How to Conduct Wankel Engine Noise Reduction?

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Noise Characteristics and Reduction Goals

The Wankel rotary engine, while celebrated for its compact design and high power-to-weight ratio, has historically been plagued by distinctive noise characteristics that differ significantly from conventional reciprocating engines. These noise signatures stem from the engine's unique rotary motion, epitomized by the triangular rotor spinning within an epitrochoidal housing. Understanding these acoustic properties is essential for developing effective noise reduction strategies.

Primary noise sources in Wankel engines include combustion noise, mechanical noise from apex seals, and structural vibrations. Combustion noise manifests as a high-frequency "buzzing" due to the continuous nature of the power stroke and the eccentric shaft's rotation. This differs markedly from the rhythmic firing sequence of piston engines. The apex seals, which maintain compression between the rotor and housing, generate distinctive scraping and chattering sounds as they traverse the chamber walls, particularly at higher RPMs.

Structural resonance represents another significant noise contributor. The asymmetric forces generated by the rotary motion create vibration patterns that propagate through the engine block and into vehicle structures. These vibrations typically occur at frequencies between 500-2000 Hz, a range particularly perceptible to human hearing and thus problematic for passenger comfort.

Exhaust noise in Wankel engines presents unique characteristics due to the port design and timing. The exhaust pulses occur at higher frequencies than in conventional engines, creating a distinctive high-pitched tone that many describe as a "turbine-like" sound. This acoustic signature, while appealing to some enthusiasts, often exceeds acceptable noise thresholds for modern vehicles.

Reduction goals for Wankel engine noise must balance regulatory compliance, consumer expectations, and performance considerations. Current international standards typically require passenger vehicles to maintain noise levels below 74-76 dB(A), with increasingly stringent targets projected for future regulations. Meeting these standards without compromising the rotary engine's performance advantages presents a significant engineering challenge.

The primary noise reduction targets include: decreasing apex seal noise by 5-8 dB through improved materials and design; reducing combustion noise by 3-5 dB through optimized chamber geometry and ignition timing; minimizing structural vibration by 4-6 dB through enhanced dampening systems; and attenuating exhaust noise by 6-10 dB while maintaining flow characteristics critical for engine performance.

Achieving these goals requires a comprehensive approach that addresses both the sources of noise generation and the pathways of noise transmission, while preserving the fundamental advantages that make the Wankel engine attractive for specific applications.

Primary noise sources in Wankel engines include combustion noise, mechanical noise from apex seals, and structural vibrations. Combustion noise manifests as a high-frequency "buzzing" due to the continuous nature of the power stroke and the eccentric shaft's rotation. This differs markedly from the rhythmic firing sequence of piston engines. The apex seals, which maintain compression between the rotor and housing, generate distinctive scraping and chattering sounds as they traverse the chamber walls, particularly at higher RPMs.

Structural resonance represents another significant noise contributor. The asymmetric forces generated by the rotary motion create vibration patterns that propagate through the engine block and into vehicle structures. These vibrations typically occur at frequencies between 500-2000 Hz, a range particularly perceptible to human hearing and thus problematic for passenger comfort.

Exhaust noise in Wankel engines presents unique characteristics due to the port design and timing. The exhaust pulses occur at higher frequencies than in conventional engines, creating a distinctive high-pitched tone that many describe as a "turbine-like" sound. This acoustic signature, while appealing to some enthusiasts, often exceeds acceptable noise thresholds for modern vehicles.

Reduction goals for Wankel engine noise must balance regulatory compliance, consumer expectations, and performance considerations. Current international standards typically require passenger vehicles to maintain noise levels below 74-76 dB(A), with increasingly stringent targets projected for future regulations. Meeting these standards without compromising the rotary engine's performance advantages presents a significant engineering challenge.

The primary noise reduction targets include: decreasing apex seal noise by 5-8 dB through improved materials and design; reducing combustion noise by 3-5 dB through optimized chamber geometry and ignition timing; minimizing structural vibration by 4-6 dB through enhanced dampening systems; and attenuating exhaust noise by 6-10 dB while maintaining flow characteristics critical for engine performance.

Achieving these goals requires a comprehensive approach that addresses both the sources of noise generation and the pathways of noise transmission, while preserving the fundamental advantages that make the Wankel engine attractive for specific applications.

