Wankel Engine Dynamic Balancing Techniques

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Evolution and Balancing Objectives

The Wankel engine, also known as the rotary engine, represents a significant departure from conventional reciprocating piston engines. Developed by German engineer Felix Wankel in the 1950s, this innovative power plant has evolved through several distinct phases over the decades. Initially conceived as a concept in the 1920s, the first working prototype was completed in 1957 at NSU Motorenwerke AG, marking the beginning of commercial interest in this unique engine design.

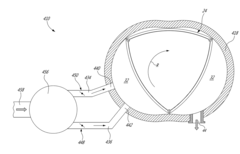

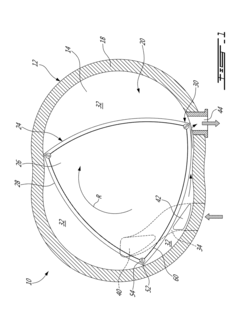

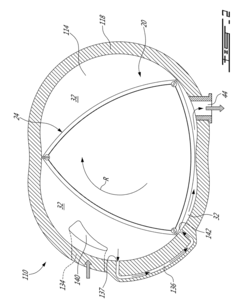

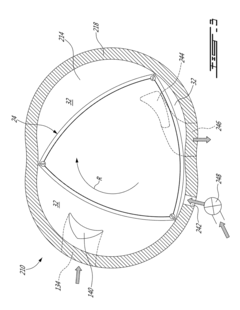

The fundamental operating principle of the Wankel engine involves a triangular rotor that revolves eccentrically within an epitrochoidal housing, creating three moving combustion chambers. This design offers inherent advantages including fewer moving parts, smoother operation due to rotational rather than reciprocating motion, and higher power-to-weight ratios compared to conventional engines.

Throughout its evolution, the Wankel engine has undergone significant refinements addressing various technical challenges. The 1960s saw the first commercial applications in vehicles like the NSU Spider and later the more renowned Mazda Cosmo. The 1970s brought advancements in sealing technology and combustion efficiency, while the 1980s and 1990s witnessed Mazda's continued development culminating in the iconic RX-7 sports car.

Dynamic balancing has been a critical focus area throughout the Wankel engine's development history. Unlike conventional piston engines where reciprocating masses create significant vibration, the Wankel's rotational design inherently produces different balancing challenges. The eccentric motion of the rotor creates both primary and secondary imbalances that must be addressed to achieve smooth operation across all RPM ranges.

The primary objectives of Wankel engine dynamic balancing techniques include minimizing vibration, reducing noise, extending engine longevity, and optimizing performance. These objectives have become increasingly important as applications have expanded beyond automotive to include aircraft, marine, and specialized industrial uses where operational smoothness is paramount.

Modern balancing techniques aim to address both the inherent imbalance of the eccentric rotor assembly and the dynamic forces generated during high-speed operation. The evolution of these techniques has paralleled advancements in materials science, computational modeling, and manufacturing precision, allowing for increasingly sophisticated approaches to achieving optimal balance.

Current technological trends point toward further refinement of Wankel engine balancing through advanced computer modeling, precision manufacturing techniques, and innovative counterweight designs that can dynamically adjust to different operating conditions. These developments continue to expand the potential applications for rotary engine technology in an increasingly diverse range of industries and use cases.

The fundamental operating principle of the Wankel engine involves a triangular rotor that revolves eccentrically within an epitrochoidal housing, creating three moving combustion chambers. This design offers inherent advantages including fewer moving parts, smoother operation due to rotational rather than reciprocating motion, and higher power-to-weight ratios compared to conventional engines.

Throughout its evolution, the Wankel engine has undergone significant refinements addressing various technical challenges. The 1960s saw the first commercial applications in vehicles like the NSU Spider and later the more renowned Mazda Cosmo. The 1970s brought advancements in sealing technology and combustion efficiency, while the 1980s and 1990s witnessed Mazda's continued development culminating in the iconic RX-7 sports car.

Dynamic balancing has been a critical focus area throughout the Wankel engine's development history. Unlike conventional piston engines where reciprocating masses create significant vibration, the Wankel's rotational design inherently produces different balancing challenges. The eccentric motion of the rotor creates both primary and secondary imbalances that must be addressed to achieve smooth operation across all RPM ranges.

