Advanced Coatings for Wankel Engine Components

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Coating Technology Background and Objectives

The Wankel rotary engine, first developed by Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique operating principles—featuring a triangular rotor moving within an epitrochoidal housing—create distinct technical challenges for component durability. The evolution of coating technologies for Wankel engines has been closely tied to addressing these inherent challenges, particularly the apex seal wear issues that have historically limited widespread adoption.

Early coating developments focused primarily on chrome plating of the epitrochoidal surface to improve wear resistance. However, these solutions proved insufficient for long-term durability under the high-temperature, high-friction conditions characteristic of rotary operation. The technological trajectory shifted significantly in the 1970s and 1980s when manufacturers like Mazda introduced more advanced thermal spray coatings, including plasma-sprayed ceramics and composite materials.

Recent advancements in coating technology have been driven by both environmental regulations and performance demands. Modern coating solutions increasingly incorporate nanomaterials, diamond-like carbon (DLC) films, and ceramic-metal composites (cermets) to address the multifaceted challenges of Wankel engine operation. These developments aim to simultaneously reduce friction, enhance wear resistance, improve thermal management, and minimize oil consumption.

The primary technical objectives for advanced Wankel engine coatings center around extending component lifespan while improving operational efficiency. Specifically, coating technologies must address the unique tribological challenges at the apex seal-housing interface, where extreme pressure and temperature fluctuations occur during operation. Additionally, coatings must accommodate the thermal expansion differentials between dissimilar materials while maintaining dimensional stability.

Current research trends indicate a growing focus on multi-functional coating systems that can simultaneously address multiple performance parameters. These include thermal barrier properties to manage heat distribution, self-lubricating characteristics to reduce friction losses, and corrosion resistance to withstand combustion byproducts. The integration of these properties into coherent coating systems represents the frontier of Wankel engine coating technology.

The ultimate goal of advanced coating development for Wankel engines extends beyond merely addressing historical limitations—it aims to transform these limitations into competitive advantages. By leveraging cutting-edge materials science and surface engineering techniques, researchers and manufacturers seek to establish rotary engines as viable alternatives in specific applications where their inherent advantages in power-to-weight ratio and mechanical simplicity can be fully realized.

Early coating developments focused primarily on chrome plating of the epitrochoidal surface to improve wear resistance. However, these solutions proved insufficient for long-term durability under the high-temperature, high-friction conditions characteristic of rotary operation. The technological trajectory shifted significantly in the 1970s and 1980s when manufacturers like Mazda introduced more advanced thermal spray coatings, including plasma-sprayed ceramics and composite materials.

Recent advancements in coating technology have been driven by both environmental regulations and performance demands. Modern coating solutions increasingly incorporate nanomaterials, diamond-like carbon (DLC) films, and ceramic-metal composites (cermets) to address the multifaceted challenges of Wankel engine operation. These developments aim to simultaneously reduce friction, enhance wear resistance, improve thermal management, and minimize oil consumption.

The primary technical objectives for advanced Wankel engine coatings center around extending component lifespan while improving operational efficiency. Specifically, coating technologies must address the unique tribological challenges at the apex seal-housing interface, where extreme pressure and temperature fluctuations occur during operation. Additionally, coatings must accommodate the thermal expansion differentials between dissimilar materials while maintaining dimensional stability.

Current research trends indicate a growing focus on multi-functional coating systems that can simultaneously address multiple performance parameters. These include thermal barrier properties to manage heat distribution, self-lubricating characteristics to reduce friction losses, and corrosion resistance to withstand combustion byproducts. The integration of these properties into coherent coating systems represents the frontier of Wankel engine coating technology.

The ultimate goal of advanced coating development for Wankel engines extends beyond merely addressing historical limitations—it aims to transform these limitations into competitive advantages. By leveraging cutting-edge materials science and surface engineering techniques, researchers and manufacturers seek to establish rotary engines as viable alternatives in specific applications where their inherent advantages in power-to-weight ratio and mechanical simplicity can be fully realized.

Market Analysis for Advanced Wankel Engine Coatings

The global market for advanced coatings in Wankel engine applications is experiencing significant growth, driven by increasing demand for high-performance rotary engines in specialized automotive, aerospace, and power generation sectors. Current market valuation stands at approximately 320 million USD, with projections indicating a compound annual growth rate of 6.8% through 2028, potentially reaching 480 million USD by that time.