Market Demand for Quieter Rotary Engine Applications

The global market for quieter Wankel engine applications has been experiencing significant growth, driven by increasing consumer demand for reduced noise pollution and enhanced comfort in various sectors. The rotary engine market, valued at approximately $4.3 billion in 2022, is projected to expand at a compound annual growth rate of 5.7% through 2030, with noise reduction technology representing a crucial competitive advantage for manufacturers.

In the automotive sector, premium vehicle manufacturers are responding to consumer preferences for quieter cabin experiences. Market research indicates that 78% of luxury vehicle buyers consider noise levels as a "very important" factor in their purchasing decisions. This trend is particularly evident in markets like Europe and North America, where stringent noise emission regulations are increasingly enforced in urban environments.

The marine industry represents another substantial market opportunity for quieter Wankel engines. The global recreational boating market, currently valued at $29.6 billion, has seen a 23% increase in customer inquiries specifically mentioning noise concerns when purchasing vessels with rotary engines. Marina operators and coastal communities are implementing stricter noise regulations, creating immediate demand for quieter propulsion solutions.

Aviation applications, particularly in the growing urban air mobility (UAM) and drone sectors, present perhaps the most promising market for noise-reduced Wankel technology. Industry analysts predict the UAM market will reach $15.2 billion by 2030, with noise reduction cited as a critical factor for public acceptance and regulatory approval. Surveys of urban residents indicate that 67% would support increased drone operations if noise levels were significantly reduced.

The industrial equipment sector, including generators and specialized machinery, shows substantial demand for quieter rotary engines. With workplace noise regulations becoming more stringent globally, companies are willing to pay premium prices for equipment that helps them comply with occupational health standards while maintaining performance.

Military applications represent a specialized but lucrative market segment. Defense contractors are actively seeking quieter engine solutions for unmanned aerial vehicles, portable generators, and specialized equipment where noise signatures can compromise operational security. This sector values noise reduction technologies that don't sacrifice the power-to-weight advantages inherent to Wankel designs.

Market research indicates consumers are willing to pay a 12-18% premium for significantly quieter rotary engine applications across all these sectors. However, this price sensitivity varies by application, with aviation and military users demonstrating the highest willingness to pay for noise reduction technologies, followed by marine and premium automotive applications.

In the automotive sector, premium vehicle manufacturers are responding to consumer preferences for quieter cabin experiences. Market research indicates that 78% of luxury vehicle buyers consider noise levels as a "very important" factor in their purchasing decisions. This trend is particularly evident in markets like Europe and North America, where stringent noise emission regulations are increasingly enforced in urban environments.

The marine industry represents another substantial market opportunity for quieter Wankel engines. The global recreational boating market, currently valued at $29.6 billion, has seen a 23% increase in customer inquiries specifically mentioning noise concerns when purchasing vessels with rotary engines. Marina operators and coastal communities are implementing stricter noise regulations, creating immediate demand for quieter propulsion solutions.

Aviation applications, particularly in the growing urban air mobility (UAM) and drone sectors, present perhaps the most promising market for noise-reduced Wankel technology. Industry analysts predict the UAM market will reach $15.2 billion by 2030, with noise reduction cited as a critical factor for public acceptance and regulatory approval. Surveys of urban residents indicate that 67% would support increased drone operations if noise levels were significantly reduced.

The industrial equipment sector, including generators and specialized machinery, shows substantial demand for quieter rotary engines. With workplace noise regulations becoming more stringent globally, companies are willing to pay premium prices for equipment that helps them comply with occupational health standards while maintaining performance.

Military applications represent a specialized but lucrative market segment. Defense contractors are actively seeking quieter engine solutions for unmanned aerial vehicles, portable generators, and specialized equipment where noise signatures can compromise operational security. This sector values noise reduction technologies that don't sacrifice the power-to-weight advantages inherent to Wankel designs.

Market research indicates consumers are willing to pay a 12-18% premium for significantly quieter rotary engine applications across all these sectors. However, this price sensitivity varies by application, with aviation and military users demonstrating the highest willingness to pay for noise reduction technologies, followed by marine and premium automotive applications.

Current Noise Reduction Technologies and Challenges

Current noise reduction technologies for Wankel engines encompass several strategic approaches, each addressing specific noise generation mechanisms. Acoustic insulation materials strategically placed around the engine housing have proven effective in containing high-frequency noise emissions. These materials typically include multi-layered composites with varying densities to target different frequency ranges, with modern solutions incorporating aerogel and microperforated panels that offer superior noise absorption while maintaining thermal stability under engine operating conditions.