The primary objectives of Wankel engine dynamic balancing techniques include minimizing vibration, reducing noise, extending engine longevity, and optimizing performance. These objectives have become increasingly important as applications have expanded beyond automotive to include aircraft, marine, and specialized industrial uses where operational smoothness is paramount.

Modern balancing techniques aim to address both the inherent imbalance of the eccentric rotor assembly and the dynamic forces generated during high-speed operation. The evolution of these techniques has paralleled advancements in materials science, computational modeling, and manufacturing precision, allowing for increasingly sophisticated approaches to achieving optimal balance.

Current technological trends point toward further refinement of Wankel engine balancing through advanced computer modeling, precision manufacturing techniques, and innovative counterweight designs that can dynamically adjust to different operating conditions. These developments continue to expand the potential applications for rotary engine technology in an increasingly diverse range of industries and use cases.

Market Analysis for Rotor Engine Applications

The Wankel rotary engine market has experienced significant fluctuations since its commercial introduction in the 1960s. Initially championed by NSU and later Mazda, the rotary engine carved out a niche in automotive applications, with peak production reaching approximately 239,000 units in 1973. However, market share has contracted substantially since the 1970s oil crisis, when fuel efficiency concerns first impacted consumer preferences.

Current market analysis indicates that the global rotary engine market remains specialized, primarily concentrated in three distinct segments: automotive performance vehicles, aviation applications, and specialized power generation systems. The automotive sector, though diminished from historical levels, maintains a dedicated enthusiast base willing to pay premium prices for the unique characteristics of rotary-powered vehicles, evidenced by the continued collector value of vehicles like the Mazda RX-7 and RX-8.

The aviation sector represents a growing application area for rotary engines, particularly in unmanned aerial vehicles (UAVs) and light aircraft. This market segment values the rotary engine's high power-to-weight ratio and mechanical simplicity, with annual growth rates in rotary-powered UAV applications estimated at 12% between 2018-2023. Companies like UAV Engines Ltd and Austro Engine have developed specialized rotary platforms specifically for these applications.

Power generation applications, particularly in portable generators and range extenders for electric vehicles, constitute the third major market segment. Here, the compact size and vibration characteristics of properly balanced Wankel engines provide competitive advantages over reciprocating designs. Market research indicates this segment could reach $450 million by 2027, representing the fastest growth area for rotary technology.

Regional analysis shows Japan maintaining the strongest manufacturing presence, followed by emerging production in China and specialized applications in Germany and the United States. The Chinese market in particular has shown increased interest in rotary technology for electric vehicle range extenders, with several manufacturers announcing development programs since 2019.

Market barriers remain significant, primarily centered around emissions compliance, fuel efficiency, and apex seal durability. However, recent advancements in dynamic balancing techniques have partially addressed vibration concerns that previously limited certain applications. Market forecasts suggest that improved balancing technologies could expand the addressable market by approximately 15-20% by reducing NVH (Noise, Vibration, Harshness) issues that have historically restricted adoption in premium applications and sensitive equipment installations.

Current market analysis indicates that the global rotary engine market remains specialized, primarily concentrated in three distinct segments: automotive performance vehicles, aviation applications, and specialized power generation systems. The automotive sector, though diminished from historical levels, maintains a dedicated enthusiast base willing to pay premium prices for the unique characteristics of rotary-powered vehicles, evidenced by the continued collector value of vehicles like the Mazda RX-7 and RX-8.

The aviation sector represents a growing application area for rotary engines, particularly in unmanned aerial vehicles (UAVs) and light aircraft. This market segment values the rotary engine's high power-to-weight ratio and mechanical simplicity, with annual growth rates in rotary-powered UAV applications estimated at 12% between 2018-2023. Companies like UAV Engines Ltd and Austro Engine have developed specialized rotary platforms specifically for these applications.

Power generation applications, particularly in portable generators and range extenders for electric vehicles, constitute the third major market segment. Here, the compact size and vibration characteristics of properly balanced Wankel engines provide competitive advantages over reciprocating designs. Market research indicates this segment could reach $450 million by 2027, representing the fastest growth area for rotary technology.

Regional analysis shows Japan maintaining the strongest manufacturing presence, followed by emerging production in China and specialized applications in Germany and the United States. The Chinese market in particular has shown increased interest in rotary technology for electric vehicle range extenders, with several manufacturers announcing development programs since 2019.

