Wankel Engine Comparisons Across Fuel Types

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Evolution and Development Goals

The Wankel rotary engine, first conceptualized by Felix Wankel in the 1920s and developed into a working prototype by 1957, represents a significant departure from conventional reciprocating piston engines. Its evolution has been marked by periods of intense development followed by relative dormancy, with recent years seeing renewed interest due to its potential advantages in specific applications, particularly when considering alternative fuel types.

The initial development phase during the 1960s and 1970s saw companies like NSU and Mazda pioneering rotary engine technology for automotive applications. Mazda's commitment to the Wankel design culminated in the RX series of sports cars, with the RX-7 and RX-8 becoming iconic representations of rotary-powered vehicles. However, challenges related to fuel efficiency, emissions, and apex seal durability limited widespread adoption.

Current technological evolution focuses on addressing these historical limitations while leveraging the Wankel's inherent advantages: compact size, high power-to-weight ratio, mechanical simplicity, and smooth operation. Modern materials science and manufacturing techniques have enabled significant improvements in apex seal technology, with silicon nitride and other advanced ceramics showing promise for extending operational life and reducing friction.

The development goals for Wankel engines across different fuel types vary significantly. For gasoline applications, the primary objectives include improving thermal efficiency, reducing hydrocarbon emissions from oil consumption, and enhancing apex seal longevity. Research indicates potential for efficiency improvements of 15-20% through optimized combustion chamber design and advanced direct injection systems.

For hydrogen fuel applications, the Wankel presents unique advantages due to its tolerance for hydrogen's high flame speed and reduced risk of backfiring compared to piston engines. Development goals include specialized sealing systems resistant to hydrogen embrittlement and optimized port designs to maximize volumetric efficiency with hydrogen's lower energy density.

Electric-rotary hybrid systems represent another evolutionary path, with the Wankel serving as a compact range extender. Here, development goals focus on optimizing the engine for constant-speed operation, minimizing emissions through precise combustion control, and achieving weight reductions to enhance overall vehicle efficiency.

The most ambitious development trajectory involves adapting Wankel engines for sustainable fuels like biofuels and synthetic e-fuels. Research suggests that the rotary's flexible combustion characteristics make it particularly suitable for these variable-composition fuels, with goals centered on combustion stability, emissions control, and material compatibility across diverse fuel formulations.

The initial development phase during the 1960s and 1970s saw companies like NSU and Mazda pioneering rotary engine technology for automotive applications. Mazda's commitment to the Wankel design culminated in the RX series of sports cars, with the RX-7 and RX-8 becoming iconic representations of rotary-powered vehicles. However, challenges related to fuel efficiency, emissions, and apex seal durability limited widespread adoption.

Current technological evolution focuses on addressing these historical limitations while leveraging the Wankel's inherent advantages: compact size, high power-to-weight ratio, mechanical simplicity, and smooth operation. Modern materials science and manufacturing techniques have enabled significant improvements in apex seal technology, with silicon nitride and other advanced ceramics showing promise for extending operational life and reducing friction.

The development goals for Wankel engines across different fuel types vary significantly. For gasoline applications, the primary objectives include improving thermal efficiency, reducing hydrocarbon emissions from oil consumption, and enhancing apex seal longevity. Research indicates potential for efficiency improvements of 15-20% through optimized combustion chamber design and advanced direct injection systems.

For hydrogen fuel applications, the Wankel presents unique advantages due to its tolerance for hydrogen's high flame speed and reduced risk of backfiring compared to piston engines. Development goals include specialized sealing systems resistant to hydrogen embrittlement and optimized port designs to maximize volumetric efficiency with hydrogen's lower energy density.

Electric-rotary hybrid systems represent another evolutionary path, with the Wankel serving as a compact range extender. Here, development goals focus on optimizing the engine for constant-speed operation, minimizing emissions through precise combustion control, and achieving weight reductions to enhance overall vehicle efficiency.

The most ambitious development trajectory involves adapting Wankel engines for sustainable fuels like biofuels and synthetic e-fuels. Research suggests that the rotary's flexible combustion characteristics make it particularly suitable for these variable-composition fuels, with goals centered on combustion stability, emissions control, and material compatibility across diverse fuel formulations.

