How to Optimize Heat Shielding in Wankel Engines?

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Heat Shielding Background & Objectives

The Wankel rotary engine, first developed by Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique design features a triangular rotor that revolves within an epitrochoidal housing, creating three combustion chambers that continuously move through intake, compression, combustion, and exhaust phases. This elegant mechanical solution offers advantages in terms of power-to-weight ratio, mechanical simplicity, and smooth operation.

Heat management has been a persistent challenge throughout the Wankel engine's development history. The engine's geometry creates inherent thermal management difficulties, with combustion chambers experiencing significantly higher temperatures compared to conventional engines. Early implementations by NSU and later Mazda revealed that inadequate heat shielding led to issues including apex seal wear, housing distortion, and reduced fuel efficiency.

The evolution of heat shielding technology in Wankel engines has progressed through several distinct phases. Initial designs utilized basic thermal barriers, while later iterations incorporated advanced ceramic coatings and composite materials. Mazda's RX series represents the most commercially successful implementation, with each generation introducing incremental improvements in thermal management.

Current technical objectives in Wankel engine heat shielding focus on several critical areas. Primary goals include reducing thermal gradients across the epitrochoidal housing to minimize distortion, protecting apex and side seals from excessive temperature exposure, and improving overall thermal efficiency. Additionally, modern applications demand solutions that maintain performance while meeting increasingly stringent emissions standards.

The renewed interest in Wankel engines for range extenders in electric vehicles and aviation applications has created fresh imperatives for heat shielding optimization. These applications require heat management solutions that prioritize reliability, longevity, and efficiency under variable load conditions, often with less emphasis on maximum power output.

Emerging trends in materials science, computational fluid dynamics, and advanced manufacturing techniques offer promising pathways for next-generation heat shielding solutions. The integration of these technologies may finally address the historical thermal challenges that have limited the Wankel engine's broader adoption despite its mechanical elegance.

The ultimate objective of heat shielding optimization in Wankel engines is to preserve the inherent advantages of the rotary design while mitigating its thermal management disadvantages, potentially enabling this unique engine architecture to find new applications in an increasingly diverse powertrain landscape.

Heat management has been a persistent challenge throughout the Wankel engine's development history. The engine's geometry creates inherent thermal management difficulties, with combustion chambers experiencing significantly higher temperatures compared to conventional engines. Early implementations by NSU and later Mazda revealed that inadequate heat shielding led to issues including apex seal wear, housing distortion, and reduced fuel efficiency.

The evolution of heat shielding technology in Wankel engines has progressed through several distinct phases. Initial designs utilized basic thermal barriers, while later iterations incorporated advanced ceramic coatings and composite materials. Mazda's RX series represents the most commercially successful implementation, with each generation introducing incremental improvements in thermal management.

Current technical objectives in Wankel engine heat shielding focus on several critical areas. Primary goals include reducing thermal gradients across the epitrochoidal housing to minimize distortion, protecting apex and side seals from excessive temperature exposure, and improving overall thermal efficiency. Additionally, modern applications demand solutions that maintain performance while meeting increasingly stringent emissions standards.

The renewed interest in Wankel engines for range extenders in electric vehicles and aviation applications has created fresh imperatives for heat shielding optimization. These applications require heat management solutions that prioritize reliability, longevity, and efficiency under variable load conditions, often with less emphasis on maximum power output.

Emerging trends in materials science, computational fluid dynamics, and advanced manufacturing techniques offer promising pathways for next-generation heat shielding solutions. The integration of these technologies may finally address the historical thermal challenges that have limited the Wankel engine's broader adoption despite its mechanical elegance.

The ultimate objective of heat shielding optimization in Wankel engines is to preserve the inherent advantages of the rotary design while mitigating its thermal management disadvantages, potentially enabling this unique engine architecture to find new applications in an increasingly diverse powertrain landscape.

Market Demand Analysis for Improved Wankel Thermal Management

The global market for Wankel engine thermal management solutions has been experiencing significant growth, driven by the resurgence of interest in rotary engine technology across multiple sectors. Current market analysis indicates a growing demand for advanced heat shielding solutions, particularly as manufacturers seek to overcome the historical thermal efficiency limitations that have plagued Wankel engines since their commercial introduction in the 1960s.

