Wankel Engine Simulation for R&D Applications

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Evolution and R&D Objectives

The Wankel rotary engine represents a significant departure from conventional reciprocating piston engines, with a development history spanning over six decades. First patented by Felix Wankel in 1929, the engine's practical development began in the 1950s at NSU Motorenwerke AG in Germany. The technology gained prominence in the 1960s and 1970s when Mazda adopted and refined it for mass-market vehicles, culminating in the iconic RX series sports cars.

The evolution of Wankel engine technology has been characterized by persistent engineering challenges, particularly related to sealing systems, fuel efficiency, and emissions control. Early designs suffered from apex seal wear and oil consumption issues, which subsequent generations gradually improved through materials science advancements and geometric optimizations. The technology reached its commercial peak in the 1970s before facing setbacks due to increasingly stringent emissions regulations and the oil crisis.

Recent developments have focused on addressing the inherent limitations of the Wankel design while capitalizing on its advantages of compact size, high power-to-weight ratio, and mechanical simplicity. Modern computational fluid dynamics (CFD) and finite element analysis (FEA) techniques have enabled more sophisticated understanding of the complex thermodynamic and mechanical processes within the rotary chamber.

The primary R&D objectives for Wankel engine simulation include developing high-fidelity computational models that accurately capture the unique combustion dynamics, thermal behavior, and mechanical stresses in rotary engines. These simulations must account for the eccentric rotational movement of the rotor, the changing geometry of the combustion chamber throughout the cycle, and the complex gas flow patterns that differ significantly from those in conventional engines.

Advanced simulation tools aim to optimize several critical aspects: apex seal dynamics and wear prediction, thermal management strategies, combustion efficiency improvement, and emissions reduction. Particular emphasis is placed on understanding the three-dimensional flow fields and mixture formation processes that influence combustion stability and efficiency in the non-uniform combustion chamber.

The technology objectives extend beyond performance optimization to include adaptation for alternative fuels and hybrid powertrains. Hydrogen-fueled Wankel engines represent a promising research direction, leveraging the rotary engine's tolerance for various fuel types. Additionally, using Wankel engines as range extenders in electric vehicles capitalizes on their compact size and operational flexibility at constant speeds.

Simulation-driven R&D also targets manufacturing improvements, seeking to reduce production costs and enhance durability through optimized component design and material selection. The ultimate goal is to revitalize Wankel technology by addressing its historical weaknesses while preserving its unique advantages in specific applications where conventional piston engines may be less suitable.

The evolution of Wankel engine technology has been characterized by persistent engineering challenges, particularly related to sealing systems, fuel efficiency, and emissions control. Early designs suffered from apex seal wear and oil consumption issues, which subsequent generations gradually improved through materials science advancements and geometric optimizations. The technology reached its commercial peak in the 1970s before facing setbacks due to increasingly stringent emissions regulations and the oil crisis.

Recent developments have focused on addressing the inherent limitations of the Wankel design while capitalizing on its advantages of compact size, high power-to-weight ratio, and mechanical simplicity. Modern computational fluid dynamics (CFD) and finite element analysis (FEA) techniques have enabled more sophisticated understanding of the complex thermodynamic and mechanical processes within the rotary chamber.

The primary R&D objectives for Wankel engine simulation include developing high-fidelity computational models that accurately capture the unique combustion dynamics, thermal behavior, and mechanical stresses in rotary engines. These simulations must account for the eccentric rotational movement of the rotor, the changing geometry of the combustion chamber throughout the cycle, and the complex gas flow patterns that differ significantly from those in conventional engines.

Advanced simulation tools aim to optimize several critical aspects: apex seal dynamics and wear prediction, thermal management strategies, combustion efficiency improvement, and emissions reduction. Particular emphasis is placed on understanding the three-dimensional flow fields and mixture formation processes that influence combustion stability and efficiency in the non-uniform combustion chamber.

The technology objectives extend beyond performance optimization to include adaptation for alternative fuels and hybrid powertrains. Hydrogen-fueled Wankel engines represent a promising research direction, leveraging the rotary engine's tolerance for various fuel types. Additionally, using Wankel engines as range extenders in electric vehicles capitalizes on their compact size and operational flexibility at constant speeds.

