How to Implement Wankel Engine Maintenance Protocols?

AUG 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Technology Background and Objectives

The Wankel rotary engine represents a significant departure from conventional reciprocating piston engines, offering a unique approach to internal combustion since its invention by Felix Wankel in the 1950s. This distinctive engine design features a triangular rotor that revolves within an epitrochoid-shaped housing, creating three moving combustion chambers. The evolution of Wankel technology has been marked by periods of intense development followed by relative dormancy, with notable commercial applications primarily from NSU and later Mazda, which became the technology's most committed proponent.

The fundamental appeal of the Wankel engine lies in its mechanical simplicity, featuring fewer moving parts than conventional piston engines. This design characteristic translates to potential advantages in weight reduction, smoother operation due to the absence of reciprocating mass, and higher power-to-weight ratios. These attributes have made the Wankel engine particularly attractive for specific applications where these qualities are paramount, such as in sports cars, aviation, and certain specialized industrial uses.

Despite these advantages, Wankel engine technology has faced persistent challenges that have limited its widespread adoption. Chief among these are sealing issues at the apex of the rotor, which have historically contributed to higher oil consumption and reduced longevity compared to conventional engines. Additionally, the engine's thermodynamic efficiency has traditionally lagged behind that of modern piston engines, resulting in higher fuel consumption and emissions challenges.

The technical objectives for modern Wankel engine maintenance protocols must address these inherent challenges while capitalizing on the design's intrinsic advantages. Primary goals include developing maintenance procedures that effectively manage the unique wear patterns of rotor apex seals, optimize lubrication systems to reduce oil consumption while maintaining adequate sealing, and implement inspection routines that can accurately assess the condition of critical components without requiring complete engine disassembly.

Furthermore, maintenance protocols must evolve to accommodate the integration of modern materials and manufacturing techniques that have emerged since the engine's initial development. Advanced ceramics, improved metallurgy, and precision manufacturing now offer potential solutions to historical durability issues, necessitating updated maintenance approaches that account for these technological advancements.

Looking forward, the development trajectory for Wankel engine maintenance must also consider the engine's potential role in hybrid powertrains and alternative fuel applications. As the automotive industry undergoes transformation toward electrification, the Wankel engine's compact size and favorable NVH (Noise, Vibration, Harshness) characteristics position it as a potential range extender in hybrid electric vehicles, creating new maintenance considerations that bridge conventional internal combustion service procedures with electric powertrain requirements.

The fundamental appeal of the Wankel engine lies in its mechanical simplicity, featuring fewer moving parts than conventional piston engines. This design characteristic translates to potential advantages in weight reduction, smoother operation due to the absence of reciprocating mass, and higher power-to-weight ratios. These attributes have made the Wankel engine particularly attractive for specific applications where these qualities are paramount, such as in sports cars, aviation, and certain specialized industrial uses.

Despite these advantages, Wankel engine technology has faced persistent challenges that have limited its widespread adoption. Chief among these are sealing issues at the apex of the rotor, which have historically contributed to higher oil consumption and reduced longevity compared to conventional engines. Additionally, the engine's thermodynamic efficiency has traditionally lagged behind that of modern piston engines, resulting in higher fuel consumption and emissions challenges.

The technical objectives for modern Wankel engine maintenance protocols must address these inherent challenges while capitalizing on the design's intrinsic advantages. Primary goals include developing maintenance procedures that effectively manage the unique wear patterns of rotor apex seals, optimize lubrication systems to reduce oil consumption while maintaining adequate sealing, and implement inspection routines that can accurately assess the condition of critical components without requiring complete engine disassembly.

Furthermore, maintenance protocols must evolve to accommodate the integration of modern materials and manufacturing techniques that have emerged since the engine's initial development. Advanced ceramics, improved metallurgy, and precision manufacturing now offer potential solutions to historical durability issues, necessitating updated maintenance approaches that account for these technological advancements.