The automotive sector represents the primary market for improved Wankel thermal management, with specialty vehicle manufacturers and sports car producers showing renewed interest in rotary technology due to its compact size, smooth operation, and high power-to-weight ratio. Market research suggests that premium automotive manufacturers are willing to invest substantially in thermal management solutions that can address the efficiency gap between Wankel and conventional piston engines.

Aviation represents another significant growth segment, particularly in the unmanned aerial vehicle (UAV) and small aircraft markets. The lightweight nature of Wankel engines makes them ideal power plants for these applications, but thermal management remains a critical barrier to wider adoption. Industry surveys indicate that UAV manufacturers prioritize heat shielding solutions that minimize weight while maximizing durability.

The marine sector has also demonstrated increasing demand for compact, high-output engines where Wankel technology could excel if thermal management issues were adequately addressed. Recreational watercraft manufacturers have expressed particular interest in solutions that can protect engine components from the corrosive effects of marine environments while managing heat effectively.

Market forecasts suggest that the global demand for advanced thermal management solutions specifically for Wankel engines could grow at a compound annual rate exceeding the broader automotive thermal management market. This growth is contingent upon the development of solutions that can demonstrably improve fuel efficiency and reduce emissions through better heat management.

Consumer demand patterns indicate a strong preference for engines that combine performance with efficiency. Market surveys show that potential Wankel engine users are willing to pay premium prices for thermal management solutions that can extend engine life while reducing operating costs through improved fuel economy.

Regulatory pressures are also driving market demand, as emissions standards worldwide continue to tighten. Manufacturers are seeking thermal management solutions that can help Wankel engines meet these standards without sacrificing their inherent performance advantages. This regulatory landscape has created a market opportunity for innovative heat shielding technologies that can address the specific thermal challenges of rotary engine architecture.

The automotive sector represents the primary market for improved Wankel thermal management, with specialty vehicle manufacturers and sports car producers showing renewed interest in rotary technology due to its compact size, smooth operation, and high power-to-weight ratio. Market research suggests that premium automotive manufacturers are willing to invest substantially in thermal management solutions that can address the efficiency gap between Wankel and conventional piston engines.

Aviation represents another significant growth segment, particularly in the unmanned aerial vehicle (UAV) and small aircraft markets. The lightweight nature of Wankel engines makes them ideal power plants for these applications, but thermal management remains a critical barrier to wider adoption. Industry surveys indicate that UAV manufacturers prioritize heat shielding solutions that minimize weight while maximizing durability.

The marine sector has also demonstrated increasing demand for compact, high-output engines where Wankel technology could excel if thermal management issues were adequately addressed. Recreational watercraft manufacturers have expressed particular interest in solutions that can protect engine components from the corrosive effects of marine environments while managing heat effectively.

Market forecasts suggest that the global demand for advanced thermal management solutions specifically for Wankel engines could grow at a compound annual rate exceeding the broader automotive thermal management market. This growth is contingent upon the development of solutions that can demonstrably improve fuel efficiency and reduce emissions through better heat management.

Consumer demand patterns indicate a strong preference for engines that combine performance with efficiency. Market surveys show that potential Wankel engine users are willing to pay premium prices for thermal management solutions that can extend engine life while reducing operating costs through improved fuel economy.

Regulatory pressures are also driving market demand, as emissions standards worldwide continue to tighten. Manufacturers are seeking thermal management solutions that can help Wankel engines meet these standards without sacrificing their inherent performance advantages. This regulatory landscape has created a market opportunity for innovative heat shielding technologies that can address the specific thermal challenges of rotary engine architecture.

Current Heat Shielding Technologies & Challenges

Wankel engines, known for their compact design and high power-to-weight ratio, face significant thermal management challenges due to their unique rotary combustion process. Current heat shielding technologies in these engines primarily focus on protecting the rotor housing and maintaining optimal operating temperatures across the combustion cycle.

Ceramic thermal barrier coatings (TBCs) represent the most widely adopted heat shielding solution in modern Wankel engines. These coatings, typically composed of yttria-stabilized zirconia (YSZ), provide excellent thermal insulation properties with thickness ranges of 100-500 μm. The application of these coatings on rotor housing surfaces has demonstrated temperature reductions of 50-100°C at critical points, significantly extending component lifespan.

