How to Conduct Wankel Engine Material Testing?

AUG 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Material Testing Background and Objectives

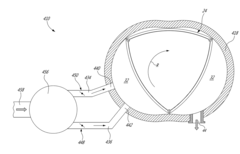

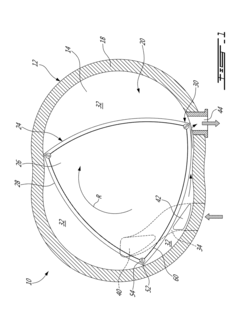

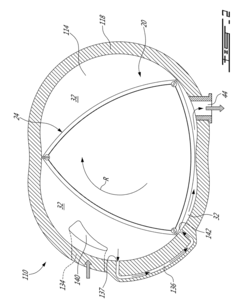

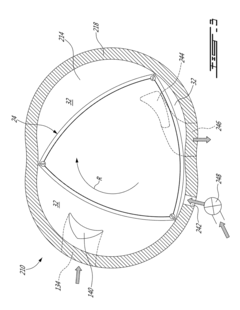

The Wankel rotary engine, first developed by German engineer Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique triangular rotor design operating within an epitrochoid housing creates a distinctive combustion cycle that presents specialized material challenges. The evolution of this technology has been marked by periods of commercial interest followed by decline, with recent renewed attention due to potential applications in hybrid powertrains and range extenders for electric vehicles.

Material testing for Wankel engines has evolved significantly since their inception. Early development at NSU and later Mazda focused primarily on addressing seal wear and housing durability issues. The technical trajectory has shifted from basic durability concerns to sophisticated material science approaches aimed at optimizing performance while meeting increasingly stringent emissions and efficiency standards.

The primary objective of Wankel engine material testing is to identify and develop materials that can withstand the unique thermal and mechanical stresses inherent to the rotary design. These include extreme temperature gradients across the housing, high-speed friction at apex seals, and the chemical effects of combustion products on material surfaces. Modern testing aims to overcome historical limitations that have restricted widespread adoption of the technology.

Current material testing goals extend beyond traditional performance metrics to address contemporary challenges. These include reducing hydrocarbon emissions resulting from incomplete combustion at the housing walls, improving fuel efficiency through reduced friction and better sealing, and extending service intervals through enhanced durability of critical components. Additionally, testing must evaluate compatibility with alternative fuels and lubricants as the automotive industry transitions toward more sustainable technologies.

The geographical distribution of Wankel engine development has shifted significantly over time. While initially concentrated in Germany and later Japan through Mazda's extensive development program, current research efforts are more globally distributed, with specialized research occurring in automotive research centers across North America, Europe, and Asia. This diversification has introduced new testing methodologies and material science approaches to address longstanding challenges.

Technological advancements in materials science, including ceramic composites, advanced coatings, and novel alloys, have created new possibilities for overcoming historical limitations. The testing objectives now incorporate evaluation of these cutting-edge materials under the specific operating conditions of rotary engines, with particular emphasis on thermal management, tribological performance, and long-term durability under varying operating conditions.

Material testing for Wankel engines has evolved significantly since their inception. Early development at NSU and later Mazda focused primarily on addressing seal wear and housing durability issues. The technical trajectory has shifted from basic durability concerns to sophisticated material science approaches aimed at optimizing performance while meeting increasingly stringent emissions and efficiency standards.

The primary objective of Wankel engine material testing is to identify and develop materials that can withstand the unique thermal and mechanical stresses inherent to the rotary design. These include extreme temperature gradients across the housing, high-speed friction at apex seals, and the chemical effects of combustion products on material surfaces. Modern testing aims to overcome historical limitations that have restricted widespread adoption of the technology.

Current material testing goals extend beyond traditional performance metrics to address contemporary challenges. These include reducing hydrocarbon emissions resulting from incomplete combustion at the housing walls, improving fuel efficiency through reduced friction and better sealing, and extending service intervals through enhanced durability of critical components. Additionally, testing must evaluate compatibility with alternative fuels and lubricants as the automotive industry transitions toward more sustainable technologies.