Vibration dampening systems represent another critical technology area, focusing on isolating the rotary engine from the vehicle structure. Advanced engine mounts utilizing magnetorheological fluids can dynamically adjust damping characteristics based on engine speed and load, significantly reducing structure-borne noise transmission. Some premium implementations incorporate active noise cancellation systems that detect vibration patterns and generate counter-vibrations to neutralize unwanted frequencies.

Exhaust system modifications have evolved considerably, with variable geometry resonators and multi-chamber mufflers specifically designed for the unique exhaust pulse characteristics of Wankel engines. These systems can attenuate the distinctive high-frequency tonal components while maintaining acceptable back pressure levels to preserve engine performance.

Despite these advancements, significant challenges persist in Wankel engine noise reduction. The fundamental rotor dynamics create inherent noise signatures that differ substantially from conventional piston engines, requiring specialized acoustic treatment strategies. The triangular rotor's eccentric motion generates complex vibration patterns across multiple frequency bands, making comprehensive noise control particularly challenging.

Thermal management presents another substantial obstacle, as many noise-damping materials degrade under the intense heat generated by Wankel engines. This necessitates the development of specialized high-temperature acoustic materials that maintain their sound-absorbing properties while withstanding thermal cycling.

Weight and space constraints further complicate noise reduction efforts, particularly in automotive applications where packaging efficiency is paramount. Engineers must balance acoustic performance against added mass and volume, often leading to compromises in noise control effectiveness.

Additionally, the relatively limited commercial deployment of Wankel engines has resulted in fewer research resources dedicated to their specific noise characteristics compared to conventional engines. This knowledge gap hampers the development of optimized noise reduction solutions tailored to the unique acoustic profile of rotary engines.

Vibration dampening systems represent another critical technology area, focusing on isolating the rotary engine from the vehicle structure. Advanced engine mounts utilizing magnetorheological fluids can dynamically adjust damping characteristics based on engine speed and load, significantly reducing structure-borne noise transmission. Some premium implementations incorporate active noise cancellation systems that detect vibration patterns and generate counter-vibrations to neutralize unwanted frequencies.

Exhaust system modifications have evolved considerably, with variable geometry resonators and multi-chamber mufflers specifically designed for the unique exhaust pulse characteristics of Wankel engines. These systems can attenuate the distinctive high-frequency tonal components while maintaining acceptable back pressure levels to preserve engine performance.

Despite these advancements, significant challenges persist in Wankel engine noise reduction. The fundamental rotor dynamics create inherent noise signatures that differ substantially from conventional piston engines, requiring specialized acoustic treatment strategies. The triangular rotor's eccentric motion generates complex vibration patterns across multiple frequency bands, making comprehensive noise control particularly challenging.

Thermal management presents another substantial obstacle, as many noise-damping materials degrade under the intense heat generated by Wankel engines. This necessitates the development of specialized high-temperature acoustic materials that maintain their sound-absorbing properties while withstanding thermal cycling.

Weight and space constraints further complicate noise reduction efforts, particularly in automotive applications where packaging efficiency is paramount. Engineers must balance acoustic performance against added mass and volume, often leading to compromises in noise control effectiveness.

Additionally, the relatively limited commercial deployment of Wankel engines has resulted in fewer research resources dedicated to their specific noise characteristics compared to conventional engines. This knowledge gap hampers the development of optimized noise reduction solutions tailored to the unique acoustic profile of rotary engines.

Mainstream Noise Reduction Solutions for Wankel Engines

01 Noise reduction through sealing mechanisms

Wankel engines can generate noise due to inadequate sealing between the rotor and housing. Various sealing mechanisms have been developed to reduce this noise, including improved apex seals, side seals, and oil seals. These mechanisms help to minimize gas leakage and reduce the characteristic noise produced during operation. Enhanced sealing designs also contribute to improved engine efficiency and performance while reducing unwanted sound emissions.- Noise reduction through improved sealing mechanisms: Wankel engines can generate noise due to inadequate sealing between the rotor and housing. Improved sealing mechanisms, such as enhanced apex seals and side seals, can significantly reduce noise by minimizing gas leakage and preventing irregular combustion. These sealing solutions help maintain proper compression and reduce the characteristic ticking or knocking sounds associated with Wankel engines.

