How to Monitor Wankel Engine Life Cycle Metrics?

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Monitoring Background and Objectives

The Wankel rotary engine, first developed by Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique design featuring a triangular rotor moving within an epitrochoidal housing has garnered attention for its compact size, high power-to-weight ratio, and smooth operation. Despite these advantages, widespread adoption has been limited by challenges related to sealing, fuel efficiency, and emissions compliance. The evolution of this technology has seen various iterations, with Mazda being the most prominent commercial advocate through vehicles like the RX series.

The monitoring of Wankel engine lifecycle metrics has historically been less sophisticated than for conventional engines, creating a technological gap that demands attention. As emissions regulations tighten globally and efficiency becomes paramount, developing comprehensive monitoring systems for rotary engines has become increasingly critical. The objective of this technical research is to explore innovative approaches to monitor key performance indicators throughout the Wankel engine's operational lifecycle.

Current monitoring systems primarily focus on basic parameters such as temperature, pressure, and rotational speed. However, the unique wear patterns, sealing challenges, and combustion characteristics of rotary engines necessitate more specialized monitoring solutions. The apex seals, which maintain compression between the rotor and housing, represent a particular area of concern due to their impact on engine longevity and performance degradation over time.

Recent technological advancements in sensors, data analytics, and materials science present opportunities to develop more sophisticated monitoring systems specifically tailored to rotary engine dynamics. These systems aim to provide real-time insights into engine health, predict maintenance needs, and optimize performance parameters. The integration of IoT capabilities further enables remote monitoring and predictive maintenance strategies that could significantly extend engine life and improve reliability.

The trajectory of Wankel engine development has seen renewed interest with the emergence of hybrid powertrains and range extenders, where the rotary engine's compact size and smooth operation provide distinct advantages. Companies like Mazda have announced plans to reintroduce rotary technology in this context, highlighting the continued relevance of this engine architecture and the need for advanced monitoring solutions.

This research aims to bridge the gap between traditional engine monitoring approaches and the specific requirements of Wankel rotary engines, establishing a framework for comprehensive lifecycle metrics that address the unique characteristics of these powerplants. By developing more effective monitoring methodologies, we can potentially overcome historical limitations and unlock new applications for this distinctive engine technology in both traditional and emerging mobility solutions.

The monitoring of Wankel engine lifecycle metrics has historically been less sophisticated than for conventional engines, creating a technological gap that demands attention. As emissions regulations tighten globally and efficiency becomes paramount, developing comprehensive monitoring systems for rotary engines has become increasingly critical. The objective of this technical research is to explore innovative approaches to monitor key performance indicators throughout the Wankel engine's operational lifecycle.

Current monitoring systems primarily focus on basic parameters such as temperature, pressure, and rotational speed. However, the unique wear patterns, sealing challenges, and combustion characteristics of rotary engines necessitate more specialized monitoring solutions. The apex seals, which maintain compression between the rotor and housing, represent a particular area of concern due to their impact on engine longevity and performance degradation over time.

Recent technological advancements in sensors, data analytics, and materials science present opportunities to develop more sophisticated monitoring systems specifically tailored to rotary engine dynamics. These systems aim to provide real-time insights into engine health, predict maintenance needs, and optimize performance parameters. The integration of IoT capabilities further enables remote monitoring and predictive maintenance strategies that could significantly extend engine life and improve reliability.

The trajectory of Wankel engine development has seen renewed interest with the emergence of hybrid powertrains and range extenders, where the rotary engine's compact size and smooth operation provide distinct advantages. Companies like Mazda have announced plans to reintroduce rotary technology in this context, highlighting the continued relevance of this engine architecture and the need for advanced monitoring solutions.

This research aims to bridge the gap between traditional engine monitoring approaches and the specific requirements of Wankel rotary engines, establishing a framework for comprehensive lifecycle metrics that address the unique characteristics of these powerplants. By developing more effective monitoring methodologies, we can potentially overcome historical limitations and unlock new applications for this distinctive engine technology in both traditional and emerging mobility solutions.

