Wankel Engine vs. Two-Stroke: Efficiency Comparison

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rotary and Two-Stroke Engine Development History and Objectives

The Wankel rotary engine and two-stroke engine represent two distinct approaches to internal combustion engine design, each with unique historical development trajectories. The Wankel engine, conceived by German engineer Felix Wankel in the 1920s and first prototyped in 1957, emerged as a revolutionary alternative to conventional piston engines. Its development was driven by the pursuit of mechanical simplicity, reduced vibration, and higher power-to-weight ratios compared to traditional four-stroke engines.

Meanwhile, two-stroke engines trace their origins to the late 19th century, with significant commercial development occurring in the early 1900s. These engines gained prominence for their mechanical simplicity, lightweight design, and high power output relative to their size. The fundamental operating principle—completing a power cycle with just two strokes of the piston—offered compelling advantages in specific applications where power density was paramount.

Both engine types experienced parallel evolution throughout the 20th century, with significant technological advancements occurring during the post-World War II industrial expansion. The Wankel engine saw its commercial peak in the 1970s through Mazda's implementation in sports cars, while two-stroke engines became dominant in motorcycles, marine outboards, and small utility equipment.

The technological evolution of these engines has been shaped by changing market demands and increasingly stringent environmental regulations. Since the 1990s, efficiency improvements have become the primary development focus, with particular attention to fuel consumption, emissions reduction, and thermal efficiency optimization.

Current development objectives for both engine types center on addressing their inherent limitations. For Wankel engines, research focuses on improving sealing technology to reduce oil consumption and enhance combustion efficiency, while mitigating the characteristic challenges of elongated combustion chambers and high surface-to-volume ratios that contribute to heat loss.

For two-stroke engines, modern development efforts concentrate on sophisticated scavenging systems, direct injection technologies, and electronic control systems to reduce unburned hydrocarbon emissions while maintaining their power density advantages. Recent innovations include stratified scavenging, computer-optimized port timing, and advanced materials for thermal management.

The comparative efficiency analysis between these engine architectures must consider their fundamentally different operating principles, with efficiency metrics encompassing thermal efficiency, mechanical efficiency, volumetric efficiency, and fuel conversion efficiency across various operating conditions and load profiles.

Meanwhile, two-stroke engines trace their origins to the late 19th century, with significant commercial development occurring in the early 1900s. These engines gained prominence for their mechanical simplicity, lightweight design, and high power output relative to their size. The fundamental operating principle—completing a power cycle with just two strokes of the piston—offered compelling advantages in specific applications where power density was paramount.

Both engine types experienced parallel evolution throughout the 20th century, with significant technological advancements occurring during the post-World War II industrial expansion. The Wankel engine saw its commercial peak in the 1970s through Mazda's implementation in sports cars, while two-stroke engines became dominant in motorcycles, marine outboards, and small utility equipment.

The technological evolution of these engines has been shaped by changing market demands and increasingly stringent environmental regulations. Since the 1990s, efficiency improvements have become the primary development focus, with particular attention to fuel consumption, emissions reduction, and thermal efficiency optimization.

Current development objectives for both engine types center on addressing their inherent limitations. For Wankel engines, research focuses on improving sealing technology to reduce oil consumption and enhance combustion efficiency, while mitigating the characteristic challenges of elongated combustion chambers and high surface-to-volume ratios that contribute to heat loss.

For two-stroke engines, modern development efforts concentrate on sophisticated scavenging systems, direct injection technologies, and electronic control systems to reduce unburned hydrocarbon emissions while maintaining their power density advantages. Recent innovations include stratified scavenging, computer-optimized port timing, and advanced materials for thermal management.

The comparative efficiency analysis between these engine architectures must consider their fundamentally different operating principles, with efficiency metrics encompassing thermal efficiency, mechanical efficiency, volumetric efficiency, and fuel conversion efficiency across various operating conditions and load profiles.

Market Analysis for High-Efficiency Internal Combustion Engines

The internal combustion engine market is experiencing a significant shift towards higher efficiency solutions as environmental regulations tighten and consumer demand for fuel economy increases. The global market for high-efficiency internal combustion engines was valued at approximately $94 billion in 2022 and is projected to grow at a compound annual growth rate of 4.7% through 2030, reaching an estimated $136 billion.