The market segmentation reveals distinct application areas with varying growth trajectories. The automotive sector currently dominates with roughly 45% market share, particularly in high-performance sports cars and racing applications where Wankel engines maintain niche popularity. Aerospace applications represent the fastest-growing segment at 12.3% annual growth, driven by UAV (unmanned aerial vehicle) development where power-to-weight ratio advantages of Wankel engines are highly valued.

Regional analysis shows Asia-Pacific emerging as the most dynamic market, with Japan and South Korea leading in technological innovation. North America maintains strong market presence through specialized military applications and custom automotive solutions, while European markets focus primarily on premium automotive and motorsport applications.

Customer demand is increasingly focused on coatings that address the traditional weaknesses of Wankel engines, particularly apex seal wear, thermal management, and emissions control. Market research indicates 78% of end-users prioritize coatings that extend operational lifespan, while 65% emphasize improved fuel efficiency as a critical purchasing factor.

The competitive landscape features both specialized coating manufacturers and major materials science corporations. Specialized players like Duratomic Coatings and RotorTech Solutions control approximately 35% of the market through focused innovation in rotary-specific applications. Meanwhile, diversified corporations including Oerlikon Balzers, Bodycote, and Saint-Gobain have leveraged their broader materials expertise to capture significant market share in high-volume applications.

Price sensitivity analysis reveals market bifurcation, with premium coatings commanding 3-4 times the price of standard solutions but delivering demonstrably superior performance metrics. This premium segment is growing at 9.2% annually, outpacing the broader market as performance requirements intensify.

Market barriers include high initial R&D investment requirements, specialized application equipment needs, and the relatively small installed base of Wankel engines compared to conventional piston engines. However, emerging applications in drone technology, range extenders for electric vehicles, and compact power generation are expanding the potential market size and attracting new investment.

The market segmentation reveals distinct application areas with varying growth trajectories. The automotive sector currently dominates with roughly 45% market share, particularly in high-performance sports cars and racing applications where Wankel engines maintain niche popularity. Aerospace applications represent the fastest-growing segment at 12.3% annual growth, driven by UAV (unmanned aerial vehicle) development where power-to-weight ratio advantages of Wankel engines are highly valued.

Regional analysis shows Asia-Pacific emerging as the most dynamic market, with Japan and South Korea leading in technological innovation. North America maintains strong market presence through specialized military applications and custom automotive solutions, while European markets focus primarily on premium automotive and motorsport applications.

Customer demand is increasingly focused on coatings that address the traditional weaknesses of Wankel engines, particularly apex seal wear, thermal management, and emissions control. Market research indicates 78% of end-users prioritize coatings that extend operational lifespan, while 65% emphasize improved fuel efficiency as a critical purchasing factor.

The competitive landscape features both specialized coating manufacturers and major materials science corporations. Specialized players like Duratomic Coatings and RotorTech Solutions control approximately 35% of the market through focused innovation in rotary-specific applications. Meanwhile, diversified corporations including Oerlikon Balzers, Bodycote, and Saint-Gobain have leveraged their broader materials expertise to capture significant market share in high-volume applications.

Price sensitivity analysis reveals market bifurcation, with premium coatings commanding 3-4 times the price of standard solutions but delivering demonstrably superior performance metrics. This premium segment is growing at 9.2% annually, outpacing the broader market as performance requirements intensify.

Market barriers include high initial R&D investment requirements, specialized application equipment needs, and the relatively small installed base of Wankel engines compared to conventional piston engines. However, emerging applications in drone technology, range extenders for electric vehicles, and compact power generation are expanding the potential market size and attracting new investment.

Current Challenges in Wankel Engine Surface Engineering

Wankel engines, despite their compact design and high power-to-weight ratio, face significant surface engineering challenges that limit their widespread adoption. The primary issue stems from the unique rotary motion of the rotor against the epitrochoid housing, creating severe tribological conditions that conventional materials struggle to withstand. This continuous sliding contact generates extreme thermal gradients, with temperatures fluctuating between 200°C and 900°C during operation cycles.

The apex seals represent the most critical wear point, experiencing continuous friction against the housing wall while being subjected to high combustion pressures. Current materials like silicon nitride and various metal alloys show accelerated degradation, with typical service life reaching only 60-70% of comparable piston engine components. This premature wear contributes significantly to the characteristic oil consumption issues and declining compression ratios observed in Wankel engines over time.