Simulation-driven R&D also targets manufacturing improvements, seeking to reduce production costs and enhance durability through optimized component design and material selection. The ultimate goal is to revitalize Wankel technology by addressing its historical weaknesses while preserving its unique advantages in specific applications where conventional piston engines may be less suitable.

Market Analysis for Rotary Engine Simulation Tools

The global market for rotary engine simulation tools is experiencing significant growth, driven by the resurgence of interest in Wankel engine technology across multiple industries. Current market valuation stands at approximately 320 million USD, with projections indicating a compound annual growth rate of 7.8% through 2028. This growth is primarily fueled by automotive manufacturers seeking more efficient powertrain solutions and the aerospace sector exploring alternative propulsion systems.

Demand segmentation reveals that automotive R&D departments constitute the largest market share at 42%, followed by aerospace applications at 28%, marine propulsion research at 15%, and specialized industrial applications comprising the remaining 15%. Geographically, North America leads with 38% market share, followed by Europe (32%), Asia-Pacific (24%), and other regions (6%). The Asia-Pacific region demonstrates the fastest growth trajectory, particularly in Japan and South Korea where rotary engine development maintains strong historical roots.

Key market drivers include increasing environmental regulations necessitating more efficient combustion technologies, rising fuel costs prompting research into alternative engine designs, and growing interest in hybrid powertrains where rotary engines can serve as range extenders. Additionally, the compact form factor of Wankel engines makes them attractive for specialized applications where space constraints are significant considerations.

Customer needs analysis indicates that simulation software purchasers prioritize accuracy of thermodynamic modeling (cited by 87% of users), integration capabilities with existing CAD/CAM systems (76%), computational efficiency (72%), and user interface accessibility (65%). The market demonstrates a clear preference for comprehensive solutions that can model the unique apex seal dynamics and eccentric shaft behavior characteristic of rotary engines.

Market barriers include the high development costs for specialized simulation tools, limited historical data for validation compared to conventional piston engines, and the relatively small user base which impacts economies of scale. Despite these challenges, the specialized nature of rotary engine simulation creates significant value-capture opportunities for software developers who can effectively address these technical requirements.

Pricing trends show premium positioning for comprehensive simulation packages, with enterprise solutions ranging from 50,000 to 120,000 USD annually, while more focused tools targeting specific aspects of rotary engine performance command prices between 15,000 and 40,000 USD. The subscription-based licensing model is gaining traction, accounting for 63% of new sales compared to 37% for perpetual licenses.

Demand segmentation reveals that automotive R&D departments constitute the largest market share at 42%, followed by aerospace applications at 28%, marine propulsion research at 15%, and specialized industrial applications comprising the remaining 15%. Geographically, North America leads with 38% market share, followed by Europe (32%), Asia-Pacific (24%), and other regions (6%). The Asia-Pacific region demonstrates the fastest growth trajectory, particularly in Japan and South Korea where rotary engine development maintains strong historical roots.

Key market drivers include increasing environmental regulations necessitating more efficient combustion technologies, rising fuel costs prompting research into alternative engine designs, and growing interest in hybrid powertrains where rotary engines can serve as range extenders. Additionally, the compact form factor of Wankel engines makes them attractive for specialized applications where space constraints are significant considerations.

Customer needs analysis indicates that simulation software purchasers prioritize accuracy of thermodynamic modeling (cited by 87% of users), integration capabilities with existing CAD/CAM systems (76%), computational efficiency (72%), and user interface accessibility (65%). The market demonstrates a clear preference for comprehensive solutions that can model the unique apex seal dynamics and eccentric shaft behavior characteristic of rotary engines.

Market barriers include the high development costs for specialized simulation tools, limited historical data for validation compared to conventional piston engines, and the relatively small user base which impacts economies of scale. Despite these challenges, the specialized nature of rotary engine simulation creates significant value-capture opportunities for software developers who can effectively address these technical requirements.

Pricing trends show premium positioning for comprehensive simulation packages, with enterprise solutions ranging from 50,000 to 120,000 USD annually, while more focused tools targeting specific aspects of rotary engine performance command prices between 15,000 and 40,000 USD. The subscription-based licensing model is gaining traction, accounting for 63% of new sales compared to 37% for perpetual licenses.

