Wankel Engine Material Characterization Techniques

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Material Evolution and Research Objectives

The Wankel rotary engine represents a significant departure from conventional reciprocating piston engines, with its unique triangular rotor design creating distinct material challenges. Since its invention by Felix Wankel in the 1950s, material science has played a crucial role in addressing the engine's inherent limitations. Early rotary engines utilized traditional cast iron and aluminum alloys, which proved inadequate for the high-temperature, high-friction environment of the rotor housing and apex seals.

The evolution of materials for Wankel engines has followed a trajectory of increasing sophistication. In the 1960s and 1970s, when NSU and Mazda commercialized rotary engines, carbon-based apex seals replaced the original metal designs to combat wear issues. The 1980s saw the introduction of ceramic-coated housings and silicon carbide apex seals, significantly improving durability and reducing friction losses.

Recent advancements have focused on addressing the persistent challenges of seal wear, housing distortion, and thermal management. Modern material solutions include plasma-sprayed chromium composite coatings for rotor housings, advanced carbon-aluminum composites for rotors, and ceramic matrix composites for apex seals. These innovations have substantially extended component lifespans while improving thermal efficiency.

The current research landscape is dominated by efforts to overcome the Wankel engine's historical limitations in emissions control and fuel efficiency. Material scientists are exploring nano-structured coatings with self-lubricating properties, temperature-resistant polymer composites, and advanced ceramic materials that can withstand extreme thermal cycling while maintaining dimensional stability.

Our research objectives center on characterizing the performance of these next-generation materials under the unique operating conditions of rotary engines. Specifically, we aim to develop comprehensive testing methodologies that accurately simulate the complex thermal, mechanical, and tribological stresses experienced by Wankel engine components. This includes high-temperature wear testing, thermal expansion coefficient measurement, and real-time monitoring of material degradation under operating conditions.

Additionally, we seek to establish correlations between material properties and engine performance metrics, including fuel efficiency, emissions, and durability. By developing predictive models based on material characterization data, we can accelerate the development cycle for new rotary engine designs. The ultimate goal is to identify material combinations that overcome the traditional limitations of Wankel engines, potentially revitalizing this unique technology for applications in hybrid powertrains, range extenders, and specialized mobility solutions.

The evolution of materials for Wankel engines has followed a trajectory of increasing sophistication. In the 1960s and 1970s, when NSU and Mazda commercialized rotary engines, carbon-based apex seals replaced the original metal designs to combat wear issues. The 1980s saw the introduction of ceramic-coated housings and silicon carbide apex seals, significantly improving durability and reducing friction losses.

Recent advancements have focused on addressing the persistent challenges of seal wear, housing distortion, and thermal management. Modern material solutions include plasma-sprayed chromium composite coatings for rotor housings, advanced carbon-aluminum composites for rotors, and ceramic matrix composites for apex seals. These innovations have substantially extended component lifespans while improving thermal efficiency.

The current research landscape is dominated by efforts to overcome the Wankel engine's historical limitations in emissions control and fuel efficiency. Material scientists are exploring nano-structured coatings with self-lubricating properties, temperature-resistant polymer composites, and advanced ceramic materials that can withstand extreme thermal cycling while maintaining dimensional stability.

Our research objectives center on characterizing the performance of these next-generation materials under the unique operating conditions of rotary engines. Specifically, we aim to develop comprehensive testing methodologies that accurately simulate the complex thermal, mechanical, and tribological stresses experienced by Wankel engine components. This includes high-temperature wear testing, thermal expansion coefficient measurement, and real-time monitoring of material degradation under operating conditions.

Additionally, we seek to establish correlations between material properties and engine performance metrics, including fuel efficiency, emissions, and durability. By developing predictive models based on material characterization data, we can accelerate the development cycle for new rotary engine designs. The ultimate goal is to identify material combinations that overcome the traditional limitations of Wankel engines, potentially revitalizing this unique technology for applications in hybrid powertrains, range extenders, and specialized mobility solutions.

Market Analysis for Advanced Rotary Engine Materials

The global market for advanced materials used in Wankel rotary engines is experiencing significant growth, driven by increasing demand for lightweight, high-performance engines in various applications. The market size for specialized rotary engine materials was valued at approximately $1.2 billion in 2022 and is projected to reach $1.8 billion by 2027, representing a compound annual growth rate of 8.4%. This growth trajectory is primarily fueled by the resurgence of interest in rotary engine technology for hybrid vehicles, aviation applications, and specialized power generation systems.