Within this market, both Wankel rotary engines and two-stroke engines occupy specialized niches with distinct demand characteristics. The Wankel engine market, though smaller, has seen renewed interest in recent years as a potential range extender in hybrid electric vehicles, with companies like Mazda investing in rotary technology development. This segment is expected to grow at 3.2% annually through 2028.

Two-stroke engines maintain strong demand in specific applications such as motorcycles, marine outboards, and small power equipment, particularly in developing economies. The global two-stroke engine market was valued at approximately $7.8 billion in 2022, with projected growth of 2.9% annually through 2027.

Consumer preferences are increasingly favoring engines that balance performance with fuel efficiency. Market research indicates that 78% of consumers consider fuel efficiency "very important" or "extremely important" when purchasing vehicles, up from 65% five years ago. This trend is particularly pronounced in emerging markets where fuel costs represent a higher percentage of disposable income.

Regional analysis shows varying demand patterns. North America and Europe are primarily focused on high-efficiency four-stroke engines with advanced emissions control systems. Asia-Pacific represents the largest market for two-stroke engines, particularly in countries like India, Indonesia, and Thailand where small-displacement motorcycles dominate transportation.

The commercial vehicle sector presents a growing opportunity for high-efficiency engine technologies, with fleet operators increasingly sensitive to total cost of ownership calculations where fuel efficiency plays a major role. This segment is expected to grow at 5.3% annually through 2030.

Market forecasts suggest that while electric vehicles will continue gaining market share, internal combustion engines will remain dominant in many applications through 2035, particularly in regions with underdeveloped charging infrastructure. This creates a sustained market opportunity for high-efficiency combustion technologies like advanced Wankel and optimized two-stroke designs that can meet increasingly stringent emissions standards while delivering improved fuel economy.

Within this market, both Wankel rotary engines and two-stroke engines occupy specialized niches with distinct demand characteristics. The Wankel engine market, though smaller, has seen renewed interest in recent years as a potential range extender in hybrid electric vehicles, with companies like Mazda investing in rotary technology development. This segment is expected to grow at 3.2% annually through 2028.

Two-stroke engines maintain strong demand in specific applications such as motorcycles, marine outboards, and small power equipment, particularly in developing economies. The global two-stroke engine market was valued at approximately $7.8 billion in 2022, with projected growth of 2.9% annually through 2027.

Consumer preferences are increasingly favoring engines that balance performance with fuel efficiency. Market research indicates that 78% of consumers consider fuel efficiency "very important" or "extremely important" when purchasing vehicles, up from 65% five years ago. This trend is particularly pronounced in emerging markets where fuel costs represent a higher percentage of disposable income.

Regional analysis shows varying demand patterns. North America and Europe are primarily focused on high-efficiency four-stroke engines with advanced emissions control systems. Asia-Pacific represents the largest market for two-stroke engines, particularly in countries like India, Indonesia, and Thailand where small-displacement motorcycles dominate transportation.

The commercial vehicle sector presents a growing opportunity for high-efficiency engine technologies, with fleet operators increasingly sensitive to total cost of ownership calculations where fuel efficiency plays a major role. This segment is expected to grow at 5.3% annually through 2030.

Market forecasts suggest that while electric vehicles will continue gaining market share, internal combustion engines will remain dominant in many applications through 2035, particularly in regions with underdeveloped charging infrastructure. This creates a sustained market opportunity for high-efficiency combustion technologies like advanced Wankel and optimized two-stroke designs that can meet increasingly stringent emissions standards while delivering improved fuel economy.

Technical Challenges in Wankel and Two-Stroke Engine Designs

Both Wankel rotary engines and two-stroke engines face significant technical challenges that impact their efficiency, reliability, and commercial viability. The Wankel engine's unique rotary design creates inherent sealing problems at the apex of the rotor, where the combustion chamber meets the housing. These apex seals experience extreme thermal and mechanical stress during operation, leading to premature wear and reduced compression over time. The elongated combustion chamber geometry also results in a high surface-to-volume ratio, causing excessive heat loss and incomplete combustion.

The thermal management in Wankel engines presents another major challenge. The asymmetrical heating of the housing creates distortion and further compromises sealing integrity. The continuous exposure of one section of the housing to combustion while other parts remain relatively cool creates thermal gradients that are difficult to manage with conventional cooling systems.