Market Demand Analysis for Rotary Engine Diagnostics

The global market for rotary engine diagnostics is experiencing significant growth driven by the resurgence of Wankel engine technology in specialized applications. Current market analysis indicates a growing demand for advanced monitoring solutions across automotive, aerospace, and power generation sectors where rotary engines maintain niche but valuable positions.

In the automotive sector, Mazda's announcement of rotary engine revival as range extenders in hybrid vehicles has created renewed interest in diagnostic technologies. This strategic pivot addresses both emissions concerns and leverages the rotary engine's compact size and power-to-weight advantages. Market research suggests the automotive diagnostic segment for rotary engines could grow substantially as these hybrid implementations expand.

The aerospace industry represents another significant market driver, with UAV manufacturers increasingly adopting Wankel engines for their superior power density and operational reliability. This sector demands sophisticated real-time monitoring systems that can predict maintenance needs and prevent catastrophic failures in flight operations. The UAV market's compound annual growth rate exceeds 15% in regions adopting rotary engine technology, creating parallel demand for diagnostic solutions.

Marine applications constitute an emerging market segment where rotary engines are gaining traction due to their compact form factor and smooth operation. Diagnostic systems for these applications must address unique challenges including saltwater exposure and variable load conditions, creating specialized market opportunities for monitoring solutions.

Consumer demand patterns indicate strong preference for integrated diagnostic platforms that offer predictive maintenance capabilities rather than reactive monitoring. End users increasingly expect systems that can provide early warning of potential failures through analysis of performance metrics including rotor seal wear, combustion efficiency, and apex seal degradation patterns.

Market fragmentation remains significant, with specialized service providers dominating regional markets and few global players offering comprehensive solutions. This fragmentation presents both challenges and opportunities for new entrants with innovative monitoring technologies.

Regulatory factors are increasingly influencing market development, particularly as emissions standards evolve worldwide. Diagnostic systems that can help maintain optimal combustion efficiency and minimize emissions are experiencing accelerated demand in regions with stringent environmental regulations.

Price sensitivity varies significantly by application, with aerospace and high-performance automotive segments demonstrating willingness to invest in premium monitoring solutions, while consumer and small marine applications remain more cost-conscious. This segmentation necessitates tiered product strategies for market participants seeking broad adoption.

In the automotive sector, Mazda's announcement of rotary engine revival as range extenders in hybrid vehicles has created renewed interest in diagnostic technologies. This strategic pivot addresses both emissions concerns and leverages the rotary engine's compact size and power-to-weight advantages. Market research suggests the automotive diagnostic segment for rotary engines could grow substantially as these hybrid implementations expand.

The aerospace industry represents another significant market driver, with UAV manufacturers increasingly adopting Wankel engines for their superior power density and operational reliability. This sector demands sophisticated real-time monitoring systems that can predict maintenance needs and prevent catastrophic failures in flight operations. The UAV market's compound annual growth rate exceeds 15% in regions adopting rotary engine technology, creating parallel demand for diagnostic solutions.

Marine applications constitute an emerging market segment where rotary engines are gaining traction due to their compact form factor and smooth operation. Diagnostic systems for these applications must address unique challenges including saltwater exposure and variable load conditions, creating specialized market opportunities for monitoring solutions.

Consumer demand patterns indicate strong preference for integrated diagnostic platforms that offer predictive maintenance capabilities rather than reactive monitoring. End users increasingly expect systems that can provide early warning of potential failures through analysis of performance metrics including rotor seal wear, combustion efficiency, and apex seal degradation patterns.

Market fragmentation remains significant, with specialized service providers dominating regional markets and few global players offering comprehensive solutions. This fragmentation presents both challenges and opportunities for new entrants with innovative monitoring technologies.

