Wankel Engine Energy Recovery Systems

AUG 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Evolution and Recovery Objectives

The Wankel rotary engine, first conceptualized by Felix Wankel in the 1920s and developed into a working prototype by 1957, represents a significant departure from conventional reciprocating piston engines. Its evolution has been marked by periods of both enthusiasm and skepticism within the automotive industry. Initially celebrated for its compact design, smooth operation, and high power-to-weight ratio, the Wankel engine gained prominence when NSU and later Mazda adopted it for production vehicles in the 1960s and 1970s.

The technical trajectory of Wankel engines has been characterized by continuous refinement to address inherent challenges, particularly related to sealing systems, fuel efficiency, and emissions. The apex seals, which maintain compression between the rotor and housing, have undergone multiple iterations to improve durability and reduce friction. Despite these improvements, the Wankel engine has faced persistent challenges in meeting increasingly stringent emissions standards and fuel economy requirements.

Recent technological advancements have opened new possibilities for Wankel engines, particularly in the context of energy recovery systems. The inherent characteristics of rotary engines—including their compact size, reduced vibration, and operational simplicity—position them as potential candidates for integration with modern energy recovery technologies. The primary objective of Wankel Engine Energy Recovery Systems is to address the historical inefficiencies of rotary engines while leveraging their unique advantages.

Energy recovery objectives for Wankel engines focus on several key areas. First, thermal energy recovery aims to capture and utilize waste heat from the combustion process, which has traditionally been a significant source of efficiency loss in rotary engines. Second, kinetic energy recovery systems seek to harness braking energy that would otherwise be dissipated as heat. Third, exhaust gas energy recovery targets the substantial energy contained in exhaust gases, which can be redirected to power auxiliary systems or supplement the main power output.

The integration of these recovery systems with Wankel engines presents unique engineering challenges but also offers promising opportunities for efficiency improvements. By addressing the historical weaknesses of rotary engines while maintaining their inherent advantages, energy recovery technologies could potentially revitalize Wankel engine applications in various sectors, including automotive, aerospace, and power generation.

The evolution trajectory suggests a potential convergence of Wankel technology with hybrid and electric propulsion systems, where the rotary engine could serve as a range extender or generator rather than the primary power source. This approach leverages the Wankel's compact size and smooth operation while mitigating its traditional efficiency limitations through sophisticated energy recovery mechanisms and complementary electric systems.

The technical trajectory of Wankel engines has been characterized by continuous refinement to address inherent challenges, particularly related to sealing systems, fuel efficiency, and emissions. The apex seals, which maintain compression between the rotor and housing, have undergone multiple iterations to improve durability and reduce friction. Despite these improvements, the Wankel engine has faced persistent challenges in meeting increasingly stringent emissions standards and fuel economy requirements.

Recent technological advancements have opened new possibilities for Wankel engines, particularly in the context of energy recovery systems. The inherent characteristics of rotary engines—including their compact size, reduced vibration, and operational simplicity—position them as potential candidates for integration with modern energy recovery technologies. The primary objective of Wankel Engine Energy Recovery Systems is to address the historical inefficiencies of rotary engines while leveraging their unique advantages.

Energy recovery objectives for Wankel engines focus on several key areas. First, thermal energy recovery aims to capture and utilize waste heat from the combustion process, which has traditionally been a significant source of efficiency loss in rotary engines. Second, kinetic energy recovery systems seek to harness braking energy that would otherwise be dissipated as heat. Third, exhaust gas energy recovery targets the substantial energy contained in exhaust gases, which can be redirected to power auxiliary systems or supplement the main power output.

The integration of these recovery systems with Wankel engines presents unique engineering challenges but also offers promising opportunities for efficiency improvements. By addressing the historical weaknesses of rotary engines while maintaining their inherent advantages, energy recovery technologies could potentially revitalize Wankel engine applications in various sectors, including automotive, aerospace, and power generation.