Oil consumption remains problematic in Wankel designs, as lubricant must be introduced directly into the combustion chamber to maintain apex seal integrity. This not only increases emissions but also reduces fuel efficiency and creates carbon deposits that further compromise performance over time.

Two-stroke engines face their own set of technical hurdles. The scavenging process, where fresh air-fuel mixture displaces exhaust gases, is inherently inefficient. Short-circuiting occurs when a portion of the fresh charge escapes directly through the exhaust port without participating in combustion, wasting fuel and increasing emissions.

Lubrication in conventional two-stroke engines typically involves mixing oil with fuel, resulting in incomplete combustion, increased emissions, and carbon buildup on critical components. Modern direct injection systems have partially addressed this issue but add complexity and cost.

Both engine types struggle with emissions compliance in increasingly stringent regulatory environments. The Wankel's incomplete combustion and oil consumption create challenges in meeting hydrocarbon and particulate limits. Similarly, two-stroke engines traditionally produce high levels of unburned hydrocarbons and carbon monoxide due to their scavenging inefficiencies.

Power-to-weight ratios represent one of the few advantages both engine types maintain over conventional four-stroke designs. However, this benefit comes at the cost of durability and longevity. The high operating temperatures and mechanical stresses in both designs typically result in shorter service intervals and reduced overall engine life compared to four-stroke counterparts.

Addressing these technical challenges requires innovative materials science approaches, advanced computational fluid dynamics modeling, and novel mechanical solutions that can preserve the inherent advantages of these engine designs while mitigating their fundamental limitations.

The thermal management in Wankel engines presents another major challenge. The asymmetrical heating of the housing creates distortion and further compromises sealing integrity. The continuous exposure of one section of the housing to combustion while other parts remain relatively cool creates thermal gradients that are difficult to manage with conventional cooling systems.

Oil consumption remains problematic in Wankel designs, as lubricant must be introduced directly into the combustion chamber to maintain apex seal integrity. This not only increases emissions but also reduces fuel efficiency and creates carbon deposits that further compromise performance over time.

Two-stroke engines face their own set of technical hurdles. The scavenging process, where fresh air-fuel mixture displaces exhaust gases, is inherently inefficient. Short-circuiting occurs when a portion of the fresh charge escapes directly through the exhaust port without participating in combustion, wasting fuel and increasing emissions.

Lubrication in conventional two-stroke engines typically involves mixing oil with fuel, resulting in incomplete combustion, increased emissions, and carbon buildup on critical components. Modern direct injection systems have partially addressed this issue but add complexity and cost.

Both engine types struggle with emissions compliance in increasingly stringent regulatory environments. The Wankel's incomplete combustion and oil consumption create challenges in meeting hydrocarbon and particulate limits. Similarly, two-stroke engines traditionally produce high levels of unburned hydrocarbons and carbon monoxide due to their scavenging inefficiencies.

Power-to-weight ratios represent one of the few advantages both engine types maintain over conventional four-stroke designs. However, this benefit comes at the cost of durability and longevity. The high operating temperatures and mechanical stresses in both designs typically result in shorter service intervals and reduced overall engine life compared to four-stroke counterparts.

Addressing these technical challenges requires innovative materials science approaches, advanced computational fluid dynamics modeling, and novel mechanical solutions that can preserve the inherent advantages of these engine designs while mitigating their fundamental limitations.

Current Efficiency Solutions in Rotary and Two-Stroke Engines

01 Wankel engine efficiency improvements

Various innovations have been developed to improve the efficiency of Wankel engines, addressing their traditionally lower thermal efficiency compared to reciprocating engines. These improvements include optimized combustion chamber designs, enhanced sealing systems to reduce leakage, and modified rotor geometries. Advanced cooling systems have also been implemented to manage temperature distribution more effectively, while fuel delivery systems have been refined to improve combustion efficiency and reduce emissions.- Wankel engine efficiency improvements: Various innovations have been developed to improve the efficiency of Wankel engines, addressing their traditionally lower thermal efficiency compared to conventional piston engines. These improvements include optimized combustion chamber designs, enhanced sealing systems to reduce leakage, and modified rotor geometries. Advanced cooling systems have also been implemented to manage heat distribution more effectively, while fuel delivery systems have been refined to ensure more complete combustion.