Market Analysis for Rotary Engine Applications

The rotary engine market presents a complex landscape with distinct segments and growth trajectories across various applications. Currently, the global rotary engine market is experiencing moderate growth, primarily driven by niche applications in aviation, marine, and specialized automotive sectors. The market size remains relatively small compared to conventional piston engines, but shows promising expansion potential in specific high-performance applications.

Aviation represents one of the most promising market segments for rotary engines. The lightweight, compact design and high power-to-weight ratio make Wankel engines particularly attractive for small aircraft, UAVs, and drone applications. This segment is projected to grow substantially as the demand for efficient, lightweight propulsion systems increases in both commercial and military unmanned aerial vehicles.

The automotive sector presents a more nuanced picture. While major manufacturers like Mazda have historically incorporated rotary engines in production vehicles, the market has contracted due to emissions challenges. However, a resurgence is emerging in two key areas: range extenders for electric vehicles and high-performance specialty vehicles. Mazda's recent development of rotary range extenders signals renewed commercial interest in this technology for hybrid applications.

Marine applications constitute another growing segment, particularly for small watercraft where the rotary engine's compact size and smooth operation provide significant advantages. The recreational boating industry has shown increased interest in rotary solutions for jet skis and small pleasure craft, valuing their reduced vibration and higher power density compared to traditional outboard motors.

Racing and motorsport applications maintain a steady demand for rotary engines, with their high-revving capabilities and compact design providing competitive advantages in certain racing categories. This niche market supports specialized manufacturers and aftermarket modification businesses catering to enthusiasts and professional racing teams.

Emerging market opportunities are developing around alternative fuel adaptations. The rotary engine's flexibility in fuel consumption creates potential growth in markets focused on hydrogen, natural gas, and biofuel applications. This versatility positions rotary technology favorably in regions pursuing diverse fuel strategies and reduced carbon emissions without complete electrification.

Regional analysis indicates stronger market presence in Japan, North America, and parts of Europe with established automotive and aerospace industries. Developing markets in Asia-Pacific show increasing interest, particularly for specialized industrial applications and small-scale power generation where the rotary engine's simplicity and reliability offer competitive advantages.

Market barriers include persistent challenges with emissions compliance, sealing technology limitations, and competition from increasingly efficient conventional engines and electric powertrains. However, technological advancements in materials science and manufacturing processes are gradually addressing these historical limitations.

Aviation represents one of the most promising market segments for rotary engines. The lightweight, compact design and high power-to-weight ratio make Wankel engines particularly attractive for small aircraft, UAVs, and drone applications. This segment is projected to grow substantially as the demand for efficient, lightweight propulsion systems increases in both commercial and military unmanned aerial vehicles.

The automotive sector presents a more nuanced picture. While major manufacturers like Mazda have historically incorporated rotary engines in production vehicles, the market has contracted due to emissions challenges. However, a resurgence is emerging in two key areas: range extenders for electric vehicles and high-performance specialty vehicles. Mazda's recent development of rotary range extenders signals renewed commercial interest in this technology for hybrid applications.

Marine applications constitute another growing segment, particularly for small watercraft where the rotary engine's compact size and smooth operation provide significant advantages. The recreational boating industry has shown increased interest in rotary solutions for jet skis and small pleasure craft, valuing their reduced vibration and higher power density compared to traditional outboard motors.

Racing and motorsport applications maintain a steady demand for rotary engines, with their high-revving capabilities and compact design providing competitive advantages in certain racing categories. This niche market supports specialized manufacturers and aftermarket modification businesses catering to enthusiasts and professional racing teams.

Emerging market opportunities are developing around alternative fuel adaptations. The rotary engine's flexibility in fuel consumption creates potential growth in markets focused on hydrogen, natural gas, and biofuel applications. This versatility positions rotary technology favorably in regions pursuing diverse fuel strategies and reduced carbon emissions without complete electrification.

Regional analysis indicates stronger market presence in Japan, North America, and parts of Europe with established automotive and aerospace industries. Developing markets in Asia-Pacific show increasing interest, particularly for specialized industrial applications and small-scale power generation where the rotary engine's simplicity and reliability offer competitive advantages.

Market barriers include persistent challenges with emissions compliance, sealing technology limitations, and competition from increasingly efficient conventional engines and electric powertrains. However, technological advancements in materials science and manufacturing processes are gradually addressing these historical limitations.