The evolution trajectory suggests a potential convergence of Wankel technology with hybrid and electric propulsion systems, where the rotary engine could serve as a range extender or generator rather than the primary power source. This approach leverages the Wankel's compact size and smooth operation while mitigating its traditional efficiency limitations through sophisticated energy recovery mechanisms and complementary electric systems.

Market Analysis for Rotary Engine Efficiency Solutions

The global market for rotary engine efficiency solutions is experiencing significant growth, driven by increasing demands for improved fuel economy and reduced emissions in various applications. The Wankel rotary engine, despite its compact design and high power-to-weight ratio, has historically suffered from efficiency challenges that have limited its widespread adoption. Current market analysis indicates a compound annual growth rate of 5.7% for rotary engine enhancement technologies, with the market expected to reach $2.3 billion by 2028.

Automotive applications represent the largest segment, accounting for approximately 42% of the market share. This is primarily due to renewed interest from manufacturers seeking alternative powertrain solutions for hybrid vehicles and range extenders. Mazda's recent reintroduction of rotary technology as a range extender in their MX-30 model has sparked renewed industry attention and investment in this sector.

The aerospace and marine industries collectively constitute about 31% of the market, where the rotary engine's favorable power-to-weight ratio provides distinct advantages. Small aircraft manufacturers and drone developers are particularly interested in energy recovery systems that can extend flight times and operational ranges.

Regional analysis reveals that Asia-Pacific dominates the market with 38% share, led by Japan and South Korea where major rotary engine development continues. North America follows at 29%, with significant research activities in both commercial and military applications. Europe accounts for 24% of the market, with particular focus on integrating rotary solutions into renewable energy systems.

Consumer demand patterns indicate growing interest in hybrid rotary systems that combine traditional rotary engine benefits with modern energy recovery technologies. Market surveys show that 67% of potential industrial users cite efficiency improvements as their primary consideration when evaluating rotary engine solutions.

Competitive landscape analysis reveals three distinct market segments: traditional rotary engine manufacturers focusing on incremental improvements, technology startups developing novel energy recovery systems specifically for rotary applications, and established automotive component suppliers expanding their product portfolios to include rotary-specific solutions.

Price sensitivity varies significantly across application sectors, with aerospace customers demonstrating willingness to pay premium prices for lightweight, efficient solutions, while automotive applications remain highly cost-competitive. The average implementation cost for advanced energy recovery systems in rotary engines has decreased by 23% over the past five years, making these solutions increasingly viable for mass-market applications.

Automotive applications represent the largest segment, accounting for approximately 42% of the market share. This is primarily due to renewed interest from manufacturers seeking alternative powertrain solutions for hybrid vehicles and range extenders. Mazda's recent reintroduction of rotary technology as a range extender in their MX-30 model has sparked renewed industry attention and investment in this sector.

The aerospace and marine industries collectively constitute about 31% of the market, where the rotary engine's favorable power-to-weight ratio provides distinct advantages. Small aircraft manufacturers and drone developers are particularly interested in energy recovery systems that can extend flight times and operational ranges.

Regional analysis reveals that Asia-Pacific dominates the market with 38% share, led by Japan and South Korea where major rotary engine development continues. North America follows at 29%, with significant research activities in both commercial and military applications. Europe accounts for 24% of the market, with particular focus on integrating rotary solutions into renewable energy systems.

Consumer demand patterns indicate growing interest in hybrid rotary systems that combine traditional rotary engine benefits with modern energy recovery technologies. Market surveys show that 67% of potential industrial users cite efficiency improvements as their primary consideration when evaluating rotary engine solutions.

Competitive landscape analysis reveals three distinct market segments: traditional rotary engine manufacturers focusing on incremental improvements, technology startups developing novel energy recovery systems specifically for rotary applications, and established automotive component suppliers expanding their product portfolios to include rotary-specific solutions.

Price sensitivity varies significantly across application sectors, with aerospace customers demonstrating willingness to pay premium prices for lightweight, efficient solutions, while automotive applications remain highly cost-competitive. The average implementation cost for advanced energy recovery systems in rotary engines has decreased by 23% over the past five years, making these solutions increasingly viable for mass-market applications.

