Wankel Engine Testing Protocols with ISO Standards

AUG 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Development History and Testing Objectives

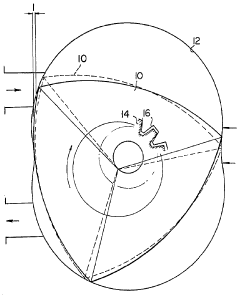

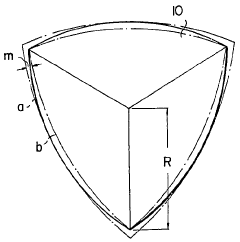

The Wankel rotary engine represents one of the most innovative departures from conventional internal combustion engine design in automotive history. Developed by German engineer Felix Wankel, the first concept was introduced in 1954, with the first working prototype completed by 1957 at NSU Motorenwerke AG. Unlike traditional reciprocating piston engines, the Wankel engine utilizes a triangular rotor that revolves within an epitrochoid-shaped housing, creating a unique combustion cycle that offers several theoretical advantages.

The historical development of Wankel engines progressed through several distinct phases. The 1960s marked the period of initial commercialization, with NSU introducing the first production Wankel-powered vehicle, the NSU Spider, in 1964. This was followed by the more refined NSU Ro80 in 1967. Mazda became the most significant adopter of the technology, beginning their rotary development program in 1961 and launching their first rotary-powered vehicle, the Cosmo Sport, in 1967.

Throughout the 1970s and 1980s, Mazda continued refining the technology while other manufacturers largely abandoned it due to challenges with emissions, fuel efficiency, and durability. The oil crisis of 1973 particularly highlighted the fuel consumption disadvantages of early Wankel designs, accelerating the retreat of most manufacturers from rotary development.

Testing protocols for Wankel engines have evolved significantly since their inception. Early testing focused primarily on performance metrics and basic durability, with limited standardization across different manufacturers. As emissions regulations tightened globally in the 1970s and 1980s, testing expanded to include more rigorous emissions evaluation, particularly addressing the unique challenges of the rotary design related to hydrocarbon emissions and oil consumption.

The primary objectives of modern Wankel engine testing align with ISO standards for internal combustion engines, particularly ISO 8178 for exhaust emission measurement and ISO 15550 for performance testing. However, the unique characteristics of rotary engines necessitate specialized testing protocols that address their specific operational parameters, including apex seal wear, rotor housing durability, and the distinctive thermal management challenges inherent to the design.

Current testing objectives focus on several key areas: emissions compliance with increasingly stringent global standards, fuel efficiency improvements to address historical disadvantages, durability testing with particular attention to seal wear and thermal stress, and performance optimization across varying operational conditions. Additionally, modern testing protocols increasingly incorporate noise, vibration, and harshness (NVH) evaluation, as the inherent smoothness of rotary operation represents one of its key advantages.

The integration of Wankel engines with new technologies, including hybrid systems and hydrogen fuel compatibility, has further expanded testing objectives to include evaluation of these novel applications, particularly as manufacturers like Mazda explore rotary engines as range extenders in electrified powertrains.

The historical development of Wankel engines progressed through several distinct phases. The 1960s marked the period of initial commercialization, with NSU introducing the first production Wankel-powered vehicle, the NSU Spider, in 1964. This was followed by the more refined NSU Ro80 in 1967. Mazda became the most significant adopter of the technology, beginning their rotary development program in 1961 and launching their first rotary-powered vehicle, the Cosmo Sport, in 1967.

Throughout the 1970s and 1980s, Mazda continued refining the technology while other manufacturers largely abandoned it due to challenges with emissions, fuel efficiency, and durability. The oil crisis of 1973 particularly highlighted the fuel consumption disadvantages of early Wankel designs, accelerating the retreat of most manufacturers from rotary development.

Testing protocols for Wankel engines have evolved significantly since their inception. Early testing focused primarily on performance metrics and basic durability, with limited standardization across different manufacturers. As emissions regulations tightened globally in the 1970s and 1980s, testing expanded to include more rigorous emissions evaluation, particularly addressing the unique challenges of the rotary design related to hydrocarbon emissions and oil consumption.