Technical Challenges Across Different Fuel Types

The Wankel rotary engine faces distinct technical challenges when operating with different fuel types, primarily due to its unique combustion chamber geometry and thermodynamic characteristics. With gasoline, the primary challenge remains apex seal durability, as the triangular rotor's seals experience significant thermal stress and wear during operation. The elongated combustion chamber creates uneven temperature distribution, leading to incomplete combustion and higher hydrocarbon emissions compared to conventional piston engines.

When adapted for diesel operation, the Wankel engine encounters fundamental obstacles related to compression ratios. The geometric constraints of the rotary design make it difficult to achieve the high compression ratios (typically 15:1 to 22:1) required for diesel combustion. Additionally, the moving combustion chamber volume presents challenges for precise fuel injection timing, critical for diesel efficiency.

For hydrogen fuel applications, the Wankel engine demonstrates promising characteristics but faces unique challenges. The high flame speed of hydrogen requires modified ignition timing strategies, while hydrogen's low energy density by volume necessitates redesigned fuel delivery systems. Backfire prevention becomes particularly critical due to hydrogen's wide flammability range and low ignition energy.

Natural gas adaptation introduces challenges related to fuel storage and delivery systems. The rotary engine's port design requires significant modification to accommodate the gaseous fuel intake efficiently. Combustion stability at varying loads presents another technical hurdle, as natural gas has different flame propagation characteristics compared to liquid fuels.

Electric-hybrid Wankel configurations face integration challenges between the rotary engine and electric powertrain components. The inherent vibration characteristics of the Wankel engine can affect the durability of electronic components, while thermal management becomes more complex in hybrid systems.

Biofuel compatibility introduces material compatibility issues, particularly with ethanol and biodiesel blends. The higher oxygen content in biofuels can accelerate deterioration of certain sealing materials commonly used in rotary engines. Additionally, the varying energy content of biofuels requires adaptive fuel management systems to maintain optimal performance.

Across all fuel types, emissions control remains a persistent challenge. The Wankel's elongated combustion chamber and inherent quenching zones create conditions that increase unburned hydrocarbon emissions. Meeting increasingly stringent emissions regulations requires sophisticated aftertreatment systems specifically tailored to the rotary engine's unique exhaust composition profile.

When adapted for diesel operation, the Wankel engine encounters fundamental obstacles related to compression ratios. The geometric constraints of the rotary design make it difficult to achieve the high compression ratios (typically 15:1 to 22:1) required for diesel combustion. Additionally, the moving combustion chamber volume presents challenges for precise fuel injection timing, critical for diesel efficiency.

For hydrogen fuel applications, the Wankel engine demonstrates promising characteristics but faces unique challenges. The high flame speed of hydrogen requires modified ignition timing strategies, while hydrogen's low energy density by volume necessitates redesigned fuel delivery systems. Backfire prevention becomes particularly critical due to hydrogen's wide flammability range and low ignition energy.

Natural gas adaptation introduces challenges related to fuel storage and delivery systems. The rotary engine's port design requires significant modification to accommodate the gaseous fuel intake efficiently. Combustion stability at varying loads presents another technical hurdle, as natural gas has different flame propagation characteristics compared to liquid fuels.

Electric-hybrid Wankel configurations face integration challenges between the rotary engine and electric powertrain components. The inherent vibration characteristics of the Wankel engine can affect the durability of electronic components, while thermal management becomes more complex in hybrid systems.

Biofuel compatibility introduces material compatibility issues, particularly with ethanol and biodiesel blends. The higher oxygen content in biofuels can accelerate deterioration of certain sealing materials commonly used in rotary engines. Additionally, the varying energy content of biofuels requires adaptive fuel management systems to maintain optimal performance.

Across all fuel types, emissions control remains a persistent challenge. The Wankel's elongated combustion chamber and inherent quenching zones create conditions that increase unburned hydrocarbon emissions. Meeting increasingly stringent emissions regulations requires sophisticated aftertreatment systems specifically tailored to the rotary engine's unique exhaust composition profile.