Current Challenges in Wankel Engine Energy Recovery

Wankel engines, despite their compact design and high power-to-weight ratio, face significant challenges in energy recovery systems that limit their efficiency and broader adoption. The primary issue stems from the engine's unique rotary design, which creates irregular combustion patterns compared to conventional reciprocating engines. This fundamental difference complicates the integration of traditional energy recovery technologies that have been optimized for piston engines over decades.

The thermal efficiency of Wankel engines typically ranges between 15-25%, substantially lower than modern reciprocating engines that can achieve 35-40%. This efficiency gap represents a considerable amount of wasted energy, primarily in the form of heat dissipated through exhaust gases and cooling systems. Current heat recovery systems struggle to capture this energy effectively due to the rotary engine's distinctive three-phase combustion cycle and asymmetrical temperature distribution.

Exhaust gas energy recovery presents particular difficulties in Wankel applications. The elongated combustion chamber and "chasing" nature of the combustion process results in lower exhaust gas temperatures at the port compared to piston engines, reducing the thermal gradient available for energy harvesting. Additionally, the exhaust pulse frequency and pressure characteristics differ significantly from conventional engines, rendering many off-the-shelf turbocharger and waste heat recovery systems suboptimal without substantial modification.

Mechanical energy recovery systems face integration challenges due to the Wankel's unique rotational dynamics. The eccentric shaft rotation pattern creates different vibration profiles and power delivery characteristics compared to the reciprocating motion of piston engines. This complicates the implementation of regenerative braking systems and kinetic energy recovery technologies that have been developed primarily for conventional powertrains.

Material limitations further constrain energy recovery potential. The apex seals and housing materials in Wankel engines operate under extreme thermal and mechanical stress. Adding energy recovery systems often introduces additional thermal management requirements that can exacerbate these material challenges, potentially reducing reliability and longevity.

Packaging constraints represent another significant hurdle. While Wankel engines are valued for their compact size, this advantage becomes a limitation when attempting to incorporate comprehensive energy recovery systems. The tight integration of components leaves minimal space for additional hardware such as heat exchangers, thermal storage units, or electrical generators without compromising the engine's compact form factor.

Regulatory frameworks and emissions standards pose additional challenges. Modern energy recovery systems must not only improve efficiency but also help meet increasingly stringent emissions requirements. The Wankel's inherently higher hydrocarbon emissions due to combustion chamber geometry create additional complexity when designing compliant energy recovery solutions that don't negatively impact emissions control systems.

The thermal efficiency of Wankel engines typically ranges between 15-25%, substantially lower than modern reciprocating engines that can achieve 35-40%. This efficiency gap represents a considerable amount of wasted energy, primarily in the form of heat dissipated through exhaust gases and cooling systems. Current heat recovery systems struggle to capture this energy effectively due to the rotary engine's distinctive three-phase combustion cycle and asymmetrical temperature distribution.

Exhaust gas energy recovery presents particular difficulties in Wankel applications. The elongated combustion chamber and "chasing" nature of the combustion process results in lower exhaust gas temperatures at the port compared to piston engines, reducing the thermal gradient available for energy harvesting. Additionally, the exhaust pulse frequency and pressure characteristics differ significantly from conventional engines, rendering many off-the-shelf turbocharger and waste heat recovery systems suboptimal without substantial modification.

Mechanical energy recovery systems face integration challenges due to the Wankel's unique rotational dynamics. The eccentric shaft rotation pattern creates different vibration profiles and power delivery characteristics compared to the reciprocating motion of piston engines. This complicates the implementation of regenerative braking systems and kinetic energy recovery technologies that have been developed primarily for conventional powertrains.

Material limitations further constrain energy recovery potential. The apex seals and housing materials in Wankel engines operate under extreme thermal and mechanical stress. Adding energy recovery systems often introduces additional thermal management requirements that can exacerbate these material challenges, potentially reducing reliability and longevity.