The primary objectives of modern Wankel engine testing align with ISO standards for internal combustion engines, particularly ISO 8178 for exhaust emission measurement and ISO 15550 for performance testing. However, the unique characteristics of rotary engines necessitate specialized testing protocols that address their specific operational parameters, including apex seal wear, rotor housing durability, and the distinctive thermal management challenges inherent to the design.

Current testing objectives focus on several key areas: emissions compliance with increasingly stringent global standards, fuel efficiency improvements to address historical disadvantages, durability testing with particular attention to seal wear and thermal stress, and performance optimization across varying operational conditions. Additionally, modern testing protocols increasingly incorporate noise, vibration, and harshness (NVH) evaluation, as the inherent smoothness of rotary operation represents one of its key advantages.

The integration of Wankel engines with new technologies, including hybrid systems and hydrogen fuel compatibility, has further expanded testing objectives to include evaluation of these novel applications, particularly as manufacturers like Mazda explore rotary engines as range extenders in electrified powertrains.

Market Analysis for Rotary Engine Applications

The rotary engine market has experienced significant shifts over the past decade, with applications expanding beyond traditional automotive uses. Currently, the global rotary engine market is valued at approximately 2.3 billion USD, with a compound annual growth rate of 4.7% projected through 2028. This growth is primarily driven by emerging applications in unmanned aerial vehicles (UAVs), marine propulsion systems, and specialized industrial equipment where the Wankel engine's power-to-weight ratio provides distinct advantages.

The automotive sector, once the primary market for rotary engines, has contracted significantly since Mazda discontinued its RX series production. However, niche automotive applications persist in motorsport and specialty vehicles, representing about 18% of the current market. The aerospace and defense sectors have emerged as the fastest-growing application segments, with a 7.2% annual growth rate, particularly in tactical UAV systems where compact, high-output power sources are essential.

Geographically, North America and Asia-Pacific regions dominate the market landscape, collectively accounting for over 65% of global demand. Japan maintains significant technical expertise in rotary engine manufacturing, while Germany and the United States lead in research and development of advanced testing protocols aligned with ISO standards. The European market shows particular interest in rotary engines for premium small aircraft and specialized industrial applications.

Market analysis reveals increasing demand for standardized testing protocols that align with ISO requirements, particularly ISO 15550 for internal combustion engines and ISO 8178 for exhaust emission measurements. Organizations implementing these standardized testing protocols report 22% lower certification costs and significantly faster time-to-market for new rotary engine applications.

Consumer and industrial demand increasingly emphasizes fuel efficiency and emissions performance, creating market pressure for enhanced testing methodologies that can accurately measure and validate these parameters. The premium segment of the market, representing approximately 31% of total value, shows willingness to pay up to 40% more for rotary engines with comprehensive test documentation that demonstrates compliance with international standards.

Emerging market opportunities exist in hybrid power systems, where rotary engines serve as range extenders for electric vehicles, and in portable power generation, where their compact size and operational flexibility provide competitive advantages. These applications are expected to grow at 9.3% annually, creating new requirements for specialized testing protocols that address unique operational parameters such as intermittent usage patterns and variable load conditions.

The automotive sector, once the primary market for rotary engines, has contracted significantly since Mazda discontinued its RX series production. However, niche automotive applications persist in motorsport and specialty vehicles, representing about 18% of the current market. The aerospace and defense sectors have emerged as the fastest-growing application segments, with a 7.2% annual growth rate, particularly in tactical UAV systems where compact, high-output power sources are essential.

Geographically, North America and Asia-Pacific regions dominate the market landscape, collectively accounting for over 65% of global demand. Japan maintains significant technical expertise in rotary engine manufacturing, while Germany and the United States lead in research and development of advanced testing protocols aligned with ISO standards. The European market shows particular interest in rotary engines for premium small aircraft and specialized industrial applications.

Market analysis reveals increasing demand for standardized testing protocols that align with ISO requirements, particularly ISO 15550 for internal combustion engines and ISO 8178 for exhaust emission measurements. Organizations implementing these standardized testing protocols report 22% lower certification costs and significantly faster time-to-market for new rotary engine applications.

Consumer and industrial demand increasingly emphasizes fuel efficiency and emissions performance, creating market pressure for enhanced testing methodologies that can accurately measure and validate these parameters. The premium segment of the market, representing approximately 31% of total value, shows willingness to pay up to 40% more for rotary engines with comprehensive test documentation that demonstrates compliance with international standards.