Regulatory factors are increasingly influencing market development, particularly as emissions standards evolve worldwide. Diagnostic systems that can help maintain optimal combustion efficiency and minimize emissions are experiencing accelerated demand in regions with stringent environmental regulations.

Price sensitivity varies significantly by application, with aerospace and high-performance automotive segments demonstrating willingness to invest in premium monitoring solutions, while consumer and small marine applications remain more cost-conscious. This segmentation necessitates tiered product strategies for market participants seeking broad adoption.

Technical Challenges in Wankel Engine Lifecycle Monitoring

Monitoring the lifecycle metrics of Wankel rotary engines presents unique technical challenges that differ significantly from conventional reciprocating engines. The triangular rotor design, eccentric shaft movement, and distinctive combustion characteristics create complexities in sensor placement and data interpretation that have not been fully resolved in current monitoring systems.

The primary challenge lies in accurately measuring the wear patterns of apex seals, which experience continuous friction against the epitrochoid housing. Unlike piston rings in conventional engines, these seals follow a complex three-dimensional path, making direct measurement during operation virtually impossible with current sensor technology. Engineers must rely on indirect indicators such as compression loss, which often manifests only after significant degradation has occurred.

Temperature monitoring presents another significant hurdle due to the Wankel's unique thermal profile. The concentrated heat in the rotor housing near the exhaust port creates thermal gradients that are difficult to map comprehensively. Conventional temperature sensors struggle to capture the rapid thermal fluctuations that occur during the eccentric rotation, particularly at high RPMs where the Wankel engine excels.

Vibration analysis, a standard technique in reciprocating engine monitoring, becomes extraordinarily complex in Wankel applications. The smooth rotational movement masks subtle changes in vibration signatures that might indicate developing problems. Current accelerometer and vibration monitoring systems lack the sensitivity and analytical algorithms specifically calibrated for the Wankel's unique motion patterns.

Oil analysis faces complications due to the engine's design requiring oil injection into the combustion chamber for apex seal lubrication. This intentional oil consumption confounds traditional oil analysis metrics and makes it difficult to distinguish between normal consumption and problematic conditions. Specialized oil analysis protocols for Wankel engines remain underdeveloped.

Emissions monitoring, while technically feasible, struggles to provide accurate lifecycle information due to the Wankel's inherent combustion characteristics. The elongated combustion chamber and moving flame front create emissions patterns that do not correlate with internal wear in the same way as in reciprocating engines.

Data integration represents perhaps the most significant technical barrier. The correlation between various sensor inputs and actual engine condition lacks the robust mathematical models that exist for conventional engines. Machine learning approaches show promise but are hampered by limited training datasets, as Wankel engines represent a small fraction of the overall engine market.

Real-time monitoring systems must also contend with the high rotational speeds typical of Wankel operation, requiring higher sampling rates and more sophisticated signal processing than many commercial engine monitoring systems currently provide.

The primary challenge lies in accurately measuring the wear patterns of apex seals, which experience continuous friction against the epitrochoid housing. Unlike piston rings in conventional engines, these seals follow a complex three-dimensional path, making direct measurement during operation virtually impossible with current sensor technology. Engineers must rely on indirect indicators such as compression loss, which often manifests only after significant degradation has occurred.

Temperature monitoring presents another significant hurdle due to the Wankel's unique thermal profile. The concentrated heat in the rotor housing near the exhaust port creates thermal gradients that are difficult to map comprehensively. Conventional temperature sensors struggle to capture the rapid thermal fluctuations that occur during the eccentric rotation, particularly at high RPMs where the Wankel engine excels.

Vibration analysis, a standard technique in reciprocating engine monitoring, becomes extraordinarily complex in Wankel applications. The smooth rotational movement masks subtle changes in vibration signatures that might indicate developing problems. Current accelerometer and vibration monitoring systems lack the sensitivity and analytical algorithms specifically calibrated for the Wankel's unique motion patterns.