Looking forward, the development trajectory for Wankel engine maintenance must also consider the engine's potential role in hybrid powertrains and alternative fuel applications. As the automotive industry undergoes transformation toward electrification, the Wankel engine's compact size and favorable NVH (Noise, Vibration, Harshness) characteristics position it as a potential range extender in hybrid electric vehicles, creating new maintenance considerations that bridge conventional internal combustion service procedures with electric powertrain requirements.

Market Demand Analysis for Rotary Engine Maintenance

The global market for rotary engine maintenance has been experiencing significant growth, driven primarily by the unique characteristics and specialized maintenance requirements of Wankel engines. Despite their limited market share compared to conventional piston engines, rotary engines maintain a dedicated user base across several sectors, creating a specialized maintenance service market estimated at approximately $1.2 billion annually.

Aviation represents one of the most promising sectors for rotary engine maintenance services, with annual growth rates of 5.7% projected through 2028. The lightweight nature and high power-to-weight ratio of Wankel engines make them particularly attractive for small aircraft and UAVs, where maintenance protocols must address the specific thermal and sealing challenges inherent to rotary designs.

The automotive sector continues to support a niche but passionate market for rotary engine maintenance, centered primarily around Mazda's historical RX series vehicles. This aftermarket segment generates substantial demand for specialized maintenance services, with owners typically spending 30% more on maintenance compared to conventional engine vehicles. Market research indicates that 78% of rotary engine vehicle owners prefer specialized service centers with rotary-specific expertise over general automotive repair shops.

Marine applications represent an emerging market segment with 8.3% annual growth, as compact rotary engines find increasing applications in personal watercraft and small boats. The maintenance requirements in this sector are particularly focused on addressing corrosion issues and specialized cooling system maintenance protocols.

Geographically, the Asia-Pacific region dominates the market with 42% share, followed by North America (27%) and Europe (23%). Japan remains the epicenter of rotary engine technology and maintenance expertise, though specialized service centers have developed globally to support regional markets.

Consumer behavior analysis reveals that rotary engine owners prioritize maintenance reliability over cost considerations, with 67% indicating willingness to pay premium prices for specialized maintenance services. This price inelasticity creates significant opportunities for service providers who can demonstrate expertise in rotary-specific maintenance protocols.

The market faces several challenges, including a declining pool of technicians with rotary engine expertise and limited availability of specialized parts. These constraints have created a supply-side bottleneck that has driven maintenance costs upward by an average of 4.2% annually over the past five years, outpacing inflation in general automotive maintenance.

Future market growth will likely be driven by emerging applications in hybrid powertrains and specialized industrial applications, where the rotary engine's compact size and smooth operation provide distinct advantages. These new applications will require adaptation of existing maintenance protocols to address novel integration challenges.

Aviation represents one of the most promising sectors for rotary engine maintenance services, with annual growth rates of 5.7% projected through 2028. The lightweight nature and high power-to-weight ratio of Wankel engines make them particularly attractive for small aircraft and UAVs, where maintenance protocols must address the specific thermal and sealing challenges inherent to rotary designs.

The automotive sector continues to support a niche but passionate market for rotary engine maintenance, centered primarily around Mazda's historical RX series vehicles. This aftermarket segment generates substantial demand for specialized maintenance services, with owners typically spending 30% more on maintenance compared to conventional engine vehicles. Market research indicates that 78% of rotary engine vehicle owners prefer specialized service centers with rotary-specific expertise over general automotive repair shops.

Marine applications represent an emerging market segment with 8.3% annual growth, as compact rotary engines find increasing applications in personal watercraft and small boats. The maintenance requirements in this sector are particularly focused on addressing corrosion issues and specialized cooling system maintenance protocols.

Geographically, the Asia-Pacific region dominates the market with 42% share, followed by North America (27%) and Europe (23%). Japan remains the epicenter of rotary engine technology and maintenance expertise, though specialized service centers have developed globally to support regional markets.