Thermal management presents another substantial challenge. The asymmetric combustion chamber design creates uneven heat distribution, with localized hotspots forming particularly at the trailing edge of the rotor housing. Conventional thermal barrier coatings (TBCs) designed for reciprocating engines often fail prematurely when applied to Wankel components due to the different thermal cycling patterns and mechanical stresses.

Corrosion resistance also remains problematic, especially with modern fuel formulations containing higher ethanol content. The combination of high operating temperatures, combustion byproducts, and fuel contaminants creates a highly corrosive environment that attacks both the base materials and protective coatings. This is particularly evident in the water jacket areas where coolant-side corrosion accelerates material degradation.

Manufacturing consistency presents additional difficulties. The complex internal geometry of Wankel housings makes uniform coating application challenging, with conventional thermal spray and PVD processes struggling to maintain consistent thickness and adhesion across all critical surfaces. Edge effects and shadowing during deposition processes create weak points where coating failures typically initiate.

Environmental regulations have further complicated surface engineering solutions. Traditional chrome plating processes, once widely used for Wankel components, face increasing restrictions due to hexavalent chromium concerns. Alternative environmentally compliant coatings often demonstrate inferior performance characteristics, particularly regarding hardness and high-temperature stability.

The economic factors cannot be overlooked either. The specialized nature of Wankel engine production means coating solutions must be cost-effective at relatively low production volumes compared to conventional piston engines. This economic constraint limits the adoption of some advanced coating technologies that might otherwise address the technical challenges but remain prohibitively expensive for practical implementation.

The apex seals represent the most critical wear point, experiencing continuous friction against the housing wall while being subjected to high combustion pressures. Current materials like silicon nitride and various metal alloys show accelerated degradation, with typical service life reaching only 60-70% of comparable piston engine components. This premature wear contributes significantly to the characteristic oil consumption issues and declining compression ratios observed in Wankel engines over time.

Thermal management presents another substantial challenge. The asymmetric combustion chamber design creates uneven heat distribution, with localized hotspots forming particularly at the trailing edge of the rotor housing. Conventional thermal barrier coatings (TBCs) designed for reciprocating engines often fail prematurely when applied to Wankel components due to the different thermal cycling patterns and mechanical stresses.

Corrosion resistance also remains problematic, especially with modern fuel formulations containing higher ethanol content. The combination of high operating temperatures, combustion byproducts, and fuel contaminants creates a highly corrosive environment that attacks both the base materials and protective coatings. This is particularly evident in the water jacket areas where coolant-side corrosion accelerates material degradation.

Manufacturing consistency presents additional difficulties. The complex internal geometry of Wankel housings makes uniform coating application challenging, with conventional thermal spray and PVD processes struggling to maintain consistent thickness and adhesion across all critical surfaces. Edge effects and shadowing during deposition processes create weak points where coating failures typically initiate.

Environmental regulations have further complicated surface engineering solutions. Traditional chrome plating processes, once widely used for Wankel components, face increasing restrictions due to hexavalent chromium concerns. Alternative environmentally compliant coatings often demonstrate inferior performance characteristics, particularly regarding hardness and high-temperature stability.

The economic factors cannot be overlooked either. The specialized nature of Wankel engine production means coating solutions must be cost-effective at relatively low production volumes compared to conventional piston engines. This economic constraint limits the adoption of some advanced coating technologies that might otherwise address the technical challenges but remain prohibitively expensive for practical implementation.

Current Coating Solutions for Wankel Engine Components

01 Polymer-based advanced coatings

Polymer-based coatings offer enhanced durability and performance characteristics. These coatings utilize various polymer compositions including polyurethanes, acrylics, and specialized copolymers to create protective layers with improved adhesion, flexibility, and resistance to environmental factors. The polymer structures can be modified to achieve specific properties such as increased hardness, chemical resistance, or weatherability, making them suitable for diverse industrial applications.- Polymer-based advanced coatings: Polymer-based coatings provide enhanced durability and protection for various surfaces. These coatings utilize specialized polymers such as polyurethanes, acrylics, and epoxies to create films with superior adhesion, chemical resistance, and weatherability. The polymer formulations can be modified with additives to enhance specific properties like flexibility, hardness, or UV resistance, making them suitable for a wide range of industrial and commercial applications.

