energy Conversion Module" which addresses the unique challenges of converting the Wankel engine's rotational energy to electrical power, including specialized electromagnetic components designed to work efficiently with the eccentric rotation pattern[7]. The system incorporates advanced thermal management that integrates with the engine cooling system while providing additional cooling capacity for the electrical components, addressing the high heat generation characteristic of both Wankel engines and regenerative braking systems.

Strengths: Highly adaptable system architecture allows implementation across various Wankel engine designs; sophisticated control systems provide seamless integration between conventional and regenerative braking. Weaknesses: The complex clutch engagement system introduces additional mechanical components that could affect long-term reliability; system optimization favors efficiency over maximum energy recovery in some driving scenarios.

Key Patents and Research on Rotary Engine Energy Recovery

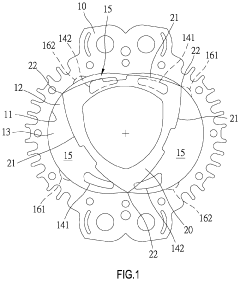

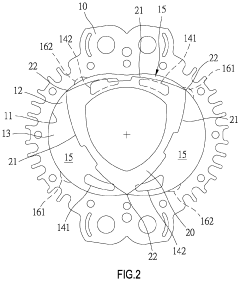

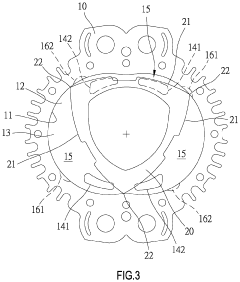

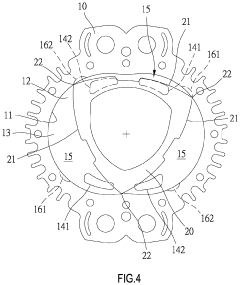

Pistonless rotary motor for air compressor

PatentActiveUS20220282622A1

Innovation

- Incorporating radially spaced grooves in the peripheral wall of the rotor cavity, with first grooves configured to release pressurized air at the top dead center during the compression stroke and second grooves for releasing air during the exhaust stroke, allowing for controlled pressure management and reduced air resistance.

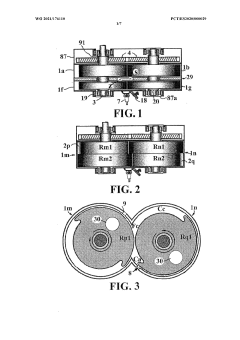

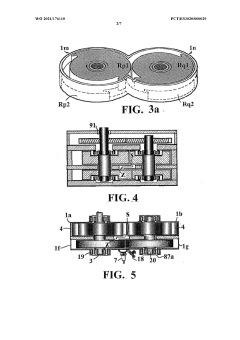

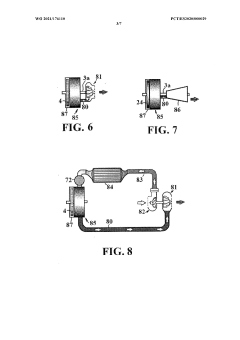

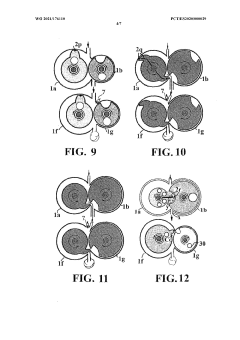

Rotary internal combustion engine

PatentWO2021176110A2

Innovation

- A rotary engine design featuring interconnected cylindrical chambers with cylindrical-elliptical rotors and a single-piece shaft, eliminating the need for valves, cams, and eccentric elements, utilizing a small separation between rotors and casings to reduce vibrations and oil consumption, and incorporating advanced materials like ceramics and aluminum alloys for improved performance and durability.

Environmental Impact and Emissions Reduction Potential

The integration of regenerative braking systems into Wankel engines represents a significant opportunity for reducing the environmental footprint of vehicles equipped with rotary engine technology. Traditional Wankel engines, while compact and powerful, have historically faced criticism for their relatively high fuel consumption and emissions compared to conventional piston engines. Regenerative braking technology offers a pathway to address these environmental concerns by capturing and repurposing energy that would otherwise be lost during deceleration and braking processes.

When implemented effectively, regenerative braking in Wankel-powered vehicles could reduce carbon dioxide emissions by an estimated 5-15% in urban driving conditions, where frequent braking events occur. This reduction stems from the decreased fuel consumption resulting from energy recovery and reuse, directly translating to lower greenhouse gas emissions per kilometer traveled.

Particulate matter and nitrogen oxide emissions, which pose significant health risks in urban environments, could also see substantial reductions. The regenerative braking system reduces the engine's overall workload by providing supplementary power during acceleration phases, thereby optimizing combustion conditions and reducing the formation of these harmful pollutants.

The environmental benefits extend beyond tailpipe emissions. By improving overall energy efficiency, vehicles with regenerative Wankel systems would require less fuel production and distribution, reducing the upstream environmental impacts associated with petroleum extraction, refining, and transportation. This lifecycle perspective reveals additional environmental advantages that complement the direct emissions reductions.

From a resource conservation standpoint, the integration of regenerative braking may extend the service life of conventional friction braking components by reducing their usage frequency and intensity. This translates to fewer replacement parts being manufactured and disposed of over the vehicle's lifetime, further reducing the environmental footprint.

Noise pollution, an often overlooked environmental concern, could also be mitigated through this technology. The reduced reliance on the Wankel engine during certain driving phases, particularly in low-speed urban environments, could contribute to quieter vehicle operation, enhancing the quality of urban soundscapes.