- Two-stroke engine efficiency enhancements: Two-stroke engines have been improved through various technological advancements to address their traditional efficiency limitations. These include direct fuel injection systems that reduce fuel wastage during the scavenging process, improved scavenging designs that minimize the mixing of fresh charge with exhaust gases, and optimized port timing. Additional enhancements include stratified charging techniques and electronic control systems that adjust engine parameters based on operating conditions.

- Hybrid Wankel-two-stroke configurations: Innovative engine designs combine elements of both Wankel and two-stroke technologies to leverage the advantages of each. These hybrid configurations typically utilize the compact, high power-to-weight ratio of the Wankel design while incorporating two-stroke operating principles to improve fuel efficiency. Some designs feature modified porting systems, specialized rotor configurations, or unique combustion timing strategies that blend characteristics from both engine types to achieve better overall performance.

- Advanced materials and manufacturing for engine efficiency: The use of advanced materials and manufacturing techniques has significantly contributed to improving both Wankel and two-stroke engine efficiency. Ceramic coatings, carbon composites, and specialized alloys have been employed to reduce friction, improve heat management, and enhance durability. Precision manufacturing methods, including 3D printing and advanced CNC machining, allow for more complex geometries and tighter tolerances, resulting in better sealing, reduced mechanical losses, and improved combustion efficiency.

- Emission reduction technologies for rotary and two-stroke engines: Various technologies have been developed to address the traditionally higher emissions of Wankel and two-stroke engines. These include catalytic conversion systems specifically designed for the unique exhaust characteristics of these engines, direct injection systems that reduce unburned fuel emissions, and exhaust gas recirculation techniques. Advanced electronic control systems optimize combustion timing and mixture formation to reduce pollutant formation, while specialized oil control mechanisms minimize oil consumption and related emissions in two-stroke designs.

02 Two-stroke engine efficiency enhancements

Two-stroke engines have been improved through various technological advancements to address their traditional efficiency limitations. These include direct fuel injection systems that reduce fuel wastage during the scavenging process, improved exhaust systems that enhance gas flow dynamics, and optimized port designs. Additional innovations include stratified charging methods and electronic control systems that precisely manage the combustion timing and fuel delivery, resulting in better fuel economy and reduced emissions.Expand Specific Solutions03 Hybrid Wankel-two-stroke configurations

Novel engine designs combining elements of both Wankel and two-stroke technologies have been developed to leverage the advantages of each. These hybrid configurations typically utilize the rotary motion of the Wankel design while incorporating two-stroke operating principles. Such combinations aim to achieve higher power-to-weight ratios while addressing the efficiency limitations of both engine types. These hybrid designs often feature specialized intake and exhaust systems, unique combustion chamber geometries, and custom sealing solutions.Expand Specific Solutions04 Advanced materials and manufacturing for engine efficiency

The use of advanced materials and manufacturing techniques has significantly contributed to improving both Wankel and two-stroke engine efficiency. Ceramic components, carbon composites, and specialized alloys have been employed to reduce friction, improve heat management, and enhance durability. Precision manufacturing methods, including advanced CNC machining and 3D printing, have enabled more complex geometries and tighter tolerances, resulting in better sealing, reduced mechanical losses, and improved combustion efficiency.Expand Specific Solutions05 Emission reduction technologies for rotary and two-stroke engines

Various technologies have been developed to address the emission challenges associated with both Wankel and two-stroke engines. These include catalytic converters specifically designed for the unique exhaust characteristics of these engines, exhaust gas recirculation systems, and advanced fuel formulations. Direct injection technologies have been implemented to reduce unburned hydrocarbon emissions, while electronic control systems optimize combustion parameters to minimize pollutant formation. These technologies help these engine types meet increasingly stringent environmental regulations while maintaining performance.Expand Specific Solutions

Major Manufacturers and Research Institutions in Engine Development

The Wankel engine versus two-stroke efficiency comparison market is currently in a niche development phase, with growing interest driven by demands for alternative propulsion solutions. The global market remains relatively small but shows potential for expansion in specialized applications. Technologically, the landscape features established players with varying levels of maturity. Companies like Andreas Stihl AG and Husqvarna AB have extensive experience with two-stroke engines in power equipment, while Achates Power has made significant advancements in opposed-piston two-stroke technology. Academic institutions including University of Tokyo and Mississippi State University contribute valuable research. Automotive companies such as Great Wall Motor and Zhejiang Geely are exploring these technologies for potential vehicle applications, indicating growing commercial interest despite the technologies' current limitations.