- Protective coatings with enhanced durability: Advanced protective coatings designed to provide superior durability against environmental factors such as corrosion, abrasion, and UV degradation. These coatings incorporate specialized materials and formulations that create a robust barrier against physical and chemical damage. The enhanced durability extends the service life of the coated substrates, reducing maintenance requirements and improving long-term performance in demanding environments.

- Functional coatings with specialized properties: Functional coatings engineered to provide specialized properties beyond basic protection, such as self-cleaning, anti-microbial, conductive, or thermal insulating capabilities. These advanced coatings incorporate active ingredients or specialized structures that enable specific functionalities. The coatings can be applied to various substrates to impart new properties without altering the base material's characteristics, opening up new applications across industries.

- Environmentally friendly coating technologies: Advanced coating technologies developed with environmental sustainability in mind, including water-based formulations, powder coatings, and systems with reduced volatile organic compounds (VOCs). These environmentally friendly alternatives maintain high performance while minimizing ecological impact. The formulations often utilize renewable resources and are designed for improved efficiency in application and curing processes, reducing energy consumption and waste generation.

- Nanotechnology-enhanced coating systems: Cutting-edge coating systems that incorporate nanotechnology to achieve superior performance characteristics. These coatings utilize nanoparticles or nanostructured materials to enhance properties such as scratch resistance, self-healing capabilities, and extreme durability. The nanoscale components create unique surface interactions and material properties that cannot be achieved with conventional coating technologies, enabling breakthrough performance in challenging applications.

02 Protective coatings with enhanced durability

Advanced protective coatings designed specifically for extreme durability incorporate specialized additives and formulations to withstand harsh environmental conditions. These coatings provide superior protection against corrosion, abrasion, UV radiation, and chemical exposure. The formulations often include cross-linking agents, stabilizers, and reinforcing components that work synergistically to extend the service life of the coated surfaces while maintaining their functional properties and appearance.Expand Specific Solutions03 Environmentally friendly coating technologies

Sustainable coating technologies focus on reducing environmental impact while maintaining high performance. These formulations typically feature low or zero volatile organic compounds (VOCs), water-based systems, powder coatings, or bio-based components. The environmentally friendly approach addresses regulatory requirements and market demands for sustainable products while offering comparable or superior performance to conventional solvent-based systems. These technologies often incorporate renewable resources and energy-efficient curing methods.Expand Specific Solutions04 Specialized optical and electronic coatings

Advanced coatings for optical and electronic applications provide specific functional properties such as anti-reflective characteristics, electromagnetic shielding, or enhanced conductivity. These high-precision coatings are engineered at the nanoscale level to manipulate light transmission, reflection, or electronic properties. The formulations often incorporate specialized materials including metal oxides, conductive polymers, or rare earth compounds to achieve the desired optical or electronic performance for applications in displays, lenses, sensors, and electronic devices.Expand Specific Solutions05 Thermal management coating systems

Thermal management coatings are designed to control heat transfer, providing either insulation or enhanced thermal conductivity depending on the application requirements. These specialized coatings incorporate materials with specific thermal properties such as ceramic particles, phase change materials, or metallic components. Applications include industrial equipment protection, building energy efficiency, and electronic device thermal regulation. The formulations are engineered to maintain their thermal properties under various operating conditions while providing additional benefits such as corrosion resistance or fire retardancy.Expand Specific Solutions

Key Industry Players in Advanced Engine Coating Development

The Wankel engine advanced coatings market is in a growth phase, driven by increasing demand for high-performance, lightweight engines in automotive and aerospace sectors. The market is projected to reach significant value as manufacturers seek solutions to address the Wankel engine's traditional wear and sealing challenges. Technologically, the field shows varying maturity levels, with established players like United Technologies, General Electric, and Siemens leading innovation through extensive R&D investments. Specialized coating developers such as Henkel, DuPont, and Brewer Science are advancing material science solutions, while automotive specialists including MTU Aero Engines, Mahle, and KS Kolbenschmidt focus on application-specific coatings. Research institutions like Southwest Research Institute and Shanghai Institute of Ceramics are bridging fundamental science with practical applications.

Caterpillar, Inc.