Current Fuel Adaptation Solutions for Wankel Engines

01 Wankel Engine Design and Structure

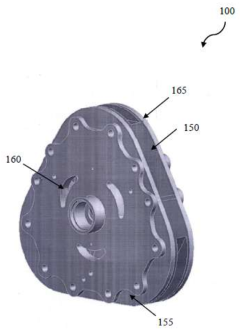

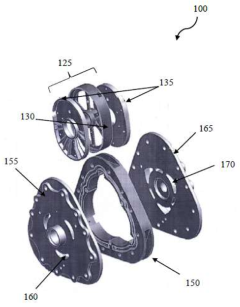

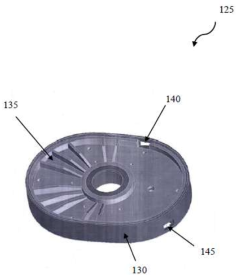

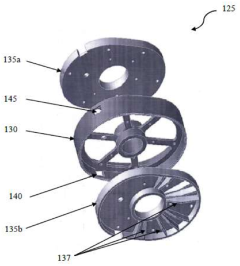

The Wankel engine features a unique rotary design with a triangular rotor that revolves inside an epitrochoid-shaped housing. This design eliminates the need for conventional reciprocating pistons, resulting in fewer moving parts, smoother operation, and higher power-to-weight ratio compared to traditional piston engines. The engine's structure includes specific components like eccentric shafts, rotor housings, and apex seals that are critical to its operation.- Wankel Engine Design and Structure: The Wankel engine features a unique rotary design with a triangular rotor that revolves inside an epitrochoid-shaped housing. This design eliminates the need for conventional reciprocating pistons, resulting in fewer moving parts, smoother operation, and higher power-to-weight ratio compared to traditional piston engines. The basic structure includes a rotor housing, eccentric shaft, and peripheral intake and exhaust ports that enable the four-stroke cycle to occur in different sections of the housing simultaneously.

- Sealing Systems for Wankel Engines: Effective sealing is critical in Wankel engines to maintain compression and prevent leakage between the chambers. Advanced sealing systems include apex seals at the rotor corners, side seals along the rotor faces, and oil seals. These components are designed to withstand high temperatures and pressures while minimizing friction. Innovations in sealing materials and configurations have addressed historical challenges with seal wear and oil consumption, improving engine durability and efficiency.

- Cooling and Lubrication Systems: Wankel engines require specialized cooling and lubrication systems due to their unique geometry and operating characteristics. The cooling system must address the uneven temperature distribution across the housing, particularly at the exhaust area. Advanced cooling solutions include liquid cooling channels, oil jets, and thermal barrier coatings. Lubrication systems are designed to provide oil to the eccentric shaft bearings, rotor bearings, and sealing elements while minimizing oil consumption and emissions.

- Combustion Optimization and Emission Control: Improving combustion efficiency and reducing emissions are key areas of Wankel engine development. Innovations include advanced fuel injection systems, optimized chamber geometry, and variable port timing. The elongated combustion chamber presents unique challenges for flame propagation and complete combustion. Modern designs incorporate direct injection, stratified charge concepts, and exhaust gas recirculation to improve thermal efficiency and reduce hydrocarbon emissions. Some designs also integrate catalytic converters specifically optimized for the rotary engine's exhaust characteristics.

- Hybrid and Alternative Fuel Applications: Wankel engines are being adapted for hybrid powertrains and alternative fuel applications. Their compact size and smooth operation make them suitable as range extenders in electric vehicles. Modifications to accommodate hydrogen, natural gas, and biofuels leverage the rotary engine's fuel flexibility. Recent developments include rotary engines optimized as generators in series hybrid configurations, taking advantage of their high power density and ability to operate efficiently at constant speeds. These applications help address traditional rotary engine challenges while utilizing their inherent advantages.

02 Sealing Systems for Wankel Engines

Effective sealing is crucial for Wankel engine performance. Advanced sealing systems are designed to maintain compression between the rotor and housing, preventing leakage of combustion gases and ensuring efficient operation. These systems typically include apex seals at the corners of the triangular rotor, side seals along the rotor faces, and oil seals. Innovations in sealing materials and configurations aim to address historical challenges with seal wear and longevity.Expand Specific Solutions03 Cooling and Lubrication Systems

Wankel engines require specialized cooling and lubrication systems due to their unique geometry and operating characteristics. These systems manage the high thermal loads generated during operation, particularly at the rotor housing where combustion occurs. Innovations include advanced oil circulation methods, strategic coolant pathways, and thermal management techniques that help maintain optimal operating temperatures and reduce wear on critical components.Expand Specific Solutions04 Combustion and Emission Control