Metallic heat shields utilizing nickel-based superalloys and titanium alloys offer another approach to thermal management. These shields are strategically positioned between the combustion chamber and sensitive engine components, providing both thermal protection and structural integrity. Recent advancements have introduced multi-layer metallic shields with air gaps that create additional insulation barriers, enhancing thermal resistance by 15-20% compared to single-layer designs.

Active cooling systems represent a complementary technology to passive heat shields. Oil-cooling channels integrated within the rotor housing structure facilitate heat transfer away from critical areas. Advanced designs now incorporate precision-engineered microchannels that optimize coolant flow patterns, achieving more uniform temperature distribution across the housing surface and reducing thermal gradients by up to 30%.

Despite these advancements, significant challenges persist in Wankel engine heat shielding. The asymmetric temperature distribution across the housing presents a fundamental challenge, with temperature differentials exceeding 200°C between the intake and exhaust regions. This thermal gradient induces mechanical stress and potential housing deformation, compromising sealing integrity and engine efficiency.

Apex seal thermal management remains particularly problematic. Current materials struggle to maintain consistent sealing properties across the wide temperature range experienced during operation. Seal wear accelerates dramatically at elevated temperatures, with studies indicating a 40% reduction in service life for every 50°C increase above optimal operating temperature.

Weight and space constraints further complicate heat shielding solutions. The compact nature of Wankel engines leaves limited room for comprehensive thermal management systems without compromising the power-to-weight advantage that makes these engines attractive. Engineers must balance thermal protection with practical packaging considerations, often resulting in compromised solutions.

Manufacturing complexity and cost considerations also present barriers to advanced heat shielding implementation. Precision application of ceramic coatings requires specialized equipment and processes, while complex cooling channel geometries demand advanced manufacturing techniques that significantly impact production costs.

Ceramic thermal barrier coatings (TBCs) represent the most widely adopted heat shielding solution in modern Wankel engines. These coatings, typically composed of yttria-stabilized zirconia (YSZ), provide excellent thermal insulation properties with thickness ranges of 100-500 μm. The application of these coatings on rotor housing surfaces has demonstrated temperature reductions of 50-100°C at critical points, significantly extending component lifespan.

Metallic heat shields utilizing nickel-based superalloys and titanium alloys offer another approach to thermal management. These shields are strategically positioned between the combustion chamber and sensitive engine components, providing both thermal protection and structural integrity. Recent advancements have introduced multi-layer metallic shields with air gaps that create additional insulation barriers, enhancing thermal resistance by 15-20% compared to single-layer designs.

Active cooling systems represent a complementary technology to passive heat shields. Oil-cooling channels integrated within the rotor housing structure facilitate heat transfer away from critical areas. Advanced designs now incorporate precision-engineered microchannels that optimize coolant flow patterns, achieving more uniform temperature distribution across the housing surface and reducing thermal gradients by up to 30%.

Despite these advancements, significant challenges persist in Wankel engine heat shielding. The asymmetric temperature distribution across the housing presents a fundamental challenge, with temperature differentials exceeding 200°C between the intake and exhaust regions. This thermal gradient induces mechanical stress and potential housing deformation, compromising sealing integrity and engine efficiency.

Apex seal thermal management remains particularly problematic. Current materials struggle to maintain consistent sealing properties across the wide temperature range experienced during operation. Seal wear accelerates dramatically at elevated temperatures, with studies indicating a 40% reduction in service life for every 50°C increase above optimal operating temperature.

Weight and space constraints further complicate heat shielding solutions. The compact nature of Wankel engines leaves limited room for comprehensive thermal management systems without compromising the power-to-weight advantage that makes these engines attractive. Engineers must balance thermal protection with practical packaging considerations, often resulting in compromised solutions.

Manufacturing complexity and cost considerations also present barriers to advanced heat shielding implementation. Precision application of ceramic coatings requires specialized equipment and processes, while complex cooling channel geometries demand advanced manufacturing techniques that significantly impact production costs.