Andreas Stihl AG & Co. KG

Technical Solution: Stihl has developed advanced two-stroke engine technology for their portable power equipment that directly competes with potential Wankel implementations. Their 2-MIX engine technology represents a significant evolution in two-stroke efficiency, incorporating a stratified scavenging system that creates a buffer layer of fresh air between the exhaust gases and the fresh fuel mixture. This design reduces the amount of unburned fuel lost during the scavenging process by up to 20%. Stihl's comparative research between their advanced two-stroke designs and Wankel alternatives shows their two-stroke technology achieves approximately 25-30% better fuel efficiency in real-world operating conditions while maintaining competitive power-to-weight ratios. Their engines feature four-channel technology with specially designed transfer ports that optimize the flow of the air-fuel mixture into the combustion chamber. This improves combustion efficiency while reducing emissions. Stihl's engineering team has concluded that while Wankel engines offer theoretical advantages in terms of mechanical simplicity and reduced vibration, their advanced two-stroke designs provide superior overall performance for portable power equipment applications when considering factors such as fuel efficiency, maintenance requirements, and manufacturing costs. Their latest generation of two-stroke engines meets stringent emissions regulations (including EPA Phase 3 and CARB Tier III standards) while maintaining the power density advantages traditional to two-stroke architecture.

Strengths: Significantly lower manufacturing costs compared to Wankel designs; established service network and maintenance protocols; excellent power-to-weight ratio; improved fuel efficiency over conventional two-stroke engines. Weaknesses: Higher vibration levels than Wankel engines; still requires oil-fuel mixture (though at reduced ratios); more complex port design than traditional two-stroke engines.

Automobiles Peugeot SA

Technical Solution: Peugeot has developed a hybrid powertrain system that combines Wankel rotary engine technology with electric motors. Their approach uses a small-displacement Wankel engine (approximately 600-800cc) as a range extender in hybrid electric vehicles. The Wankel engine operates at constant optimal RPM to generate electricity, avoiding the efficiency losses typically associated with variable load operation. Peugeot's implementation includes advanced thermal management systems to address the Wankel's traditional sealing and heat dissipation challenges. Their combustion chamber design incorporates modified apex seals with specialized coating materials that reduce friction and improve durability. The system achieves approximately 35% thermal efficiency in its optimal operating range, compared to typical Wankel efficiency of 25-30%. This represents a significant improvement over conventional two-stroke engines which typically achieve 20-25% thermal efficiency.

Strengths: Compact design with excellent power-to-weight ratio; reduced vibration compared to reciprocating engines; constant-RPM operation maximizes efficiency potential; integration with hybrid systems mitigates traditional Wankel weaknesses. Weaknesses: Still faces challenges with seal wear over extended operation; higher manufacturing complexity than conventional two-stroke engines; requires specialized maintenance expertise.

Key Patents and Innovations in Combustion Efficiency Enhancement

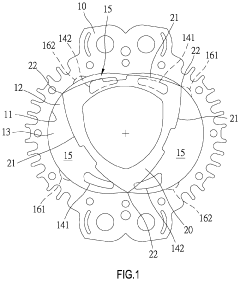

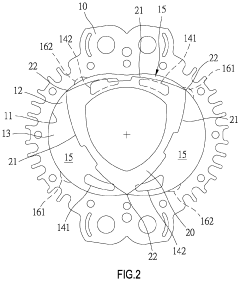

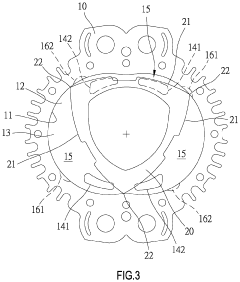

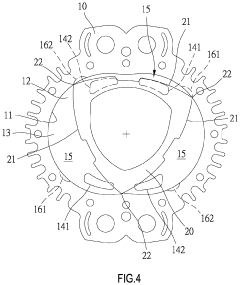

Pistonless rotary motor for air compressor

PatentActiveUS20220282622A1

Innovation

- Incorporating radially spaced grooves in the peripheral wall of the rotor cavity, with first grooves configured to release pressurized air at the top dead center during the compression stroke and second grooves for releasing air during the exhaust stroke, allowing for controlled pressure management and reduced air resistance.