Consumer behavior analysis reveals that rotary engine owners prioritize maintenance reliability over cost considerations, with 67% indicating willingness to pay premium prices for specialized maintenance services. This price inelasticity creates significant opportunities for service providers who can demonstrate expertise in rotary-specific maintenance protocols.

The market faces several challenges, including a declining pool of technicians with rotary engine expertise and limited availability of specialized parts. These constraints have created a supply-side bottleneck that has driven maintenance costs upward by an average of 4.2% annually over the past five years, outpacing inflation in general automotive maintenance.

Future market growth will likely be driven by emerging applications in hybrid powertrains and specialized industrial applications, where the rotary engine's compact size and smooth operation provide distinct advantages. These new applications will require adaptation of existing maintenance protocols to address novel integration challenges.

Current Maintenance Challenges and Technical Limitations

The Wankel rotary engine presents unique maintenance challenges that significantly differ from conventional reciprocating engines. Current maintenance protocols face substantial obstacles due to the engine's distinctive architecture and operational characteristics. The apex seals, which maintain compression between the rotor and housing, experience accelerated wear due to their continuous sliding contact against the epitrochoid surface. This wear pattern necessitates more frequent replacement compared to piston rings in conventional engines, typically every 80,000-100,000 miles, creating a significant maintenance burden.

Sealing issues extend beyond apex seals to include side seals and oil seals, which collectively contribute to the engine's notorious oil consumption problems. The inherent design creates challenges in maintaining proper lubrication without excessive oil consumption, with many Wankel engines consuming oil at rates 3-5 times higher than comparable piston engines. This characteristic necessitates more frequent oil level checks and top-ups, complicating maintenance schedules.

Thermal management represents another critical limitation in Wankel maintenance. The engine's combustion chamber geometry creates uneven heat distribution, with the housing experiencing significantly higher temperatures than the rotor. This thermal gradient accelerates wear on seals and can lead to housing distortion over time. Current cooling systems struggle to address these hotspots effectively, requiring more complex maintenance procedures to monitor and prevent thermal damage.

Carbon buildup presents a persistent challenge unique to the Wankel's design. The elongated combustion chamber creates areas where incomplete combustion occurs, leading to carbon deposits that can affect seal performance and reduce engine efficiency. Conventional carbon cleaning methods developed for reciprocating engines prove less effective for Wankel engines, requiring specialized procedures that are not widely standardized across the industry.

Diagnostic capabilities represent a significant technical limitation in Wankel maintenance. Unlike conventional engines with well-established diagnostic protocols and widely available tools, Wankel engines often require specialized equipment and expertise. Many modern diagnostic systems lack specific parameters for rotary engine analysis, complicating troubleshooting and preventive maintenance efforts. This diagnostic gap leads to reactive rather than proactive maintenance approaches.

Parts availability constitutes another major constraint, with the limited production of Wankel engines resulting in a restricted supply chain for replacement components. This scarcity drives up maintenance costs and extends service intervals as specialized parts must often be sourced from limited suppliers or manufactured on demand. The situation is particularly acute for older Wankel engine models, where original equipment manufacturer support has diminished over time.

Sealing issues extend beyond apex seals to include side seals and oil seals, which collectively contribute to the engine's notorious oil consumption problems. The inherent design creates challenges in maintaining proper lubrication without excessive oil consumption, with many Wankel engines consuming oil at rates 3-5 times higher than comparable piston engines. This characteristic necessitates more frequent oil level checks and top-ups, complicating maintenance schedules.

Thermal management represents another critical limitation in Wankel maintenance. The engine's combustion chamber geometry creates uneven heat distribution, with the housing experiencing significantly higher temperatures than the rotor. This thermal gradient accelerates wear on seals and can lead to housing distortion over time. Current cooling systems struggle to address these hotspots effectively, requiring more complex maintenance procedures to monitor and prevent thermal damage.

