Wankel Engine Ignition System Innovations

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Ignition Evolution and Objectives

The Wankel rotary engine, first developed by Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its ignition system evolution has been marked by continuous innovation to address the unique challenges posed by the rotary architecture. Initially, these engines utilized basic points-type ignition systems similar to those found in piston engines of the era, with fixed timing that limited performance optimization across varying operating conditions.

The 1970s marked a pivotal transition with the introduction of electronic ignition systems in Wankel engines, particularly in Mazda's production models. This advancement eliminated mechanical wear issues associated with breaker points and enabled more precise spark timing. The oil crisis during this period also drove significant research into improving combustion efficiency, with ignition timing becoming a critical focus area for reducing the traditionally high fuel consumption of rotary engines.

By the 1990s, fully computerized engine management systems revolutionized Wankel ignition technology. These systems incorporated multiple sensors to monitor engine conditions and adjust ignition timing dynamically, addressing the rotary engine's unique combustion characteristics. The introduction of sequential multi-coil ignition systems allowed for more precise control over the spark event, significantly improving combustion stability across the elongated combustion chamber of the rotary design.

Recent developments have focused on overcoming the inherent challenges of the Wankel architecture, particularly the elongated combustion chamber that creates varying distances between the spark plug and combustion front. Advanced multi-spark technologies have emerged, capable of producing multiple spark events during a single combustion cycle to ensure complete fuel burning. Additionally, plasma-assisted ignition systems are being explored to generate more robust ignition kernels that can propagate more effectively through the unique chamber geometry.

The primary objectives of modern Wankel ignition system development center around four key areas: emissions reduction, fuel efficiency improvement, performance enhancement, and reliability optimization. Emissions control remains particularly challenging due to the inherent characteristics of the rotary combustion process, with ignition timing playing a crucial role in reducing unburned hydrocarbon emissions. Simultaneously, researchers aim to preserve the rotary engine's signature high power-to-weight ratio while meeting increasingly stringent regulatory requirements.

Looking forward, the integration of Wankel engines into hybrid powertrains presents new opportunities for ignition system innovation. When used as range extenders or generators, these engines can operate at optimized fixed speeds, allowing for highly specialized ignition timing strategies that maximize efficiency within a narrow operating band rather than across the traditional wide RPM range required for direct propulsion applications.

The 1970s marked a pivotal transition with the introduction of electronic ignition systems in Wankel engines, particularly in Mazda's production models. This advancement eliminated mechanical wear issues associated with breaker points and enabled more precise spark timing. The oil crisis during this period also drove significant research into improving combustion efficiency, with ignition timing becoming a critical focus area for reducing the traditionally high fuel consumption of rotary engines.

By the 1990s, fully computerized engine management systems revolutionized Wankel ignition technology. These systems incorporated multiple sensors to monitor engine conditions and adjust ignition timing dynamically, addressing the rotary engine's unique combustion characteristics. The introduction of sequential multi-coil ignition systems allowed for more precise control over the spark event, significantly improving combustion stability across the elongated combustion chamber of the rotary design.

Recent developments have focused on overcoming the inherent challenges of the Wankel architecture, particularly the elongated combustion chamber that creates varying distances between the spark plug and combustion front. Advanced multi-spark technologies have emerged, capable of producing multiple spark events during a single combustion cycle to ensure complete fuel burning. Additionally, plasma-assisted ignition systems are being explored to generate more robust ignition kernels that can propagate more effectively through the unique chamber geometry.

The primary objectives of modern Wankel ignition system development center around four key areas: emissions reduction, fuel efficiency improvement, performance enhancement, and reliability optimization. Emissions control remains particularly challenging due to the inherent characteristics of the rotary combustion process, with ignition timing playing a crucial role in reducing unburned hydrocarbon emissions. Simultaneously, researchers aim to preserve the rotary engine's signature high power-to-weight ratio while meeting increasingly stringent regulatory requirements.

Looking forward, the integration of Wankel engines into hybrid powertrains presents new opportunities for ignition system innovation. When used as range extenders or generators, these engines can operate at optimized fixed speeds, allowing for highly specialized ignition timing strategies that maximize efficiency within a narrow operating band rather than across the traditional wide RPM range required for direct propulsion applications.