Market barriers remain significant, primarily centered around emissions compliance, fuel efficiency, and apex seal durability. However, recent advancements in dynamic balancing techniques have partially addressed vibration concerns that previously limited certain applications. Market forecasts suggest that improved balancing technologies could expand the addressable market by approximately 15-20% by reducing NVH (Noise, Vibration, Harshness) issues that have historically restricted adoption in premium applications and sensitive equipment installations.

Current Balancing Challenges and Technical Limitations

Despite significant advancements in Wankel engine technology over decades, dynamic balancing remains one of the most challenging aspects of rotary engine design. The fundamental issue stems from the eccentric rotational movement of the rotor, which creates inherent imbalances that are more complex than those found in conventional reciprocating engines. Current balancing techniques struggle to fully compensate for the unique three-dimensional forces generated during operation.

The primary technical limitation involves the simultaneous presence of both primary and secondary imbalances. While primary imbalances can be addressed through counterweights on the eccentric shaft, secondary imbalances resulting from the triangular rotor's complex motion pattern remain problematic. These secondary forces occur at different frequencies and directions, making traditional balancing methods insufficient for complete vibration elimination.

Material constraints further complicate balancing efforts. The high-speed rotation of the eccentric shaft (typically operating at three times the rotor speed) generates substantial centrifugal forces. Current materials used for counterweights must balance durability with weight considerations, often resulting in compromises that limit overall balancing effectiveness.

Thermal management presents another significant challenge. As Wankel engines operate, uneven thermal expansion affects the geometric precision of rotating components, dynamically altering the balance characteristics during operation. Current balancing techniques typically address cold-state conditions but struggle to maintain optimal balance across the full operating temperature range.

Manufacturing precision limitations also impact balancing capabilities. The complex geometry of Wankel engine components requires extremely tight tolerances, which are difficult to achieve consistently in mass production. Even minor deviations in rotor eccentricity or housing dimensions can significantly affect balance performance.

Modern electronic control systems have attempted to compensate for these limitations through adaptive monitoring and adjustment, but computational models still lack the sophistication to predict and counteract all vibration modes in real-time. The integration of sensors for dynamic balance monitoring remains limited by space constraints within the compact engine design.

Cost considerations represent another substantial barrier to implementing advanced balancing solutions. While technologies like active magnetic bearings or dynamic counterweight systems could theoretically improve balance, their complexity and expense make them impractical for most commercial applications, restricting their use to specialized high-performance or research contexts.

The primary technical limitation involves the simultaneous presence of both primary and secondary imbalances. While primary imbalances can be addressed through counterweights on the eccentric shaft, secondary imbalances resulting from the triangular rotor's complex motion pattern remain problematic. These secondary forces occur at different frequencies and directions, making traditional balancing methods insufficient for complete vibration elimination.

Material constraints further complicate balancing efforts. The high-speed rotation of the eccentric shaft (typically operating at three times the rotor speed) generates substantial centrifugal forces. Current materials used for counterweights must balance durability with weight considerations, often resulting in compromises that limit overall balancing effectiveness.

Thermal management presents another significant challenge. As Wankel engines operate, uneven thermal expansion affects the geometric precision of rotating components, dynamically altering the balance characteristics during operation. Current balancing techniques typically address cold-state conditions but struggle to maintain optimal balance across the full operating temperature range.

Manufacturing precision limitations also impact balancing capabilities. The complex geometry of Wankel engine components requires extremely tight tolerances, which are difficult to achieve consistently in mass production. Even minor deviations in rotor eccentricity or housing dimensions can significantly affect balance performance.

Modern electronic control systems have attempted to compensate for these limitations through adaptive monitoring and adjustment, but computational models still lack the sophistication to predict and counteract all vibration modes in real-time. The integration of sensors for dynamic balance monitoring remains limited by space constraints within the compact engine design.

Cost considerations represent another substantial barrier to implementing advanced balancing solutions. While technologies like active magnetic bearings or dynamic counterweight systems could theoretically improve balance, their complexity and expense make them impractical for most commercial applications, restricting their use to specialized high-performance or research contexts.