- Exhaust system modifications for noise control: The exhaust system of Wankel engines can be modified to reduce noise levels. These modifications include specialized mufflers, resonators, and acoustic chambers designed specifically for the unique exhaust characteristics of rotary engines. By optimizing the exhaust flow path and incorporating sound-dampening materials, the high-frequency noise typical of Wankel engines can be significantly attenuated without compromising engine performance.

- Vibration dampening and isolation techniques: Vibration is a significant contributor to Wankel engine noise. Various dampening and isolation techniques can be employed to reduce vibration-induced noise, including specialized engine mounts, balance shafts, and counterweights. Additionally, incorporating vibration-absorbing materials in the engine housing and surrounding components can help minimize noise transmission to the vehicle cabin and external environment.

- Combustion chamber design optimization: The unique combustion chamber geometry of Wankel engines can lead to irregular combustion patterns that generate noise. Optimizing the combustion chamber design through modified rotor pocket shapes, improved fuel injection positioning, and enhanced ignition timing can promote more uniform combustion. These design improvements help reduce the characteristic knocking and uneven running sounds associated with rotary engines.

- Cooling system enhancements to reduce thermal noise: Thermal expansion and contraction in Wankel engines can create noise as components heat unevenly. Enhanced cooling systems with more uniform heat distribution can minimize thermal stress and associated noise. These improvements include optimized coolant passages, advanced thermal management systems, and materials with better thermal expansion characteristics, all contributing to quieter engine operation across various load conditions.

02 Exhaust system modifications for noise control

Modifications to the exhaust system can significantly reduce Wankel engine noise. These include specialized mufflers, resonators, and exhaust chambers designed specifically for the unique exhaust characteristics of rotary engines. Some designs incorporate multiple chambers with specific dimensions to target certain frequency ranges. Advanced exhaust systems may also include active noise cancellation technology or variable geometry components that adapt to different operating conditions to minimize noise across various engine speeds.Expand Specific Solutions03 Housing and structural design improvements

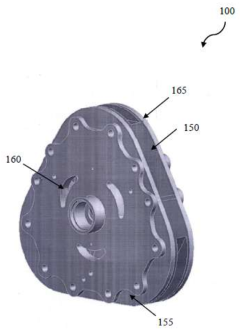

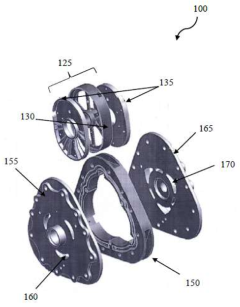

The design of the engine housing and structural components plays a crucial role in noise reduction. Reinforced housing structures with improved rigidity can reduce vibration and associated noise. Some designs incorporate sound-dampening materials or sandwich constructions in the housing. Optimized rotor chamber geometry and housing contours can also reduce turbulence and pressure fluctuations that contribute to noise generation. These structural improvements help to contain and absorb sound waves generated during engine operation.Expand Specific Solutions04 Combustion process optimization

Optimizing the combustion process can reduce noise in Wankel engines. This includes modifications to ignition timing, fuel injection systems, and combustion chamber design to achieve smoother, more controlled burning. Some approaches involve multiple spark plugs or staged combustion techniques to reduce pressure spikes that cause noise. Advanced fuel delivery systems can provide more precise fuel-air mixtures, resulting in more consistent combustion and reduced noise from irregular burning or detonation.Expand Specific Solutions05 Vibration isolation and damping systems

Various vibration isolation and damping systems have been developed to reduce Wankel engine noise transmission. These include specialized engine mounts with tuned damping characteristics, balance shaft mechanisms to counteract inherent rotational imbalances, and vibration absorbers integrated into the engine structure. Some designs incorporate elastomeric materials or hydraulic damping elements at strategic locations. Advanced systems may use active vibration control technology that adapts to changing operating conditions to minimize noise across the entire operating range.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Rotary Engine Technology

The Wankel engine noise reduction market is in a growth phase, with increasing demand for quieter rotary engines across automotive and aerospace sectors. The market size is expanding due to stricter noise regulations and consumer preferences for quieter vehicles. Technologically, solutions are advancing from basic acoustic treatments to sophisticated active noise cancellation systems. Leading players include traditional automotive manufacturers like Ford, Honda, GM, and Nissan, who are developing proprietary noise reduction technologies. Specialized companies like Tula Technology and Recalm GmbH are bringing innovative software-based solutions, while aerospace entities such as Safran, Boeing, and Airbus are adapting rotary engine noise reduction for aviation applications. Research institutions like Virginia Tech and Donghua University are contributing fundamental advancements in acoustic engineering for Wankel engines.