Improving combustion efficiency and reducing emissions are key areas of development for Wankel engines. Innovations include modified combustion chamber designs, advanced fuel injection systems, and exhaust treatment technologies. These developments aim to address traditional challenges with fuel efficiency and emissions compliance while maintaining the inherent advantages of the rotary design. Some approaches incorporate hybrid technologies or alternative fuels to enhance environmental performance.Expand Specific Solutions05 Applications and Adaptations

Wankel engines have been adapted for various applications beyond conventional automotive use. These include aviation, marine propulsion, power generation, and specialized industrial applications. The engine's compact size, high power density, and smooth operation make it suitable for these diverse uses. Recent innovations focus on integrating Wankel engines into hybrid powertrains, range extenders for electric vehicles, and other novel applications that leverage the unique characteristics of rotary engine technology.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Wankel engine market across fuel types is in a growth phase, with increasing interest in alternative fuels driving innovation. The market is expanding as companies seek more efficient rotary engine solutions, though it remains relatively niche compared to conventional engines. Technologically, the field shows varying maturity levels, with established players like Pratt & Whitney Canada and Ford Global Technologies possessing advanced capabilities, while newer entrants like Shaanxi New Year Power and Quest Engines are developing innovative adaptations. Chinese institutions (Beijing University of Technology, Xi'an Jiaotong University) are making significant research contributions, while companies like Shell and Caterpillar are exploring applications across different fuel types, indicating growing commercial viability despite remaining technical challenges.

Ford Global Technologies LLC

Technical Solution: Ford has developed a hybrid Wankel engine system that can operate on multiple fuel types including gasoline, ethanol blends, and hydrogen. Their approach incorporates a modified rotor housing with variable compression ratio technology that automatically adjusts based on fuel characteristics. The system features advanced direct injection technology with multiple injectors positioned strategically around the housing to optimize fuel delivery for different fuel types. Ford's design includes a thermal barrier coating on the rotor faces that reduces heat transfer and improves thermal efficiency across various fuels. Their electronic control system incorporates predictive algorithms that adjust timing, fuel delivery, and emissions control strategies based on fuel composition detection. The company has also addressed traditional Wankel sealing issues with a new composite apex seal material that performs consistently across different fuel types and operating temperatures.

Strengths: Excellent adaptability to market fuel availability fluctuations; maintains consistent power output across different fuel types; integrated with Ford's existing hybrid powertrain systems. Weaknesses: Higher initial manufacturing cost compared to conventional engines; still exhibits higher fuel consumption than traditional piston engines; requires more frequent maintenance intervals for apex seal replacement.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced fuel injection and engine management system specifically optimized for multi-fuel Wankel engine applications. Their technology features high-precision direct injection systems with variable spray patterns that adapt to different fuel properties and combustion characteristics. The company's multi-fuel sensor array provides real-time analysis of fuel composition, allowing the engine control unit to dynamically adjust operating parameters. Bosch's system incorporates specialized injector nozzles with ceramic components that resist wear from different fuel types, including those with varying levels of lubricity and corrosiveness. Their engine management software includes adaptive learning algorithms that optimize combustion timing and duration based on fuel properties and engine operating conditions. The technology also features integrated thermal management systems that adjust cooling strategies based on the different heat rejection characteristics of various fuels in Wankel engines. Bosch has additionally developed specialized ignition systems with multiple spark strategies optimized for the elongated combustion chamber of Wankel engines using different fuel types.

Strengths: Industry-leading precision in fuel delivery and combustion control; seamless integration with existing vehicle systems; extensive validation across multiple fuel types and engine designs. Weaknesses: Requires sophisticated electronic controls that increase system complexity; higher component costs compared to conventional systems; dependent on engine manufacturers adopting their technology.

Key Patents and Innovations in Rotary Engine Design

Aqueous fuel for internal combustion engines

PatentWO1995025154A2

Innovation

- Aqueous fuel mixtures comprising water (0.5%-70%) and various fuels (methanol, isopropanol, ethylene glycol, glycerol, petrol, diesel, ethanol, kerosene) with optional additives, formulated to reduce pollutant emissions in internal combustion engines.