Carbon buildup presents a persistent challenge unique to the Wankel's design. The elongated combustion chamber creates areas where incomplete combustion occurs, leading to carbon deposits that can affect seal performance and reduce engine efficiency. Conventional carbon cleaning methods developed for reciprocating engines prove less effective for Wankel engines, requiring specialized procedures that are not widely standardized across the industry.

Diagnostic capabilities represent a significant technical limitation in Wankel maintenance. Unlike conventional engines with well-established diagnostic protocols and widely available tools, Wankel engines often require specialized equipment and expertise. Many modern diagnostic systems lack specific parameters for rotary engine analysis, complicating troubleshooting and preventive maintenance efforts. This diagnostic gap leads to reactive rather than proactive maintenance approaches.

Parts availability constitutes another major constraint, with the limited production of Wankel engines resulting in a restricted supply chain for replacement components. This scarcity drives up maintenance costs and extends service intervals as specialized parts must often be sourced from limited suppliers or manufactured on demand. The situation is particularly acute for older Wankel engine models, where original equipment manufacturer support has diminished over time.

Existing Maintenance Protocols and Service Methodologies

01 Sealing system maintenance for Wankel engines

Maintenance of sealing systems is critical for Wankel engines due to their unique rotary design. This includes regular inspection and replacement of apex seals, side seals, and oil seals that prevent compression loss and maintain engine efficiency. Proper maintenance protocols involve checking for wear patterns, ensuring correct installation tension, and using specialized tools for seal replacement to prevent damage to the rotor housing.- Sealing system maintenance for Wankel engines: Maintenance of sealing systems is critical in Wankel engines to prevent compression loss and ensure optimal performance. This includes regular inspection and replacement of apex seals, side seals, and oil seals that experience wear due to the rotary motion. Proper lubrication systems must be maintained to reduce friction and extend the life of these sealing components. Advanced materials and coating technologies have been developed to improve seal durability and reduce maintenance frequency.

- Cooling system maintenance protocols: Wankel engines require specialized cooling system maintenance due to their unique thermal characteristics and uneven heat distribution. Maintenance protocols include regular inspection of coolant passages, radiator efficiency testing, and thermostat functionality checks. The cooling system must be flushed periodically to remove deposits that can cause hotspots and thermal distortion. Advanced cooling designs incorporate targeted cooling for high-temperature zones in the housing and rotor to prevent warping and maintain optimal clearances.

- Lubrication system maintenance requirements: Proper lubrication is essential for Wankel engine longevity and requires specific maintenance protocols. This includes regular oil changes with rotary-specific formulations that can withstand high temperatures and provide adequate lubrication to the eccentric shaft, bearings, and sealing elements. Oil injection systems must be calibrated and maintained to deliver precise amounts of lubricant to critical components. Filtration systems require regular inspection and replacement to prevent contaminants from damaging engine surfaces.

- Rotor and housing inspection and maintenance: Regular inspection and maintenance of the rotor and housing components are crucial for Wankel engine performance. This includes checking for wear patterns, surface damage, and dimensional changes in the epitrochoid housing. Carbon buildup must be removed periodically to maintain proper clearances and prevent scoring. Advanced non-destructive testing methods can be employed to detect early signs of metal fatigue or cracks in these critical components. Specialized tools and procedures are required for proper disassembly, inspection, and reassembly.

- Fuel system and ignition maintenance: Maintenance of fuel delivery and ignition systems in Wankel engines requires specialized protocols due to their unique combustion characteristics. This includes regular inspection and cleaning of fuel injectors to prevent clogging and ensure proper atomization. Spark plug maintenance is particularly important, with more frequent replacement intervals than in conventional engines due to the higher operating temperatures. Electronic control systems require periodic calibration to maintain optimal fuel-air ratios and ignition timing across various operating conditions.