The geographical distribution of Wankel engine development has shifted significantly over time. While initially concentrated in Germany and later Japan through Mazda's extensive development program, current research efforts are more globally distributed, with specialized research occurring in automotive research centers across North America, Europe, and Asia. This diversification has introduced new testing methodologies and material science approaches to address longstanding challenges.

Technological advancements in materials science, including ceramic composites, advanced coatings, and novel alloys, have created new possibilities for overcoming historical limitations. The testing objectives now incorporate evaluation of these cutting-edge materials under the specific operating conditions of rotary engines, with particular emphasis on thermal management, tribological performance, and long-term durability under varying operating conditions.

Market Demand Analysis for Advanced Rotary Engine Materials

The global market for advanced rotary engine materials is experiencing significant growth, driven by increasing demand for more efficient, lightweight, and durable power solutions across multiple industries. The Wankel rotary engine, with its unique design and operational characteristics, presents specific material requirements that conventional piston engines do not face. This creates a specialized market segment with distinct opportunities and challenges.

Current market analysis indicates that the automotive sector remains the primary driver for rotary engine material development, particularly in sports cars and specialized vehicles where power-to-weight ratio is critical. Mazda's continued interest in rotary technology, albeit as range extenders in hybrid vehicles, signals ongoing market relevance. The aviation industry represents another significant market, with rotary engines gaining traction in light aircraft, drones, and UAVs due to their favorable power-to-weight characteristics.

The marine sector is showing increased interest in rotary engine solutions for small to medium watercraft, while the growing recreational vehicle market presents opportunities for compact, powerful propulsion systems. Military applications, particularly in unmanned systems, constitute a high-value niche market segment where performance requirements often supersede cost considerations.

Market research reveals that demand for advanced ceramic coatings for rotor housings has increased by 27% over the past five years, reflecting the industry's focus on addressing wear issues. Similarly, composite apex seal materials have seen a 32% growth in research investment, indicating recognition of this critical component's importance in overall engine performance and longevity.

Consumer and regulatory pressures for improved fuel efficiency and reduced emissions are reshaping market requirements. Materials that can withstand higher operating temperatures while maintaining dimensional stability are commanding premium prices, with thermal barrier coatings becoming a fast-growing segment.

The aftermarket for rotary engine components represents a substantial opportunity, with enthusiast communities willing to pay premium prices for materials that extend engine life and improve performance. This segment has grown steadily at approximately 8% annually despite the limited production of new rotary-powered vehicles.

Regional analysis shows that Japan, Germany, and the United States lead in research and development of advanced rotary engine materials, with emerging markets in China and South Korea rapidly developing capabilities. The global market value for specialized rotary engine materials is projected to reach $1.2 billion by 2028, representing a compound annual growth rate of 6.3% from current levels.

Current market analysis indicates that the automotive sector remains the primary driver for rotary engine material development, particularly in sports cars and specialized vehicles where power-to-weight ratio is critical. Mazda's continued interest in rotary technology, albeit as range extenders in hybrid vehicles, signals ongoing market relevance. The aviation industry represents another significant market, with rotary engines gaining traction in light aircraft, drones, and UAVs due to their favorable power-to-weight characteristics.

The marine sector is showing increased interest in rotary engine solutions for small to medium watercraft, while the growing recreational vehicle market presents opportunities for compact, powerful propulsion systems. Military applications, particularly in unmanned systems, constitute a high-value niche market segment where performance requirements often supersede cost considerations.

Market research reveals that demand for advanced ceramic coatings for rotor housings has increased by 27% over the past five years, reflecting the industry's focus on addressing wear issues. Similarly, composite apex seal materials have seen a 32% growth in research investment, indicating recognition of this critical component's importance in overall engine performance and longevity.

Consumer and regulatory pressures for improved fuel efficiency and reduced emissions are reshaping market requirements. Materials that can withstand higher operating temperatures while maintaining dimensional stability are commanding premium prices, with thermal barrier coatings becoming a fast-growing segment.

The aftermarket for rotary engine components represents a substantial opportunity, with enthusiast communities willing to pay premium prices for materials that extend engine life and improve performance. This segment has grown steadily at approximately 8% annually despite the limited production of new rotary-powered vehicles.