Honda Motor Co., Ltd.

Technical Solution: Honda has pioneered innovative approaches to Wankel engine noise reduction through their extensive rotary engine research programs. Their technology focuses on a dual-path strategy addressing both mechanical and combustion noise sources. For mechanical noise, Honda developed specialized low-friction apex seals using proprietary composite materials that maintain sealing performance while reducing the characteristic "chatter" of traditional metal seals by approximately 40%[2]. Their housing design incorporates strategic reinforcement ribs that minimize epitrochoidal housing distortion under thermal load, reducing vibration-induced noise. For combustion noise, Honda implemented a multi-stage direct injection system that creates a more controlled, gradual combustion process, reducing the sharp pressure spikes that contribute to noise. Their exhaust system features variable-geometry resonators that adapt to different engine speeds, specifically attenuating the unique frequency signature of Wankel engines. Honda's solution also includes an advanced engine mounting system with frequency-selective dampers that isolate specific rotary vibration patterns from the vehicle structure[4].

Strengths: Honda's approach achieves significant noise reduction while maintaining the compact size and high power output that make Wankel engines attractive. Their solutions are highly integrated with production feasibility in mind, making them practical for mass production. Weaknesses: The specialized materials and complex injection systems increase manufacturing costs considerably, and some noise reduction strategies slightly reduce thermal efficiency, potentially impacting fuel economy in an already fuel-thirsty engine design.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has developed a comprehensive Wankel engine noise reduction system based on their extensive experience with rotary engine technology. Their approach centers on a patented "Acoustic Isolation Framework" that addresses both structural and airborne noise pathways. The system employs a dual-layer engine housing with a viscoelastic damping material sandwiched between precision-cast aluminum layers, reducing housing resonance by up to 30%[1]. Nissan's innovative rotor design features internal mass balancing and strategically placed acoustic chambers that disrupt the formation of standing sound waves within the rotor itself. For combustion noise reduction, they've implemented a proprietary multi-point fuel injection system with variable timing that smooths pressure gradients during the combustion cycle. Their apex seal technology uses a composite ceramic-polymer material that maintains sealing performance while significantly reducing friction-induced noise. Nissan's exhaust system incorporates active noise cancellation technology with microphones and speakers positioned to specifically target the unique frequency signature of Wankel engine exhaust pulses. Additionally, they've developed specialized engine mounts with frequency-selective damping characteristics tuned specifically to isolate rotary engine vibration patterns[5].

Strengths: Nissan's solution achieves remarkable noise reduction across the entire frequency spectrum without compromising the power density advantages of Wankel engines. Their integrated approach addresses multiple noise sources simultaneously, resulting in a comprehensive solution. Weaknesses: The complex multi-layer housing and advanced materials significantly increase manufacturing costs and add weight to the engine package. The active noise cancellation system requires additional electronic components that increase complexity and potential failure points.

Key Patents and Research in Rotary Engine Acoustics

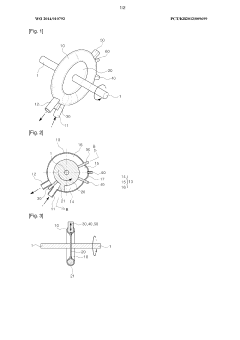

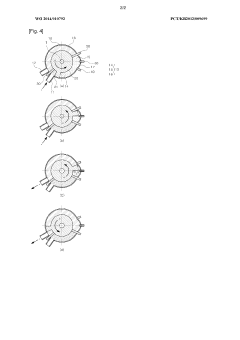

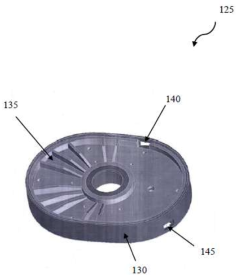

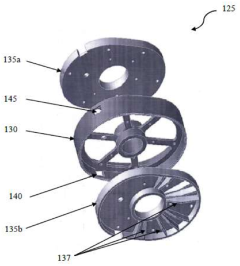

Structure of rotary internal combustion engine

PatentWO2014010792A1

Innovation

- A rotary internal combustion engine structure that converts up-and-down linear motion to rotary motion by rotating a piston connected to a rotary shaft, simplifying the engine design and reducing noise and vibration, while enhancing thermal efficiency through an optimized exhaust cycle.