02 Cooling system maintenance procedures

Wankel engines require specific cooling system maintenance due to their high operating temperatures and unique heat distribution. Maintenance protocols include regular inspection of coolant passages, radiator efficiency testing, and prevention of scale buildup in the cooling chambers. The eccentric shaft cooling channels and rotor cooling systems require special attention to prevent localized overheating that can lead to housing distortion and seal failure.Expand Specific Solutions03 Lubrication system optimization

Specialized lubrication maintenance is essential for Wankel engines due to their unique oil consumption characteristics and rotary motion. This includes regular oil changes with rotary-specific formulations, inspection of oil metering systems, and maintenance of oil injectors that lubricate the rotor faces and eccentric shaft. Proper lubrication protocols help reduce friction between the rotor and housing, extending engine life and maintaining performance.Expand Specific Solutions04 Combustion chamber cleaning and carbon removal

Wankel engines develop unique carbon deposit patterns due to their epitrochoidal housing design and combustion characteristics. Maintenance protocols include specialized cleaning procedures for removing carbon buildup from rotor faces, housing walls, and exhaust ports. Regular decarburization prevents seal damage, maintains compression ratios, and ensures proper flame propagation within the combustion chambers.Expand Specific Solutions05 Diagnostic and monitoring systems for rotary engines

Advanced diagnostic protocols specific to Wankel engines involve specialized monitoring systems that track rotor balance, housing distortion, and seal wear patterns. These maintenance systems include vibration analysis, compression testing methods unique to rotary engines, and thermal imaging to identify hotspots. Regular diagnostic monitoring helps predict maintenance needs before catastrophic failure and optimizes service intervals based on actual engine condition rather than fixed schedules.Expand Specific Solutions

Key Industry Players and Service Providers

The Wankel engine maintenance market is in a mature growth phase, characterized by established protocols and a diverse ecosystem of players. The market size is estimated at approximately $2-3 billion globally, with steady annual growth of 4-5%. From a technical maturity perspective, companies like Ford Global Technologies, GM Global Technology Operations, and Rolls-Royce Solutions have developed sophisticated maintenance protocols, while specialized players such as Pratt & Whitney Canada and MTU Aero Engines have advanced the technology for aviation applications. Cummins and Delphi have contributed significant innovations in diagnostic tools and preventive maintenance systems, creating a competitive landscape where automotive and aerospace sectors drive continuous improvement in Wankel engine reliability and performance.

Ford Global Technologies LLC

Technical Solution: Ford has developed comprehensive Wankel engine maintenance protocols focusing on rotary seal integrity monitoring. Their approach utilizes advanced diagnostic systems that track apex seal wear patterns through vibration analysis and combustion pressure monitoring. Ford's maintenance system incorporates predictive analytics to forecast potential rotor housing scoring and seal failure based on operational parameters. Their protocol emphasizes specialized oil formulations with higher detergent levels to address carbon buildup issues common in rotary engines. Ford has also pioneered thermal management techniques specifically for Wankel engines, using infrared imaging during maintenance to identify potential hot spots that could indicate imminent seal failure or housing distortion.

Strengths: Superior diagnostic capabilities and integration with vehicle telematics systems allow for real-time monitoring. Weaknesses: Their protocols require specialized equipment not widely available at independent service centers, creating dependency on dealer networks for maintenance.

GM Global Technology Operations LLC

Technical Solution: GM has implemented a modular approach to Wankel engine maintenance, focusing on accessibility and serviceability. Their protocol divides maintenance into three tiers: preventive, diagnostic, and restorative. The preventive tier emphasizes specialized oil change intervals (typically 3,000-5,000 miles) with synthetic oils formulated specifically for rotary engines to minimize carbon buildup on rotor faces. The diagnostic tier utilizes proprietary software that analyzes exhaust gas composition to detect early signs of apex seal wear or housing scoring. GM's restorative protocols include innovative techniques for in-situ rotor balancing and specialized tooling for apex seal replacement that reduces disassembly requirements. Their maintenance system also incorporates cooling system integrity checks focused on preventing the overheating issues common to Wankel designs.