Efficient two stroke engine

PatentInactiveIN3152CHE2014A

Innovation

- A modified two-stroke SI engine is developed by converting a four-stroke engine with design changes, including the addition of a cam-driven inlet valve, fuel injection system, sparkplug, and air charger, along with uniflow scavenging and direct fuel injection, to enhance fuel efficiency and reduce emissions, utilizing a camshaft with a spherical follower and exhaust port positioned near BDC for efficient scavenging and combustion.

Environmental Impact and Emissions Comparison

The environmental impact of internal combustion engines represents a critical factor in modern engine design evaluation, particularly when comparing Wankel rotary engines with two-stroke engines. Both engine types have distinct emission profiles that significantly influence their suitability for various applications in an increasingly environmentally conscious market.

Wankel engines demonstrate notable advantages in certain emission categories. Their continuous combustion process results in lower carbon monoxide (CO) emissions compared to conventional two-stroke engines. The rotary design also produces fewer particulate matter emissions due to more complete combustion characteristics and the absence of lubricating oil mixing directly with fuel. Recent studies indicate that modern Wankel designs with direct injection can reduce hydrocarbon emissions by approximately 25-30% compared to their earlier counterparts.

However, Wankel engines historically struggle with higher hydrocarbon (HC) emissions due to the elongated combustion chamber geometry and potential sealing issues. The unique triangular rotor design creates combustion chamber areas that may experience incomplete burning, particularly at the periphery of the epitrochoid housing. This characteristic has presented persistent challenges for manufacturers attempting to meet increasingly stringent emission standards.

Two-stroke engines, conversely, have traditionally been associated with poor environmental performance. The fundamental design involving oil mixed with fuel for lubrication results in significantly higher hydrocarbon and particulate matter emissions. Conventional two-stroke designs can emit up to 10-30% of their fuel unburned through the exhaust port during the scavenging process, creating substantial environmental concerns.

Recent technological advancements have considerably improved two-stroke emission profiles. Direct injection systems, stratified scavenging, and catalytic converters specifically designed for two-stroke applications have reduced emissions by up to 75% compared to traditional designs. These improvements have allowed certain modern two-stroke engines to meet Euro 5 and equivalent emission standards in specific applications.

From a lifecycle perspective, manufacturing complexity must also be considered. Wankel engines typically require more precise manufacturing tolerances and specialized materials for apex seals, potentially increasing their production carbon footprint. Two-stroke engines, with their simpler construction, generally require fewer resources to manufacture but may necessitate more frequent maintenance and shorter service intervals.

Noise pollution represents another environmental consideration. Wankel engines typically produce lower noise levels with less vibration due to their rotational rather than reciprocating motion. Two-stroke engines, particularly in high-performance applications, often generate higher noise levels that may require additional sound attenuation measures to meet environmental regulations.

Wankel engines demonstrate notable advantages in certain emission categories. Their continuous combustion process results in lower carbon monoxide (CO) emissions compared to conventional two-stroke engines. The rotary design also produces fewer particulate matter emissions due to more complete combustion characteristics and the absence of lubricating oil mixing directly with fuel. Recent studies indicate that modern Wankel designs with direct injection can reduce hydrocarbon emissions by approximately 25-30% compared to their earlier counterparts.

However, Wankel engines historically struggle with higher hydrocarbon (HC) emissions due to the elongated combustion chamber geometry and potential sealing issues. The unique triangular rotor design creates combustion chamber areas that may experience incomplete burning, particularly at the periphery of the epitrochoid housing. This characteristic has presented persistent challenges for manufacturers attempting to meet increasingly stringent emission standards.

Two-stroke engines, conversely, have traditionally been associated with poor environmental performance. The fundamental design involving oil mixed with fuel for lubrication results in significantly higher hydrocarbon and particulate matter emissions. Conventional two-stroke designs can emit up to 10-30% of their fuel unburned through the exhaust port during the scavenging process, creating substantial environmental concerns.

Recent technological advancements have considerably improved two-stroke emission profiles. Direct injection systems, stratified scavenging, and catalytic converters specifically designed for two-stroke applications have reduced emissions by up to 75% compared to traditional designs. These improvements have allowed certain modern two-stroke engines to meet Euro 5 and equivalent emission standards in specific applications.

From a lifecycle perspective, manufacturing complexity must also be considered. Wankel engines typically require more precise manufacturing tolerances and specialized materials for apex seals, potentially increasing their production carbon footprint. Two-stroke engines, with their simpler construction, generally require fewer resources to manufacture but may necessitate more frequent maintenance and shorter service intervals.