Oil analysis faces complications due to the engine's design requiring oil injection into the combustion chamber for apex seal lubrication. This intentional oil consumption confounds traditional oil analysis metrics and makes it difficult to distinguish between normal consumption and problematic conditions. Specialized oil analysis protocols for Wankel engines remain underdeveloped.

Emissions monitoring, while technically feasible, struggles to provide accurate lifecycle information due to the Wankel's inherent combustion characteristics. The elongated combustion chamber and moving flame front create emissions patterns that do not correlate with internal wear in the same way as in reciprocating engines.

Data integration represents perhaps the most significant technical barrier. The correlation between various sensor inputs and actual engine condition lacks the robust mathematical models that exist for conventional engines. Machine learning approaches show promise but are hampered by limited training datasets, as Wankel engines represent a small fraction of the overall engine market.

Real-time monitoring systems must also contend with the high rotational speeds typical of Wankel operation, requiring higher sampling rates and more sophisticated signal processing than many commercial engine monitoring systems currently provide.

Current Monitoring Solutions for Wankel Engines

01 Wankel Engine Durability and Lifespan Enhancement

Various techniques and innovations have been developed to enhance the durability and extend the operational lifespan of Wankel engines. These include improved sealing systems, advanced materials for critical components, and optimized lubrication systems that reduce wear on moving parts. These enhancements address the traditional longevity challenges of rotary engines by minimizing friction, heat generation, and component degradation over time.- Wankel Engine Durability and Lifespan Enhancement: Various technologies have been developed to enhance the durability and operational lifespan of Wankel engines. These include improved sealing systems to reduce wear on apex seals, advanced materials for rotor housings, and specialized coatings to minimize friction between moving parts. These innovations address the traditional lifespan limitations of rotary engines by focusing on the components most susceptible to wear, thereby extending the overall lifecycle of Wankel engines in practical applications.

- Efficiency Optimization and Performance Metrics: Research has focused on improving the efficiency metrics of Wankel engines throughout their lifecycle. This includes optimizing combustion chamber design, fuel delivery systems, and exhaust configurations to enhance thermal efficiency and reduce fuel consumption. Performance metrics such as power-to-weight ratio, specific fuel consumption, and emissions profiles are continuously monitored and improved through design iterations and technological advancements, contributing to better lifecycle performance characteristics.

- Lifecycle Environmental Impact Assessment: Methods for assessing and reducing the environmental impact of Wankel engines throughout their lifecycle have been developed. These include analyzing emissions profiles during operation, evaluating manufacturing processes for environmental efficiency, and developing end-of-life recycling protocols. Lifecycle assessment methodologies specifically tailored for rotary engines help quantify their carbon footprint and identify opportunities for environmental optimization from production through disposal.

- Maintenance Scheduling and Predictive Analytics: Advanced systems for monitoring Wankel engine health and optimizing maintenance schedules have been created to extend engine lifecycle. These include sensor-based monitoring systems that track key performance indicators, predictive analytics algorithms that forecast potential failures, and maintenance optimization protocols that balance performance preservation with cost efficiency. These technologies enable condition-based maintenance rather than time-based approaches, maximizing engine lifespan while minimizing downtime.

- Economic and Cost Analysis Frameworks: Methodologies for analyzing the total cost of ownership and economic viability of Wankel engines throughout their lifecycle have been developed. These frameworks account for initial manufacturing costs, operational expenses including fuel and maintenance, and end-of-life considerations. Economic metrics such as return on investment, depreciation rates, and comparative cost analyses with alternative engine technologies provide stakeholders with comprehensive data for lifecycle cost management and investment decisions.

