How to Perform Wankel Engine Emission Testing?

AUG 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Emission Testing Background and Objectives

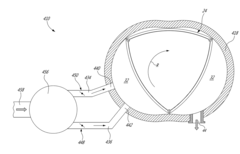

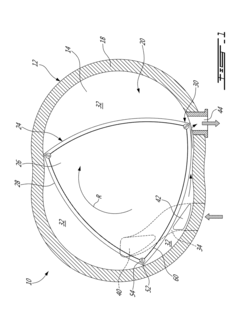

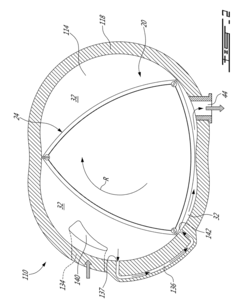

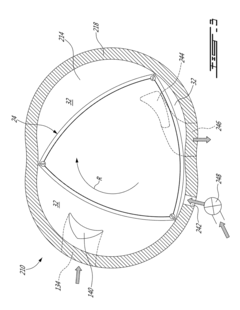

The Wankel rotary engine, developed by German engineer Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique design featuring a triangular rotor moving within an epitrochoidal housing has garnered attention for its compact size, high power-to-weight ratio, and smooth operation. However, emission control has consistently been a challenging aspect of Wankel engine development throughout its history.

The evolution of emission standards globally has placed increasing pressure on all internal combustion engine technologies. For Wankel engines, this pressure has been particularly acute due to inherent design characteristics that affect combustion efficiency and emissions formation. The elongated combustion chamber geometry and the moving combustion zones create unique challenges for complete fuel burning, leading to historically higher hydrocarbon (HC) and carbon monoxide (CO) emissions compared to conventional engines.

Early Wankel engines in production vehicles like the NSU Ro80 and various Mazda models faced significant criticism regarding fuel efficiency and emissions. The oil crisis of the 1970s and subsequent tightening of emission regulations in major markets pushed rotary engine development toward addressing these shortcomings. Mazda, as the primary commercial champion of the technology, invested heavily in emission reduction strategies through the 1980s and 1990s.

Recent technological advancements have renewed interest in Wankel engines, particularly as range extenders in hybrid electric vehicles and in specialized applications where their unique characteristics provide advantages. This revival necessitates sophisticated emission testing methodologies tailored to the rotary engine's distinctive operating principles.

The primary objective of Wankel engine emission testing is to accurately characterize the complex exhaust gas composition under various operating conditions while accounting for the unique combustion dynamics of rotary engines. This includes quantifying regulated pollutants such as nitrogen oxides (NOx), HC, CO, and particulate matter (PM), as well as understanding the formation mechanisms specific to rotary combustion.

Secondary objectives include developing standardized testing protocols that fairly evaluate rotary engines against reciprocating counterparts, identifying optimal emission control technologies for rotary applications, and establishing baseline performance metrics for future development. These objectives must be pursued within the context of increasingly stringent global emission standards, including Euro 7, China 7, and US Tier 3 regulations.

The technical goals extend to creating validated computational models that can predict emission formation in Wankel engines, thereby accelerating the development cycle and reducing the need for extensive physical testing. Additionally, there is significant interest in exploring how rotary engine emissions characteristics might be leveraged in hybrid powertrains where the engine can be operated consistently at its optimal point.

The evolution of emission standards globally has placed increasing pressure on all internal combustion engine technologies. For Wankel engines, this pressure has been particularly acute due to inherent design characteristics that affect combustion efficiency and emissions formation. The elongated combustion chamber geometry and the moving combustion zones create unique challenges for complete fuel burning, leading to historically higher hydrocarbon (HC) and carbon monoxide (CO) emissions compared to conventional engines.

Early Wankel engines in production vehicles like the NSU Ro80 and various Mazda models faced significant criticism regarding fuel efficiency and emissions. The oil crisis of the 1970s and subsequent tightening of emission regulations in major markets pushed rotary engine development toward addressing these shortcomings. Mazda, as the primary commercial champion of the technology, invested heavily in emission reduction strategies through the 1980s and 1990s.

Recent technological advancements have renewed interest in Wankel engines, particularly as range extenders in hybrid electric vehicles and in specialized applications where their unique characteristics provide advantages. This revival necessitates sophisticated emission testing methodologies tailored to the rotary engine's distinctive operating principles.