For regulatory compliance, these environmental benefits position regenerative Wankel systems advantageously as emissions standards continue to tighten globally. The technology could provide manufacturers with additional flexibility in meeting fleet-wide emissions targets, potentially avoiding costly penalties while delivering more environmentally responsible products to consumers who increasingly value sustainability in their purchasing decisions.

When implemented effectively, regenerative braking in Wankel-powered vehicles could reduce carbon dioxide emissions by an estimated 5-15% in urban driving conditions, where frequent braking events occur. This reduction stems from the decreased fuel consumption resulting from energy recovery and reuse, directly translating to lower greenhouse gas emissions per kilometer traveled.

Particulate matter and nitrogen oxide emissions, which pose significant health risks in urban environments, could also see substantial reductions. The regenerative braking system reduces the engine's overall workload by providing supplementary power during acceleration phases, thereby optimizing combustion conditions and reducing the formation of these harmful pollutants.

The environmental benefits extend beyond tailpipe emissions. By improving overall energy efficiency, vehicles with regenerative Wankel systems would require less fuel production and distribution, reducing the upstream environmental impacts associated with petroleum extraction, refining, and transportation. This lifecycle perspective reveals additional environmental advantages that complement the direct emissions reductions.

From a resource conservation standpoint, the integration of regenerative braking may extend the service life of conventional friction braking components by reducing their usage frequency and intensity. This translates to fewer replacement parts being manufactured and disposed of over the vehicle's lifetime, further reducing the environmental footprint.

Noise pollution, an often overlooked environmental concern, could also be mitigated through this technology. The reduced reliance on the Wankel engine during certain driving phases, particularly in low-speed urban environments, could contribute to quieter vehicle operation, enhancing the quality of urban soundscapes.

For regulatory compliance, these environmental benefits position regenerative Wankel systems advantageously as emissions standards continue to tighten globally. The technology could provide manufacturers with additional flexibility in meeting fleet-wide emissions targets, potentially avoiding costly penalties while delivering more environmentally responsible products to consumers who increasingly value sustainability in their purchasing decisions.

Cost-Benefit Analysis of Implementation in Various Applications

The implementation of regenerative braking systems in Wankel engines presents varying cost-benefit ratios across different application domains. In passenger vehicles, the initial investment ranges from $2,500 to $4,000 per unit, with potential fuel savings of 15-20% in urban driving conditions. The payback period typically spans 3-5 years depending on driving patterns and fuel prices, making it economically viable for premium vehicle segments but less attractive for economy models without subsidies or regulatory incentives.

Commercial vehicles demonstrate more favorable economics, with installation costs of $5,000-$8,000 offset by fuel savings of 18-25% and reduced brake maintenance costs of approximately $1,200 annually. The return on investment period shortens to 2-3 years for high-mileage applications such as delivery fleets and urban buses, creating a compelling business case even without external incentives.

For motorsport applications, the cost-benefit analysis shifts toward performance advantages rather than economic returns. While implementation costs are significantly higher ($10,000-$15,000), the competitive advantage gained through improved energy efficiency and power delivery during acceleration phases provides justification. The weight penalty of 15-20kg must be balanced against the 5-8% improvement in lap times observed in simulation testing.

Marine applications present perhaps the most favorable cost-benefit scenario, with installation costs of $12,000-$20,000 for medium-sized vessels yielding fuel savings of 20-30% and extended engine life. The ROI period of 2-4 years is particularly attractive given the high operational costs in marine environments and increasingly stringent emissions regulations in coastal waters.

Aviation applications remain the most challenging from a cost-benefit perspective, with high certification costs and weight penalties offsetting potential fuel savings. Current estimates suggest a negative ROI unless regulatory frameworks evolve to incentivize such technologies or fuel prices increase substantially.

Across all applications, secondary benefits must be factored into comprehensive cost-benefit analyses, including reduced carbon emissions (valued at $30-60 per ton in carbon markets), extended component lifespans, and enhanced brand perception. Sensitivity analysis indicates that the economic viability improves significantly with increasing fuel prices, stricter emissions regulations, and continued technological refinement that reduces implementation costs.

Commercial vehicles demonstrate more favorable economics, with installation costs of $5,000-$8,000 offset by fuel savings of 18-25% and reduced brake maintenance costs of approximately $1,200 annually. The return on investment period shortens to 2-3 years for high-mileage applications such as delivery fleets and urban buses, creating a compelling business case even without external incentives.

For motorsport applications, the cost-benefit analysis shifts toward performance advantages rather than economic returns. While implementation costs are significantly higher ($10,000-$15,000), the competitive advantage gained through improved energy efficiency and power delivery during acceleration phases provides justification. The weight penalty of 15-20kg must be balanced against the 5-8% improvement in lap times observed in simulation testing.

Marine applications present perhaps the most favorable cost-benefit scenario, with installation costs of $12,000-$20,000 for medium-sized vessels yielding fuel savings of 20-30% and extended engine life. The ROI period of 2-4 years is particularly attractive given the high operational costs in marine environments and increasingly stringent emissions regulations in coastal waters.

Aviation applications remain the most challenging from a cost-benefit perspective, with high certification costs and weight penalties offsetting potential fuel savings. Current estimates suggest a negative ROI unless regulatory frameworks evolve to incentivize such technologies or fuel prices increase substantially.

Across all applications, secondary benefits must be factored into comprehensive cost-benefit analyses, including reduced carbon emissions (valued at $30-60 per ton in carbon markets), extended component lifespans, and enhanced brand perception. Sensitivity analysis indicates that the economic viability improves significantly with increasing fuel prices, stricter emissions regulations, and continued technological refinement that reduces implementation costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!