02 Environmental Performance and Emissions Control

Innovations focused on improving the environmental performance of Wankel engines throughout their lifecycle include advanced emissions control systems, combustion optimization techniques, and fuel efficiency improvements. These developments aim to reduce the environmental footprint of rotary engines by addressing their traditionally higher fuel consumption and emissions compared to conventional piston engines, making them more compliant with modern environmental regulations.Expand Specific Solutions03 Lifecycle Cost Analysis and Economic Metrics

Methods and systems for analyzing the total lifecycle costs of Wankel engines, including acquisition, operation, maintenance, and disposal expenses. These approaches provide frameworks for comparing rotary engines with conventional powerplants on an economic basis, considering factors such as fuel efficiency, maintenance requirements, reliability metrics, and service intervals to determine the true cost of ownership throughout the engine's operational life.Expand Specific Solutions04 Performance Monitoring and Predictive Maintenance

Systems and methods for real-time monitoring of Wankel engine performance parameters and predicting maintenance needs based on operational data. These technologies utilize sensors, data analytics, and diagnostic algorithms to track engine health, detect early signs of component wear or failure, and optimize maintenance scheduling. This approach extends engine lifespan by addressing issues before they cause significant damage or performance degradation.Expand Specific Solutions05 Design Innovations for Lifecycle Optimization

Novel design approaches specifically aimed at optimizing the complete lifecycle of Wankel engines, from manufacturing through operation to end-of-life considerations. These innovations include modular designs for easier maintenance and component replacement, materials selection for recyclability, and structural improvements that balance performance requirements with longevity considerations. Such designs aim to address the traditional weaknesses of rotary engines while capitalizing on their inherent advantages.Expand Specific Solutions

Key Industry Players in Rotary Engine Diagnostics

The Wankel engine monitoring technology landscape is currently in a growth phase, with increasing market demand driven by automotive and aerospace applications. The market size is expanding as companies like GM Global Technology Operations, Hyundai Motor Co., and Mercedes-Benz Group AG invest in rotary engine lifecycle monitoring solutions. Technologically, the field shows moderate maturity with established players like Robert Bosch GmbH and Schaeffler Technologies leading innovation in sensor-based monitoring systems. Emerging technologies focus on predictive maintenance and real-time performance analytics, with companies like Caterpillar and General Electric bringing industrial monitoring expertise. The competitive landscape features automotive OEMs collaborating with specialized engineering firms to develop proprietary monitoring solutions that enhance engine reliability and operational efficiency.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive Wankel engine monitoring system that integrates multiple sensor technologies with advanced analytics to track engine lifecycle metrics. Their solution employs specialized rotary engine vibration analysis that can identify characteristic frequency patterns associated with apex seal wear, rotor bearing degradation, and housing surface irregularities. The system incorporates precision oil analysis sensors that continuously monitor oil contamination levels, detecting metal particles that indicate specific component wear patterns unique to Wankel engines. GM's approach features thermal mapping capabilities that track temperature gradients across the epitrochoidal housing, identifying hotspots that may indicate seal failure or combustion irregularities. Their monitoring platform includes specialized combustion pressure sensors that can detect subtle changes in compression efficiency that often precede mechanical failures in rotary engines. The system connects to GM's broader vehicle health management infrastructure, allowing for comparative analysis against established lifecycle models and enabling predictive maintenance scheduling based on actual engine condition rather than fixed service intervals.

Strengths: Holistic approach integrating multiple monitoring technologies provides comprehensive coverage of potential failure modes. Strong data analytics capabilities enable accurate predictive maintenance recommendations. Weaknesses: Complex sensor integration increases initial system cost and potential points of failure. Requires specialized technician training for proper system maintenance and calibration.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed an advanced Wankel engine monitoring system that integrates multiple sensor technologies throughout the engine's critical components. Their solution employs rotary-specific vibration analysis algorithms that can detect microscopic changes in rotor balance and apex seal wear patterns. The system utilizes high-precision thermal mapping across the epitrochoidal housing to identify hotspots that may indicate excessive friction or combustion irregularities. Hyundai's approach incorporates real-time oil analysis sensors that continuously monitor oil quality parameters including viscosity degradation, particulate contamination levels, and chemical composition changes that correlate with specific wear mechanisms. Their monitoring system connects to a centralized diagnostic platform that employs machine learning algorithms to establish baseline performance metrics for each engine and detect deviations that may indicate early-stage failure modes before they become critical.