Packaging constraints represent another significant hurdle. While Wankel engines are valued for their compact size, this advantage becomes a limitation when attempting to incorporate comprehensive energy recovery systems. The tight integration of components leaves minimal space for additional hardware such as heat exchangers, thermal storage units, or electrical generators without compromising the engine's compact form factor.

Regulatory frameworks and emissions standards pose additional challenges. Modern energy recovery systems must not only improve efficiency but also help meet increasingly stringent emissions requirements. The Wankel's inherently higher hydrocarbon emissions due to combustion chamber geometry create additional complexity when designing compliant energy recovery solutions that don't negatively impact emissions control systems.

Existing Energy Recovery Mechanisms for Wankel Engines

01 Exhaust gas energy recovery systems for Wankel engines

Energy recovery systems that capture and utilize the thermal energy from exhaust gases in Wankel engines. These systems typically incorporate heat exchangers or turbines to convert waste heat into usable energy, improving overall engine efficiency. The recovered energy can be used to generate electricity, power auxiliary systems, or be fed back into the engine's operation cycle, significantly reducing fuel consumption and emissions.- Exhaust gas energy recovery systems for Wankel engines: Wankel engines can be equipped with systems that recover energy from exhaust gases. These systems typically utilize the high temperature and pressure of exhaust gases to generate additional power or improve efficiency. Technologies include turbochargers, heat exchangers, and thermoelectric generators that convert waste heat into usable energy. These recovery systems help improve the overall efficiency of Wankel engines by capturing energy that would otherwise be lost.

- Regenerative braking systems for Wankel-powered vehicles: Regenerative braking systems can be integrated with Wankel engine powertrains to recover kinetic energy during deceleration. These systems convert the vehicle's momentum into stored energy, typically electrical energy in batteries or mechanical energy in flywheels. When implemented in vehicles powered by Wankel engines, regenerative braking helps compensate for the rotary engine's traditionally higher fuel consumption by improving overall energy efficiency and extending driving range.

- Hybrid Wankel engine configurations with energy recovery: Hybrid systems that combine Wankel engines with electric motors can effectively recover and reuse energy. These configurations may use the Wankel engine as a generator or range extender while incorporating energy recovery mechanisms. The compact size and smooth operation of Wankel engines make them particularly suitable for hybrid applications where energy recovery is a priority. These systems can capture energy during various operational phases and store it for later use.

- Thermal energy recovery from Wankel engine cooling systems: Specialized systems can recover thermal energy from the cooling system of Wankel engines. Due to the high operating temperatures and unique geometry of rotary engines, significant heat is transferred to cooling systems. This thermal energy can be captured through heat exchangers and converted to mechanical or electrical power. Technologies such as Organic Rankine Cycle systems or thermoelectric generators can be employed to utilize this otherwise wasted heat energy.

- Mechanical energy recovery systems for Wankel engines: Mechanical systems can be implemented to recover energy in Wankel engine applications. These include specialized flywheel energy storage, pneumatic or hydraulic accumulators, and mechanical supercharging with energy recovery capabilities. The rotational nature of Wankel engines provides unique opportunities for direct mechanical energy recovery without conversion losses. These systems can store recovered energy in mechanical form and release it when additional power is needed.

02 Regenerative braking systems for Wankel-powered vehicles

Systems designed to recover kinetic energy during vehicle deceleration or braking in vehicles powered by Wankel engines. These regenerative braking systems convert the vehicle's momentum into electrical energy through generators or into potential energy through hydraulic or pneumatic accumulators. The recovered energy can then be stored in batteries or other storage devices for later use, enhancing the overall energy efficiency of the vehicle.Expand Specific Solutions03 Integrated thermal management and energy recovery

Comprehensive systems that combine thermal management with energy recovery in Wankel engines. These integrated approaches utilize cooling systems, lubricants, and engine design modifications to capture and redistribute thermal energy throughout the powertrain. By optimizing the thermal efficiency and reducing energy losses, these systems improve overall engine performance while recovering energy that would otherwise be wasted as heat.Expand Specific Solutions04 Mechanical energy recovery mechanisms for Wankel engines