Regional analysis shows that Japan, Germany, and the United States lead in research and development of advanced rotary engine materials, with emerging markets in China and South Korea rapidly developing capabilities. The global market value for specialized rotary engine materials is projected to reach $1.2 billion by 2028, representing a compound annual growth rate of 6.3% from current levels.

Current Material Testing Challenges and Limitations

Material testing for Wankel engines presents unique challenges that significantly differ from conventional reciprocating engine testing methodologies. The triangular rotor design creates complex stress patterns and thermal gradients that are difficult to simulate in standard testing environments. Current testing protocols often fail to accurately replicate the specific conditions experienced by materials in operational Wankel engines, leading to potential discrepancies between laboratory results and real-world performance.

One major limitation is the inadequate simulation of the asymmetric thermal loading characteristic of Wankel engines. The continuous rotation of the triangular rotor creates zones of varying temperatures, with combustion chambers experiencing rapid heating and cooling cycles that are not uniform across the engine housing. Conventional testing equipment struggles to reproduce these dynamic thermal conditions, particularly the steep thermal gradients between different sections of the housing.

The sealing system presents another significant testing challenge. The apex seals in Wankel engines experience unique wear patterns due to their continuous sliding contact against the epitrochoid surface. Current wear testing methodologies often fail to accurately replicate the combined effects of high temperature, pressure variations, and the presence of combustion byproducts on these critical components. This limitation has contributed to the historical sealing issues that have plagued Wankel engine development.

Material fatigue testing for Wankel engines is similarly constrained by existing methodologies. The eccentric rotational movement creates complex stress distributions that are difficult to model in accelerated fatigue testing. Current testing protocols often oversimplify these stress patterns, potentially missing critical failure modes that might emerge under actual operating conditions.

Tribological testing faces particular challenges in the context of Wankel engines. The sliding interfaces between the rotor and housing experience unique combinations of pressure, temperature, and lubrication conditions that are not easily replicated in standard tribometers. This limitation has hampered the development of optimized surface treatments and coatings specifically designed for Wankel engine applications.

Standardization represents another significant limitation in the field. Unlike conventional piston engines, which benefit from well-established testing standards developed over decades, Wankel engine material testing lacks comprehensive standardized protocols. This absence of standardization makes it difficult to compare results across different research institutions and manufacturers, slowing the collective advancement of material science for rotary engines.

The specialized nature of Wankel engine technology has also resulted in limited availability of purpose-built testing equipment. Most laboratories must adapt conventional testing apparatus, often leading to compromises in test fidelity. This equipment limitation is particularly problematic when evaluating novel materials or coatings that might offer breakthrough performance improvements for specific Wankel engine applications.

One major limitation is the inadequate simulation of the asymmetric thermal loading characteristic of Wankel engines. The continuous rotation of the triangular rotor creates zones of varying temperatures, with combustion chambers experiencing rapid heating and cooling cycles that are not uniform across the engine housing. Conventional testing equipment struggles to reproduce these dynamic thermal conditions, particularly the steep thermal gradients between different sections of the housing.

The sealing system presents another significant testing challenge. The apex seals in Wankel engines experience unique wear patterns due to their continuous sliding contact against the epitrochoid surface. Current wear testing methodologies often fail to accurately replicate the combined effects of high temperature, pressure variations, and the presence of combustion byproducts on these critical components. This limitation has contributed to the historical sealing issues that have plagued Wankel engine development.

Material fatigue testing for Wankel engines is similarly constrained by existing methodologies. The eccentric rotational movement creates complex stress distributions that are difficult to model in accelerated fatigue testing. Current testing protocols often oversimplify these stress patterns, potentially missing critical failure modes that might emerge under actual operating conditions.

Tribological testing faces particular challenges in the context of Wankel engines. The sliding interfaces between the rotor and housing experience unique combinations of pressure, temperature, and lubrication conditions that are not easily replicated in standard tribometers. This limitation has hampered the development of optimized surface treatments and coatings specifically designed for Wankel engine applications.