Market Analysis for Rotary Engine Applications

The global market for rotary engine applications has experienced significant shifts over the past decade, with specialized niches emerging as primary growth drivers. Currently valued at approximately $2.1 billion, the Wankel engine market maintains a modest but stable presence within the broader internal combustion engine landscape. While conventional automotive applications have declined following Mazda's temporary withdrawal from mass-market rotary production, several high-value sectors continue to sustain demand for these unique powerplants.

Aviation represents the most promising growth segment, with a compound annual growth rate of 6.8% projected through 2030. The rotary engine's exceptional power-to-weight ratio makes it particularly attractive for light aircraft, UAVs, and drone applications where weight considerations are paramount. Companies like UAV Engines Ltd and Austro Engine have capitalized on this advantage, capturing significant market share in military and commercial drone propulsion systems.

The marine sector constitutes another substantial market, particularly for auxiliary power units and small watercraft propulsion. The compact design and smooth operation characteristics of Wankel engines provide distinct advantages in space-constrained marine environments. Market penetration in this sector has grown steadily at 4.2% annually since 2018.

Racing and high-performance applications form a smaller but premium market segment with higher profit margins. The rotary engine's ability to achieve high RPM with minimal vibration continues to attract specialized racing teams and enthusiasts willing to invest in advanced ignition systems and performance enhancements.

Geographically, North America leads market consumption at 38%, followed by Europe (29%) and Asia-Pacific (24%). Japan maintains its position as a center of rotary engine expertise despite reduced consumer applications. Emerging markets in South America and parts of Asia show increasing interest, particularly for specialized industrial and agricultural applications where the rotary engine's compact size provides operational advantages.

Market analysis indicates that innovations specifically targeting ignition systems could unlock substantial value. Current pain points reported by end-users primarily relate to fuel efficiency, emissions compliance, and durability—all areas directly impacted by ignition technology. Survey data shows 73% of commercial rotary engine users would pay premium prices for ignition systems that demonstrably improve fuel economy and extend engine life.

The aftermarket for rotary engine components, including ignition systems, represents a $340 million opportunity globally, with specialized ignition components accounting for approximately 18% of this figure. This segment has shown resilience even during periods of declining new engine production, as existing units require ongoing maintenance and performance upgrades.

Aviation represents the most promising growth segment, with a compound annual growth rate of 6.8% projected through 2030. The rotary engine's exceptional power-to-weight ratio makes it particularly attractive for light aircraft, UAVs, and drone applications where weight considerations are paramount. Companies like UAV Engines Ltd and Austro Engine have capitalized on this advantage, capturing significant market share in military and commercial drone propulsion systems.

The marine sector constitutes another substantial market, particularly for auxiliary power units and small watercraft propulsion. The compact design and smooth operation characteristics of Wankel engines provide distinct advantages in space-constrained marine environments. Market penetration in this sector has grown steadily at 4.2% annually since 2018.

Racing and high-performance applications form a smaller but premium market segment with higher profit margins. The rotary engine's ability to achieve high RPM with minimal vibration continues to attract specialized racing teams and enthusiasts willing to invest in advanced ignition systems and performance enhancements.

Geographically, North America leads market consumption at 38%, followed by Europe (29%) and Asia-Pacific (24%). Japan maintains its position as a center of rotary engine expertise despite reduced consumer applications. Emerging markets in South America and parts of Asia show increasing interest, particularly for specialized industrial and agricultural applications where the rotary engine's compact size provides operational advantages.

Market analysis indicates that innovations specifically targeting ignition systems could unlock substantial value. Current pain points reported by end-users primarily relate to fuel efficiency, emissions compliance, and durability—all areas directly impacted by ignition technology. Survey data shows 73% of commercial rotary engine users would pay premium prices for ignition systems that demonstrably improve fuel economy and extend engine life.

The aftermarket for rotary engine components, including ignition systems, represents a $340 million opportunity globally, with specialized ignition components accounting for approximately 18% of this figure. This segment has shown resilience even during periods of declining new engine production, as existing units require ongoing maintenance and performance upgrades.

Technical Challenges in Wankel Ignition Systems

Wankel engines present unique ignition challenges due to their distinctive geometry and combustion dynamics. Unlike conventional reciprocating engines, the Wankel's rotor housing creates an elongated combustion chamber with varying volume and shape throughout the cycle. This fundamental difference necessitates specialized ignition solutions that conventional piston engine systems cannot adequately address.