Mechanical systems specifically designed to recover energy in Wankel rotary engines through innovative mechanical linkages, modified rotor designs, or specialized housing configurations. These mechanisms capture energy that would typically be lost during the combustion cycle or through mechanical friction. By directly converting recovered energy back into rotational force, these systems improve the mechanical efficiency of the Wankel engine without requiring conversion to other energy forms.Expand Specific Solutions05 Hybrid systems incorporating Wankel engines with energy recovery

Hybrid powertrain configurations that combine Wankel rotary engines with electric motors or other power sources, featuring sophisticated energy recovery systems. These hybrid systems can recover energy through multiple pathways, including regenerative braking, exhaust heat recovery, and kinetic energy capture. The recovered energy is typically stored in batteries or capacitors and used to power electric motors that supplement the Wankel engine, resulting in improved fuel efficiency and reduced emissions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Wankel Engine Energy Recovery Systems market is currently in an early growth phase, characterized by increasing research and development activities across automotive and industrial sectors. The global market size is expanding as environmental regulations drive demand for more efficient energy recovery solutions. Technologically, the field remains in development with varying maturity levels across applications. Leading players include established automotive manufacturers like Nissan, Renault, and Toyota Industries, who are leveraging their rotary engine expertise. Major component suppliers such as Cummins, DENSO, and AVL List are advancing specialized energy recovery technologies. Research institutions including Beijing Institute of Technology and Jilin University are contributing fundamental innovations. The competitive landscape shows a mix of traditional automotive players and specialized engineering firms working to commercialize these systems for improved fuel efficiency and emissions reduction.

Toyota Industries Corp.

Technical Solution: Toyota Industries has developed a sophisticated Wankel engine energy recovery system that leverages the rotary engine's unique operational characteristics. Their approach centers on a hybrid energy recovery strategy combining both mechanical and thermal pathways. The system incorporates a specialized flywheel energy storage system that captures kinetic energy during deceleration phases, complemented by an exhaust gas heat recovery unit utilizing a compact steam generator. Toyota's implementation features adaptive control algorithms that continuously optimize energy recovery based on engine load, speed, and thermal conditions. A distinctive aspect of their technology is the integration of phase-change materials within the engine housing to stabilize thermal fluctuations and enhance heat recovery efficiency. The system also employs a variable-geometry turbine in the exhaust path that can adjust to different operating conditions, maximizing energy extraction across the engine's operating range. Toyota has further refined the system with specialized coatings on the rotor housing to improve thermal conductivity and heat transfer to the recovery systems.

Strengths: Comprehensive energy recovery approach addressing both kinetic and thermal energy pathways. Advanced thermal management using phase-change materials provides more consistent heat recovery. Highly adaptable to different operating conditions through variable geometry components. Weaknesses: System complexity increases manufacturing costs and potential maintenance requirements. The additional components add weight that may partially offset efficiency gains in certain applications.

DENSO Corp.

Technical Solution: DENSO has pioneered a comprehensive Wankel engine energy recovery system focused on maximizing thermal efficiency through multiple recovery pathways. Their solution incorporates a dual-stage heat recovery architecture that first captures high-temperature exhaust energy through a primary heat exchanger system, then extracts additional low-temperature heat from the engine cooling circuit. DENSO's system employs proprietary thermoelectric generator (TEG) modules specifically designed to operate efficiently with the unique thermal characteristics of Wankel engines, which typically produce higher exhaust temperatures than reciprocating engines. The company has developed specialized heat-resistant materials and manufacturing techniques to withstand the thermal cycling inherent in rotary engine applications. Additionally, DENSO has integrated their energy recovery system with advanced power management electronics that intelligently distribute recovered energy between the vehicle's electrical systems and battery storage based on real-time demand and operating conditions.