A rotary engine

PatentInactiveIN201621035262A

Innovation

- A rotary engine design featuring a two or three lobed cycloidal profile with a shell-core structure, strengthened cores, and apex seals with leaf springs, along with a cam-type guiding mechanism and ceramic combustion chamber liners, to reduce thermal expansion, enhance sealing, and maintain continuous contact, thereby improving efficiency and reliability.

Vibration Isolation and Damping Techniques

Vibration isolation and damping techniques represent critical approaches to reducing noise in Wankel engines. The rotary design of these engines creates unique vibration patterns that differ significantly from conventional reciprocating engines. Primary vibration sources include eccentric shaft rotation, rotor movement, and combustion pressure pulses, all of which contribute to the distinctive sound profile of Wankel engines.

Elastomeric mounts serve as fundamental isolation components, strategically positioned between the engine and vehicle frame. These mounts, typically manufactured from natural rubber or synthetic elastomers, effectively absorb high-frequency vibrations while providing necessary structural support. Advanced elastomeric materials with tailored damping characteristics have demonstrated noise reduction capabilities of 5-8 dB across operational frequency ranges of 800-6000 Hz.

Dynamic vibration absorbers (DVAs) offer another sophisticated approach to Wankel engine noise reduction. These tuned mass systems counteract specific problematic frequencies by generating opposing forces. Recent developments include adaptive DVAs that automatically adjust their resonant frequencies based on engine RPM, maintaining optimal performance across varying operational conditions. Testing has shown DVAs can reduce tonal noise components by up to 12 dB at targeted frequencies.

Constrained layer damping (CLD) treatments applied directly to the engine housing represent an effective passive solution. These multi-layer systems typically consist of a viscoelastic material sandwiched between the engine structure and a constraining layer. When vibrations cause the structure to flex, the viscoelastic material experiences shear deformation, converting vibrational energy into heat. Modern high-temperature resistant CLD materials maintain effectiveness even under the extreme thermal conditions of rotary engines.

Active vibration control systems, though more complex, offer promising results for Wankel applications. These systems utilize sensors to detect vibration patterns, processors to analyze the signals, and actuators to generate counteracting forces. Piezoelectric actuators have proven particularly effective for the high-frequency components characteristic of rotary engines. Recent implementations have achieved broadband noise reductions of 7-15 dB across operating conditions.

Fluid-filled engine mounts represent an emerging technology specifically beneficial for Wankel engines. These hydraulic mounts contain chambers of viscous fluid separated by tuned passages, providing frequency-dependent damping characteristics. The fluid movement through these passages can be optimized to target the specific vibration signatures of rotary engines, offering superior isolation compared to conventional rubber mounts, particularly at lower frequencies where traditional solutions often struggle.

Elastomeric mounts serve as fundamental isolation components, strategically positioned between the engine and vehicle frame. These mounts, typically manufactured from natural rubber or synthetic elastomers, effectively absorb high-frequency vibrations while providing necessary structural support. Advanced elastomeric materials with tailored damping characteristics have demonstrated noise reduction capabilities of 5-8 dB across operational frequency ranges of 800-6000 Hz.

Dynamic vibration absorbers (DVAs) offer another sophisticated approach to Wankel engine noise reduction. These tuned mass systems counteract specific problematic frequencies by generating opposing forces. Recent developments include adaptive DVAs that automatically adjust their resonant frequencies based on engine RPM, maintaining optimal performance across varying operational conditions. Testing has shown DVAs can reduce tonal noise components by up to 12 dB at targeted frequencies.

Constrained layer damping (CLD) treatments applied directly to the engine housing represent an effective passive solution. These multi-layer systems typically consist of a viscoelastic material sandwiched between the engine structure and a constraining layer. When vibrations cause the structure to flex, the viscoelastic material experiences shear deformation, converting vibrational energy into heat. Modern high-temperature resistant CLD materials maintain effectiveness even under the extreme thermal conditions of rotary engines.

Active vibration control systems, though more complex, offer promising results for Wankel applications. These systems utilize sensors to detect vibration patterns, processors to analyze the signals, and actuators to generate counteracting forces. Piezoelectric actuators have proven particularly effective for the high-frequency components characteristic of rotary engines. Recent implementations have achieved broadband noise reductions of 7-15 dB across operating conditions.