The primary technical challenge stems from the Wankel's extended combustion chamber, which creates significant distance between the spark plug and the furthest point of the chamber. This distance can exceed 10 cm in some designs, requiring stronger ignition energy and precise timing to ensure complete combustion. The moving flame front must travel farther than in conventional engines, increasing the likelihood of incomplete combustion and higher hydrocarbon emissions.

Another critical challenge is the thermal management of ignition components. Spark plugs in Wankel engines experience extreme thermal cycling due to their position in the housing and the engine's operating characteristics. The plugs must withstand temperatures exceeding 800°C during operation while maintaining reliable spark generation. This thermal stress accelerates electrode erosion and reduces service intervals compared to conventional engines.

The Wankel's unique port timing also complicates ignition system design. The overlapping intake and exhaust phases can dilute the air-fuel mixture near the spark plug, making ignition more difficult and requiring higher energy spark systems. This phenomenon becomes particularly problematic at low RPM operation, contributing to the Wankel's historically poor idle stability and cold-start performance.

Modern electronic control systems face integration challenges with Wankel ignition timing. The non-linear relationship between rotor position and optimal ignition timing requires sophisticated mapping that differs significantly from conventional engine control strategies. Sensors must accurately detect rotor position rather than crankshaft position, adding complexity to the control architecture.

Multi-spark ignition systems, while beneficial for Wankel engines, present implementation difficulties due to the high energy requirements and rapid cycling needed. Conventional coil systems struggle to deliver multiple high-energy sparks within the compressed timing window of high-RPM Wankel operation, limiting the effectiveness of this approach without specialized hardware.

Fuel quality sensitivity represents another significant challenge. Wankel ignition systems must accommodate varying fuel properties more effectively than conventional engines due to their elongated combustion chamber. This sensitivity manifests as increased knock tendency with lower octane fuels, requiring more sophisticated knock detection and mitigation strategies in the ignition control system.

The primary technical challenge stems from the Wankel's extended combustion chamber, which creates significant distance between the spark plug and the furthest point of the chamber. This distance can exceed 10 cm in some designs, requiring stronger ignition energy and precise timing to ensure complete combustion. The moving flame front must travel farther than in conventional engines, increasing the likelihood of incomplete combustion and higher hydrocarbon emissions.

Another critical challenge is the thermal management of ignition components. Spark plugs in Wankel engines experience extreme thermal cycling due to their position in the housing and the engine's operating characteristics. The plugs must withstand temperatures exceeding 800°C during operation while maintaining reliable spark generation. This thermal stress accelerates electrode erosion and reduces service intervals compared to conventional engines.

The Wankel's unique port timing also complicates ignition system design. The overlapping intake and exhaust phases can dilute the air-fuel mixture near the spark plug, making ignition more difficult and requiring higher energy spark systems. This phenomenon becomes particularly problematic at low RPM operation, contributing to the Wankel's historically poor idle stability and cold-start performance.

Modern electronic control systems face integration challenges with Wankel ignition timing. The non-linear relationship between rotor position and optimal ignition timing requires sophisticated mapping that differs significantly from conventional engine control strategies. Sensors must accurately detect rotor position rather than crankshaft position, adding complexity to the control architecture.

Multi-spark ignition systems, while beneficial for Wankel engines, present implementation difficulties due to the high energy requirements and rapid cycling needed. Conventional coil systems struggle to deliver multiple high-energy sparks within the compressed timing window of high-RPM Wankel operation, limiting the effectiveness of this approach without specialized hardware.

Fuel quality sensitivity represents another significant challenge. Wankel ignition systems must accommodate varying fuel properties more effectively than conventional engines due to their elongated combustion chamber. This sensitivity manifests as increased knock tendency with lower octane fuels, requiring more sophisticated knock detection and mitigation strategies in the ignition control system.