Emerging market opportunities exist in hybrid power systems, where rotary engines serve as range extenders for electric vehicles, and in portable power generation, where their compact size and operational flexibility provide competitive advantages. These applications are expected to grow at 9.3% annually, creating new requirements for specialized testing protocols that address unique operational parameters such as intermittent usage patterns and variable load conditions.

Current Testing Challenges and Technical Limitations

The testing of Wankel rotary engines presents unique challenges that conventional reciprocating engine testing protocols fail to adequately address. Current ISO standards, primarily developed for traditional piston engines, lack specific provisions for the distinctive operational characteristics of rotary engines. This standardization gap creates significant inconsistencies in performance evaluation, emissions testing, and durability assessment across different testing facilities and manufacturers.

A primary technical limitation involves the measurement of combustion efficiency in the Wankel's elongated combustion chamber. The continuous rotation of the triangular rotor creates varying chamber volumes and geometries throughout the combustion cycle, making traditional in-cylinder pressure measurement techniques inadequate. Existing pressure transducers designed for reciprocating engines cannot be optimally positioned to capture the dynamic pressure changes in the epitrochoidal housing.

Thermal management assessment presents another substantial challenge. The Wankel engine's unique architecture results in uneven temperature distribution across the housing and rotor, with apex seals experiencing particularly extreme thermal conditions. Current testing equipment lacks specialized thermal imaging capabilities and temperature sensors designed for the rotary configuration, leading to incomplete thermal profile data that compromises reliability predictions.

Emissions testing protocols face significant limitations when applied to Wankel engines. The distinctive combustion characteristics, including longer combustion duration and potential for incomplete combustion near the trailing edge of the chamber, create emission profiles that differ substantially from those of conventional engines. Existing sampling methods and measurement cycles fail to accurately capture these unique emission patterns, particularly during transient operations.

Durability testing frameworks show considerable deficiencies when applied to rotary engines. The wear patterns of apex seals, side seals, and housing surfaces follow mechanisms not adequately represented in current accelerated life testing protocols. The correlation between bench testing and real-world durability remains poorly established for Wankel-specific components.

Noise, vibration, and harshness (NVH) testing methodologies require substantial adaptation for rotary engines. The Wankel's inherently different vibration signature, characterized by higher frequency but lower amplitude vibrations compared to reciprocating engines, demands specialized measurement equipment and analysis techniques that current ISO standards do not specify.

The absence of standardized test cycles specifically designed to evaluate the unique operational characteristics of Wankel engines further complicates comparative analysis. This lack of rotary-specific test procedures creates significant barriers to objective performance benchmarking and regulatory compliance verification, ultimately hindering wider adoption and continued development of this engine technology.

A primary technical limitation involves the measurement of combustion efficiency in the Wankel's elongated combustion chamber. The continuous rotation of the triangular rotor creates varying chamber volumes and geometries throughout the combustion cycle, making traditional in-cylinder pressure measurement techniques inadequate. Existing pressure transducers designed for reciprocating engines cannot be optimally positioned to capture the dynamic pressure changes in the epitrochoidal housing.

Thermal management assessment presents another substantial challenge. The Wankel engine's unique architecture results in uneven temperature distribution across the housing and rotor, with apex seals experiencing particularly extreme thermal conditions. Current testing equipment lacks specialized thermal imaging capabilities and temperature sensors designed for the rotary configuration, leading to incomplete thermal profile data that compromises reliability predictions.

Emissions testing protocols face significant limitations when applied to Wankel engines. The distinctive combustion characteristics, including longer combustion duration and potential for incomplete combustion near the trailing edge of the chamber, create emission profiles that differ substantially from those of conventional engines. Existing sampling methods and measurement cycles fail to accurately capture these unique emission patterns, particularly during transient operations.

Durability testing frameworks show considerable deficiencies when applied to rotary engines. The wear patterns of apex seals, side seals, and housing surfaces follow mechanisms not adequately represented in current accelerated life testing protocols. The correlation between bench testing and real-world durability remains poorly established for Wankel-specific components.

Noise, vibration, and harshness (NVH) testing methodologies require substantial adaptation for rotary engines. The Wankel's inherently different vibration signature, characterized by higher frequency but lower amplitude vibrations compared to reciprocating engines, demands specialized measurement equipment and analysis techniques that current ISO standards do not specify.