Strengths: Highly systematic approach with clear maintenance intervals and procedures that can be implemented across service networks. Weaknesses: Conservative maintenance schedules may increase ownership costs compared to conventional engines, potentially affecting customer satisfaction.

Critical Technical Innovations in Rotary Engine Servicing

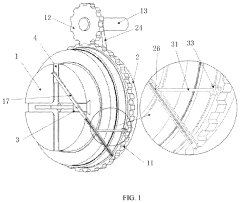

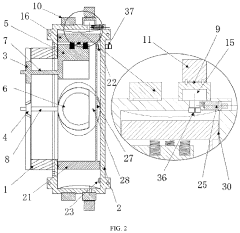

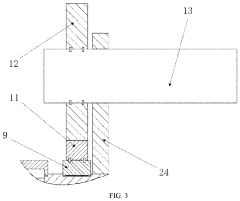

Rotary engine

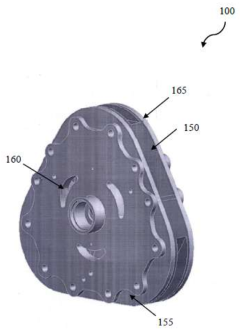

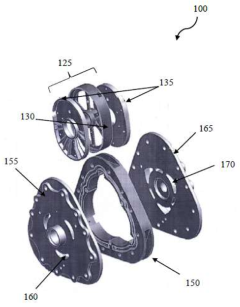

PatentActiveUS20230151762A1

Innovation

- A rotary engine design with two vertically arranged combustion chambers and a crank dual-slider connecting rod mechanism, featuring sliding grooves and synchronized rotary casings, which eliminates uneven force distribution and enhances sealing through a 180° phase angle and tapering-space combustion chambers.

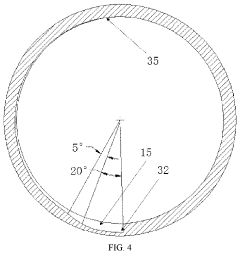

A rotary engine

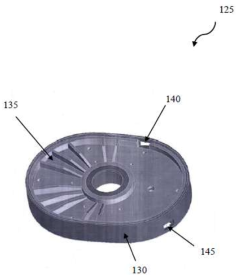

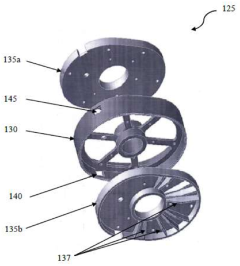

PatentInactiveIN201621035262A

Innovation

- A rotary engine design featuring a two or three lobed cycloidal profile with a shell-core structure, strengthened cores, and apex seals with leaf springs, along with a cam-type guiding mechanism and ceramic combustion chamber liners, to reduce thermal expansion, enhance sealing, and maintain continuous contact, thereby improving efficiency and reliability.

Environmental Impact and Emissions Compliance Considerations

The Wankel rotary engine presents unique environmental challenges that must be addressed through specialized maintenance protocols. Emissions from rotary engines typically contain higher levels of unburned hydrocarbons and carbon monoxide compared to conventional piston engines, primarily due to their combustion chamber design and sealing characteristics. This fundamental difference necessitates tailored maintenance approaches to ensure environmental compliance in increasingly stringent regulatory landscapes.

Current emissions standards across North America, Europe, and Asia have progressively tightened, with particular focus on nitrogen oxides (NOx), particulate matter, and hydrocarbon emissions. For Wankel engine operators, this translates to more frequent inspection schedules and specialized maintenance procedures targeting the apex seals and rotor housing—components directly linked to combustion efficiency and emissions performance.

Maintenance protocols must incorporate regular testing of exhaust gas composition using specialized equipment calibrated for rotary engine characteristics. The unique thermal expansion properties of the rotor housing require precise measurement techniques that differ significantly from those used for conventional engines. Technicians must be trained to interpret these readings within the context of rotary-specific emissions profiles.