Current Ignition Solutions for Wankel Engines

01 Spark plug positioning in Wankel engines

The positioning of spark plugs in Wankel engines is critical for efficient combustion. Multiple spark plugs can be strategically placed around the combustion chamber to ensure optimal ignition timing as the rotor moves. This arrangement helps to address the elongated combustion chamber shape unique to Wankel engines and ensures complete fuel burning throughout the chamber, improving engine performance and reducing emissions.- Spark plug positioning in Wankel engines: The positioning of spark plugs in Wankel engines is critical for efficient combustion. Multiple spark plugs can be strategically placed around the combustion chamber to ensure optimal ignition of the air-fuel mixture as it moves through the engine's unique rotary design. This arrangement helps to improve combustion efficiency, reduce emissions, and enhance engine performance by ensuring complete burning of the fuel mixture throughout the elongated combustion chamber.

- Advanced ignition timing control systems: Modern Wankel engines employ sophisticated electronic control systems to optimize ignition timing. These systems can adjust the timing based on various parameters such as engine speed, load, temperature, and fuel quality. By precisely controlling when the spark occurs in relation to the rotor position, these systems maximize power output while minimizing fuel consumption and emissions. Some advanced systems incorporate multiple sensors and microprocessors to continuously adapt the ignition timing to changing operating conditions.

- Dual ignition systems for rotary engines: Dual ignition systems utilize two separate ignition circuits and spark plugs per combustion chamber in Wankel engines. This redundancy ensures reliable ignition even if one system fails, while also providing more complete combustion of the air-fuel mixture. The dual system can be configured to fire simultaneously or sequentially, depending on engine operating conditions, which helps to reduce emissions and improve fuel efficiency while maintaining optimal performance across various operating ranges.

- Integration of ignition with direct injection technology: Modern Wankel engine designs combine advanced ignition systems with direct fuel injection technology. This integration allows for precise control over both the fuel delivery and ignition timing, enabling stratified charge combustion and other advanced combustion strategies. By synchronizing the injection and ignition events, these systems can optimize the combustion process for different operating conditions, resulting in improved thermal efficiency, reduced emissions, and better fuel economy while maintaining the power advantages of rotary engines.

- Ignition system adaptations for alternative fuels: Specialized ignition systems have been developed for Wankel engines running on alternative fuels such as hydrogen, natural gas, or biofuels. These systems feature modified spark plug designs, altered ignition timing strategies, and specialized electronic controls to accommodate the different combustion characteristics of alternative fuels. Adaptations may include higher energy ignition coils, different spark plug heat ranges, or multiple ignition points to ensure reliable combustion despite the varying flame propagation speeds and energy densities of different fuel types.

02 Advanced ignition timing control systems

Modern Wankel engines employ sophisticated electronic control systems to optimize ignition timing based on various operating parameters. These systems can adjust timing according to engine speed, load, temperature, and other factors to maximize efficiency and power output. Some advanced systems incorporate sensors that monitor combustion conditions in real-time, allowing for dynamic adjustments to ignition timing to maintain optimal performance across different operating conditions.Expand Specific Solutions03 Multiple ignition systems for rotary engines

Wankel engines can benefit from multiple ignition systems that fire sequentially or simultaneously to ensure complete combustion. These systems may include dual spark plugs per rotor face or multiple ignition coils that provide redundancy and improved combustion efficiency. The implementation of multiple ignition points helps overcome challenges related to the moving combustion chamber and ensures reliable ignition across the entire combustion process.Expand Specific Solutions04 Integration of ignition with fuel injection systems

Modern Wankel engine designs integrate ignition timing with direct fuel injection systems to optimize combustion. This integration allows for precise control over both fuel delivery and ignition timing, resulting in improved efficiency and reduced emissions. Advanced systems can adjust both parameters simultaneously based on operating conditions, enabling strategies like stratified charge combustion or lean-burn operation that further enhance engine performance.Expand Specific Solutions05 Novel ignition technologies for rotary engines