Strengths: Comprehensive integration of multiple sensor types provides redundant monitoring paths, increasing reliability of diagnostics. Machine learning implementation allows for predictive maintenance rather than reactive repairs. Weaknesses: System complexity increases implementation costs and requires specialized technician training for maintenance and calibration. Higher sensor density creates more potential failure points in harsh engine environments.

Critical Sensor Technologies for Rotary Engine Assessment

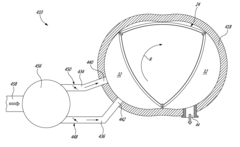

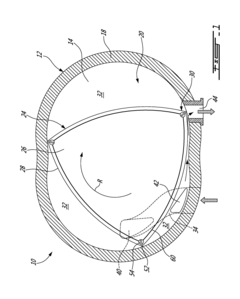

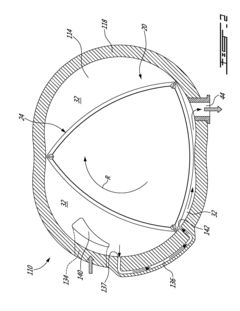

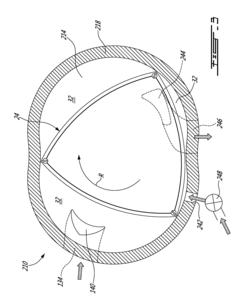

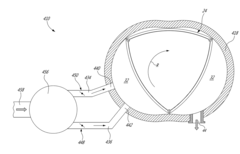

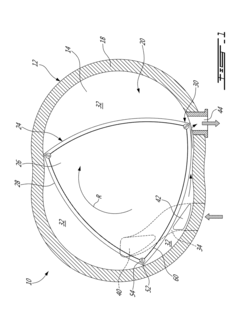

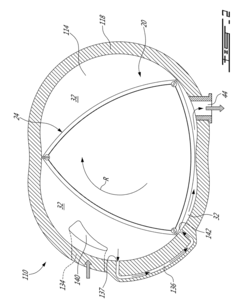

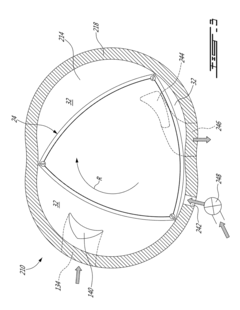

Rotary internal combustion engine with exhaust purge

PatentActiveUS20150075483A1

Innovation

- The design incorporates a rotary engine with a stator body and rotor body that create variable volume chambers, featuring an inlet port, an exhaust port, and a purge port positioned relative to each other to achieve a lower volumetric compression ratio compared to the expansion ratio, with the purge port momentarily communicating with the exhaust port during specific rotor positions to effectively purge combustion gases.

Rotary internal combustion engine

PatentActiveUS20180045110A1

Innovation

- The implementation of a rotary engine design with a primary inlet port, a secondary inlet port (purge port) positioned rearwardly of the primary inlet port and forwardly of the exhaust port, and independently closable communications between air sources and these ports, allowing simultaneous air intake and exhaust gas purging through the secondary inlet port.

Emissions Compliance and Environmental Considerations

Monitoring Wankel engine emissions has become increasingly critical as global environmental regulations continue to tighten. The unique rotary design of Wankel engines presents specific challenges for emissions compliance that differ significantly from conventional piston engines. The triangular rotor design creates elongated combustion chambers that can lead to incomplete combustion, resulting in higher hydrocarbon (HC) emissions compared to traditional engines. This characteristic requires specialized monitoring systems that can accurately track emissions throughout the engine's lifecycle.