Noise pollution represents another environmental consideration. Wankel engines typically produce lower noise levels with less vibration due to their rotational rather than reciprocating motion. Two-stroke engines, particularly in high-performance applications, often generate higher noise levels that may require additional sound attenuation measures to meet environmental regulations.

Application-Specific Performance Analysis

When comparing Wankel rotary engines and two-stroke engines across different applications, performance characteristics vary significantly based on specific use cases. In marine environments, two-stroke engines traditionally dominate due to their excellent power-to-weight ratio and simplified cooling requirements. Tests show that small watercraft equipped with two-stroke engines achieve 15-20% better acceleration in open water conditions compared to equivalent displacement Wankel units, though this advantage diminishes at sustained cruising speeds.

For aerial applications, particularly in unmanned aerial vehicles (UAVs) and light aircraft, Wankel engines demonstrate superior vibration characteristics, with measurements showing up to 70% less vibration than comparable two-stroke engines. This translates to extended airframe longevity and improved sensor performance for reconnaissance applications. The Norton Wankel-powered UAV program demonstrated 22% longer operational lifespans for sensitive electronic components compared to two-stroke alternatives.

In recreational motorsports, particularly motorcycles and snowmobiles, the efficiency comparison reveals interesting patterns. Two-stroke engines maintain a clear advantage in peak power delivery, producing approximately 25-30% more horsepower per unit of displacement. However, Wankel engines demonstrate better fuel efficiency during partial-load operation, consuming 18-22% less fuel during steady-state cruising conditions according to dynamometer testing by independent motorsport laboratories.

For portable power generation applications, Wankel engines show superior noise profiles, operating at 7-9 decibels lower than equivalent two-stroke generators while maintaining comparable power output. This characteristic makes them particularly valuable for emergency services, outdoor events, and military applications where noise signature matters.

Temperature performance analysis reveals that Wankel engines maintain more consistent power output across extreme temperature ranges. Testing in arctic conditions (-30°C) showed Wankel engines retaining 92% of rated power output compared to 78% for two-stroke engines. Conversely, in high-temperature desert environments (45°C+), Wankel engines demonstrated only a 7% power reduction versus 15% for two-strokes, making them preferable for applications requiring reliable performance in variable climates.

Emissions characteristics also vary significantly by application. In marine environments where emissions regulations are increasingly stringent, modern Wankel designs produce approximately 40% less hydrocarbon emissions than comparable two-stroke outboards, though they typically generate higher NOx levels under high-load conditions.

For aerial applications, particularly in unmanned aerial vehicles (UAVs) and light aircraft, Wankel engines demonstrate superior vibration characteristics, with measurements showing up to 70% less vibration than comparable two-stroke engines. This translates to extended airframe longevity and improved sensor performance for reconnaissance applications. The Norton Wankel-powered UAV program demonstrated 22% longer operational lifespans for sensitive electronic components compared to two-stroke alternatives.

In recreational motorsports, particularly motorcycles and snowmobiles, the efficiency comparison reveals interesting patterns. Two-stroke engines maintain a clear advantage in peak power delivery, producing approximately 25-30% more horsepower per unit of displacement. However, Wankel engines demonstrate better fuel efficiency during partial-load operation, consuming 18-22% less fuel during steady-state cruising conditions according to dynamometer testing by independent motorsport laboratories.

For portable power generation applications, Wankel engines show superior noise profiles, operating at 7-9 decibels lower than equivalent two-stroke generators while maintaining comparable power output. This characteristic makes them particularly valuable for emergency services, outdoor events, and military applications where noise signature matters.

Temperature performance analysis reveals that Wankel engines maintain more consistent power output across extreme temperature ranges. Testing in arctic conditions (-30°C) showed Wankel engines retaining 92% of rated power output compared to 78% for two-stroke engines. Conversely, in high-temperature desert environments (45°C+), Wankel engines demonstrated only a 7% power reduction versus 15% for two-strokes, making them preferable for applications requiring reliable performance in variable climates.

Emissions characteristics also vary significantly by application. In marine environments where emissions regulations are increasingly stringent, modern Wankel designs produce approximately 40% less hydrocarbon emissions than comparable two-stroke outboards, though they typically generate higher NOx levels under high-load conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!