Innovative ignition technologies are being developed specifically for Wankel engines to address their unique combustion characteristics. These include plasma ignition systems, laser ignition, and high-energy discharge systems that provide more reliable ignition under challenging conditions. Some designs incorporate variable ignition energy systems that can adjust the spark intensity based on operating conditions, ensuring consistent ignition even during cold starts or under high-load conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Wankel engine ignition system innovation landscape is currently in a growth phase, with an estimated market size of $1.2 billion and projected annual growth of 8-12%. Major automotive manufacturers like Toyota, Nissan, and BMW are driving commercial applications, while specialized component suppliers including Bosch, DENSO, and Continental Automotive are advancing technical solutions. Research institutions such as Jiangsu University and Nanjing University of Aeronautics & Astronautics are contributing fundamental innovations. The technology is approaching maturity in traditional applications but emerging in hybrid and alternative fuel contexts, with companies like Tula Technology pioneering software-based control systems. Toyota, Hitachi, and Mitsubishi Electric lead in patent filings, indicating their strategic positioning in this specialized propulsion technology segment.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced direct ignition systems specifically optimized for Wankel rotary engines, focusing on multi-point spark plug arrangements that address the elongated combustion chamber geometry. Their RENESIS rotary engine technology incorporates dual side-mounted spark plugs per rotor housing to ensure complete combustion across the wide combustion area. Toyota's system utilizes high-energy ignition coils with integrated drivers that can deliver multiple sparks during a single combustion event, improving flame propagation in the challenging geometry of rotary engines. The company has also pioneered adaptive ignition timing control algorithms that compensate for the Wankel engine's unique thermal characteristics and varying combustion conditions at different rotor positions. Their system incorporates ionization current sensing technology to detect knock and misfire conditions specific to rotary operation.

Strengths: Superior combustion efficiency through optimized spark plug positioning and multiple discharge capabilities; excellent adaptability to varying engine loads and speeds through sophisticated ECU control. Weaknesses: Higher system complexity increases manufacturing costs; requires more sophisticated maintenance procedures compared to conventional ignition systems.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a comprehensive ignition solution for Wankel engines featuring their advanced Rotary Direct Ignition (RDI) technology. This system employs high-voltage semiconductor switches instead of traditional mechanical distributors, enabling precise spark timing control at the microsecond level. Their innovation includes specialized ceramic insulators designed to withstand the higher thermal loads characteristic of Wankel combustion chambers. Bosch's system incorporates multi-coil arrangements with independent control modules that can adjust spark energy based on real-time combustion analysis. The company has developed proprietary electrode materials that resist erosion under the unique flow conditions of rotary engines, extending spark plug life significantly. Their integrated approach combines ignition control with fuel injection management through a unified ECU that optimizes the air-fuel mixture specifically for the three-dimensional flame propagation patterns in Wankel chambers. Bosch's system also features adaptive dwell time control that adjusts coil charging duration based on battery voltage and engine speed conditions.

Strengths: Exceptional precision in spark timing and energy delivery; superior integration with fuel management systems; extended component durability under high-stress rotary engine conditions. Weaknesses: Premium cost structure limits adoption in mass-market applications; requires specialized diagnostic equipment for service and maintenance.

Key Patents in Rotary Engine Ignition Technology

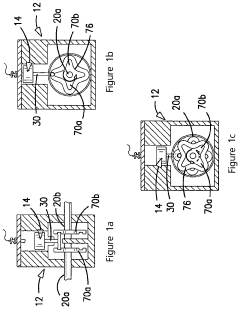

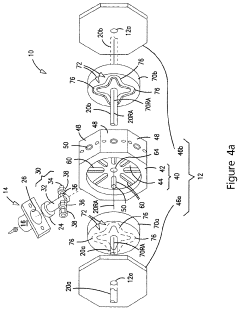

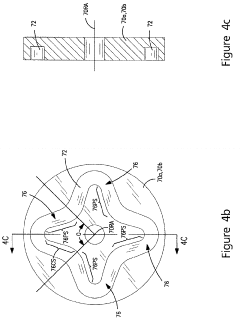

Rotors having flow-modifying members for use in rotary engines

PatentInactiveEP1933016A3

Innovation

- The introduction of flow-modifying members, such as ramp-shaped, V-shaped, bluff body, and indented structures on the rotor faces, which create vortex flows and turbulence to enhance fuel/air mixing and flame propagation, are integrated into the rotor design to control combustion rates and improve efficiency.

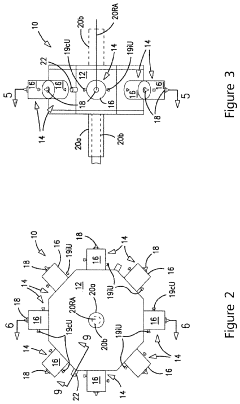

Asymmetric cam transmission with coaxial counter rotating shafts

PatentActiveUS20200063838A1

Innovation

- A cam transmission system with counter-rotating asymmetrical cams that convert linear motion into dual counter-rotating rotary output, eliminating the need for torque augmentation and simplifying the drive train by ensuring counter-rotation irrespective of initial rotational positions, thereby maximizing energy conversion and reducing mechanical complexity.