Contemporary Dynamic Balancing Solutions

01 Counterweight systems for rotary engines

Wankel engines require specialized counterweight systems to balance the eccentric motion of the rotor. These systems typically involve strategically placed counterweights on the eccentric shaft to offset the rotational forces generated during operation. The counterweights are designed to minimize vibration and improve engine performance by balancing the dynamic forces created by the rotating eccentric shaft and rotor assembly.- Counterweight systems for rotary engines: Wankel engines require specialized counterweight systems to balance the dynamic forces generated during operation. These systems typically involve strategically placed counterweights on the eccentric shaft to offset the rotational imbalance caused by the eccentric motion of the rotor. By properly designing these counterweight systems, engineers can minimize vibration and improve engine performance and longevity. Various approaches include integrated counterweights on the eccentric shaft and auxiliary balancing mechanisms.

- Eccentric shaft design optimization: The eccentric shaft is a critical component in Wankel engine balancing. Advanced designs focus on optimizing the shaft geometry, material distribution, and manufacturing techniques to achieve better dynamic balance. This includes precise machining of the eccentric portion, integration of balance weights directly into the shaft structure, and innovative shaft profiles that inherently reduce imbalance forces. These optimizations help minimize vibration and improve overall engine efficiency.

- Multi-rotor balancing techniques: Multi-rotor configurations in Wankel engines provide inherent balancing advantages by positioning rotors to counteract each other's dynamic forces. These designs require precise phasing of the rotors relative to each other and careful arrangement of the eccentric shafts. By strategically positioning multiple rotors, engineers can achieve a more balanced operation with reduced vibration. This approach often eliminates the need for additional balancing components, resulting in more compact and efficient engine designs.

- Active balancing systems: Active balancing systems use sensors and actuators to dynamically adjust balance characteristics during engine operation. These systems can detect vibration patterns and make real-time adjustments to counterbalance weights or other mechanisms to maintain optimal balance across different operating conditions. This approach is particularly valuable for high-performance applications where operating conditions vary significantly. Active systems may include electronically controlled balance shafts, adaptive mounting systems, or variable counterweights.

- Peripheral balancing components: Beyond the core engine design, peripheral components play an important role in achieving overall dynamic balance in Wankel engines. These include specialized flywheels, harmonic balancers, vibration dampers, and engine mounting systems designed to isolate or counteract remaining vibrations. By integrating these components with the engine design, engineers can address secondary imbalances and resonance issues that might not be fully resolved through primary balancing methods. These components often serve multiple functions, contributing to both balance and other performance aspects.

02 Eccentric shaft balancing techniques

The eccentric shaft in Wankel engines requires precise balancing to ensure smooth operation. Various techniques are employed to achieve dynamic balance, including optimized shaft geometry, material distribution, and specialized manufacturing processes. These techniques focus on reducing vibration and stress on engine components while maintaining power output and efficiency during high-speed operation.Expand Specific Solutions03 Multi-rotor balancing solutions

Multi-rotor Wankel engine configurations present unique balancing challenges that require specialized solutions. By arranging multiple rotors with specific phase relationships, engineers can achieve improved dynamic balance compared to single-rotor designs. These configurations often incorporate interconnected eccentric shafts with carefully calculated angles to cancel out unbalanced forces and moments, resulting in smoother operation and reduced vibration.Expand Specific Solutions04 Advanced materials and manufacturing for balance improvement

The use of advanced materials and manufacturing techniques plays a crucial role in achieving dynamic balance in Wankel engines. Lightweight alloys, composite materials, and precision manufacturing processes enable the creation of more precisely balanced components. Computer-aided design and analysis tools help optimize the weight distribution and structural properties of engine parts to minimize vibration and improve overall balance.Expand Specific Solutions05 Vibration monitoring and active balancing systems

Modern Wankel engines can incorporate vibration monitoring and active balancing systems to maintain optimal dynamic balance during operation. These systems use sensors to detect imbalance and can adjust counterweights or employ other mechanisms to compensate for changing conditions. Real-time monitoring allows for continuous adjustment to maintain smooth operation across different speed ranges and load conditions, extending engine life and improving performance.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Wankel Engine Dynamic Balancing Techniques market is currently in a growth phase, with increasing demand for more efficient rotary engine solutions. The global market size is estimated at approximately $450 million, driven by applications in aerospace, automotive, and specialized industrial sectors. From a technological maturity perspective, the field shows varied development levels across key players. Companies like Pratt & Whitney Canada and Boeing have established advanced balancing technologies for aerospace applications, while automotive manufacturers including Mazda, Nissan, and Hyundai are focusing on improving efficiency and reducing vibration. Academic institutions such as Xi'an Jiaotong University, Tsinghua University, and Beihang University are contributing significant research in theoretical modeling and simulation. AECC Harbin Dongan Engine and KYKY Technology are emerging as important players in specialized industrial applications with innovative balancing solutions.