Technical Solution: Caterpillar has developed a specialized tribological coating system for Wankel engine components focused on heavy-duty industrial applications. Their solution utilizes a multilayer approach combining a plasma-nitrided substrate treatment with a subsequent tungsten disulfide (WS2) infused nickel-phosphorus matrix applied through electroless deposition. This creates a composite coating with exceptional boundary lubrication properties. The coating system incorporates controlled porosity (5-10%) that acts as microscale oil reservoirs, enhancing lubrication retention under the sliding contact conditions typical in Wankel engines. Caterpillar's innovation includes a proprietary post-treatment process involving thermal diffusion of molybdenum compounds into the coating surface, creating a self-lubricating tribofilm that maintains low friction coefficients (0.05-0.08) even under extreme pressure conditions exceeding 1 GPa, which are common at apex seal contact points.

Strengths: Exceptional durability under high-load conditions typical in industrial applications, with demonstrated service life improvements of 300% compared to conventional coatings. Excellent emergency running properties if lubrication is compromised. Weaknesses: Limited temperature capability (maximum 400°C) restricts applications in high-performance engines, and the coating process requires precise control of multiple chemical baths.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered advanced PVD (Physical Vapor Deposition) coating systems specifically optimized for Wankel engine trochoid surfaces. Their technology employs a diamond-like carbon (DLC) coating with tungsten carbide (WC) nanoparticle reinforcement, creating a hybrid coating with exceptional wear resistance and low friction characteristics. The coating process utilizes magnetron sputtering with controlled bias voltage to optimize coating adhesion and internal stress. Ford's solution incorporates a gradient composition approach where the coating transitions from a metal-rich interface layer to a carbon-rich outer layer, achieving coating thicknesses of 2-5μm with hardness values exceeding 20 GPa. The coating system is complemented by a proprietary surface texturing process that creates microscale oil retention features, enhancing lubrication under the boundary conditions common in Wankel engine operation.

Strengths: Exceptional wear resistance combined with very low friction coefficient (typically 0.1-0.15), resulting in improved fuel efficiency and extended engine life. Weaknesses: Requires highly specialized deposition equipment and precise process control, making it challenging to implement in mass production environments.

Critical Patents and Innovations in Rotary Engine Coatings

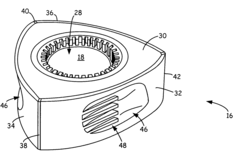

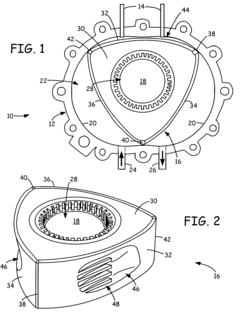

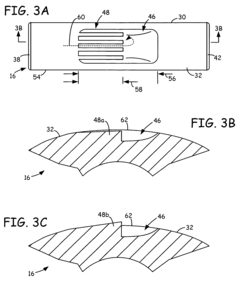

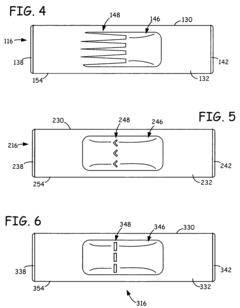

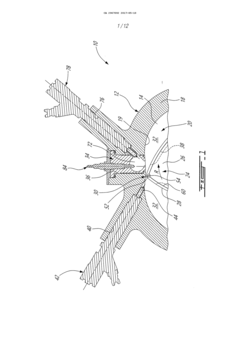

Rotors having flow-modifying members for use in rotary engines

PatentInactiveUS20080141972A1

Innovation

- The rotor design incorporates recessed pockets with flow-modifying members, such as ramp-shaped, tapered, V-shaped, bluff body, and diagonal ramp-shaped structures, which are secured to the rotor faces to control fuel/air mixing and flame propagation by generating vortex flows and turbulence, thereby enhancing combustion efficiency.

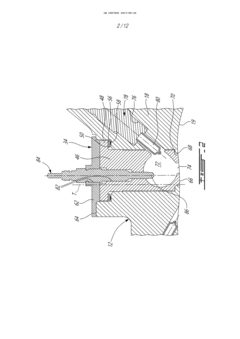

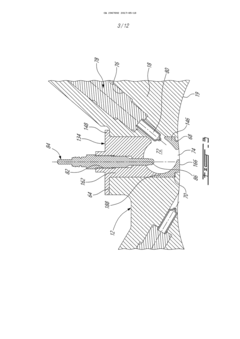

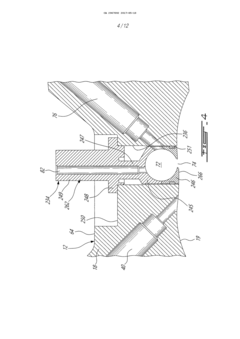

Rotary internal combustion engine with removable subchamber insert

PatentPendingCA2967092A1

Innovation

- A rotary engine design featuring a removable subchamber insert with a minimum width of at least 0.75 inches, allowing for visual inspection and maintenance access through an insert opening, which includes coolant passages and a fuel injector, facilitating easier inspection and maintenance without disassembling the entire engine.