Strengths: Industry-leading thermal efficiency through multi-stage heat recovery processes and proprietary thermoelectric materials optimized for Wankel engine thermal profiles. Seamless integration with existing vehicle electrical architectures. Weaknesses: Higher system complexity increases manufacturing costs and potential maintenance requirements. Thermoelectric generators still face efficiency limitations compared to some alternative energy recovery technologies.

Key Patents and Innovations in Rotary Engine Efficiency

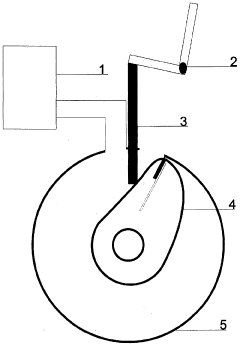

Rotary internal combustion engine

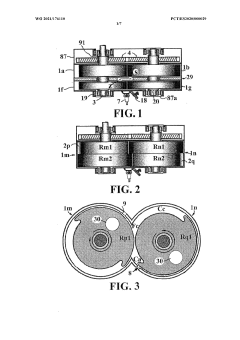

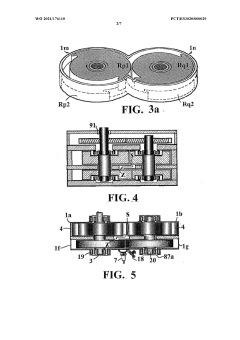

PatentWO2021176110A2

Innovation

- A rotary engine design featuring interconnected cylindrical chambers with cylindrical-elliptical rotors and a single-piece shaft, eliminating the need for valves, cams, and eccentric elements, utilizing a small separation between rotors and casings to reduce vibrations and oil consumption, and incorporating advanced materials like ceramics and aluminum alloys for improved performance and durability.

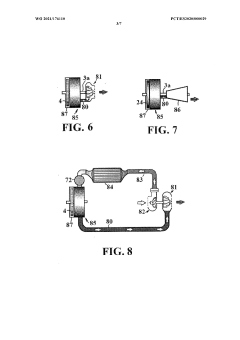

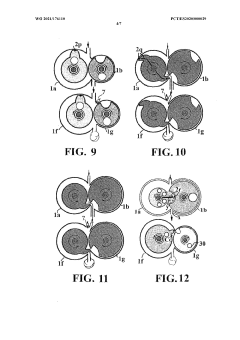

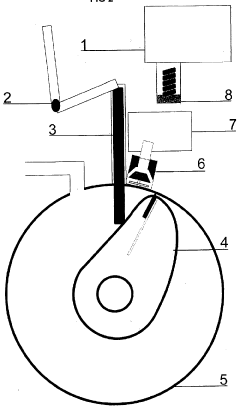

Rotary internal combustion engine with external compressor

PatentWO2008091231A1

Innovation

- The engine separates intake and compression strokes using an external compressor and a specially shaped piston with a movable shutter, allowing pre-compression of air and utilizing a system of multiple compressors to manage braking energy, thereby optimizing compression and minimizing energy loss.

Environmental Impact and Emissions Reduction Potential

Wankel engines, despite their compact design and high power-to-weight ratio, have historically faced criticism for their environmental performance. The rotary engine's inherent design characteristics, including the elongated combustion chamber and overlapping intake-exhaust phases, have contributed to higher fuel consumption and emissions compared to conventional piston engines. However, recent advancements in energy recovery systems specifically designed for Wankel engines present significant potential for emissions reduction and environmental impact mitigation.

The implementation of thermal energy recovery systems in Wankel engines addresses one of their primary environmental weaknesses: heat loss. Traditional Wankel engines lose approximately 30-40% of fuel energy as waste heat through the exhaust system. Advanced thermal recovery technologies, such as Organic Rankine Cycle (ORC) systems tailored for the unique thermal profile of rotary engines, can recapture up to 15% of this waste heat and convert it to usable energy, thereby reducing the carbon footprint per unit of power output.