A rotary engine

PatentInactiveIN201621035262A

Innovation

- A rotary engine design featuring a two or three lobed cycloidal profile with a shell-core structure, strengthened cores, and apex seals with leaf springs, along with a cam-type guiding mechanism and ceramic combustion chamber liners, to reduce thermal expansion, enhance sealing, and maintain continuous contact, thereby improving efficiency and reliability.

Emissions and Environmental Impact Assessment

The Wankel rotary engine presents a unique emissions profile that varies significantly across different fuel types. When operating on traditional gasoline, these engines typically produce higher hydrocarbon (HC) emissions compared to conventional piston engines, primarily due to the elongated combustion chamber geometry and the inherent challenges in achieving complete combustion. The characteristic "chatter marks" on the rotor housing contribute to unburned fuel pockets, resulting in elevated HC levels that have historically challenged Wankel designs in meeting stringent emissions standards.

Carbon monoxide (CO) emissions from Wankel engines show interesting variations across fuel types. Gasoline-powered Wankel engines generally produce moderate CO levels, while hydrogen-fueled variants demonstrate near-zero CO emissions—a significant environmental advantage. However, the thermal efficiency limitations of the Wankel design often necessitate higher fuel consumption rates, indirectly increasing the carbon footprint regardless of fuel type.

Nitrogen oxide (NOx) emissions present a more favorable scenario for Wankel engines. The lower combustion temperatures compared to reciprocating engines typically result in reduced NOx formation. This advantage becomes particularly pronounced when using hydrogen as fuel, where NOx emissions can be controlled more effectively through precise combustion management techniques.

Particulate matter emissions vary dramatically across fuel types. Diesel-adapted Wankel engines produce significantly lower particulate emissions than conventional diesel piston engines, primarily due to the continuous combustion process and absence of high-pressure injection systems. When operating on hydrogen, particulate emissions are virtually eliminated, positioning hydrogen-powered Wankel engines as potentially zero-emission powerplants.

The environmental impact assessment must also consider the full lifecycle emissions profile. While operational emissions may favor certain fuel types, the production and distribution infrastructure for alternative fuels like hydrogen currently carries significant carbon penalties. The energy intensity of hydrogen production, particularly when derived from non-renewable sources, can offset the operational emissions advantages.

Recent advancements in catalytic converter technology specifically designed for rotary engines have improved the environmental performance across all fuel types. These systems address the unique exhaust gas composition and temperature profiles of Wankel engines, with specialized formulations showing particular promise for natural gas and hydrogen applications.

Regulatory compliance remains a critical challenge for Wankel engine development. While hydrogen and natural gas variants show promise in meeting future emissions targets, gasoline-powered versions face increasing difficulty in satisfying Euro 7, China 7, and California LEV III standards without substantial modifications or hybridization strategies.

Carbon monoxide (CO) emissions from Wankel engines show interesting variations across fuel types. Gasoline-powered Wankel engines generally produce moderate CO levels, while hydrogen-fueled variants demonstrate near-zero CO emissions—a significant environmental advantage. However, the thermal efficiency limitations of the Wankel design often necessitate higher fuel consumption rates, indirectly increasing the carbon footprint regardless of fuel type.

Nitrogen oxide (NOx) emissions present a more favorable scenario for Wankel engines. The lower combustion temperatures compared to reciprocating engines typically result in reduced NOx formation. This advantage becomes particularly pronounced when using hydrogen as fuel, where NOx emissions can be controlled more effectively through precise combustion management techniques.

Particulate matter emissions vary dramatically across fuel types. Diesel-adapted Wankel engines produce significantly lower particulate emissions than conventional diesel piston engines, primarily due to the continuous combustion process and absence of high-pressure injection systems. When operating on hydrogen, particulate emissions are virtually eliminated, positioning hydrogen-powered Wankel engines as potentially zero-emission powerplants.

The environmental impact assessment must also consider the full lifecycle emissions profile. While operational emissions may favor certain fuel types, the production and distribution infrastructure for alternative fuels like hydrogen currently carries significant carbon penalties. The energy intensity of hydrogen production, particularly when derived from non-renewable sources, can offset the operational emissions advantages.

Recent advancements in catalytic converter technology specifically designed for rotary engines have improved the environmental performance across all fuel types. These systems address the unique exhaust gas composition and temperature profiles of Wankel engines, with specialized formulations showing particular promise for natural gas and hydrogen applications.