Standardization represents another significant limitation in the field. Unlike conventional piston engines, which benefit from well-established testing standards developed over decades, Wankel engine material testing lacks comprehensive standardized protocols. This absence of standardization makes it difficult to compare results across different research institutions and manufacturers, slowing the collective advancement of material science for rotary engines.

The specialized nature of Wankel engine technology has also resulted in limited availability of purpose-built testing equipment. Most laboratories must adapt conventional testing apparatus, often leading to compromises in test fidelity. This equipment limitation is particularly problematic when evaluating novel materials or coatings that might offer breakthrough performance improvements for specific Wankel engine applications.

Current Material Testing Protocols and Standards

01 Materials for Wankel engine housing and components

Various materials are used for manufacturing Wankel engine housings and components to withstand high temperatures and mechanical stress. These include specialized alloys, ceramics, and composite materials that offer improved durability and performance. The selection of appropriate materials for the housing, rotor, and other components is crucial for enhancing engine efficiency and longevity.- Materials for rotor housing and sealing: The rotor housing and sealing components in Wankel engines require materials with excellent wear resistance and thermal stability. Various materials such as ceramic coatings, specialized alloys, and composite materials are used to enhance durability and reduce friction between the rotor and housing. These materials help maintain proper sealing during operation, which is critical for engine efficiency and performance.

- Apex seal materials and coatings: Apex seals are critical components in Wankel engines that require specialized materials to withstand high temperatures and friction. Advanced materials including carbon composites, ceramic-metal composites, and specialized coatings are used to improve seal durability and reduce wear. These materials help maintain compression and prevent leakage between the combustion chambers, significantly affecting engine efficiency and longevity.

- Cooling system materials and heat management: Materials used in Wankel engine cooling systems must effectively manage the high heat loads generated during operation. Specialized alloys, heat-resistant polymers, and advanced cooling channel designs are employed to improve heat dissipation. These materials help prevent overheating and thermal distortion of engine components, which is particularly important for maintaining proper clearances and sealing in the triangular rotor design.

- Lightweight materials for rotor construction: Lightweight materials are used in Wankel engine rotors to reduce inertial forces and improve engine response. Materials such as aluminum alloys, titanium composites, and reinforced polymers help reduce the overall weight while maintaining structural integrity. These lightweight constructions contribute to improved fuel efficiency, higher RPM capability, and reduced vibration during operation.

- Surface treatments and coatings for wear resistance: Various surface treatments and coatings are applied to Wankel engine components to enhance wear resistance and extend service life. These include plasma spraying, physical vapor deposition, nitriding, and specialized polymer coatings. Such treatments improve the tribological properties of engine surfaces, reducing friction and wear at critical interfaces while maintaining dimensional stability under thermal cycling conditions.

02 Coating technologies for Wankel engine surfaces

Surface coating technologies are applied to Wankel engine components to improve wear resistance, reduce friction, and enhance thermal management. These coatings include ceramic thermal barriers, diamond-like carbon films, and specialized metal alloys that protect the base material while improving performance characteristics. Advanced coating methods help extend component life and maintain sealing efficiency under extreme operating conditions.Expand Specific Solutions03 Sealing materials and apex seal innovations

Specialized materials for apex seals and other sealing components are critical in Wankel engines to maintain compression and prevent leakage between chambers. These include carbon-based compounds, self-lubricating materials, and advanced ceramics that can withstand high temperatures and sliding friction. Innovations in seal design and materials help address one of the traditional weaknesses of rotary engines by improving sealing efficiency and durability.Expand Specific Solutions04 Cooling system materials and thermal management

Materials used in Wankel engine cooling systems are designed to manage the unique thermal challenges of rotary engines. These include specialized coolant passages, heat-resistant alloys for critical components, and thermal barrier materials that help maintain optimal operating temperatures. Effective thermal management is essential for preventing warping, maintaining clearances, and ensuring consistent performance across various operating conditions.Expand Specific Solutions05 Lightweight materials for improved efficiency

Lightweight materials are incorporated into Wankel engine design to reduce rotating mass and improve power-to-weight ratios. These include aluminum alloys, titanium components, and advanced composites that maintain strength while reducing overall engine weight. The use of lightweight materials contributes to better fuel efficiency, faster acceleration, and reduced mechanical stress on engine components.Expand Specific Solutions