Current emissions regulations, including Euro 6d in Europe, Tier 3 in the United States, and China 6 standards, impose strict limits on nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. Wankel engines must meet these standards while maintaining their performance advantages. Continuous monitoring of these pollutants throughout the engine's lifecycle is essential for ensuring ongoing compliance, particularly as emission control systems may degrade over time.

The integration of On-Board Diagnostics (OBD) systems specifically calibrated for Wankel engines represents a significant advancement in emissions monitoring. These systems can detect malfunctions in emission control components before they lead to excessive emissions. Advanced OBD systems incorporate machine learning algorithms that can predict potential emissions issues based on engine performance metrics, allowing for preventive maintenance before regulatory thresholds are exceeded.

Temperature management presents another critical environmental consideration for Wankel engines. The high operating temperatures can affect catalyst efficiency and emissions performance. Monitoring thermal metrics throughout the engine's lifecycle helps maintain optimal catalyst operation and reduces the formation of thermal NOx. Thermal sensors strategically placed throughout the exhaust system provide valuable data for emissions compliance strategies.

Fuel efficiency metrics also play a crucial role in environmental considerations. Wankel engines have historically faced challenges with fuel economy, which directly impacts their carbon footprint. Monitoring fuel consumption patterns throughout the engine's lifecycle can identify opportunities for optimization and reduce greenhouse gas emissions. Advanced monitoring systems now track the relationship between operating conditions, fuel consumption, and emissions output to develop more environmentally friendly control strategies.

The development of specialized catalytic converters for Wankel engines has improved their environmental performance significantly. Monitoring catalyst efficiency throughout the lifecycle is essential for maintaining emissions compliance. Sensors that measure pre- and post-catalyst emissions levels can detect degradation and ensure timely replacement before environmental standards are compromised.

As regulations continue to evolve toward zero-emission goals, lifecycle monitoring of Wankel engines must also consider end-of-life environmental impacts. This includes tracking materials used in emission control systems, potential for recycling components, and overall environmental footprint assessment. Comprehensive lifecycle monitoring now extends beyond operational emissions to encompass the entire environmental impact from manufacturing through disposal.

Current emissions regulations, including Euro 6d in Europe, Tier 3 in the United States, and China 6 standards, impose strict limits on nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. Wankel engines must meet these standards while maintaining their performance advantages. Continuous monitoring of these pollutants throughout the engine's lifecycle is essential for ensuring ongoing compliance, particularly as emission control systems may degrade over time.

The integration of On-Board Diagnostics (OBD) systems specifically calibrated for Wankel engines represents a significant advancement in emissions monitoring. These systems can detect malfunctions in emission control components before they lead to excessive emissions. Advanced OBD systems incorporate machine learning algorithms that can predict potential emissions issues based on engine performance metrics, allowing for preventive maintenance before regulatory thresholds are exceeded.

Temperature management presents another critical environmental consideration for Wankel engines. The high operating temperatures can affect catalyst efficiency and emissions performance. Monitoring thermal metrics throughout the engine's lifecycle helps maintain optimal catalyst operation and reduces the formation of thermal NOx. Thermal sensors strategically placed throughout the exhaust system provide valuable data for emissions compliance strategies.

Fuel efficiency metrics also play a crucial role in environmental considerations. Wankel engines have historically faced challenges with fuel economy, which directly impacts their carbon footprint. Monitoring fuel consumption patterns throughout the engine's lifecycle can identify opportunities for optimization and reduce greenhouse gas emissions. Advanced monitoring systems now track the relationship between operating conditions, fuel consumption, and emissions output to develop more environmentally friendly control strategies.

The development of specialized catalytic converters for Wankel engines has improved their environmental performance significantly. Monitoring catalyst efficiency throughout the lifecycle is essential for maintaining emissions compliance. Sensors that measure pre- and post-catalyst emissions levels can detect degradation and ensure timely replacement before environmental standards are compromised.