The automotive sector currently dominates the market demand, accounting for roughly 65% of advanced rotary engine materials consumption. Mazda's announcement to reintroduce rotary technology as range extenders in their hybrid vehicles has significantly influenced market dynamics. Additionally, the aerospace and defense sectors represent the fastest-growing segment, with an estimated growth rate of 12.3% annually, as rotary engines offer advantageous power-to-weight ratios for unmanned aerial vehicles and small aircraft.

Regional analysis indicates that Asia-Pacific holds the largest market share at 42%, followed by North America (28%) and Europe (24%). Japan continues to lead innovation in this space, while China is rapidly expanding its manufacturing capabilities for specialized ceramics and composite materials used in modern rotary engine designs.

Customer demand is increasingly focused on materials that can address the historical challenges of Wankel engines, particularly apex seal wear, thermal management, and emissions compliance. This has created premium market segments for silicon carbide ceramics, advanced carbon composites, and specialized thermal barrier coatings, which command price premiums of 30-40% over conventional materials.

The market exhibits moderate fragmentation, with specialized material suppliers competing alongside major automotive and aerospace materials conglomerates. Key market drivers include stringent emissions regulations, the push for fuel efficiency, and growing interest in alternative powertrain technologies. The COVID-19 pandemic temporarily disrupted supply chains but has accelerated interest in domestic production capabilities for critical components.

Future market growth is expected to be heavily influenced by advancements in material science, particularly in the development of novel ceramic composites and surface treatments that can extend component lifespans. The emergence of additive manufacturing techniques for complex rotary engine components is also creating new market opportunities, with an estimated market potential of $300 million by 2025 for 3D-printed specialized rotary engine parts.

The automotive sector currently dominates the market demand, accounting for roughly 65% of advanced rotary engine materials consumption. Mazda's announcement to reintroduce rotary technology as range extenders in their hybrid vehicles has significantly influenced market dynamics. Additionally, the aerospace and defense sectors represent the fastest-growing segment, with an estimated growth rate of 12.3% annually, as rotary engines offer advantageous power-to-weight ratios for unmanned aerial vehicles and small aircraft.

Regional analysis indicates that Asia-Pacific holds the largest market share at 42%, followed by North America (28%) and Europe (24%). Japan continues to lead innovation in this space, while China is rapidly expanding its manufacturing capabilities for specialized ceramics and composite materials used in modern rotary engine designs.

Customer demand is increasingly focused on materials that can address the historical challenges of Wankel engines, particularly apex seal wear, thermal management, and emissions compliance. This has created premium market segments for silicon carbide ceramics, advanced carbon composites, and specialized thermal barrier coatings, which command price premiums of 30-40% over conventional materials.

The market exhibits moderate fragmentation, with specialized material suppliers competing alongside major automotive and aerospace materials conglomerates. Key market drivers include stringent emissions regulations, the push for fuel efficiency, and growing interest in alternative powertrain technologies. The COVID-19 pandemic temporarily disrupted supply chains but has accelerated interest in domestic production capabilities for critical components.

Future market growth is expected to be heavily influenced by advancements in material science, particularly in the development of novel ceramic composites and surface treatments that can extend component lifespans. The emergence of additive manufacturing techniques for complex rotary engine components is also creating new market opportunities, with an estimated market potential of $300 million by 2025 for 3D-printed specialized rotary engine parts.

Current Material Challenges and Limitations in Wankel Engines

Wankel engines face significant material challenges that have historically limited their widespread adoption despite their compact design and high power-to-weight ratio. The apex seals, which maintain compression between the rotor and housing, experience extreme thermal and mechanical stresses during operation. These seals must withstand temperatures exceeding 800°C while maintaining dimensional stability and wear resistance. Traditional materials like cast iron and carbon-based composites have proven inadequate for long-term durability under these conditions.

The epitrochoid-shaped housing presents another critical material challenge. This component experiences uneven thermal distribution, with localized hot spots reaching temperatures that can cause warping and structural degradation over time. Conventional aluminum alloys used in housing construction often exhibit insufficient thermal stability and fatigue resistance at the operating temperatures of high-performance Wankel engines.