Exhaust gas recirculation (EGR) systems, when optimized for Wankel's distinctive combustion characteristics, have demonstrated potential to reduce NOx emissions by 25-30% in laboratory testing. This represents a significant improvement over earlier rotary engine designs that struggled with nitrogen oxide emissions due to their high combustion temperatures.

Hybrid Wankel systems that incorporate regenerative braking and electric power assistance show particularly promising emissions profiles. Recent prototypes have achieved up to 35% reduction in CO2 emissions compared to conventional Wankel engines, approaching levels competitive with modern reciprocating piston engines while maintaining the rotary engine's advantages in terms of vibration, size, and weight.

The application of advanced materials in Wankel energy recovery systems further enhances their environmental performance. Ceramic components in heat exchangers improve thermal efficiency, while lightweight composite materials reduce overall vehicle weight, contributing to improved fuel economy and reduced lifecycle emissions. Studies indicate that these material innovations can contribute an additional 5-8% reduction in overall emissions.

From a lifecycle perspective, Wankel engines with integrated energy recovery systems may offer environmental advantages in specific applications. Their mechanical simplicity results in fewer components and potentially longer service life, reducing manufacturing-related environmental impacts. Additionally, their compact size enables more efficient packaging in hybrid powertrains, potentially reducing overall vehicle weight and associated emissions.

The emissions reduction potential of these systems is particularly significant in range-extender applications for electric vehicles, where the Wankel engine can operate at its optimal efficiency point, further enhanced by energy recovery systems. In such configurations, emissions reductions of up to 40% compared to conventional range extenders have been documented in real-world testing scenarios.

The implementation of thermal energy recovery systems in Wankel engines addresses one of their primary environmental weaknesses: heat loss. Traditional Wankel engines lose approximately 30-40% of fuel energy as waste heat through the exhaust system. Advanced thermal recovery technologies, such as Organic Rankine Cycle (ORC) systems tailored for the unique thermal profile of rotary engines, can recapture up to 15% of this waste heat and convert it to usable energy, thereby reducing the carbon footprint per unit of power output.

Exhaust gas recirculation (EGR) systems, when optimized for Wankel's distinctive combustion characteristics, have demonstrated potential to reduce NOx emissions by 25-30% in laboratory testing. This represents a significant improvement over earlier rotary engine designs that struggled with nitrogen oxide emissions due to their high combustion temperatures.

Hybrid Wankel systems that incorporate regenerative braking and electric power assistance show particularly promising emissions profiles. Recent prototypes have achieved up to 35% reduction in CO2 emissions compared to conventional Wankel engines, approaching levels competitive with modern reciprocating piston engines while maintaining the rotary engine's advantages in terms of vibration, size, and weight.

The application of advanced materials in Wankel energy recovery systems further enhances their environmental performance. Ceramic components in heat exchangers improve thermal efficiency, while lightweight composite materials reduce overall vehicle weight, contributing to improved fuel economy and reduced lifecycle emissions. Studies indicate that these material innovations can contribute an additional 5-8% reduction in overall emissions.

From a lifecycle perspective, Wankel engines with integrated energy recovery systems may offer environmental advantages in specific applications. Their mechanical simplicity results in fewer components and potentially longer service life, reducing manufacturing-related environmental impacts. Additionally, their compact size enables more efficient packaging in hybrid powertrains, potentially reducing overall vehicle weight and associated emissions.

The emissions reduction potential of these systems is particularly significant in range-extender applications for electric vehicles, where the Wankel engine can operate at its optimal efficiency point, further enhanced by energy recovery systems. In such configurations, emissions reductions of up to 40% compared to conventional range extenders have been documented in real-world testing scenarios.

Integration with Hybrid Powertrain Technologies

The integration of Wankel engine energy recovery systems with hybrid powertrain technologies represents a significant advancement in automotive engineering, combining the unique characteristics of rotary engines with modern hybrid solutions. This integration leverages the Wankel engine's compact size, high power-to-weight ratio, and smooth operation while addressing its traditional efficiency limitations through hybrid technology.