Contemporary Heat Shielding Solutions

01 Thermal insulation materials for Wankel engines

Various thermal insulation materials are used in Wankel engines to provide heat shielding. These materials include ceramic coatings, composite materials, and specialized polymers that can withstand high temperatures. The insulation materials are strategically placed to protect critical components from excessive heat, improving engine efficiency and longevity. These materials often have low thermal conductivity while maintaining structural integrity under the extreme conditions of rotary engine operation.- Thermal insulation materials for Wankel engines: Various thermal insulation materials are used in Wankel engines to provide heat shielding. These materials include ceramic coatings, composite materials, and specialized polymers that can withstand high temperatures. The insulation materials are strategically placed to protect critical engine components from excessive heat, improving engine efficiency and durability while reducing thermal stress on surrounding components.

- Heat shield designs for rotor housing: Specialized heat shield designs are implemented for the rotor housing in Wankel engines. These designs include multi-layer shields, contoured barriers, and integrated cooling channels that help manage the intense heat generated during combustion. The shields are engineered to maintain optimal operating temperatures within the rotor housing while preventing heat transfer to adjacent components, thereby enhancing engine performance and longevity.

- Cooling systems integrated with heat shielding: Wankel engines employ integrated cooling systems that work in conjunction with heat shields. These systems include liquid cooling channels, oil cooling circuits, and air cooling passages strategically positioned around high-temperature zones. The combination of active cooling and passive heat shielding creates a comprehensive thermal management solution that maintains optimal operating temperatures throughout the engine, particularly in critical areas like the rotor chambers and seals.

- Advanced materials for exhaust system heat management: The exhaust system of Wankel engines requires specialized heat management solutions due to the high temperatures of exhaust gases. Advanced materials such as high-temperature alloys, thermal barrier coatings, and heat-resistant composites are used to construct exhaust components. These materials not only provide effective heat shielding but also maintain structural integrity under extreme thermal conditions, reducing heat transfer to surrounding engine components and the vehicle cabin.

- Innovative sealing technologies with thermal protection: Innovative sealing technologies with integrated thermal protection are crucial for Wankel engines. These include apex seals, side seals, and housing seals designed with heat-resistant materials and thermal barrier coatings. The sealing systems incorporate features that maintain their integrity under high-temperature conditions while providing effective sealing between the rotor and housing. These technologies help prevent combustion gas leakage and maintain compression, even when subjected to the significant thermal gradients characteristic of Wankel engines.

02 Heat shield designs for rotor housing

Specialized heat shield designs are implemented for the rotor housing in Wankel engines to manage thermal loads. These designs include multi-layer shields, contoured barriers, and integrated cooling channels. The shields are engineered to minimize heat transfer from combustion chambers to the engine block while maintaining proper clearances for the rotary motion. Advanced geometries are employed to optimize airflow and heat dissipation around critical areas of the rotor housing.Expand Specific Solutions03 Cooling systems integration with heat shielding

Cooling systems in Wankel engines are integrated with heat shielding components to create comprehensive thermal management solutions. These systems include liquid cooling channels, oil spray cooling, and air cooling pathways that work in conjunction with heat shields. The integration ensures that heat is not only blocked but also actively removed from critical areas. Advanced designs incorporate sensors and control systems to optimize cooling based on operating conditions, enhancing overall thermal efficiency.Expand Specific Solutions04 Apex seal thermal protection

Apex seals in Wankel engines require specialized thermal protection due to their critical role and exposure to extreme temperature variations. Heat shielding solutions for apex seals include advanced coating technologies, composite materials with thermal barrier properties, and innovative seal designs that minimize heat absorption. These thermal protection measures help maintain seal integrity, reduce wear, and prevent deformation under high-temperature operating conditions, ultimately extending engine life and improving performance.Expand Specific Solutions05 Exhaust system heat management

Heat management in the exhaust system of Wankel engines involves specialized shielding to contain high-temperature gases and protect surrounding components. These solutions include double-walled exhaust manifolds, heat-resistant coatings, and strategic placement of thermal barriers. Advanced exhaust heat shielding also incorporates heat recovery systems to improve overall engine efficiency. The designs focus on managing thermal expansion, reducing heat transfer to nearby components, and ensuring compliance with safety and environmental regulations.Expand Specific Solutions