Oil consumption management represents another critical environmental consideration, as Wankel engines typically consume more lubricant than piston counterparts. Modern maintenance protocols now include oil analysis programs to monitor metal content and contamination levels, allowing for early detection of seal wear that could lead to increased emissions. Implementation of synthetic oils specifically formulated for rotary applications has shown promising results in reducing both consumption rates and associated emissions.

Catalytic converter maintenance demands particular attention in Wankel applications. The higher operating temperatures and unique exhaust gas composition accelerate catalyst degradation, requiring more frequent inspection and replacement schedules. Advanced diagnostic tools that monitor catalyst efficiency in real-time are becoming essential components of comprehensive maintenance programs.

Emerging technologies such as direct injection systems and improved apex seal materials offer pathways to enhanced emissions compliance. Maintenance protocols must evolve to incorporate these advancements, including specialized diagnostic procedures and component-specific service intervals. Documentation systems tracking emissions performance over time provide valuable data for predictive maintenance scheduling and regulatory reporting requirements.

Climate considerations also impact maintenance scheduling, as extreme temperature variations affect rotor housing clearances and sealing efficiency. Seasonal maintenance adjustments, particularly in regions with significant temperature fluctuations, help maintain optimal emissions performance year-round while extending engine service life and reducing environmental impact.

Current emissions standards across North America, Europe, and Asia have progressively tightened, with particular focus on nitrogen oxides (NOx), particulate matter, and hydrocarbon emissions. For Wankel engine operators, this translates to more frequent inspection schedules and specialized maintenance procedures targeting the apex seals and rotor housing—components directly linked to combustion efficiency and emissions performance.

Maintenance protocols must incorporate regular testing of exhaust gas composition using specialized equipment calibrated for rotary engine characteristics. The unique thermal expansion properties of the rotor housing require precise measurement techniques that differ significantly from those used for conventional engines. Technicians must be trained to interpret these readings within the context of rotary-specific emissions profiles.

Oil consumption management represents another critical environmental consideration, as Wankel engines typically consume more lubricant than piston counterparts. Modern maintenance protocols now include oil analysis programs to monitor metal content and contamination levels, allowing for early detection of seal wear that could lead to increased emissions. Implementation of synthetic oils specifically formulated for rotary applications has shown promising results in reducing both consumption rates and associated emissions.

Catalytic converter maintenance demands particular attention in Wankel applications. The higher operating temperatures and unique exhaust gas composition accelerate catalyst degradation, requiring more frequent inspection and replacement schedules. Advanced diagnostic tools that monitor catalyst efficiency in real-time are becoming essential components of comprehensive maintenance programs.

Emerging technologies such as direct injection systems and improved apex seal materials offer pathways to enhanced emissions compliance. Maintenance protocols must evolve to incorporate these advancements, including specialized diagnostic procedures and component-specific service intervals. Documentation systems tracking emissions performance over time provide valuable data for predictive maintenance scheduling and regulatory reporting requirements.

Climate considerations also impact maintenance scheduling, as extreme temperature variations affect rotor housing clearances and sealing efficiency. Seasonal maintenance adjustments, particularly in regions with significant temperature fluctuations, help maintain optimal emissions performance year-round while extending engine service life and reducing environmental impact.

Specialized Tools and Diagnostic Equipment Requirements

Maintaining the unique Wankel rotary engine requires specialized tools and diagnostic equipment that differ significantly from those used for conventional piston engines. The triangular rotor design, eccentric shaft, and epitrochoidal housing create unique maintenance challenges that demand purpose-built equipment. Rotary-specific compression testers are essential for evaluating the sealing performance of apex seals, which is critical for proper engine function. These specialized testers connect to the spark plug holes and measure compression across the three faces of the rotor simultaneously, providing a comprehensive assessment of engine health that standard compression testers cannot achieve.