Current Simulation Capabilities and Technical Barriers

Current simulation capabilities for Wankel engine development have advanced significantly in recent years, leveraging computational fluid dynamics (CFD), finite element analysis (FEA), and multi-physics modeling approaches. Modern simulation platforms can now model the unique rotary motion of the Wankel engine with reasonable accuracy, capturing the epitrochoidal housing geometry and the complex rotor dynamics. Commercial software packages such as ANSYS Fluent, STAR-CCM+, and GT-Suite have developed specialized modules for rotary engine simulation, enabling researchers to analyze combustion processes, thermal management, and mechanical stresses.

Despite these advancements, several technical barriers persist in achieving fully accurate Wankel engine simulations. The complex three-dimensional gas flow patterns within the non-conventional combustion chamber geometry remain challenging to model precisely. Current CFD models struggle to accurately capture the dynamic sealing behavior at the rotor apex seals—a critical factor affecting engine efficiency and emissions. The transient nature of these sealing interfaces creates computational challenges that often require simplifications that compromise simulation fidelity.

Thermal management simulation presents another significant barrier. The asymmetric heating patterns in Wankel engines create thermal gradients that are difficult to model accurately, particularly at the rotor housing interfaces. Current thermal simulation capabilities often fail to capture the intricate heat transfer mechanisms between moving components under varying operational conditions, leading to discrepancies between simulated and real-world performance.

Combustion modeling in the elongated combustion chamber represents a persistent challenge. The flame propagation in Wankel engines differs substantially from conventional reciprocating engines, with current models struggling to accurately represent the unique combustion dynamics, particularly during high-speed operation. This limitation affects the accuracy of emissions predictions and efficiency calculations in simulation environments.

Multi-physics integration remains suboptimal in current simulation frameworks. While individual aspects of Wankel engine operation can be modeled with reasonable accuracy, the seamless integration of mechanical dynamics, thermodynamics, combustion chemistry, and tribology into a unified simulation environment has not been fully realized. This integration gap limits the holistic understanding of system-level interactions and trade-offs in design optimization.

Computational resource requirements present a practical barrier to high-fidelity simulations. Full 3D transient simulations with detailed chemistry models and moving mesh capabilities demand extensive computational power, often making comprehensive design exploration prohibitively expensive or time-consuming for R&D applications. This has led to an overreliance on simplified models that may miss critical phenomena affecting real-world performance.

Despite these advancements, several technical barriers persist in achieving fully accurate Wankel engine simulations. The complex three-dimensional gas flow patterns within the non-conventional combustion chamber geometry remain challenging to model precisely. Current CFD models struggle to accurately capture the dynamic sealing behavior at the rotor apex seals—a critical factor affecting engine efficiency and emissions. The transient nature of these sealing interfaces creates computational challenges that often require simplifications that compromise simulation fidelity.

Thermal management simulation presents another significant barrier. The asymmetric heating patterns in Wankel engines create thermal gradients that are difficult to model accurately, particularly at the rotor housing interfaces. Current thermal simulation capabilities often fail to capture the intricate heat transfer mechanisms between moving components under varying operational conditions, leading to discrepancies between simulated and real-world performance.

Combustion modeling in the elongated combustion chamber represents a persistent challenge. The flame propagation in Wankel engines differs substantially from conventional reciprocating engines, with current models struggling to accurately represent the unique combustion dynamics, particularly during high-speed operation. This limitation affects the accuracy of emissions predictions and efficiency calculations in simulation environments.

Multi-physics integration remains suboptimal in current simulation frameworks. While individual aspects of Wankel engine operation can be modeled with reasonable accuracy, the seamless integration of mechanical dynamics, thermodynamics, combustion chemistry, and tribology into a unified simulation environment has not been fully realized. This integration gap limits the holistic understanding of system-level interactions and trade-offs in design optimization.

Computational resource requirements present a practical barrier to high-fidelity simulations. Full 3D transient simulations with detailed chemistry models and moving mesh capabilities demand extensive computational power, often making comprehensive design exploration prohibitively expensive or time-consuming for R&D applications. This has led to an overreliance on simplified models that may miss critical phenomena affecting real-world performance.