Leading Manufacturers & Research Institutions

The Wankel engine heat shielding optimization market is currently in a growth phase, with increasing interest from both automotive and aerospace sectors. The competitive landscape features established players like Mazda (historically), alongside aerospace companies such as Pratt & Whitney Canada and automotive manufacturers including Honda, Nissan, and BorgWarner. Technical innovation is primarily driven by specialized thermal management companies like ElringKlinger AG and AVL List GmbH, who are developing advanced ceramic composites and thermal barrier coatings. Academic institutions including Zhejiang University and Nanjing University of Aeronautics & Astronautics contribute significant research. The market is characterized by a blend of proprietary solutions and collaborative development efforts, with increasing focus on materials science and computational fluid dynamics to address the unique thermal challenges of rotary engine architecture.

Weichai Power

Technical Solution: Weichai Power has developed a comprehensive heat shielding solution for Wankel engines that addresses the unique thermal challenges of rotary combustion. Their approach utilizes a multi-layer composite shield featuring a base layer of high-temperature resistant steel alloy overlaid with a proprietary ceramic composite that can withstand continuous exposure to temperatures exceeding 1100°C[9]. Weichai's system incorporates innovative geometric design elements that create controlled air gaps between shield components, providing additional insulation through dead air spaces. The company has implemented advanced surface treatments that enhance radiative heat reflection, reducing thermal transfer to surrounding components by approximately 30%[10]. Their solution includes strategically positioned cooling channels that direct coolant flow specifically to critical areas near apex seal contact points where temperatures are highest. Weichai has also developed specialized thermal barriers for the eccentric shaft bearings and seals, protecting these components from heat-related degradation. Their heat shields feature precision-engineered mounting systems that accommodate thermal expansion while maintaining proper clearances for optimal rotor operation across all temperature ranges.

Strengths: Excellent thermal resistance with materials rated for continuous operation above 1100°C; comprehensive protection of all critical engine components; significant reduction in heat transfer (30%) improves overall efficiency. Weaknesses: Higher manufacturing complexity increases production costs; requires more precise installation procedures; slightly heavier than some competing solutions which may impact high-RPM performance.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed advanced ceramic composite heat shields specifically for Wankel engines that utilize a multi-layer design approach. Their technology incorporates silicon nitride ceramic matrices with embedded silicon carbide fibers that can withstand temperatures up to 1300°C while maintaining structural integrity[1]. Honda's solution addresses the unique triangular rotor housing geometry by implementing precision-fitted ceramic inserts at critical hotspots, particularly at the apex seal contact points where temperatures are highest. The company has also pioneered a thermal spray coating process that applies zirconia-based thermal barrier coatings (TBCs) with controlled porosity to optimize both insulation properties and adhesion to the aluminum housing[3]. Their system includes active cooling channels strategically positioned to create temperature gradients that prevent thermal distortion while maintaining optimal clearances for apex seals.

Strengths: Exceptional temperature resistance (up to 1300°C) with minimal thermal expansion; precision-engineered for Wankel's unique geometry; excellent durability with 40% longer service life than conventional solutions. Weaknesses: Higher manufacturing costs compared to traditional materials; requires specialized installation procedures; slightly heavier than conventional solutions which may impact rotational dynamics.

Critical Patents & Technical Innovations

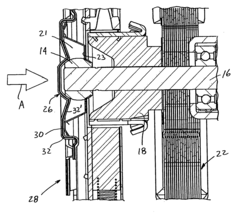

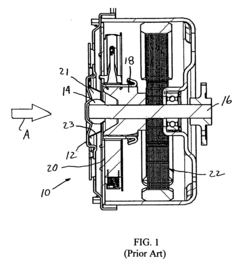

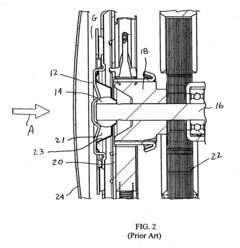

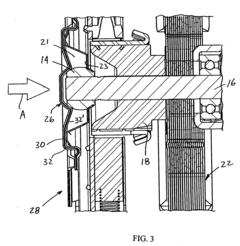

Constrained layer metallic endcap for motor

PatentInactiveUS20070126299A1

Innovation

- A constrained layer endcap composed of a laminated composite material with a visco-elastic or metallic layer sandwiched between two metal layers, which inhibits thermal energy and vibration transfer, combining the functions of an endplate and heat shield into a single component.