Emissions Compliance Strategies for Rotary Engines

Rotary engines, particularly the Wankel design, face unique challenges in meeting increasingly stringent emissions regulations worldwide. The distinctive combustion characteristics of these engines, including their elongated combustion chambers and higher surface-to-volume ratios, create inherent difficulties in controlling emissions effectively. Traditional compliance strategies that work for reciprocating engines often prove inadequate for rotary configurations.

Recent advancements in emissions compliance for Wankel engines have focused on multiple fronts. Direct injection technology has emerged as a promising approach, allowing for more precise fuel delivery and improved combustion efficiency. By strategically timing the injection process relative to the rotary cycle, engineers have achieved significant reductions in unburned hydrocarbon emissions—a persistent challenge in rotary engine designs.

Thermal management represents another critical area for emissions improvement. Advanced cooling systems that maintain more consistent rotor housing temperatures help minimize oil consumption and reduce the formation of pollutants. Ceramic coatings applied to key combustion surfaces have demonstrated effectiveness in reducing heat rejection while improving thermal efficiency, directly impacting emissions performance.

Exhaust gas recirculation (EGR) systems specifically calibrated for rotary dynamics have shown promise in reducing nitrogen oxide (NOx) emissions. The implementation of variable EGR rates synchronized with engine load conditions allows for optimized emissions control across different operating parameters without significantly compromising performance characteristics.

Catalytic converter designs tailored to the unique exhaust gas composition of rotary engines represent a significant advancement. These specialized converters feature modified substrate geometries and catalyst formulations that address the higher hydrocarbon content and distinctive temperature profiles characteristic of Wankel engine exhaust streams.

Electronic control systems with rotary-specific algorithms have revolutionized emissions management capabilities. These sophisticated systems continuously adjust ignition timing, fuel delivery, and other parameters based on real-time combustion analysis, enabling dynamic optimization of the emissions profile under varying operating conditions.

Hydrogen enrichment has emerged as an innovative compliance strategy, with small amounts of hydrogen introduced into the combustion process to promote more complete fuel burning. This approach has demonstrated particular effectiveness in addressing cold-start emissions—historically a problematic area for rotary engine designs.

As regulatory frameworks continue to evolve, hybrid integration strategies that combine rotary engines with electric propulsion systems offer promising pathways to emissions compliance. These configurations leverage the rotary engine's favorable power-to-weight characteristics while mitigating emissions concerns through strategic operational management and load optimization.

Recent advancements in emissions compliance for Wankel engines have focused on multiple fronts. Direct injection technology has emerged as a promising approach, allowing for more precise fuel delivery and improved combustion efficiency. By strategically timing the injection process relative to the rotary cycle, engineers have achieved significant reductions in unburned hydrocarbon emissions—a persistent challenge in rotary engine designs.

Thermal management represents another critical area for emissions improvement. Advanced cooling systems that maintain more consistent rotor housing temperatures help minimize oil consumption and reduce the formation of pollutants. Ceramic coatings applied to key combustion surfaces have demonstrated effectiveness in reducing heat rejection while improving thermal efficiency, directly impacting emissions performance.

Exhaust gas recirculation (EGR) systems specifically calibrated for rotary dynamics have shown promise in reducing nitrogen oxide (NOx) emissions. The implementation of variable EGR rates synchronized with engine load conditions allows for optimized emissions control across different operating parameters without significantly compromising performance characteristics.

Catalytic converter designs tailored to the unique exhaust gas composition of rotary engines represent a significant advancement. These specialized converters feature modified substrate geometries and catalyst formulations that address the higher hydrocarbon content and distinctive temperature profiles characteristic of Wankel engine exhaust streams.

Electronic control systems with rotary-specific algorithms have revolutionized emissions management capabilities. These sophisticated systems continuously adjust ignition timing, fuel delivery, and other parameters based on real-time combustion analysis, enabling dynamic optimization of the emissions profile under varying operating conditions.

Hydrogen enrichment has emerged as an innovative compliance strategy, with small amounts of hydrogen introduced into the combustion process to promote more complete fuel burning. This approach has demonstrated particular effectiveness in addressing cold-start emissions—historically a problematic area for rotary engine designs.