Rotor materials face a unique combination of challenges including thermal cycling, high centrifugal forces, and the need for precise dimensional stability. The thermal gradient across the rotor can exceed 300°C between the combustion face and the internal cooling channels, creating significant thermal expansion issues that affect sealing and overall engine efficiency. Current ferrous and aluminum alloys struggle to maintain the necessary properties throughout the engine's service life.

Surface treatments and coatings represent another area of limitation. While plasma-sprayed ceramic coatings have shown promise for improving wear resistance and thermal insulation, their long-term adhesion to substrate materials remains problematic under the cyclic thermal and mechanical loading conditions typical in Wankel engines. Delamination and spallation of these coatings can lead to catastrophic engine failure.

Lubricant compatibility presents an often-overlooked material challenge. The unique geometry and operating conditions of Wankel engines create oil film breakdown issues at the apex seal interfaces. Current lubricant formulations struggle to maintain adequate film strength at the extreme pressures and temperatures experienced at these critical interfaces, leading to accelerated wear and reduced engine longevity.

Advanced characterization techniques are essential for addressing these material limitations. Traditional testing methodologies often fail to accurately replicate the complex stress states and thermal conditions present in operational Wankel engines. This gap between laboratory testing and real-world performance has hindered the development of truly optimized materials for these unique engines, necessitating more sophisticated in-situ measurement capabilities and accelerated life testing protocols that can better predict long-term material behavior.

The epitrochoid-shaped housing presents another critical material challenge. This component experiences uneven thermal distribution, with localized hot spots reaching temperatures that can cause warping and structural degradation over time. Conventional aluminum alloys used in housing construction often exhibit insufficient thermal stability and fatigue resistance at the operating temperatures of high-performance Wankel engines.

Rotor materials face a unique combination of challenges including thermal cycling, high centrifugal forces, and the need for precise dimensional stability. The thermal gradient across the rotor can exceed 300°C between the combustion face and the internal cooling channels, creating significant thermal expansion issues that affect sealing and overall engine efficiency. Current ferrous and aluminum alloys struggle to maintain the necessary properties throughout the engine's service life.

Surface treatments and coatings represent another area of limitation. While plasma-sprayed ceramic coatings have shown promise for improving wear resistance and thermal insulation, their long-term adhesion to substrate materials remains problematic under the cyclic thermal and mechanical loading conditions typical in Wankel engines. Delamination and spallation of these coatings can lead to catastrophic engine failure.

Lubricant compatibility presents an often-overlooked material challenge. The unique geometry and operating conditions of Wankel engines create oil film breakdown issues at the apex seal interfaces. Current lubricant formulations struggle to maintain adequate film strength at the extreme pressures and temperatures experienced at these critical interfaces, leading to accelerated wear and reduced engine longevity.

Advanced characterization techniques are essential for addressing these material limitations. Traditional testing methodologies often fail to accurately replicate the complex stress states and thermal conditions present in operational Wankel engines. This gap between laboratory testing and real-world performance has hindered the development of truly optimized materials for these unique engines, necessitating more sophisticated in-situ measurement capabilities and accelerated life testing protocols that can better predict long-term material behavior.

Contemporary Material Characterization Methods for Rotary Engines

01 Materials for Wankel engine housing and components

The housing and main components of Wankel engines require specific materials to withstand high temperatures and mechanical stress. Various materials including aluminum alloys, cast iron, and specialized metal composites are used for the engine housing, rotor, and other critical components. These materials are selected for their thermal stability, wear resistance, and ability to maintain dimensional accuracy under operating conditions.- Materials for Wankel engine housing and components: Various materials are used for manufacturing Wankel engine housings and components to withstand high temperatures and mechanical stress. These materials include specialized alloys, ceramics, and composite materials that offer improved durability and performance. The selection of appropriate materials for the housing, rotor, and other components is critical for ensuring the engine's reliability, efficiency, and longevity under operating conditions.

- Coating technologies for Wankel engine components: Surface coating technologies are applied to Wankel engine components to enhance wear resistance, reduce friction, and improve thermal management. These coatings include thermal barrier coatings, anti-wear coatings, and specialized surface treatments that protect the base materials from extreme operating conditions. Advanced coating techniques help extend component life and maintain performance characteristics over extended periods of operation.