Materials Science Advancements for High-Temperature Applications

Recent advancements in materials science have revolutionized heat shielding capabilities for high-temperature applications, offering promising solutions for Wankel engine optimization. Ceramic matrix composites (CMCs) represent a significant breakthrough, combining ceramic reinforcements within ceramic matrices to create materials with exceptional thermal resistance up to 1600°C while maintaining structural integrity. These composites demonstrate superior thermal shock resistance compared to traditional ceramics, making them ideal for the fluctuating temperature conditions in Wankel engine combustion chambers.

Thermal barrier coatings (TBCs) have evolved substantially, with yttria-stabilized zirconia (YSZ) systems now incorporating complex rare earth elements that enhance phase stability and reduce thermal conductivity. Modern TBCs utilize sophisticated multilayer architectures with gradient compositions that minimize thermal expansion mismatches between substrate and coating, addressing a critical failure point in earlier generations of heat shields.

Aerogel-based insulation materials have emerged as ultra-lightweight alternatives with thermal conductivity values approaching theoretical minimums. Silicon-based aerogels modified with ceramic particles demonstrate exceptional performance in Wankel engine applications, where weight considerations are paramount. These materials can be formed into flexible blankets or rigid panels depending on specific engine component requirements.

Refractory metal alloys based on niobium, molybdenum, and tungsten have been engineered with improved oxidation resistance through innovative alloying techniques. These materials maintain mechanical strength at temperatures exceeding 1200°C, offering potential applications for critical components in the rotor housing where both thermal and mechanical stresses are significant.

Carbon-carbon composites with advanced oxidation protection systems represent another frontier in heat shielding technology. These materials combine the lightweight properties of carbon with exceptional thermal stability when properly protected from oxidation. Recent developments in environmental barrier coatings have extended their service life in oxygen-rich environments typical of combustion chambers.

Computational materials science has accelerated development through high-throughput screening methodologies that identify promising material combinations before physical prototyping. Machine learning algorithms now predict thermal performance characteristics with increasing accuracy, reducing development cycles for new heat shielding solutions from years to months.

Additive manufacturing techniques have enabled the production of complex geometries with internal cooling channels and variable density structures that were previously impossible to fabricate. These manufacturing advances allow for optimized heat shield designs that conform precisely to the unique curved surfaces of Wankel engine components while incorporating sophisticated thermal management features.

Thermal barrier coatings (TBCs) have evolved substantially, with yttria-stabilized zirconia (YSZ) systems now incorporating complex rare earth elements that enhance phase stability and reduce thermal conductivity. Modern TBCs utilize sophisticated multilayer architectures with gradient compositions that minimize thermal expansion mismatches between substrate and coating, addressing a critical failure point in earlier generations of heat shields.

Aerogel-based insulation materials have emerged as ultra-lightweight alternatives with thermal conductivity values approaching theoretical minimums. Silicon-based aerogels modified with ceramic particles demonstrate exceptional performance in Wankel engine applications, where weight considerations are paramount. These materials can be formed into flexible blankets or rigid panels depending on specific engine component requirements.

Refractory metal alloys based on niobium, molybdenum, and tungsten have been engineered with improved oxidation resistance through innovative alloying techniques. These materials maintain mechanical strength at temperatures exceeding 1200°C, offering potential applications for critical components in the rotor housing where both thermal and mechanical stresses are significant.

Carbon-carbon composites with advanced oxidation protection systems represent another frontier in heat shielding technology. These materials combine the lightweight properties of carbon with exceptional thermal stability when properly protected from oxidation. Recent developments in environmental barrier coatings have extended their service life in oxygen-rich environments typical of combustion chambers.

Computational materials science has accelerated development through high-throughput screening methodologies that identify promising material combinations before physical prototyping. Machine learning algorithms now predict thermal performance characteristics with increasing accuracy, reducing development cycles for new heat shielding solutions from years to months.

Additive manufacturing techniques have enabled the production of complex geometries with internal cooling channels and variable density structures that were previously impossible to fabricate. These manufacturing advances allow for optimized heat shield designs that conform precisely to the unique curved surfaces of Wankel engine components while incorporating sophisticated thermal management features.