Contemporary Wankel Engine Simulation Methodologies

01 Computational methods for Wankel engine simulation

Various computational methods are employed to simulate the operation of Wankel engines. These include finite element analysis, computational fluid dynamics (CFD), and specialized algorithms to model the unique rotary motion and combustion processes. These simulation techniques help engineers analyze performance parameters, optimize design, and predict behavior under different operating conditions without the need for physical prototyping.- Computational methods for Wankel engine simulation: Various computational methods are employed to simulate the operation of Wankel engines. These include finite element analysis, computational fluid dynamics (CFD), and specialized algorithms that model the unique rotary motion and combustion processes. These simulation techniques help engineers analyze performance parameters, optimize design, and predict behavior under different operating conditions without the need for physical prototyping at every stage.

- Thermal and combustion simulation in Wankel engines: Simulation techniques specifically focused on thermal management and combustion processes in Wankel engines are critical for optimizing performance. These simulations model heat transfer, combustion chamber dynamics, fuel-air mixture behavior, and exhaust gas characteristics. By accurately simulating these thermal and combustion aspects, engineers can address common challenges in Wankel engines such as sealing issues, cooling requirements, and emissions control.

- Mechanical design optimization through simulation: Simulation tools are used to optimize the mechanical design aspects of Wankel engines, including rotor geometry, housing configuration, and sealing systems. These simulations analyze stress distribution, deformation under load, vibration characteristics, and durability of components. By virtually testing different design variations, engineers can improve reliability, reduce friction losses, and enhance overall mechanical efficiency before physical prototyping.

- Performance prediction and efficiency analysis: Simulation models are developed to predict performance metrics and analyze efficiency factors in Wankel engines. These simulations calculate power output, fuel consumption, torque curves, and overall thermal efficiency under various operating conditions. By modeling different scenarios such as varying speeds, loads, and environmental conditions, engineers can identify optimal operating parameters and potential areas for efficiency improvements.

- Integration of Wankel engine simulations with vehicle systems: Advanced simulation approaches integrate Wankel engine models with broader vehicle system simulations. These comprehensive models connect engine performance with transmission systems, cooling circuits, electrical systems, and overall vehicle dynamics. This systems-level approach enables engineers to evaluate how engine modifications affect vehicle-level performance metrics such as acceleration, fuel economy, emissions compliance, and drivability across different driving cycles.

02 Thermal and combustion simulation in Wankel engines

Simulation techniques focused on thermal dynamics and combustion processes within Wankel engines are essential for optimizing performance. These simulations model heat transfer, combustion efficiency, and temperature distribution throughout the engine components. By accurately simulating these thermal aspects, engineers can address cooling challenges, improve combustion chamber design, and enhance overall engine efficiency.Expand Specific Solutions03 Mechanical design optimization through simulation

Simulation tools are used to optimize the mechanical design aspects of Wankel engines, including rotor geometry, housing configuration, and sealing systems. These simulations analyze stress distribution, deformation, vibration characteristics, and mechanical efficiency. By virtually testing different design parameters, engineers can improve durability, reduce friction losses, and enhance the overall mechanical performance of Wankel engines.Expand Specific Solutions04 Emissions and environmental performance simulation

Simulation techniques focused on emissions and environmental performance help engineers understand and improve the ecological footprint of Wankel engines. These simulations model exhaust gas composition, pollutant formation processes, and efficiency of emission control systems. By accurately predicting emissions under various operating conditions, engineers can develop strategies to meet increasingly stringent environmental regulations while maintaining performance.Expand Specific Solutions05 Real-time simulation and control system development

Real-time simulation platforms are developed for Wankel engines to facilitate control system design and testing. These simulations model engine dynamics with sufficient speed to interact with actual control hardware or software. Engineers use these tools to develop and validate engine management systems, optimize operating parameters on-the-fly, and create advanced control strategies that adapt to changing conditions, improving both performance and efficiency.Expand Specific Solutions

Leading Organizations in Rotary Engine Simulation

The Wankel engine simulation market is in a growth phase, characterized by increasing R&D investment across automotive, aerospace, and power generation sectors. The global market size is expanding as companies seek more efficient rotary engine solutions with reduced emissions. From a technological maturity perspective, the field shows varying levels of advancement among key players. Academic institutions like Tsinghua University, Nanjing University of Aeronautics & Astronautics, and University of Tokyo are driving fundamental research, while industrial leaders such as Pratt & Whitney Canada, AVL List GmbH, and MAN Truck & Bus SE are developing practical applications. Companies like Guangxi Yuchai Machinery and Hino Motors are integrating simulation technologies into product development cycles, creating a competitive landscape where collaboration between academic research and industrial application is increasingly vital for innovation.