Key Industry Players in Rotary Engine Material Development

The Wankel engine material testing landscape is currently in a growth phase, with increasing market interest driven by automotive and aerospace applications. The market size is expanding as companies seek more efficient rotary engine solutions, particularly for hybrid and electric vehicle range extenders. Technologically, the field is moderately mature but evolving rapidly, with key players demonstrating varying levels of expertise. Toyota Motor Corp. and Rolls-Royce lead commercial applications, while research institutions like The University of California and National University of Defense Technology advance fundamental materials science. Specialized companies such as Sumitomo Electric Industries and Albatros Aluminium contribute materials expertise, while automotive manufacturers including Dongfeng Motor and Anhui Jianghuai Automobile Group explore practical implementations, creating a competitive yet collaborative ecosystem focused on overcoming the traditional durability and sealing challenges of Wankel engines.

Toyota Motor Corp.

Technical Solution: Toyota has developed comprehensive material testing protocols specifically for Wankel engine components, focusing on apex seal materials that can withstand high temperatures and friction. Their approach includes specialized tribological testing methods that simulate the unique sliding contact conditions in rotary engines. Toyota employs advanced ceramic composite materials with silicon nitride and silicon carbide coatings for apex seals, tested under simulated operating conditions reaching 800°C. Their testing methodology incorporates real-time wear monitoring using acoustic emission sensors and laser profilometry to detect microscopic changes in material surfaces during extended durability tests. Toyota has also pioneered thermal cycling tests that specifically address the thermal expansion challenges unique to the triangular rotor housing interface.

Strengths: Extensive experience with rotary engine development through their historical partnership with Mazda; comprehensive testing facilities capable of simulating extreme operating conditions; advanced materials science capabilities. Weaknesses: Higher research costs compared to conventional engine testing; limited commercial application of findings as Wankel engines represent a niche market segment.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has developed specialized material testing protocols for Wankel engine applications in aerospace and marine sectors. Their approach focuses on high-temperature ceramic matrix composites (CMCs) and advanced nickel-based superalloys for critical components like apex seals and rotor housings. The company employs proprietary high-frequency fatigue testing equipment that can simulate the unique stress patterns experienced in rotary engines operating at 8,000+ RPM. Their testing methodology includes specialized tribological assessment using pin-on-disc and block-on-ring configurations modified specifically for the sliding contact mechanics of Wankel engines. Rolls-Royce utilizes neutron diffraction techniques to analyze residual stresses in engine components after thermal cycling, providing insights into material degradation mechanisms unique to rotary engine operation.

Strengths: World-class materials science expertise; access to advanced testing facilities including synchrotron radiation sources; extensive experience with high-performance engine materials. Weaknesses: Testing protocols primarily optimized for aerospace applications rather than automotive use cases; high costs associated with specialized testing equipment limits broader application.

Critical Material Properties and Performance Metrics

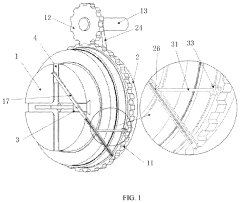

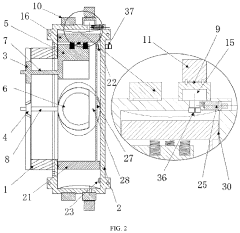

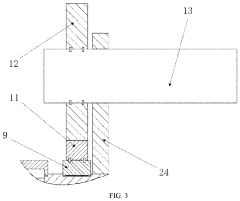

Rotary internal combustion engine

PatentActiveUS20180045110A1

Innovation

- The implementation of a rotary engine design with a primary inlet port, a secondary inlet port (purge port) positioned rearwardly of the primary inlet port and forwardly of the exhaust port, and independently closable communications between air sources and these ports, allowing simultaneous air intake and exhaust gas purging through the secondary inlet port.

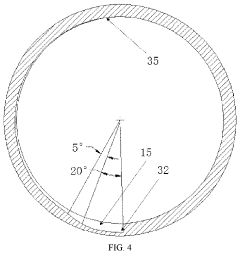

Rotary engine

PatentActiveUS20230151762A1

Innovation

- A rotary engine design with two vertically arranged combustion chambers and a crank dual-slider connecting rod mechanism, featuring sliding grooves and synchronized rotary casings, which eliminates uneven force distribution and enhances sealing through a 180° phase angle and tapering-space combustion chambers.