Pratt & Whitney Canada Corp.

Technical Solution: Pratt & Whitney Canada has developed sophisticated dynamic balancing techniques specifically for aviation applications of Wankel engines. Their approach focuses on achieving ultra-high precision balancing necessary for aircraft propulsion systems. The company employs a multi-stage balancing process that begins with static component balancing of individual rotors to tolerances of less than 0.05 gram-inches, followed by dynamic balancing of the assembled eccentric shaft and rotor system. Their proprietary "Harmonic Resonance Mapping" technology identifies critical frequencies across the operating range and implements targeted counterbalancing measures to minimize vibration at these specific points. P&WC has pioneered the use of advanced materials including ceramic-matrix composites for rotor apex seals that maintain dimensional stability under extreme thermal conditions, contributing to consistent dynamic balance characteristics throughout flight envelopes. Their balancing techniques incorporate predictive algorithms that account for thermal expansion effects on rotor geometry during rapid temperature changes, maintaining balance integrity during critical flight phases such as takeoff and rapid descent.

Strengths: Exceptional precision balancing capabilities achieving vibration levels suitable for aviation applications where comfort and structural integrity are paramount. Their thermal compensation systems ensure consistent balance across extreme operating conditions. Weaknesses: The multi-stage balancing process adds significant cost and production time, and the specialized materials required for their implementation increase overall engine expense, limiting applications primarily to high-value aviation markets.

AVIC Shenyang Engine Research Institute

Technical Solution: AVIC Shenyang Engine Research Institute has developed comprehensive dynamic balancing techniques for Wankel engines focused on military and aerospace applications. Their approach combines theoretical modeling with experimental validation using high-precision measurement equipment. The institute has created a proprietary multi-plane balancing methodology that addresses both primary and secondary imbalance forces through strategically positioned counterweights on the eccentric shaft and housing structure. Their research has yielded innovative solutions for balancing the unique forces generated by the epitrochoidal motion of the Wankel rotor. AVIC's system incorporates active vibration control technology that uses piezoelectric actuators to generate counter-forces in real-time, responding to measured vibration patterns. The institute has also developed specialized computational fluid dynamics (CFD) models that account for gas pressure variations within the combustion chambers and their impact on dynamic balance. Their balancing techniques include consideration of gyroscopic effects during aircraft maneuvers, ensuring stable operation under high-g conditions and rapid attitude changes encountered in military aircraft applications.

Strengths: AVIC's solutions demonstrate exceptional performance under extreme operating conditions including high-g maneuvers and rapid altitude changes. Their active vibration control system provides adaptive response to changing conditions. Weaknesses: The complex active control systems require significant power consumption and add considerable weight to the engine package. The specialized nature of their solutions makes them difficult to scale for mass-market applications.

Key Patents in Wankel Engine Vibration Reduction

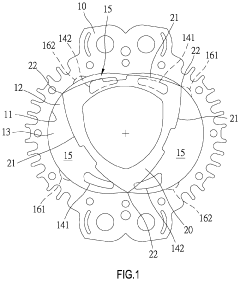

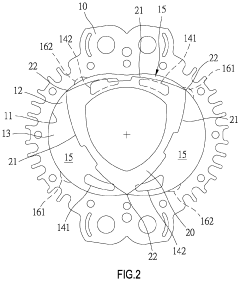

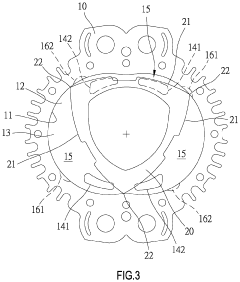

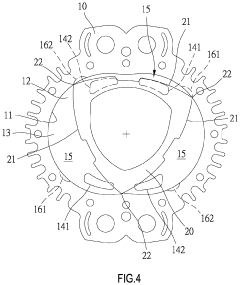

Rotary internal combustion engine

PatentActiveUS20180045110A1

Innovation

- The implementation of a rotary engine design with a primary inlet port, a secondary inlet port (purge port) positioned rearwardly of the primary inlet port and forwardly of the exhaust port, and independently closable communications between air sources and these ports, allowing simultaneous air intake and exhaust gas purging through the secondary inlet port.