United Technologies Corp.

Technical Solution: United Technologies Corporation (now part of Raytheon Technologies) has developed sophisticated Wankel engine simulation capabilities through their Pratt & Whitney division, focusing on aerospace and specialized power generation applications. Their simulation framework incorporates multi-scale modeling approaches that bridge detailed component-level analysis with system-level performance prediction. UTC's simulation technology features advanced computational fluid dynamics models specifically adapted for the unique flow patterns in rotary engines, including specialized turbulence models calibrated for the eccentric rotor motion. Their approach includes detailed thermal simulation capabilities that can predict temperature distributions across critical components with high accuracy, enabling optimized cooling system design for reliability in demanding applications. UTC has developed proprietary algorithms for simulating the tribological behavior of apex seals under various operating conditions, addressing one of the traditional reliability challenges of Wankel engines. Their simulation platform incorporates materials science considerations, allowing engineers to evaluate advanced materials and coatings for rotors, housings, and seals. The company has validated their simulation models through extensive testing programs, demonstrating particular strength in predicting durability and performance retention over extended operating periods - critical factors for aerospace applications where reliability is paramount.

Strengths: Exceptional expertise in high-performance and reliability-critical applications; strong integration with advanced materials development; extensive validation in demanding operating environments. Weaknesses: Simulation tools may be highly specialized for aerospace applications rather than automotive use cases; potentially high computational requirements; proprietary nature may limit accessibility and external validation.

Jilin University

Technical Solution: Jilin University has established a specialized Wankel Engine Research Center that has developed proprietary simulation tools focusing on the unique challenges of rotary engine design. Their simulation platform integrates multi-dimensional modeling approaches to capture the complex thermodynamic and fluid dynamic processes within Wankel engines. The university's research team has created advanced algorithms for simulating the eccentric rotary motion and its effects on combustion stability, with particular emphasis on the transitional flow characteristics between the intake, compression, combustion, and exhaust phases. Their simulation framework incorporates detailed models of apex seal dynamics, including the effects of centrifugal forces, gas pressure differentials, and lubricant distribution on sealing performance. Jilin University researchers have developed specialized combustion models that account for the elongated combustion chamber geometry and the resulting challenges in flame propagation and emissions formation. Their simulation tools include thermal analysis capabilities that can predict hotspots and thermal gradients across the rotor and housing, enabling targeted improvements in cooling system design. The university has validated their simulation results through an extensive experimental program using their in-house Wankel engine test facilities, demonstrating good correlation between predicted and measured performance parameters.

Strengths: Deep specialization in rotary engine technology; strong integration between simulation and experimental validation; particular expertise in apex seal dynamics and thermal management. Weaknesses: Potentially limited international exposure and collaboration; simulation tools may be less commercially polished than industry alternatives; possible focus on academic rather than production applications.

Critical Patents and Research in Rotary Engine Simulation

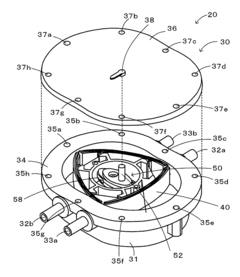

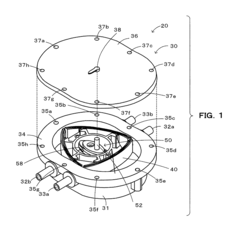

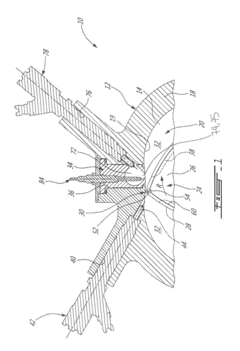

Wankel rotary engine

PatentInactiveUS20110126794A1

Innovation

- Incorporating an eccentric member with a rotating support shaft and a rotating member, such as a roller or ball bearing, that reduces sliding resistance between the rotor's inner periphery and the eccentric member, along with strategically placed fluid intake and exhaust ports, allows efficient rotation of the rotor even with low energy input.