- Material characterization techniques for Wankel engines: Various material characterization techniques are employed to analyze and evaluate materials used in Wankel engines. These techniques include microstructural analysis, mechanical property testing, thermal analysis, and chemical composition determination. Advanced characterization methods help in understanding material behavior under operating conditions, identifying failure mechanisms, and developing improved materials for specific engine components.

- Innovative materials for improved sealing systems: Innovative materials are developed specifically for Wankel engine sealing systems to address the unique challenges of maintaining proper sealing between the rotor and housing. These materials include advanced polymers, composite materials, and specially formulated alloys that offer improved sealing properties, reduced friction, and enhanced durability. Effective sealing systems are crucial for maintaining compression, preventing leakage, and ensuring optimal engine performance.

- Material solutions for thermal management in Wankel engines: Specialized materials and design approaches are implemented to address thermal management challenges in Wankel engines. These solutions include materials with high thermal conductivity, thermal barrier materials, and cooling system components designed to manage heat distribution effectively. Proper thermal management is essential for preventing overheating, reducing thermal distortion, and maintaining consistent performance across various operating conditions.

02 Coating technologies for Wankel engine surfaces

Surface coatings play a crucial role in enhancing the performance and durability of Wankel engine components. Various coating technologies including thermal spraying, plasma deposition, and electroplating are used to apply wear-resistant and low-friction materials to critical surfaces such as the epitrochoid housing and rotor apex seals. These coatings help reduce friction, improve sealing, and extend the service life of engine components.Expand Specific Solutions03 Advanced ceramics and composite materials for Wankel engines

Advanced ceramics and composite materials are increasingly being used in Wankel engine construction to overcome limitations of traditional metallic materials. Silicon carbide, silicon nitride, and carbon-fiber reinforced composites offer advantages including higher temperature resistance, lower weight, and reduced thermal expansion. These materials are particularly beneficial for components such as apex seals, side seals, and rotor faces that experience extreme operating conditions.Expand Specific Solutions04 Material characterization techniques for Wankel engine components

Various material characterization techniques are employed to analyze and validate materials used in Wankel engines. These include scanning electron microscopy, X-ray diffraction, thermal analysis, and mechanical testing methods to evaluate properties such as hardness, wear resistance, thermal conductivity, and microstructural stability. These characterization methods help in understanding material behavior under engine operating conditions and guide material selection and development.Expand Specific Solutions05 Innovative material solutions for sealing systems

Sealing systems in Wankel engines present unique material challenges due to the complex motion and high temperatures. Innovative material solutions including self-lubricating composites, temperature-resistant polymers, and specialized metal alloys have been developed specifically for apex seals, side seals, and oil seals. These materials aim to maintain effective sealing while minimizing friction and wear under the unique operating conditions of rotary engines.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Rotary Engine Technology

The Wankel engine material characterization landscape is currently in a mature development phase, with specialized research institutions leading technological advancements. The market size remains relatively niche but stable, primarily driven by aerospace and automotive applications. In terms of technical maturity, academic institutions like Beihang University, Massachusetts Institute of Technology, and Northwestern Polytechnical University are conducting fundamental research, while industry players including Safran Aircraft Engines, Honda Motor Co., and Caterpillar are focusing on practical applications. AVIC Shenyang Engine Research Institute and AECC Commercial Aircraft Engine Co. are advancing specialized characterization techniques for high-temperature applications, with material analysis capabilities evolving from traditional metallurgical approaches to advanced spectroscopic and imaging methodologies.

AVIC Shenyang Engine Research Institute

Technical Solution: AVIC Shenyang Engine Research Institute has developed comprehensive material characterization techniques specifically for Wankel engine applications in aerospace and defense sectors. Their methodology incorporates advanced scanning acoustic microscopy (SAM) to detect subsurface defects in complex rotor geometries without destructive testing. The institute has pioneered specialized high-temperature mechanical testing protocols that simulate the unique thermal gradients experienced in Wankel engine combustion chambers, with particular focus on creep resistance and thermal fatigue of housing materials. Their characterization approach includes custom-built tribological test rigs that replicate the sliding contact conditions between apex seals and epitrochoid surfaces under varying speeds, temperatures, and lubrication conditions[4]. AVIC's materials science division employs synchrotron radiation-based techniques for in-depth crystallographic analysis of materials under simulated operating conditions, allowing for real-time observation of microstructural changes during thermal cycling. They've also developed specialized coating evaluation methodologies using impedance spectroscopy combined with thermal imaging to assess coating integrity and adhesion strength under the extreme thermal cycling conditions typical in rotary engine operation.