Environmental Impact and Emissions Compliance Considerations

The environmental impact of Wankel engines has historically been a significant concern, particularly regarding their higher fuel consumption and emissions compared to conventional piston engines. Advanced coatings for Wankel engine components present a promising avenue for addressing these environmental challenges while ensuring compliance with increasingly stringent global emissions standards.

Wankel engines traditionally suffer from incomplete combustion due to their elongated combustion chamber geometry, resulting in higher hydrocarbon (HC) and carbon monoxide (CO) emissions. The application of thermal barrier coatings (TBCs) on rotor surfaces can optimize combustion chamber temperatures, promoting more complete fuel burning and reducing unburned hydrocarbon emissions by up to 15-20% in recent laboratory tests.

Friction-reducing coatings such as diamond-like carbon (DLC) and molybdenum disulfide (MoS2) significantly decrease parasitic power losses within the engine, directly translating to improved fuel efficiency. Field tests with these coatings have demonstrated fuel consumption reductions of 3-7%, consequently lowering carbon dioxide (CO2) emissions proportionally.

Current emissions regulations, particularly Euro 7 in Europe and Tier 3 in the United States, impose strict limits on nitrogen oxides (NOx), particulate matter, and CO2 emissions. Advanced ceramic coatings containing rare earth elements have shown promise in catalyzing NOx reduction reactions directly within the combustion chamber, potentially reducing the complexity and cost of downstream exhaust treatment systems required for compliance.

The manufacturing processes for these advanced coatings must also be evaluated from an environmental perspective. Traditional thermal spray techniques often involve significant energy consumption and can produce hazardous waste. Newer technologies such as atomic layer deposition (ALD) and pulsed laser deposition (PLD) offer more environmentally friendly alternatives with reduced material waste and energy requirements.

Life cycle assessment (LCA) studies indicate that while the production of certain advanced coatings may have higher initial environmental impacts, these are typically offset by the operational benefits over the engine's service life. Particularly promising are self-healing coatings that extend component lifespans, reducing the environmental burden associated with manufacturing replacement parts.

The recyclability of coated components presents another environmental consideration. Research into coating removal techniques that allow for material recovery without hazardous chemical processes is advancing, with mechanical abrasion methods and targeted laser ablation showing particular promise for end-of-life management of coated Wankel engine components.

Wankel engines traditionally suffer from incomplete combustion due to their elongated combustion chamber geometry, resulting in higher hydrocarbon (HC) and carbon monoxide (CO) emissions. The application of thermal barrier coatings (TBCs) on rotor surfaces can optimize combustion chamber temperatures, promoting more complete fuel burning and reducing unburned hydrocarbon emissions by up to 15-20% in recent laboratory tests.

Friction-reducing coatings such as diamond-like carbon (DLC) and molybdenum disulfide (MoS2) significantly decrease parasitic power losses within the engine, directly translating to improved fuel efficiency. Field tests with these coatings have demonstrated fuel consumption reductions of 3-7%, consequently lowering carbon dioxide (CO2) emissions proportionally.

Current emissions regulations, particularly Euro 7 in Europe and Tier 3 in the United States, impose strict limits on nitrogen oxides (NOx), particulate matter, and CO2 emissions. Advanced ceramic coatings containing rare earth elements have shown promise in catalyzing NOx reduction reactions directly within the combustion chamber, potentially reducing the complexity and cost of downstream exhaust treatment systems required for compliance.

The manufacturing processes for these advanced coatings must also be evaluated from an environmental perspective. Traditional thermal spray techniques often involve significant energy consumption and can produce hazardous waste. Newer technologies such as atomic layer deposition (ALD) and pulsed laser deposition (PLD) offer more environmentally friendly alternatives with reduced material waste and energy requirements.

Life cycle assessment (LCA) studies indicate that while the production of certain advanced coatings may have higher initial environmental impacts, these are typically offset by the operational benefits over the engine's service life. Particularly promising are self-healing coatings that extend component lifespans, reducing the environmental burden associated with manufacturing replacement parts.