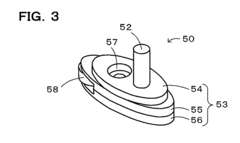

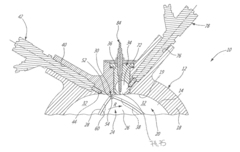

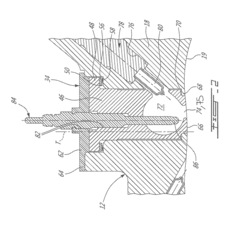

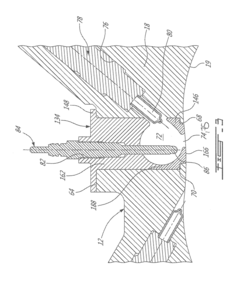

Rotary internal combustion engine with pilot subchamber

PatentActiveUS20180080371A1

Innovation

- A rotary engine design with a stator body and rotor assembly that includes a heat-resistant insert with a subchamber for pilot fuel injection and ignition, along with a main fuel injector, allowing for sequential fuel injection and ignition within rotating chambers of varying volume, enhancing combustion efficiency with heavy fuels.

Computational Requirements and Infrastructure Considerations

Wankel engine simulation for R&D applications demands substantial computational resources due to the complex rotary motion and unique thermodynamic processes involved. High-fidelity simulations typically require multi-core processors with at least 16-32 cores and clock speeds exceeding 3.5 GHz to handle the intensive calculations of fluid dynamics, combustion processes, and mechanical interactions. Memory requirements are equally demanding, with 64-128 GB RAM recommended for comprehensive models that account for all operational parameters simultaneously.

Storage infrastructure must accommodate both the simulation software packages and the extensive data outputs generated during testing cycles. A minimum of 2 TB high-speed SSD storage is advisable, with additional network-attached storage for archiving completed simulations. The data transfer rates between storage and processing units become critical bottlenecks in simulation performance, necessitating NVMe drives with read/write speeds of at least 3000 MB/s.

Graphics processing capabilities represent another crucial consideration, as modern simulation environments leverage GPU acceleration for computational fluid dynamics (CFD) and visualization. Professional-grade GPUs with at least 16 GB VRAM provide optimal performance for real-time rendering of complex rotary motion and combustion visualization. For organizations conducting parallel simulations, GPU clusters may offer significant performance advantages despite their higher implementation costs.

Network infrastructure requirements depend on deployment scenarios. For collaborative R&D environments, 10 Gbps Ethernet connections are recommended to facilitate seamless data sharing and remote access capabilities. Cloud-based simulation alternatives present viable options for organizations seeking scalability without significant capital investment, though they introduce considerations regarding data security and consistent performance.

Power and cooling infrastructure must not be overlooked, as high-performance simulation workstations can consume 1000-1500 watts during peak operation. Adequate cooling systems are essential to maintain optimal operating temperatures and prevent thermal throttling that would compromise simulation accuracy and efficiency. For enterprise-scale deployments, dedicated server rooms with appropriate environmental controls represent a necessary investment.

Storage infrastructure must accommodate both the simulation software packages and the extensive data outputs generated during testing cycles. A minimum of 2 TB high-speed SSD storage is advisable, with additional network-attached storage for archiving completed simulations. The data transfer rates between storage and processing units become critical bottlenecks in simulation performance, necessitating NVMe drives with read/write speeds of at least 3000 MB/s.

Graphics processing capabilities represent another crucial consideration, as modern simulation environments leverage GPU acceleration for computational fluid dynamics (CFD) and visualization. Professional-grade GPUs with at least 16 GB VRAM provide optimal performance for real-time rendering of complex rotary motion and combustion visualization. For organizations conducting parallel simulations, GPU clusters may offer significant performance advantages despite their higher implementation costs.

Network infrastructure requirements depend on deployment scenarios. For collaborative R&D environments, 10 Gbps Ethernet connections are recommended to facilitate seamless data sharing and remote access capabilities. Cloud-based simulation alternatives present viable options for organizations seeking scalability without significant capital investment, though they introduce considerations regarding data security and consistent performance.