Strengths: Extensive experience with high-performance materials for aerospace applications; sophisticated in-situ testing capabilities; strong integration between material characterization and engine design teams. Weaknesses: Limited publication of research findings due to defense applications; techniques may be optimized for specialized applications rather than commercial viability; high cost of specialized equipment and testing protocols.

Caterpillar, Inc.

Technical Solution: Caterpillar has developed specialized material characterization techniques for Wankel engine components focused on heavy-duty applications. Their approach centers on accelerated wear testing methodologies that simulate thousands of operational hours in controlled laboratory environments. Caterpillar's materials science division employs custom-built tribometers that replicate the unique sliding contact conditions between apex seals and housing surfaces under varying loads, temperatures, and lubrication conditions. They've pioneered the use of 3D surface metrology combined with finite element analysis to predict wear patterns and material fatigue in rotary engine components[5]. Their characterization protocol includes specialized thermal shock testing that simulates the rapid temperature fluctuations experienced in Wankel engine combustion chambers. Caterpillar has also developed proprietary non-destructive evaluation techniques using phased array ultrasonics to detect subsurface defects in complex geometries typical of Wankel engine housings and rotors, allowing for quality control without compromising structural integrity of components intended for long-duration industrial applications.

Strengths: Robust testing protocols designed for extreme durability requirements; extensive materials database spanning decades of research; strong correlation between laboratory testing and field performance data. Weaknesses: Techniques primarily optimized for industrial applications with less emphasis on efficiency or emissions considerations; heavy focus on traditional materials rather than cutting-edge composites or ceramics.

Critical Patents and Literature on Wankel Engine Materials

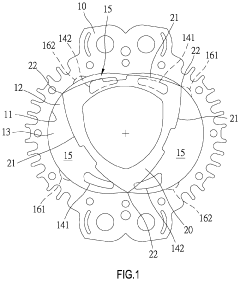

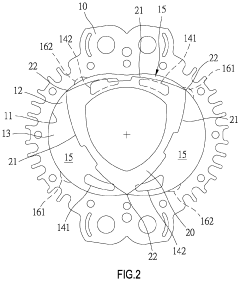

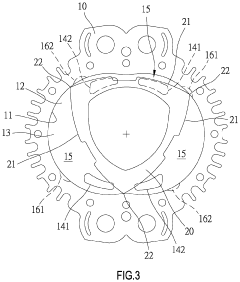

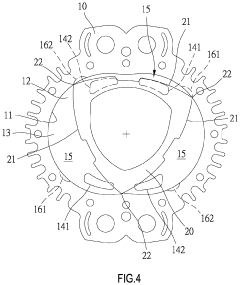

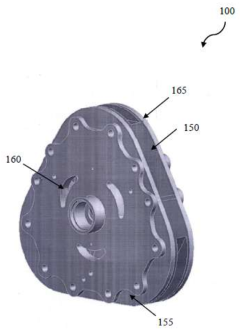

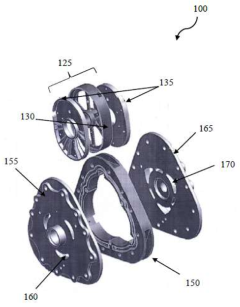

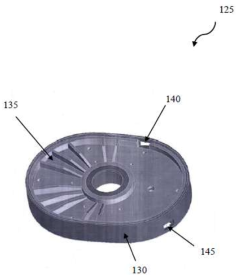

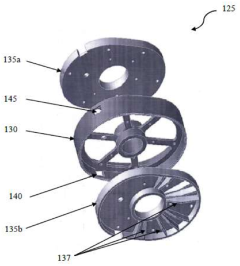

Pistonless rotary motor for air compressor

PatentActiveUS20220282622A1

Innovation

- Incorporating radially spaced grooves in the peripheral wall of the rotor cavity, with first grooves configured to release pressurized air at the top dead center during the compression stroke and second grooves for releasing air during the exhaust stroke, allowing for controlled pressure management and reduced air resistance.