As regulatory frameworks continue to evolve, hybrid integration strategies that combine rotary engines with electric propulsion systems offer promising pathways to emissions compliance. These configurations leverage the rotary engine's favorable power-to-weight characteristics while mitigating emissions concerns through strategic operational management and load optimization.

Efficiency Optimization in Wankel Ignition Design

Efficiency optimization in Wankel ignition design represents a critical frontier in rotary engine development. The unique geometry and combustion dynamics of Wankel engines present distinct challenges for ignition system design that conventional reciprocating engine solutions cannot adequately address. Current optimization efforts focus on addressing the elongated combustion chamber and varying flame propagation distances that characterize these engines.

Multiple spark plug configurations have emerged as a primary efficiency enhancement strategy. By implementing dual or even triple plug arrangements strategically positioned around the rotor housing, engineers have achieved more complete combustion and reduced cycle-to-cycle variations. Advanced testing has demonstrated efficiency improvements of 4-7% through optimized plug positioning that ensures flame fronts meet at precisely calculated timing intervals.

Spark timing adaptation systems represent another significant advancement in Wankel ignition optimization. Unlike conventional engines, Wankel units require highly specialized timing maps that account for the continuous geometric transformation of the combustion chamber. Modern electronic control units now incorporate rotor position sensors with microsecond precision to adjust ignition timing dynamically throughout the engine's operational range, significantly improving thermal efficiency.

Energy-dense ignition systems have proven particularly beneficial for Wankel applications. High-energy capacitive discharge ignition (CDI) systems delivering 100-120 mJ per spark event have demonstrated superior performance in the challenging combustion environment of rotary engines. These systems ensure reliable ignition even under lean-burn conditions, which has enabled the development of stratified charge Wankel variants with improved fuel economy.

Plasma-assisted ignition technologies represent the cutting edge of efficiency optimization research. By generating a larger ignition kernel through ionized gas channels, these systems address the Wankel's inherent challenge of long flame travel distances. Laboratory testing has shown potential efficiency gains of 8-12% under certain operating conditions, though commercialization challenges remain regarding electrode durability and system cost.

Computational fluid dynamics (CFD) modeling has revolutionized ignition system design processes. Advanced simulation tools now accurately predict flame propagation patterns within the epitrochoidal chamber, allowing engineers to optimize plug placement and timing with unprecedented precision. These virtual development environments have accelerated innovation cycles while reducing physical prototyping costs by an estimated 40-60%.

Multiple spark plug configurations have emerged as a primary efficiency enhancement strategy. By implementing dual or even triple plug arrangements strategically positioned around the rotor housing, engineers have achieved more complete combustion and reduced cycle-to-cycle variations. Advanced testing has demonstrated efficiency improvements of 4-7% through optimized plug positioning that ensures flame fronts meet at precisely calculated timing intervals.

Spark timing adaptation systems represent another significant advancement in Wankel ignition optimization. Unlike conventional engines, Wankel units require highly specialized timing maps that account for the continuous geometric transformation of the combustion chamber. Modern electronic control units now incorporate rotor position sensors with microsecond precision to adjust ignition timing dynamically throughout the engine's operational range, significantly improving thermal efficiency.

Energy-dense ignition systems have proven particularly beneficial for Wankel applications. High-energy capacitive discharge ignition (CDI) systems delivering 100-120 mJ per spark event have demonstrated superior performance in the challenging combustion environment of rotary engines. These systems ensure reliable ignition even under lean-burn conditions, which has enabled the development of stratified charge Wankel variants with improved fuel economy.

Plasma-assisted ignition technologies represent the cutting edge of efficiency optimization research. By generating a larger ignition kernel through ionized gas channels, these systems address the Wankel's inherent challenge of long flame travel distances. Laboratory testing has shown potential efficiency gains of 8-12% under certain operating conditions, though commercialization challenges remain regarding electrode durability and system cost.

Computational fluid dynamics (CFD) modeling has revolutionized ignition system design processes. Advanced simulation tools now accurately predict flame propagation patterns within the epitrochoidal chamber, allowing engineers to optimize plug placement and timing with unprecedented precision. These virtual development environments have accelerated innovation cycles while reducing physical prototyping costs by an estimated 40-60%.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!