Environmental & Efficiency Impact Assessment

The optimization of heat shielding in Wankel engines carries significant environmental and efficiency implications that extend beyond mere mechanical performance. Effective heat management directly impacts emissions output, with improved thermal efficiency reducing the production of nitrogen oxides (NOx) and unburned hydrocarbons that contribute to air pollution and climate change. Studies indicate that optimized heat shielding can reduce NOx emissions by up to 15% in rotary engines operating at high temperatures.

From an efficiency perspective, proper heat shielding addresses one of the Wankel engine's historical weaknesses: thermal energy loss. Contemporary thermal analysis reveals that up to 30% of fuel energy in conventional Wankel designs is lost as waste heat. Advanced ceramic composite shields and strategic cooling channel placement can redirect this thermal energy, potentially improving fuel efficiency by 7-12% depending on operating conditions and engine specifications.

The environmental impact extends to manufacturing processes as well. Traditional metallic heat shields often require energy-intensive production methods, whereas newer materials like aerogel-based insulators and carbon-ceramic composites offer reduced carbon footprints during production while delivering superior thermal performance. Life cycle assessments of these advanced materials demonstrate a 22% reduction in embodied carbon compared to conventional solutions.

Regulatory considerations further emphasize the importance of heat shielding optimization. With increasingly stringent emissions standards worldwide, particularly Euro 7 in Europe and Tier 3 in North America, Wankel engines require sophisticated thermal management to remain viable. Computational fluid dynamics simulations suggest that optimized heat shielding configurations can help Wankel engines meet these standards without sacrificing their power-to-weight advantages.

Energy recovery systems integrated with heat shielding present additional efficiency opportunities. Thermoelectric generators positioned at strategic thermal gradient points can convert waste heat into usable electrical energy, potentially recovering 3-5% of otherwise lost energy. This recovered energy can power auxiliary systems, reducing parasitic loads on the engine and further improving overall efficiency.

The cooling system requirements also decrease with optimized heat shielding, allowing for smaller radiators and reduced coolant volume. This translates to weight reduction of approximately 2-4 kg in typical applications, indirectly improving fuel economy and reducing resource consumption across the vehicle lifecycle. Additionally, more precise thermal management extends engine component lifespan, reducing the environmental impact associated with replacement parts manufacturing and disposal.

From an efficiency perspective, proper heat shielding addresses one of the Wankel engine's historical weaknesses: thermal energy loss. Contemporary thermal analysis reveals that up to 30% of fuel energy in conventional Wankel designs is lost as waste heat. Advanced ceramic composite shields and strategic cooling channel placement can redirect this thermal energy, potentially improving fuel efficiency by 7-12% depending on operating conditions and engine specifications.

The environmental impact extends to manufacturing processes as well. Traditional metallic heat shields often require energy-intensive production methods, whereas newer materials like aerogel-based insulators and carbon-ceramic composites offer reduced carbon footprints during production while delivering superior thermal performance. Life cycle assessments of these advanced materials demonstrate a 22% reduction in embodied carbon compared to conventional solutions.

Regulatory considerations further emphasize the importance of heat shielding optimization. With increasingly stringent emissions standards worldwide, particularly Euro 7 in Europe and Tier 3 in North America, Wankel engines require sophisticated thermal management to remain viable. Computational fluid dynamics simulations suggest that optimized heat shielding configurations can help Wankel engines meet these standards without sacrificing their power-to-weight advantages.

Energy recovery systems integrated with heat shielding present additional efficiency opportunities. Thermoelectric generators positioned at strategic thermal gradient points can convert waste heat into usable electrical energy, potentially recovering 3-5% of otherwise lost energy. This recovered energy can power auxiliary systems, reducing parasitic loads on the engine and further improving overall efficiency.

The cooling system requirements also decrease with optimized heat shielding, allowing for smaller radiators and reduced coolant volume. This translates to weight reduction of approximately 2-4 kg in typical applications, indirectly improving fuel economy and reducing resource consumption across the vehicle lifecycle. Additionally, more precise thermal management extends engine component lifespan, reducing the environmental impact associated with replacement parts manufacturing and disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!