A rotary engine

PatentInactiveIN201621035262A

Innovation

- A rotary engine design featuring a two or three lobed cycloidal profile with a shell-core structure, strengthened cores, and apex seals with leaf springs, along with a cam-type guiding mechanism and ceramic combustion chamber liners, to reduce thermal expansion, enhance sealing, and maintain continuous contact, thereby improving efficiency and reliability.

Environmental Impact and Sustainability Considerations

The environmental impact of Wankel engine material characterization techniques extends beyond the laboratory setting to influence the entire lifecycle of rotary engine development and operation. Traditional characterization methods often involve hazardous chemicals, high energy consumption, and waste generation. For instance, metallographic preparation of apex seal materials typically requires lubricants and etching solutions containing acids and solvents that pose environmental risks if improperly handled or disposed of. Advanced techniques such as scanning electron microscopy (SEM) and X-ray diffraction (XRD) consume significant electrical power during operation, contributing to indirect carbon emissions.

Sustainability considerations are increasingly driving innovation in material characterization for Wankel engines. Non-destructive testing methods like ultrasonic inspection and thermography are gaining prominence as they minimize material waste while providing crucial data on component integrity. These techniques allow for repeated testing of the same components throughout their lifecycle, reducing the need for manufacturing test specimens specifically for destructive evaluation. Additionally, computational modeling and simulation approaches are being integrated with physical testing to optimize material selection and reduce the environmental footprint of the characterization process.

The circular economy concept is becoming central to Wankel engine material development. Characterization techniques that facilitate material recycling and reuse are prioritized, particularly for rare earth elements and precious metals used in catalytic converters and specialized coatings. Life cycle assessment (LCA) methodologies are now being incorporated into material characterization protocols to quantify environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal or recycling.

Water consumption represents another significant environmental concern in material testing. Wet grinding and polishing processes traditionally used in metallographic preparation consume substantial quantities of water. Industry leaders are transitioning to dry or minimal-lubrication techniques that maintain characterization accuracy while dramatically reducing water usage. Similarly, chemical analysis methods are evolving toward greener alternatives that minimize the use of toxic reagents and generate less hazardous waste.

Energy efficiency improvements in characterization equipment are advancing sustainability goals. Modern instruments feature power management systems, more efficient vacuum pumps for electron microscopy, and optimized heating elements for thermal analysis. These innovations reduce the carbon footprint of material research while maintaining or enhancing analytical capabilities. Furthermore, remote monitoring capabilities and automation reduce the need for physical presence in laboratories, decreasing transportation-related emissions associated with material characterization activities.

Sustainability considerations are increasingly driving innovation in material characterization for Wankel engines. Non-destructive testing methods like ultrasonic inspection and thermography are gaining prominence as they minimize material waste while providing crucial data on component integrity. These techniques allow for repeated testing of the same components throughout their lifecycle, reducing the need for manufacturing test specimens specifically for destructive evaluation. Additionally, computational modeling and simulation approaches are being integrated with physical testing to optimize material selection and reduce the environmental footprint of the characterization process.

The circular economy concept is becoming central to Wankel engine material development. Characterization techniques that facilitate material recycling and reuse are prioritized, particularly for rare earth elements and precious metals used in catalytic converters and specialized coatings. Life cycle assessment (LCA) methodologies are now being incorporated into material characterization protocols to quantify environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal or recycling.

Water consumption represents another significant environmental concern in material testing. Wet grinding and polishing processes traditionally used in metallographic preparation consume substantial quantities of water. Industry leaders are transitioning to dry or minimal-lubrication techniques that maintain characterization accuracy while dramatically reducing water usage. Similarly, chemical analysis methods are evolving toward greener alternatives that minimize the use of toxic reagents and generate less hazardous waste.

Energy efficiency improvements in characterization equipment are advancing sustainability goals. Modern instruments feature power management systems, more efficient vacuum pumps for electron microscopy, and optimized heating elements for thermal analysis. These innovations reduce the carbon footprint of material research while maintaining or enhancing analytical capabilities. Furthermore, remote monitoring capabilities and automation reduce the need for physical presence in laboratories, decreasing transportation-related emissions associated with material characterization activities.