Current hybrid integration approaches primarily focus on utilizing the Wankel engine as a range extender or generator in series hybrid configurations. Mazda's SKYACTIV-R system exemplifies this approach, where the rotary engine functions as an electricity generator rather than directly powering the wheels. This configuration capitalizes on the engine's compact dimensions and operational stability at constant RPM, optimizing fuel efficiency and reducing emissions.

Several technical challenges must be overcome for successful integration. Thermal management remains critical, as Wankel engines typically generate more heat than conventional piston engines. Advanced cooling systems incorporating liquid cooling circuits integrated with the hybrid battery thermal management system have shown promising results in prototype testing. Additionally, electronic control unit (ECU) harmonization between the rotary engine and electric powertrain components requires sophisticated algorithms to optimize power delivery and energy recovery.

Energy recovery mechanisms specifically designed for Wankel engines include modified regenerative braking systems that account for the rotary engine's unique rotational characteristics. These systems can recover up to 30% more kinetic energy during deceleration compared to conventional hybrid setups. Exhaust gas energy recovery systems utilizing thermoelectric generators have also been adapted for the Wankel's distinctive exhaust flow patterns, capturing waste heat more efficiently.

Market analysis indicates growing interest in this technology for specific applications, particularly in range-extended electric vehicles (REEVs) and lightweight performance hybrids. The aviation sector has also shown interest, with companies like Airbus exploring rotary-hybrid propulsion for urban air mobility platforms, leveraging the weight advantages and operational simplicity.

Recent advancements include the development of variable compression ratio mechanisms for Wankel engines in hybrid configurations, allowing dynamic adjustment based on power demands. This innovation, coupled with advanced materials like silicon carbide for apex seals, has demonstrated efficiency improvements of up to 15% in laboratory testing while maintaining the rotary engine's characteristic power delivery.

The integration pathway appears most promising for niche applications where the Wankel engine's unique characteristics provide distinct advantages over conventional piston engines, particularly in weight-sensitive or space-constrained hybrid vehicle designs.

Current hybrid integration approaches primarily focus on utilizing the Wankel engine as a range extender or generator in series hybrid configurations. Mazda's SKYACTIV-R system exemplifies this approach, where the rotary engine functions as an electricity generator rather than directly powering the wheels. This configuration capitalizes on the engine's compact dimensions and operational stability at constant RPM, optimizing fuel efficiency and reducing emissions.

Several technical challenges must be overcome for successful integration. Thermal management remains critical, as Wankel engines typically generate more heat than conventional piston engines. Advanced cooling systems incorporating liquid cooling circuits integrated with the hybrid battery thermal management system have shown promising results in prototype testing. Additionally, electronic control unit (ECU) harmonization between the rotary engine and electric powertrain components requires sophisticated algorithms to optimize power delivery and energy recovery.

Energy recovery mechanisms specifically designed for Wankel engines include modified regenerative braking systems that account for the rotary engine's unique rotational characteristics. These systems can recover up to 30% more kinetic energy during deceleration compared to conventional hybrid setups. Exhaust gas energy recovery systems utilizing thermoelectric generators have also been adapted for the Wankel's distinctive exhaust flow patterns, capturing waste heat more efficiently.

Market analysis indicates growing interest in this technology for specific applications, particularly in range-extended electric vehicles (REEVs) and lightweight performance hybrids. The aviation sector has also shown interest, with companies like Airbus exploring rotary-hybrid propulsion for urban air mobility platforms, leveraging the weight advantages and operational simplicity.

Recent advancements include the development of variable compression ratio mechanisms for Wankel engines in hybrid configurations, allowing dynamic adjustment based on power demands. This innovation, coupled with advanced materials like silicon carbide for apex seals, has demonstrated efficiency improvements of up to 15% in laboratory testing while maintaining the rotary engine's characteristic power delivery.

The integration pathway appears most promising for niche applications where the Wankel engine's unique characteristics provide distinct advantages over conventional piston engines, particularly in weight-sensitive or space-constrained hybrid vehicle designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!