The absence of standardized test cycles specifically designed to evaluate the unique operational characteristics of Wankel engines further complicates comparative analysis. This lack of rotary-specific test procedures creates significant barriers to objective performance benchmarking and regulatory compliance verification, ultimately hindering wider adoption and continued development of this engine technology.

ISO-Compliant Testing Protocols and Implementation

01 Performance and Efficiency Testing Methods

Various testing protocols are employed to evaluate the performance and efficiency of Wankel engines. These methods include measuring power output, fuel consumption, and thermal efficiency under different operating conditions. Testing equipment and procedures are designed to accurately assess the rotary engine's unique characteristics compared to conventional piston engines. These protocols help in optimizing the engine design for better performance and fuel economy.- Performance and Efficiency Testing Methods: Various testing protocols are employed to evaluate the performance and efficiency of Wankel engines. These methods include measuring power output, fuel consumption, and thermal efficiency under different operating conditions. Testing equipment and procedures are designed to capture data on rotary engine performance characteristics, allowing for comparison with conventional piston engines and optimization of design parameters.

- Emissions and Environmental Testing: Protocols for testing emissions from Wankel engines involve measuring exhaust gases and particulate matter under standardized conditions. These tests evaluate compliance with environmental regulations and help in developing cleaner rotary engine technologies. Testing procedures include analysis of hydrocarbon emissions, NOx levels, and carbon monoxide output across various engine speeds and loads to ensure environmental performance.

- Durability and Reliability Testing: Durability testing protocols for Wankel engines involve extended operation under stress conditions to evaluate component longevity and system reliability. These tests include continuous running at high RPM, thermal cycling, and accelerated wear testing. Specific attention is given to apex seals, rotor housings, and eccentric shafts which are critical components subject to unique wear patterns in rotary engines.

- Vibration and Noise Testing Methodologies: Specialized protocols for measuring vibration characteristics and noise emissions of Wankel engines help evaluate their refinement and identify potential mechanical issues. These tests utilize accelerometers, sound pressure level meters, and spectral analysis to quantify NVH (Noise, Vibration, Harshness) performance. Testing procedures compare rotary engine vibration signatures against baseline measurements to detect abnormalities and validate design improvements.

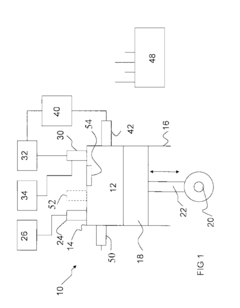

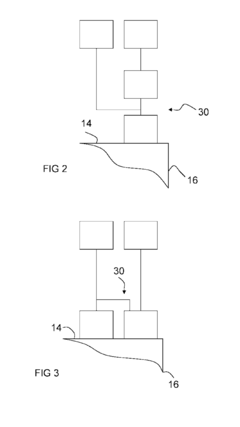

- Automated Testing Systems and Diagnostics: Advanced automated testing systems for Wankel engines incorporate computerized diagnostics and real-time monitoring capabilities. These systems enable precise control of test parameters, data acquisition, and analysis of engine performance metrics. Testing protocols include fault simulation, automated test sequences, and integration with digital twins for predictive analysis, enhancing the efficiency and accuracy of rotary engine development and validation.

02 Emissions and Environmental Testing

Specialized protocols for testing emissions from Wankel engines are essential for regulatory compliance and environmental impact assessment. These tests measure exhaust gas composition, including hydrocarbon, NOx, and CO2 emissions under various operating conditions. Testing methods may include continuous monitoring systems and standardized test cycles designed specifically for rotary engine characteristics. Environmental testing also evaluates noise levels and vibration patterns unique to Wankel engine operation.Expand Specific Solutions03 Durability and Reliability Testing

Durability testing protocols for Wankel engines involve extended operation under stress conditions to evaluate component longevity and system reliability. These tests include continuous running at maximum power, thermal cycling, and accelerated wear testing of critical components such as apex seals and rotor housings. Testing procedures monitor changes in performance parameters over time to predict service life and maintenance requirements. Reliability testing also evaluates the engine's response to various fuel qualities and operating environments.Expand Specific Solutions04 Automated Testing Systems and Data Analysis