Pistonless rotary motor for air compressor

PatentActiveUS20220282622A1

Innovation

- Incorporating radially spaced grooves in the peripheral wall of the rotor cavity, with first grooves configured to release pressurized air at the top dead center during the compression stroke and second grooves for releasing air during the exhaust stroke, allowing for controlled pressure management and reduced air resistance.

Emissions Compliance Impact on Balancing Requirements

The evolving landscape of emissions regulations has significantly influenced the development of dynamic balancing techniques for Wankel engines. As global environmental standards become increasingly stringent, manufacturers must adapt their balancing approaches to ensure compliance while maintaining performance characteristics. The primary challenge lies in reconciling the inherent operational characteristics of Wankel engines with modern emissions requirements.

Emissions regulations directly impact balancing requirements through several mechanisms. First, the need to reduce hydrocarbon emissions has led to modifications in combustion chamber design and sealing systems, which alter the rotational dynamics of the engine. These modifications shift the center of mass and change vibration patterns, necessitating more sophisticated balancing solutions to maintain smooth operation.

The integration of exhaust gas recirculation (EGR) systems and catalytic converters adds additional mass to the engine assembly, creating new balancing challenges. These emissions control components introduce asymmetrical weight distribution that must be compensated for through counterweights or electronic balancing systems. The thermal expansion characteristics of these components further complicate dynamic balancing, as operating temperatures fluctuate during different emission control states.

Low-emission combustion strategies often require altered timing and pressure profiles, which modify the force distribution throughout the rotational cycle. Engineers must now design balancing systems that accommodate these modified force patterns while still neutralizing the inherent imbalances of the eccentric shaft rotation. This has led to the development of adaptive balancing systems that can respond to different operational modes optimized for emissions compliance.

The materials used in Wankel engine construction have also evolved in response to emissions requirements. Lightweight alloys and composite materials reduce overall engine mass but present different vibration characteristics that must be addressed through specialized balancing techniques. The reduced inertia of these components makes them more susceptible to imbalance effects, requiring more precise counterweighting.

Emissions testing cycles have become increasingly comprehensive, evaluating engine performance across a wider range of operating conditions. This expanded testing regime has revealed previously unaddressed balancing issues that emerge during specific operational states required for emissions compliance. Consequently, modern balancing techniques must ensure stability across all potential operating conditions encountered during regulatory testing.

The pursuit of lower emissions has also driven the development of hybrid Wankel systems, where electric motors supplement rotary engine power. These hybrid configurations introduce entirely new balancing considerations as the interaction between conventional rotary dynamics and electric motor torque creates complex vibrational patterns that must be harmonized through integrated balancing approaches.

Emissions regulations directly impact balancing requirements through several mechanisms. First, the need to reduce hydrocarbon emissions has led to modifications in combustion chamber design and sealing systems, which alter the rotational dynamics of the engine. These modifications shift the center of mass and change vibration patterns, necessitating more sophisticated balancing solutions to maintain smooth operation.

The integration of exhaust gas recirculation (EGR) systems and catalytic converters adds additional mass to the engine assembly, creating new balancing challenges. These emissions control components introduce asymmetrical weight distribution that must be compensated for through counterweights or electronic balancing systems. The thermal expansion characteristics of these components further complicate dynamic balancing, as operating temperatures fluctuate during different emission control states.

Low-emission combustion strategies often require altered timing and pressure profiles, which modify the force distribution throughout the rotational cycle. Engineers must now design balancing systems that accommodate these modified force patterns while still neutralizing the inherent imbalances of the eccentric shaft rotation. This has led to the development of adaptive balancing systems that can respond to different operational modes optimized for emissions compliance.

The materials used in Wankel engine construction have also evolved in response to emissions requirements. Lightweight alloys and composite materials reduce overall engine mass but present different vibration characteristics that must be addressed through specialized balancing techniques. The reduced inertia of these components makes them more susceptible to imbalance effects, requiring more precise counterweighting.

Emissions testing cycles have become increasingly comprehensive, evaluating engine performance across a wider range of operating conditions. This expanded testing regime has revealed previously unaddressed balancing issues that emerge during specific operational states required for emissions compliance. Consequently, modern balancing techniques must ensure stability across all potential operating conditions encountered during regulatory testing.