Power and cooling infrastructure must not be overlooked, as high-performance simulation workstations can consume 1000-1500 watts during peak operation. Adequate cooling systems are essential to maintain optimal operating temperatures and prevent thermal throttling that would compromise simulation accuracy and efficiency. For enterprise-scale deployments, dedicated server rooms with appropriate environmental controls represent a necessary investment.

Environmental Impact Assessment of Rotary Engine Development

The environmental impact of Wankel rotary engine development presents a complex landscape of challenges and opportunities that must be carefully evaluated in R&D simulation contexts. Traditional rotary engines have historically faced criticism for their higher fuel consumption and emissions compared to conventional piston engines. These engines typically exhibit 10-15% lower fuel efficiency, resulting in increased carbon dioxide emissions per kilometer traveled. Additionally, the unique combustion chamber geometry of rotary engines has traditionally led to higher hydrocarbon emissions due to incomplete combustion in the elongated chamber design.

The sealing system, particularly the apex seals, represents another environmental concern. These components experience significant wear, requiring more frequent replacement and generating additional waste streams. The lubricating oil consumption in rotary engines has also been substantially higher than in piston engines, with some models consuming oil at rates 2-3 times higher, contributing to increased particulate matter emissions.

Recent simulation advancements have enabled more precise modeling of these environmental impacts. Computational fluid dynamics (CFD) simulations now allow researchers to visualize and optimize combustion patterns, potentially reducing unburned hydrocarbon emissions by up to 30% in next-generation designs. Thermal analysis simulations have identified opportunities to improve cooling system efficiency, potentially reducing the auxiliary power requirements that negatively impact overall efficiency.

Material science innovations, when incorporated into simulation models, suggest that advanced ceramic apex seals could reduce friction by approximately 25%, improving both durability and fuel efficiency. Similarly, surface coating technologies simulated in virtual environments indicate potential reductions in oil consumption by up to 40%, directly addressing one of the rotary engine's most significant environmental weaknesses.

Emissions control system simulations have demonstrated that specially designed catalytic converters optimized for the rotary engine's exhaust temperature profile could achieve conversion efficiencies approaching those of modern piston engines. This represents a significant advancement, as historical rotary engines have struggled to meet increasingly stringent emissions standards without substantial performance penalties.

Life cycle assessment (LCA) simulations comparing next-generation rotary engines to both conventional piston engines and emerging electric powertrains provide critical insights for strategic R&D investment. These analyses suggest that while rotary engines may never match battery electric vehicles in operational emissions, they could potentially achieve environmental parity with hybrid systems in specific applications where power density and packaging advantages outweigh efficiency concerns.

The sealing system, particularly the apex seals, represents another environmental concern. These components experience significant wear, requiring more frequent replacement and generating additional waste streams. The lubricating oil consumption in rotary engines has also been substantially higher than in piston engines, with some models consuming oil at rates 2-3 times higher, contributing to increased particulate matter emissions.

Recent simulation advancements have enabled more precise modeling of these environmental impacts. Computational fluid dynamics (CFD) simulations now allow researchers to visualize and optimize combustion patterns, potentially reducing unburned hydrocarbon emissions by up to 30% in next-generation designs. Thermal analysis simulations have identified opportunities to improve cooling system efficiency, potentially reducing the auxiliary power requirements that negatively impact overall efficiency.

Material science innovations, when incorporated into simulation models, suggest that advanced ceramic apex seals could reduce friction by approximately 25%, improving both durability and fuel efficiency. Similarly, surface coating technologies simulated in virtual environments indicate potential reductions in oil consumption by up to 40%, directly addressing one of the rotary engine's most significant environmental weaknesses.

Emissions control system simulations have demonstrated that specially designed catalytic converters optimized for the rotary engine's exhaust temperature profile could achieve conversion efficiencies approaching those of modern piston engines. This represents a significant advancement, as historical rotary engines have struggled to meet increasingly stringent emissions standards without substantial performance penalties.

Life cycle assessment (LCA) simulations comparing next-generation rotary engines to both conventional piston engines and emerging electric powertrains provide critical insights for strategic R&D investment. These analyses suggest that while rotary engines may never match battery electric vehicles in operational emissions, they could potentially achieve environmental parity with hybrid systems in specific applications where power density and packaging advantages outweigh efficiency concerns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!