Advanced automated testing systems have been developed specifically for Wankel engine evaluation, incorporating computerized control and data acquisition capabilities. These systems enable precise control of test parameters and continuous monitoring of multiple engine variables simultaneously. Testing protocols include sophisticated data analysis methods to interpret complex relationships between operating parameters and engine performance. Machine learning algorithms may be employed to optimize testing procedures and predict engine behavior under various conditions.Expand Specific Solutions05 Prototype and Development Testing

Specialized testing protocols are used during the development phase of new Wankel engine designs. These include bench testing of individual components, cold-start performance evaluation, and thermal management assessment. Testing procedures focus on validating design innovations and identifying potential issues before full production. Development testing also includes comparative analysis with previous models or competing engine technologies to quantify improvements. These protocols often incorporate simulation validation and correlation with theoretical models.Expand Specific Solutions

Key Industry Players and Testing Equipment Manufacturers

The Wankel engine testing protocols market is currently in a growth phase, characterized by increasing adoption of ISO standards to ensure reliability and performance. The market size is expanding due to renewed interest in rotary engine technology for specialized applications. Toyota Motor Corp. leads the technical maturity landscape with significant R&D investments, followed by BYD and BMW who are exploring Wankel engines for range extenders in electric vehicles. Academic institutions like Harbin Institute of Technology and Chongqing University contribute valuable research, while specialized testing equipment providers such as Launch Tech Co. offer complementary solutions. The collaboration between automotive manufacturers and research institutions is accelerating standardization efforts, creating a competitive yet collaborative ecosystem.

Toyota Motor Corp.

Technical Solution: Toyota has developed comprehensive Wankel engine testing protocols that align with ISO 9001:2015 quality management standards. Their approach includes specialized dynamometer testing facilities designed specifically for rotary engines, with capabilities to measure power output, fuel efficiency, and emissions under various operating conditions. Toyota's testing methodology incorporates real-time monitoring systems that track rotor apex seal wear patterns and housing surface degradation - critical factors in Wankel engine reliability assessment. Their protocols include thermal stress testing under extreme temperature conditions (from -40°C to +120°C) to evaluate housing distortion and coolant system efficiency. Additionally, Toyota has implemented automated test sequences that comply with ISO 16183 for exhaust emission measurement, adapted specifically for the unique combustion characteristics of rotary engines.

Strengths: Toyota's testing protocols benefit from their extensive experience in powertrain development and quality control systems. Their facilities can simulate diverse operating conditions with high precision. Weaknesses: Their testing methodology may be overly optimized for hybrid applications rather than pure Wankel configurations, potentially missing some unique characteristics of standalone rotary engines.

China FAW Co., Ltd.

Technical Solution: China FAW has established comprehensive Wankel engine testing protocols that integrate with ISO 9001 and ISO/TS 16949 quality management standards. Their approach includes specialized dynamometer facilities calibrated for the unique power delivery characteristics of rotary engines, with capabilities to measure torque fluctuations throughout the rotation cycle. FAW's testing methodology incorporates extensive emissions testing under the Chinese 6b standards, with specialized calibration for the unique combustion characteristics of Wankel engines. Their protocols include accelerated wear testing that simulates 200,000 km of operation under varying conditions, with particular focus on apex seal durability and housing surface wear patterns. FAW has implemented specialized vibration analysis techniques that can identify rotor imbalance and eccentric shaft alignment issues with high precision. Their testing regimen also includes cold-start performance evaluation at temperatures as low as -30°C, addressing one of the traditional challenges of Wankel engine operation in extreme conditions.

Strengths: FAW's testing protocols benefit from integration with their mass production quality systems, ensuring consistency and repeatability across large sample sizes. Weaknesses: Their methodology may be overly influenced by conventional piston engine testing approaches, potentially missing some unique characteristics specific to rotary engine optimization.

Critical Patents and Technical Literature on Rotary Engine Testing

Rotor for a rotary internal combustion wankel engine

PatentInactiveGB1487118A

Innovation

- A rotor with a specific profile that maintains a minimum clearance between its peripheral flanks and the inner surface of the epitrochoidal housing by radially displacing the rotor profile inwardly, preventing contact with the housing and optimizing the clearance to minimize gas communication between intake and exhaust ports.

Internal combustion engine

PatentActiveUS20190063374A1

Innovation

- A modified diesel cycle that incorporates steam reformation, where a mixture of fuel and steam is introduced during the compression stroke to separate hydrogen, which is then combusted, enhancing fuel efficiency and reducing emissions by utilizing the heat generated during compression to produce additional fuel with a higher calorific value.