Regulatory compliance remains a critical challenge for Wankel engine development. While hydrogen and natural gas variants show promise in meeting future emissions targets, gasoline-powered versions face increasing difficulty in satisfying Euro 7, China 7, and California LEV III standards without substantial modifications or hybridization strategies.

Efficiency Benchmarking Methodology

To establish a comprehensive comparison of Wankel engines across different fuel types, a standardized efficiency benchmarking methodology is essential. This methodology must account for the unique rotary design characteristics while enabling fair comparisons with conventional reciprocating engines.

The primary efficiency metrics for Wankel engine evaluation include brake-specific fuel consumption (BSFC), thermal efficiency, mechanical efficiency, and volumetric efficiency. These metrics must be measured under controlled conditions that simulate real-world operating scenarios while maintaining scientific rigor. Testing protocols should incorporate both steady-state and transient operation conditions to capture the full performance envelope.

For cross-fuel type comparisons, the methodology employs energy-equivalent normalization techniques. This approach converts the energy content of different fuels (gasoline, diesel, hydrogen, natural gas, and biofuels) to a common energy unit, typically megajoules (MJ), enabling direct efficiency comparisons regardless of fuel energy density differences. This normalization is crucial when comparing hydrogen-powered Wankel engines to their fossil fuel counterparts.

Test cycles must be carefully designed to reflect the intended application domain. For automotive applications, standardized driving cycles such as WLTP or EPA cycles provide a foundation, while aviation applications require specialized flight profile simulations. Marine and stationary power applications each demand their own representative load profiles to ensure relevant benchmarking results.

Advanced instrumentation requirements include high-precision fuel flow meters calibrated for different fuel types, exhaust gas analyzers capable of measuring emissions across fuel varieties, and specialized rotary engine dynamometers that can accurately capture the unique power delivery characteristics of Wankel engines. Thermal imaging systems are employed to map heat distribution patterns, which vary significantly between fuel types.

Data normalization procedures account for ambient conditions, including temperature, pressure, and humidity corrections according to SAE J1349 or similar standards. Statistical analysis methods incorporate uncertainty quantification to establish confidence intervals for all efficiency metrics, ensuring scientific validity of comparative results.

The methodology also incorporates a life-cycle efficiency assessment component, evaluating not just point-of-use efficiency but also well-to-wheel or well-to-propeller efficiency depending on application. This holistic approach provides a more complete picture of the environmental impact across different fuel pathways when used in Wankel engine configurations.

The primary efficiency metrics for Wankel engine evaluation include brake-specific fuel consumption (BSFC), thermal efficiency, mechanical efficiency, and volumetric efficiency. These metrics must be measured under controlled conditions that simulate real-world operating scenarios while maintaining scientific rigor. Testing protocols should incorporate both steady-state and transient operation conditions to capture the full performance envelope.

For cross-fuel type comparisons, the methodology employs energy-equivalent normalization techniques. This approach converts the energy content of different fuels (gasoline, diesel, hydrogen, natural gas, and biofuels) to a common energy unit, typically megajoules (MJ), enabling direct efficiency comparisons regardless of fuel energy density differences. This normalization is crucial when comparing hydrogen-powered Wankel engines to their fossil fuel counterparts.

Test cycles must be carefully designed to reflect the intended application domain. For automotive applications, standardized driving cycles such as WLTP or EPA cycles provide a foundation, while aviation applications require specialized flight profile simulations. Marine and stationary power applications each demand their own representative load profiles to ensure relevant benchmarking results.

Advanced instrumentation requirements include high-precision fuel flow meters calibrated for different fuel types, exhaust gas analyzers capable of measuring emissions across fuel varieties, and specialized rotary engine dynamometers that can accurately capture the unique power delivery characteristics of Wankel engines. Thermal imaging systems are employed to map heat distribution patterns, which vary significantly between fuel types.

Data normalization procedures account for ambient conditions, including temperature, pressure, and humidity corrections according to SAE J1349 or similar standards. Statistical analysis methods incorporate uncertainty quantification to establish confidence intervals for all efficiency metrics, ensuring scientific validity of comparative results.

The methodology also incorporates a life-cycle efficiency assessment component, evaluating not just point-of-use efficiency but also well-to-wheel or well-to-propeller efficiency depending on application. This holistic approach provides a more complete picture of the environmental impact across different fuel pathways when used in Wankel engine configurations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!