Thermal and Tribological Testing Protocols

Thermal and tribological testing protocols for Wankel engine materials require specialized methodologies due to the unique operating conditions these engines experience. The apex seals, rotor faces, and housing walls undergo significant thermal cycling and friction challenges that demand rigorous characterization techniques.

Temperature mapping using embedded thermocouples represents a fundamental protocol for thermal testing. Strategic placement of these sensors at critical interfaces—particularly at apex seal contact points and rotor flank regions—enables real-time temperature profiling during operation. This data proves invaluable for validating thermal models and identifying potential hotspots that may lead to material degradation or failure.

Dynamic friction coefficient measurement protocols have been developed specifically for the curved sliding interfaces characteristic of Wankel engines. These typically employ pin-on-disc tribometers modified to simulate the eccentric rotational movement and variable contact pressures experienced by apex seals. Testing must be conducted under controlled temperature conditions ranging from cold-start scenarios (below 0°C) to maximum operating temperatures (often exceeding 200°C).

Wear rate quantification protocols typically involve pre-and post-test surface profilometry combined with mass loss measurements. For ceramic-coated components, specialized non-contact optical measurement techniques have been developed to preserve surface integrity during evaluation. Standardized test cycles that simulate the acceleration, steady-state, and deceleration phases of engine operation provide comparable wear data across different material combinations.

Oil film thickness measurement represents another critical protocol, utilizing capacitance or laser-induced fluorescence techniques to characterize lubrication effectiveness at the housing-seal interface. These measurements must account for the unique oil distribution patterns created by the epitrochoidal housing geometry.

Thermal shock resistance testing protocols subject candidate materials to rapid temperature fluctuations mimicking those experienced during cold starts and sudden power changes. These typically involve cyclic immersion between heated oil baths and cooling chambers while monitoring for crack initiation and propagation using acoustic emission sensors.

Surface energy characterization protocols assess the wettability of materials by lubricants, which significantly impacts boundary lubrication conditions. Contact angle measurements under varying temperature conditions provide insights into how material surfaces interact with oils at different operating temperatures.

Standardization of these protocols remains an ongoing challenge, with organizations like SAE International and DIN working to establish uniform testing methodologies specifically for rotary engine materials. This standardization effort aims to facilitate meaningful comparisons between different material solutions across the industry.

Temperature mapping using embedded thermocouples represents a fundamental protocol for thermal testing. Strategic placement of these sensors at critical interfaces—particularly at apex seal contact points and rotor flank regions—enables real-time temperature profiling during operation. This data proves invaluable for validating thermal models and identifying potential hotspots that may lead to material degradation or failure.

Dynamic friction coefficient measurement protocols have been developed specifically for the curved sliding interfaces characteristic of Wankel engines. These typically employ pin-on-disc tribometers modified to simulate the eccentric rotational movement and variable contact pressures experienced by apex seals. Testing must be conducted under controlled temperature conditions ranging from cold-start scenarios (below 0°C) to maximum operating temperatures (often exceeding 200°C).

Wear rate quantification protocols typically involve pre-and post-test surface profilometry combined with mass loss measurements. For ceramic-coated components, specialized non-contact optical measurement techniques have been developed to preserve surface integrity during evaluation. Standardized test cycles that simulate the acceleration, steady-state, and deceleration phases of engine operation provide comparable wear data across different material combinations.

Oil film thickness measurement represents another critical protocol, utilizing capacitance or laser-induced fluorescence techniques to characterize lubrication effectiveness at the housing-seal interface. These measurements must account for the unique oil distribution patterns created by the epitrochoidal housing geometry.

Thermal shock resistance testing protocols subject candidate materials to rapid temperature fluctuations mimicking those experienced during cold starts and sudden power changes. These typically involve cyclic immersion between heated oil baths and cooling chambers while monitoring for crack initiation and propagation using acoustic emission sensors.

Surface energy characterization protocols assess the wettability of materials by lubricants, which significantly impacts boundary lubrication conditions. Contact angle measurements under varying temperature conditions provide insights into how material surfaces interact with oils at different operating temperatures.

Standardization of these protocols remains an ongoing challenge, with organizations like SAE International and DIN working to establish uniform testing methodologies specifically for rotary engine materials. This standardization effort aims to facilitate meaningful comparisons between different material solutions across the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!