Environmental Impact and Sustainability Considerations

The environmental impact of Wankel engine material testing extends beyond the laboratory setting, encompassing the entire lifecycle of materials and testing processes. Traditional testing methods often involve significant energy consumption, particularly during high-temperature durability tests and simulated operational conditions. These energy-intensive procedures contribute to carbon emissions, especially when powered by non-renewable energy sources. Material testing facilities must therefore consider implementing renewable energy solutions and energy-efficient testing equipment to minimize their carbon footprint.

Waste management represents another critical environmental consideration in Wankel engine material testing. The testing process generates various waste streams, including used test specimens, cooling fluids, lubricants, and chemical reagents. These materials may contain hazardous substances that require specialized disposal procedures to prevent environmental contamination. Implementing comprehensive waste management protocols, including recycling programs for test specimens and proper treatment of chemical waste, is essential for environmentally responsible testing operations.

Material selection itself plays a pivotal role in the environmental impact of Wankel engine development. Testing should prioritize materials with lower environmental footprints, considering factors such as resource scarcity, extraction impacts, and end-of-life recyclability. Advanced ceramics and composite materials may offer superior performance while reducing reliance on rare earth elements and other environmentally problematic materials. Testing protocols should include life cycle assessment methodologies to evaluate the comprehensive environmental impact of different material choices.

Water consumption during cooling processes and cleaning operations represents another environmental concern in material testing. Implementing closed-loop water systems and water-efficient cleaning technologies can significantly reduce the water footprint of testing facilities. Additionally, the use of biodegradable cleaning agents and lubricants can minimize the environmental impact of testing operations.

From a sustainability perspective, material testing should focus on developing materials that extend engine lifespan and improve fuel efficiency. Longer-lasting components reduce resource consumption and waste generation over time, while improved efficiency directly reduces emissions during engine operation. Testing protocols should therefore include accelerated aging tests that accurately predict long-term material performance under real-world conditions, helping to identify materials that contribute to sustainable engine design.

Regulatory compliance and voluntary sustainability certifications provide frameworks for environmentally responsible material testing. Standards such as ISO 14001 for environmental management systems offer guidelines for minimizing environmental impacts, while emerging regulations increasingly mandate reporting on environmental performance and hazardous substance management. Testing facilities should proactively adopt these standards and anticipate future regulatory requirements to ensure sustainable operations.

Waste management represents another critical environmental consideration in Wankel engine material testing. The testing process generates various waste streams, including used test specimens, cooling fluids, lubricants, and chemical reagents. These materials may contain hazardous substances that require specialized disposal procedures to prevent environmental contamination. Implementing comprehensive waste management protocols, including recycling programs for test specimens and proper treatment of chemical waste, is essential for environmentally responsible testing operations.

Material selection itself plays a pivotal role in the environmental impact of Wankel engine development. Testing should prioritize materials with lower environmental footprints, considering factors such as resource scarcity, extraction impacts, and end-of-life recyclability. Advanced ceramics and composite materials may offer superior performance while reducing reliance on rare earth elements and other environmentally problematic materials. Testing protocols should include life cycle assessment methodologies to evaluate the comprehensive environmental impact of different material choices.

Water consumption during cooling processes and cleaning operations represents another environmental concern in material testing. Implementing closed-loop water systems and water-efficient cleaning technologies can significantly reduce the water footprint of testing facilities. Additionally, the use of biodegradable cleaning agents and lubricants can minimize the environmental impact of testing operations.

From a sustainability perspective, material testing should focus on developing materials that extend engine lifespan and improve fuel efficiency. Longer-lasting components reduce resource consumption and waste generation over time, while improved efficiency directly reduces emissions during engine operation. Testing protocols should therefore include accelerated aging tests that accurately predict long-term material performance under real-world conditions, helping to identify materials that contribute to sustainable engine design.