Environmental Impact and Emissions Testing Requirements

The environmental impact assessment of Wankel engines requires rigorous emissions testing protocols that align with international standards. Current ISO standards mandate specific testing methodologies for rotary engines, with particular emphasis on their unique combustion characteristics. The primary emissions concerns for Wankel engines include higher hydrocarbon (HC) emissions due to the elongated combustion chamber and potential for unburned fuel, nitrogen oxides (NOx) resulting from high operating temperatures, and carbon monoxide (CO) emissions that vary significantly based on air-fuel mixture ratios.

ISO 8178 provides the foundational framework for emissions testing of non-road engines, including specialized protocols for rotary engines. These standards require measurement across multiple load points to account for the Wankel engine's distinctive power delivery curve. Additionally, the European Union's Euro 6/VI standards and the United States EPA Tier 4 regulations have established increasingly stringent emissions limits that present significant challenges for Wankel engine development.

Testing equipment for Wankel engines must be calibrated to account for the pulsating exhaust flow patterns characteristic of rotary operation. Constant volume sampling (CVS) systems require modification to accurately capture emissions during the engine's unique three-phase combustion cycle. Particulate matter (PM) measurement presents additional challenges due to the oil consumption inherent in many Wankel designs, necessitating specialized filtration and measurement techniques.

Recent advancements in emissions reduction technologies for Wankel engines include modified apex seal designs that reduce oil consumption, catalytic converter systems optimized for the higher exhaust temperatures, and electronic fuel injection systems that provide more precise mixture control. These technologies must undergo validation through standardized test cycles that represent real-world operating conditions.

Life cycle assessment (LCA) methodologies are increasingly being incorporated into Wankel engine testing protocols to evaluate environmental impact beyond tailpipe emissions. These assessments consider manufacturing processes, material selection, operational efficiency, and end-of-life recycling potential. ISO 14040 and 14044 standards provide the framework for these comprehensive environmental evaluations.

Climate chamber testing represents another critical component of environmental assessment, with Wankel engines requiring evaluation across temperature ranges from -40°C to +50°C to ensure emissions compliance in diverse operating environments. Cold-start emissions testing is particularly important due to the Wankel's thermal characteristics and potential for increased hydrocarbon emissions during warm-up phases.

The integration of on-board diagnostics (OBD) systems for continuous emissions monitoring presents unique challenges for Wankel engines, requiring specialized algorithms to interpret rotary-specific operating parameters and identify potential emissions control system malfunctions in accordance with ISO 15031 standards.

ISO 8178 provides the foundational framework for emissions testing of non-road engines, including specialized protocols for rotary engines. These standards require measurement across multiple load points to account for the Wankel engine's distinctive power delivery curve. Additionally, the European Union's Euro 6/VI standards and the United States EPA Tier 4 regulations have established increasingly stringent emissions limits that present significant challenges for Wankel engine development.

Testing equipment for Wankel engines must be calibrated to account for the pulsating exhaust flow patterns characteristic of rotary operation. Constant volume sampling (CVS) systems require modification to accurately capture emissions during the engine's unique three-phase combustion cycle. Particulate matter (PM) measurement presents additional challenges due to the oil consumption inherent in many Wankel designs, necessitating specialized filtration and measurement techniques.

Recent advancements in emissions reduction technologies for Wankel engines include modified apex seal designs that reduce oil consumption, catalytic converter systems optimized for the higher exhaust temperatures, and electronic fuel injection systems that provide more precise mixture control. These technologies must undergo validation through standardized test cycles that represent real-world operating conditions.

Life cycle assessment (LCA) methodologies are increasingly being incorporated into Wankel engine testing protocols to evaluate environmental impact beyond tailpipe emissions. These assessments consider manufacturing processes, material selection, operational efficiency, and end-of-life recycling potential. ISO 14040 and 14044 standards provide the framework for these comprehensive environmental evaluations.

Climate chamber testing represents another critical component of environmental assessment, with Wankel engines requiring evaluation across temperature ranges from -40°C to +50°C to ensure emissions compliance in diverse operating environments. Cold-start emissions testing is particularly important due to the Wankel's thermal characteristics and potential for increased hydrocarbon emissions during warm-up phases.