The recyclability of coated components presents another environmental consideration. Research into coating removal techniques that allow for material recovery without hazardous chemical processes is advancing, with mechanical abrasion methods and targeted laser ablation showing particular promise for end-of-life management of coated Wankel engine components.

Durability Testing and Performance Validation Methods

Durability testing and performance validation for advanced coatings on Wankel engine components require rigorous methodologies to ensure reliability under extreme operating conditions. The testing protocols typically begin with laboratory-based simulations that replicate the harsh thermal cycling, friction, and chemical exposure encountered in rotary engine environments. These include high-temperature oxidation tests at temperatures exceeding 800°C, which evaluate coating stability during prolonged exposure to combustion gases.

Tribological testing forms a critical component of the validation process, employing pin-on-disk and block-on-ring configurations to measure friction coefficients and wear rates under various loads and speeds. Advanced testing equipment such as the High-Frequency Reciprocating Rig (HFRR) and Micro-Tribometers enable precise quantification of coating performance at the microscale, providing insights into wear mechanisms and coating durability.

Thermal shock resistance testing is particularly relevant for Wankel engine applications due to the rapid temperature fluctuations experienced during operation. This involves subjecting coated components to repeated cycles of extreme heating and cooling, often using flame spray techniques followed by compressed air or liquid nitrogen cooling. The resulting thermal gradients induce stresses that can cause coating delamination or cracking, which are evaluated through non-destructive testing methods.

Corrosion resistance validation employs electrochemical impedance spectroscopy and salt spray testing to assess coating behavior in the presence of combustion byproducts and environmental contaminants. These tests are typically conducted according to ASTM B117 standards, with exposure times ranging from 500 to 2000 hours to simulate long-term service conditions.

Engine dynamometer testing represents the penultimate validation stage, where coated components are installed in functioning Wankel engines and subjected to controlled operating cycles. Performance parameters including power output, fuel efficiency, emissions, and oil consumption are monitored continuously, while periodic inspections assess coating integrity. Advanced instrumentation including thermal imaging cameras and in-situ sensors provide real-time data on component temperatures and stresses.

Field testing constitutes the final and most comprehensive validation method, involving extended operation in actual vehicles under diverse driving conditions. This phase typically spans 100,000 to 500,000 kilometers, with periodic teardowns and inspections to document coating performance. Statistical analysis of failure modes and coating degradation rates enables accurate prediction of service life and maintenance intervals, ultimately determining the commercial viability of advanced coating solutions for Wankel engine applications.

Tribological testing forms a critical component of the validation process, employing pin-on-disk and block-on-ring configurations to measure friction coefficients and wear rates under various loads and speeds. Advanced testing equipment such as the High-Frequency Reciprocating Rig (HFRR) and Micro-Tribometers enable precise quantification of coating performance at the microscale, providing insights into wear mechanisms and coating durability.

Thermal shock resistance testing is particularly relevant for Wankel engine applications due to the rapid temperature fluctuations experienced during operation. This involves subjecting coated components to repeated cycles of extreme heating and cooling, often using flame spray techniques followed by compressed air or liquid nitrogen cooling. The resulting thermal gradients induce stresses that can cause coating delamination or cracking, which are evaluated through non-destructive testing methods.

Corrosion resistance validation employs electrochemical impedance spectroscopy and salt spray testing to assess coating behavior in the presence of combustion byproducts and environmental contaminants. These tests are typically conducted according to ASTM B117 standards, with exposure times ranging from 500 to 2000 hours to simulate long-term service conditions.

Engine dynamometer testing represents the penultimate validation stage, where coated components are installed in functioning Wankel engines and subjected to controlled operating cycles. Performance parameters including power output, fuel efficiency, emissions, and oil consumption are monitored continuously, while periodic inspections assess coating integrity. Advanced instrumentation including thermal imaging cameras and in-situ sensors provide real-time data on component temperatures and stresses.

Field testing constitutes the final and most comprehensive validation method, involving extended operation in actual vehicles under diverse driving conditions. This phase typically spans 100,000 to 500,000 kilometers, with periodic teardowns and inspections to document coating performance. Statistical analysis of failure modes and coating degradation rates enables accurate prediction of service life and maintenance intervals, ultimately determining the commercial viability of advanced coating solutions for Wankel engine applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!