Regulatory compliance and voluntary sustainability certifications provide frameworks for environmentally responsible material testing. Standards such as ISO 14001 for environmental management systems offer guidelines for minimizing environmental impacts, while emerging regulations increasingly mandate reporting on environmental performance and hazardous substance management. Testing facilities should proactively adopt these standards and anticipate future regulatory requirements to ensure sustainable operations.

Regulatory Compliance and Certification Requirements

Wankel engine material testing must adhere to stringent regulatory frameworks established by various international and national bodies. The International Organization for Standardization (ISO) provides comprehensive guidelines through ISO 6621-1 through 6621-5, specifically addressing internal combustion engine materials. These standards outline testing methodologies for thermal resistance, wear characteristics, and material compatibility essential for rotary engine components.

In the United States, the Environmental Protection Agency (EPA) and Department of Transportation (DOT) impose specific requirements for engine materials that impact emissions and safety. Material testing must demonstrate compliance with Clean Air Act provisions, particularly regarding catalytic converter compatibility and emissions durability over the engine's lifecycle. The EPA's Tier 3 standards specifically address material degradation patterns that could affect emissions performance.

European regulations, governed by the European Committee for Standardization (CEN), mandate additional testing requirements through EN 13599 for copper and copper alloys commonly used in Wankel engine applications. The European Union's End-of-Life Vehicle Directive further restricts certain materials, necessitating certification that components meet recyclability and recoverability targets of 95%.

Japan's Industrial Standards Committee (JISC) has established JIS H 5202 standards specifically addressing aluminum alloy castings for automotive applications, including rotary engines. These standards are particularly relevant for Wankel engines given their historical development and production in Japan through Mazda.

Certification processes typically require third-party validation from accredited testing laboratories. The material testing protocols must be documented according to ISO/IEC 17025 standards for testing and calibration laboratories. This includes maintaining calibration records, testing methodologies, and quality assurance procedures that demonstrate traceability and repeatability of results.

Aviation applications of Wankel engines face additional scrutiny from aviation authorities such as the Federal Aviation Administration (FAA) in the US and the European Union Aviation Safety Agency (EASA). These bodies require extensive material certification under regulations like FAR Part 33 for aircraft engines, including fatigue testing under simulated flight conditions and extreme temperature cycling.

Emerging regulations concerning sustainable manufacturing are increasingly impacting material selection and testing requirements. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation in Europe requires thorough documentation of chemical compositions and potential environmental impacts of materials used in engine manufacturing.

In the United States, the Environmental Protection Agency (EPA) and Department of Transportation (DOT) impose specific requirements for engine materials that impact emissions and safety. Material testing must demonstrate compliance with Clean Air Act provisions, particularly regarding catalytic converter compatibility and emissions durability over the engine's lifecycle. The EPA's Tier 3 standards specifically address material degradation patterns that could affect emissions performance.

European regulations, governed by the European Committee for Standardization (CEN), mandate additional testing requirements through EN 13599 for copper and copper alloys commonly used in Wankel engine applications. The European Union's End-of-Life Vehicle Directive further restricts certain materials, necessitating certification that components meet recyclability and recoverability targets of 95%.

Japan's Industrial Standards Committee (JISC) has established JIS H 5202 standards specifically addressing aluminum alloy castings for automotive applications, including rotary engines. These standards are particularly relevant for Wankel engines given their historical development and production in Japan through Mazda.

Certification processes typically require third-party validation from accredited testing laboratories. The material testing protocols must be documented according to ISO/IEC 17025 standards for testing and calibration laboratories. This includes maintaining calibration records, testing methodologies, and quality assurance procedures that demonstrate traceability and repeatability of results.

Aviation applications of Wankel engines face additional scrutiny from aviation authorities such as the Federal Aviation Administration (FAA) in the US and the European Union Aviation Safety Agency (EASA). These bodies require extensive material certification under regulations like FAR Part 33 for aircraft engines, including fatigue testing under simulated flight conditions and extreme temperature cycling.

Emerging regulations concerning sustainable manufacturing are increasingly impacting material selection and testing requirements. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation in Europe requires thorough documentation of chemical compositions and potential environmental impacts of materials used in engine manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!