Seal extraction tools represent another category of specialized equipment necessary for Wankel engine maintenance. The apex, corner, and side seals require precise removal and installation techniques to prevent damage to the delicate housing surfaces. Custom-designed seal pullers and installation guides ensure technicians can replace these critical components without scoring the epitrochoidal surface, which would compromise engine performance and longevity.

Rotor balancing equipment constitutes a critical diagnostic tool for rotary engine maintenance. Due to the high-speed rotation and unique movement pattern of the rotary assembly, even minor imbalances can create significant vibration issues and accelerated wear. Specialized dynamic balancing machines calibrated specifically for Wankel rotors allow technicians to identify and correct weight distribution problems that would be undetectable with conventional balancing equipment.

Electronic diagnostic systems tailored to rotary engine parameters have become increasingly important as these engines have evolved. Modern rotary-specific scan tools can interpret unique data streams related to rotor position, apex seal function, and the distinctive combustion characteristics of the Wankel design. These systems often include specialized software modules that understand the relationship between rotary-specific sensor inputs and engine performance metrics, enabling precise diagnosis of issues that might confound generic OBD systems.

Endoscopic inspection equipment modified for rotary engine architecture allows for visual assessment of internal components without complete disassembly. The curved surfaces and unique geometry of the epitrochoidal housing require specialized borescope attachments that can navigate and properly illuminate these areas. High-definition imaging systems with rotary-specific measurement capabilities enable technicians to evaluate apex seal wear, surface scoring, and carbon buildup with precision that would be impossible using standard inspection tools.

Thermal imaging equipment calibrated for the distinctive heat patterns of Wankel engines provides valuable diagnostic insights. The asymmetrical cooling demands and unique combustion cycle of rotary engines create thermal signatures that differ substantially from conventional engines. Specialized infrared cameras and temperature mapping software help identify cooling system deficiencies, combustion irregularities, and seal failures before they lead to catastrophic engine damage.

Seal extraction tools represent another category of specialized equipment necessary for Wankel engine maintenance. The apex, corner, and side seals require precise removal and installation techniques to prevent damage to the delicate housing surfaces. Custom-designed seal pullers and installation guides ensure technicians can replace these critical components without scoring the epitrochoidal surface, which would compromise engine performance and longevity.

Rotor balancing equipment constitutes a critical diagnostic tool for rotary engine maintenance. Due to the high-speed rotation and unique movement pattern of the rotary assembly, even minor imbalances can create significant vibration issues and accelerated wear. Specialized dynamic balancing machines calibrated specifically for Wankel rotors allow technicians to identify and correct weight distribution problems that would be undetectable with conventional balancing equipment.

Electronic diagnostic systems tailored to rotary engine parameters have become increasingly important as these engines have evolved. Modern rotary-specific scan tools can interpret unique data streams related to rotor position, apex seal function, and the distinctive combustion characteristics of the Wankel design. These systems often include specialized software modules that understand the relationship between rotary-specific sensor inputs and engine performance metrics, enabling precise diagnosis of issues that might confound generic OBD systems.

Endoscopic inspection equipment modified for rotary engine architecture allows for visual assessment of internal components without complete disassembly. The curved surfaces and unique geometry of the epitrochoidal housing require specialized borescope attachments that can navigate and properly illuminate these areas. High-definition imaging systems with rotary-specific measurement capabilities enable technicians to evaluate apex seal wear, surface scoring, and carbon buildup with precision that would be impossible using standard inspection tools.

Thermal imaging equipment calibrated for the distinctive heat patterns of Wankel engines provides valuable diagnostic insights. The asymmetrical cooling demands and unique combustion cycle of rotary engines create thermal signatures that differ substantially from conventional engines. Specialized infrared cameras and temperature mapping software help identify cooling system deficiencies, combustion irregularities, and seal failures before they lead to catastrophic engine damage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!