The integration of on-board diagnostics (OBD) systems for continuous emissions monitoring presents unique challenges for Wankel engines, requiring specialized algorithms to interpret rotary-specific operating parameters and identify potential emissions control system malfunctions in accordance with ISO 15031 standards.

Calibration and Validation Procedures for Test Equipment

The calibration and validation of test equipment for Wankel engine testing represents a critical foundation for ensuring measurement accuracy and test result reliability. In accordance with ISO standards, particularly ISO 17025 and ISO 9001, all measurement devices must undergo systematic calibration procedures at predetermined intervals. For Wankel engines, which feature unique rotary motion and triangular rotor dynamics, specialized calibration protocols have been developed to address their distinctive characteristics.

Primary measurement equipment requiring calibration includes dynamometers, fuel flow meters, emission analyzers, temperature sensors, and pressure transducers. Each device category demands specific calibration methodologies. Dynamometers, essential for measuring the Wankel engine's torque output, require calibration using certified weights and lever arms, with verification against reference standards traceable to national metrology institutes. The calibration frequency typically ranges from quarterly to annually, depending on usage intensity.

Fuel flow measurement systems demand particular attention due to the Wankel engine's unique fuel consumption patterns. Calibration involves comparing measured values against reference flow meters with certified accuracy, typically using gravimetric methods for ultimate precision. Temperature sensors, critical for monitoring the Wankel's distinctive thermal characteristics, undergo calibration against reference thermometers in controlled temperature baths across the operational range of -40°C to 1200°C.

Validation procedures complement calibration by confirming that the measurement system functions appropriately within the specific testing environment. This includes system response testing, linearity verification, and cross-checking between redundant measurement systems. For Wankel engine testing, validation must specifically address the pulsation effects from the rotary motion and the unique pressure wave patterns generated during operation.

Documentation requirements form an integral component of the calibration and validation framework. All procedures must be thoroughly documented, including calibration certificates, traceability records, uncertainty calculations, and deviation reports. Digital calibration management systems have become increasingly prevalent, offering automated scheduling, documentation storage, and measurement uncertainty analysis capabilities.

Uncertainty analysis represents the final critical element in the calibration process. For Wankel engine testing, measurement uncertainties must be quantified for all key parameters, with combined standard uncertainties calculated according to the Guide to the Expression of Uncertainty in Measurement (GUM). This analysis must account for the unique characteristics of rotary engine operation, including the non-uniform combustion processes and distinctive vibration patterns that can influence measurement accuracy.

Primary measurement equipment requiring calibration includes dynamometers, fuel flow meters, emission analyzers, temperature sensors, and pressure transducers. Each device category demands specific calibration methodologies. Dynamometers, essential for measuring the Wankel engine's torque output, require calibration using certified weights and lever arms, with verification against reference standards traceable to national metrology institutes. The calibration frequency typically ranges from quarterly to annually, depending on usage intensity.

Fuel flow measurement systems demand particular attention due to the Wankel engine's unique fuel consumption patterns. Calibration involves comparing measured values against reference flow meters with certified accuracy, typically using gravimetric methods for ultimate precision. Temperature sensors, critical for monitoring the Wankel's distinctive thermal characteristics, undergo calibration against reference thermometers in controlled temperature baths across the operational range of -40°C to 1200°C.

Validation procedures complement calibration by confirming that the measurement system functions appropriately within the specific testing environment. This includes system response testing, linearity verification, and cross-checking between redundant measurement systems. For Wankel engine testing, validation must specifically address the pulsation effects from the rotary motion and the unique pressure wave patterns generated during operation.

Documentation requirements form an integral component of the calibration and validation framework. All procedures must be thoroughly documented, including calibration certificates, traceability records, uncertainty calculations, and deviation reports. Digital calibration management systems have become increasingly prevalent, offering automated scheduling, documentation storage, and measurement uncertainty analysis capabilities.

Uncertainty analysis represents the final critical element in the calibration process. For Wankel engine testing, measurement uncertainties must be quantified for all key parameters, with combined standard uncertainties calculated according to the Guide to the Expression of Uncertainty in Measurement (GUM). This analysis must account for the unique characteristics of rotary engine operation, including the non-uniform combustion processes and distinctive vibration patterns that can influence measurement accuracy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!