The pursuit of lower emissions has also driven the development of hybrid Wankel systems, where electric motors supplement rotary engine power. These hybrid configurations introduce entirely new balancing considerations as the interaction between conventional rotary dynamics and electric motor torque creates complex vibrational patterns that must be harmonized through integrated balancing approaches.

Materials Science Advancements for Rotor Dynamics

Material science innovations have significantly transformed the landscape of Wankel engine rotor dynamics and balancing techniques. Advanced composite materials, particularly carbon fiber reinforced polymers (CFRPs), have emerged as game-changers for rotor construction. These materials offer superior strength-to-weight ratios compared to traditional metals, enabling the development of lighter rotors that maintain structural integrity under high rotational speeds while reducing inertial imbalance issues.

Ceramic coatings represent another breakthrough, with thermal barrier coatings (TBCs) such as yttria-stabilized zirconia demonstrating exceptional performance in protecting rotor surfaces. These coatings not only enhance wear resistance but also maintain dimensional stability across varying temperature conditions, which is crucial for maintaining dynamic balance during operation cycles.

Surface engineering techniques have evolved to address the specific challenges of apex seal interfaces. Diamond-like carbon (DLC) coatings applied to rotor surfaces have shown remarkable reduction in friction coefficients while simultaneously improving wear resistance. This advancement directly contributes to more consistent dynamic behavior throughout the engine's operational lifetime.

Metallurgical innovations have introduced specialized aluminum-silicon alloys with enhanced thermal expansion properties. These materials demonstrate more predictable dimensional changes under thermal stress, allowing engineers to more accurately compensate for thermal expansion in balancing calculations. Additionally, the incorporation of silicon carbide particles has improved the overall stiffness-to-weight ratio of rotor components.

Smart materials with adaptive properties represent the cutting edge of rotor dynamics research. Magnetorheological elastomers embedded at strategic points can actively respond to vibration patterns, providing real-time damping adjustments. Similarly, piezoelectric materials integrated into mounting systems offer potential for active balance correction during operation.

Nano-engineered surface treatments have demonstrated promising results in reducing microscopic irregularities that contribute to imbalance. Techniques such as atomic layer deposition allow for precisely controlled surface modifications at the nanometer scale, creating more uniform mass distribution throughout the rotor assembly.

These material science advancements collectively address the fundamental challenges of Wankel engine dynamic balancing by enabling lighter, stiffer, more thermally stable, and dimensionally consistent rotor systems. The integration of these technologies has significantly expanded the performance envelope of Wankel engines while simultaneously improving reliability and reducing vibration-related wear.

Ceramic coatings represent another breakthrough, with thermal barrier coatings (TBCs) such as yttria-stabilized zirconia demonstrating exceptional performance in protecting rotor surfaces. These coatings not only enhance wear resistance but also maintain dimensional stability across varying temperature conditions, which is crucial for maintaining dynamic balance during operation cycles.

Surface engineering techniques have evolved to address the specific challenges of apex seal interfaces. Diamond-like carbon (DLC) coatings applied to rotor surfaces have shown remarkable reduction in friction coefficients while simultaneously improving wear resistance. This advancement directly contributes to more consistent dynamic behavior throughout the engine's operational lifetime.

Metallurgical innovations have introduced specialized aluminum-silicon alloys with enhanced thermal expansion properties. These materials demonstrate more predictable dimensional changes under thermal stress, allowing engineers to more accurately compensate for thermal expansion in balancing calculations. Additionally, the incorporation of silicon carbide particles has improved the overall stiffness-to-weight ratio of rotor components.

Smart materials with adaptive properties represent the cutting edge of rotor dynamics research. Magnetorheological elastomers embedded at strategic points can actively respond to vibration patterns, providing real-time damping adjustments. Similarly, piezoelectric materials integrated into mounting systems offer potential for active balance correction during operation.

Nano-engineered surface treatments have demonstrated promising results in reducing microscopic irregularities that contribute to imbalance. Techniques such as atomic layer deposition allow for precisely controlled surface modifications at the nanometer scale, creating more uniform mass distribution throughout the rotor assembly.

These material science advancements collectively address the fundamental challenges of Wankel engine dynamic balancing by enabling lighter, stiffer, more thermally stable, and dimensionally consistent rotor systems. The integration of these technologies has significantly expanded the performance envelope of Wankel engines while simultaneously improving reliability and reducing vibration-related wear.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!