As regulations continue to evolve toward zero-emission goals, lifecycle monitoring of Wankel engines must also consider end-of-life environmental impacts. This includes tracking materials used in emission control systems, potential for recycling components, and overall environmental footprint assessment. Comprehensive lifecycle monitoring now extends beyond operational emissions to encompass the entire environmental impact from manufacturing through disposal.

Cost-Benefit Analysis of Predictive Maintenance Systems

Implementing predictive maintenance systems for Wankel engine lifecycle monitoring requires careful cost-benefit analysis to justify the investment. Initial implementation costs typically range from $50,000 to $250,000 depending on the scale and complexity of the monitoring system, including sensors, data acquisition hardware, software platforms, and integration expenses. These systems also incur ongoing operational costs of approximately 5-15% of the initial investment annually for maintenance, updates, and technical support.

The financial benefits of these systems are substantial when properly implemented. Studies across rotary engine applications show a 15-30% reduction in unplanned downtime, which translates to significant operational savings. For commercial applications, each hour of avoided downtime represents $1,000-$5,000 in preserved productivity. Additionally, predictive maintenance extends Wankel engine service life by 20-25% on average, delaying capital expenditure on replacement engines.

Parts inventory optimization represents another major cost advantage. Traditional maintenance approaches require extensive spare parts inventories, typically valued at 15-20% of the total engine asset value. Predictive systems reduce this inventory requirement by 30-40% through just-in-time parts procurement based on actual condition monitoring data rather than fixed schedules.

Labor efficiency improvements also contribute significantly to the return on investment. Maintenance staff utilization improves by 25-35% as technicians can focus on genuinely necessary tasks rather than performing routine inspections and preventive maintenance on healthy components. This efficiency gain allows organizations to either reduce maintenance staffing costs or redirect technical resources to higher-value activities.

The payback period for Wankel engine predictive maintenance systems typically ranges from 12 to 24 months, with more sophisticated implementations showing faster returns in high-utilization scenarios. Risk mitigation benefits must also be considered, as catastrophic engine failures can cost 5-10 times more than controlled maintenance interventions, not including potential safety incidents, environmental impacts, or regulatory penalties.

When evaluating these systems, organizations should consider both tangible and intangible benefits. While direct cost savings are easily quantifiable, improved reliability, enhanced safety records, and extended asset lifecycles contribute significantly to long-term organizational value that may not appear in immediate financial calculations.

The financial benefits of these systems are substantial when properly implemented. Studies across rotary engine applications show a 15-30% reduction in unplanned downtime, which translates to significant operational savings. For commercial applications, each hour of avoided downtime represents $1,000-$5,000 in preserved productivity. Additionally, predictive maintenance extends Wankel engine service life by 20-25% on average, delaying capital expenditure on replacement engines.

Parts inventory optimization represents another major cost advantage. Traditional maintenance approaches require extensive spare parts inventories, typically valued at 15-20% of the total engine asset value. Predictive systems reduce this inventory requirement by 30-40% through just-in-time parts procurement based on actual condition monitoring data rather than fixed schedules.

Labor efficiency improvements also contribute significantly to the return on investment. Maintenance staff utilization improves by 25-35% as technicians can focus on genuinely necessary tasks rather than performing routine inspections and preventive maintenance on healthy components. This efficiency gain allows organizations to either reduce maintenance staffing costs or redirect technical resources to higher-value activities.

The payback period for Wankel engine predictive maintenance systems typically ranges from 12 to 24 months, with more sophisticated implementations showing faster returns in high-utilization scenarios. Risk mitigation benefits must also be considered, as catastrophic engine failures can cost 5-10 times more than controlled maintenance interventions, not including potential safety incidents, environmental impacts, or regulatory penalties.

When evaluating these systems, organizations should consider both tangible and intangible benefits. While direct cost savings are easily quantifiable, improved reliability, enhanced safety records, and extended asset lifecycles contribute significantly to long-term organizational value that may not appear in immediate financial calculations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!