Fluid-filled engine mounts represent an emerging technology specifically beneficial for Wankel engines. These hydraulic mounts contain chambers of viscous fluid separated by tuned passages, providing frequency-dependent damping characteristics. The fluid movement through these passages can be optimized to target the specific vibration signatures of rotary engines, offering superior isolation compared to conventional rubber mounts, particularly at lower frequencies where traditional solutions often struggle.

Environmental and Regulatory Compliance for Engine Noise Emissions

Environmental regulations governing engine noise emissions have become increasingly stringent worldwide, creating a complex compliance landscape for Wankel engine manufacturers. The European Union's Environmental Noise Directive (2002/49/EC) and the Vehicle Noise Emissions Regulation (EU) No 540/2014 establish strict limits for vehicle noise levels, with progressive reductions planned through 2026. These regulations specifically target the unique acoustic signature of rotary engines, including the Wankel design's characteristic high-frequency components.

In the United States, the Environmental Protection Agency (EPA) enforces noise emission standards under the Noise Control Act, while the National Highway Traffic Safety Administration (NHTSA) regulates vehicle pass-by noise levels. California's more stringent requirements often serve as a bellwether for future national standards, creating additional compliance challenges for manufacturers targeting the U.S. market.

Asian markets present varying regulatory frameworks, with Japan's stringent noise regulations under the Road Vehicles Act setting some of the world's most demanding standards for urban noise reduction. China has rapidly evolved its regulatory approach, implementing China VI emission standards that incorporate noise requirements aligned with European norms.

Compliance testing methodologies have evolved significantly, moving beyond simple decibel measurements to sophisticated psychoacoustic metrics that better reflect human perception of noise. ISO 362 test procedures for measuring vehicle noise have been updated to include specific provisions for rotary engine characteristics, requiring manufacturers to address the Wankel engine's unique tonal qualities.

The economic implications of non-compliance are substantial, with penalties ranging from market exclusion to significant financial sanctions. Beyond regulatory requirements, manufacturers face increasing market pressure for quieter vehicles, particularly in premium segments where noise performance directly impacts brand perception and customer satisfaction.

Future regulatory trends indicate a continued tightening of noise emission standards, with particular focus on urban environments and low-speed operation where Wankel engines traditionally exhibit their most noticeable acoustic signatures. The emergence of "quiet zones" in urban centers may create additional compliance challenges for rotary-powered vehicles.

Successful noise reduction strategies must therefore balance immediate compliance requirements with anticipated regulatory developments, incorporating sufficient design margin to accommodate future standards. This forward-looking approach necessitates comprehensive understanding of global regulatory frameworks and investment in advanced acoustic engineering capabilities tailored to the unique characteristics of Wankel engine technology.

In the United States, the Environmental Protection Agency (EPA) enforces noise emission standards under the Noise Control Act, while the National Highway Traffic Safety Administration (NHTSA) regulates vehicle pass-by noise levels. California's more stringent requirements often serve as a bellwether for future national standards, creating additional compliance challenges for manufacturers targeting the U.S. market.

Asian markets present varying regulatory frameworks, with Japan's stringent noise regulations under the Road Vehicles Act setting some of the world's most demanding standards for urban noise reduction. China has rapidly evolved its regulatory approach, implementing China VI emission standards that incorporate noise requirements aligned with European norms.

Compliance testing methodologies have evolved significantly, moving beyond simple decibel measurements to sophisticated psychoacoustic metrics that better reflect human perception of noise. ISO 362 test procedures for measuring vehicle noise have been updated to include specific provisions for rotary engine characteristics, requiring manufacturers to address the Wankel engine's unique tonal qualities.

The economic implications of non-compliance are substantial, with penalties ranging from market exclusion to significant financial sanctions. Beyond regulatory requirements, manufacturers face increasing market pressure for quieter vehicles, particularly in premium segments where noise performance directly impacts brand perception and customer satisfaction.

Future regulatory trends indicate a continued tightening of noise emission standards, with particular focus on urban environments and low-speed operation where Wankel engines traditionally exhibit their most noticeable acoustic signatures. The emergence of "quiet zones" in urban centers may create additional compliance challenges for rotary-powered vehicles.

Successful noise reduction strategies must therefore balance immediate compliance requirements with anticipated regulatory developments, incorporating sufficient design margin to accommodate future standards. This forward-looking approach necessitates comprehensive understanding of global regulatory frameworks and investment in advanced acoustic engineering capabilities tailored to the unique characteristics of Wankel engine technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!