The primary objective of Wankel engine emission testing is to accurately characterize the complex exhaust gas composition under various operating conditions while accounting for the unique combustion dynamics of rotary engines. This includes quantifying regulated pollutants such as nitrogen oxides (NOx), HC, CO, and particulate matter (PM), as well as understanding the formation mechanisms specific to rotary combustion.

Secondary objectives include developing standardized testing protocols that fairly evaluate rotary engines against reciprocating counterparts, identifying optimal emission control technologies for rotary applications, and establishing baseline performance metrics for future development. These objectives must be pursued within the context of increasingly stringent global emission standards, including Euro 7, China 7, and US Tier 3 regulations.

The technical goals extend to creating validated computational models that can predict emission formation in Wankel engines, thereby accelerating the development cycle and reducing the need for extensive physical testing. Additionally, there is significant interest in exploring how rotary engine emissions characteristics might be leveraged in hybrid powertrains where the engine can be operated consistently at its optimal point.

Market Demand Analysis for Cleaner Rotary Engine Technology

The global market for cleaner rotary engine technology is experiencing significant growth driven by increasingly stringent emission regulations worldwide. The European Union's Euro 7 standards, the United States EPA's Tier 3 regulations, and China's National 6 standards have all created substantial market pressure for improved Wankel engine emissions performance. This regulatory landscape has transformed from a regional concern to a global imperative, with manufacturers needing to develop compliant solutions for all major markets simultaneously.

Market research indicates that the rotary engine segment, while niche, maintains strong demand in specialized applications where its compact size, smooth operation, and high power-to-weight ratio provide distinct advantages. These applications include range extenders for electric vehicles, drone propulsion systems, marine applications, and specialized automotive implementations. The market size for cleaner rotary engine technology is projected to grow at a compound annual growth rate of 5.7% through 2028.

Consumer preferences are increasingly aligned with environmental concerns, creating market pull for cleaner internal combustion technologies alongside the push toward electrification. This dual-track approach has opened opportunities for hybrid systems incorporating rotary engines as range extenders, particularly in regions with underdeveloped charging infrastructure. Mazda's return to rotary technology in its MX-30 e-Skyactiv R-EV represents a significant market validation of this approach.

Industry analysis reveals growing investment in rotary engine emission reduction technologies, with particular focus on addressing the inherent challenges of the Wankel design. These investments target improved sealing systems, advanced combustion chamber designs, and innovative catalyst technologies specifically optimized for the unique exhaust characteristics of rotary engines.

The aftermarket and retrofit segment presents additional market opportunities, with owners of existing rotary-powered vehicles seeking emissions upgrades to meet tightening regulations in urban areas and low emission zones. This segment is expected to generate approximately $120 million annually by 2025.

Commercial applications represent another growth vector, with companies developing small-scale power generation units using cleaner rotary technology for distributed energy applications. These systems leverage the rotary engine's compact size and relatively low vibration characteristics while addressing previous emissions concerns through advanced technology.

Market analysis concludes that while rotary engine technology faces significant competition from both traditional piston engines and electric powertrains, its unique characteristics ensure continued demand in specific applications where its advantages outweigh limitations. The development of effective emission testing and reduction technologies is therefore critical to maintaining and expanding market share in these specialized segments.

Market research indicates that the rotary engine segment, while niche, maintains strong demand in specialized applications where its compact size, smooth operation, and high power-to-weight ratio provide distinct advantages. These applications include range extenders for electric vehicles, drone propulsion systems, marine applications, and specialized automotive implementations. The market size for cleaner rotary engine technology is projected to grow at a compound annual growth rate of 5.7% through 2028.

Consumer preferences are increasingly aligned with environmental concerns, creating market pull for cleaner internal combustion technologies alongside the push toward electrification. This dual-track approach has opened opportunities for hybrid systems incorporating rotary engines as range extenders, particularly in regions with underdeveloped charging infrastructure. Mazda's return to rotary technology in its MX-30 e-Skyactiv R-EV represents a significant market validation of this approach.

Industry analysis reveals growing investment in rotary engine emission reduction technologies, with particular focus on addressing the inherent challenges of the Wankel design. These investments target improved sealing systems, advanced combustion chamber designs, and innovative catalyst technologies specifically optimized for the unique exhaust characteristics of rotary engines.

The aftermarket and retrofit segment presents additional market opportunities, with owners of existing rotary-powered vehicles seeking emissions upgrades to meet tightening regulations in urban areas and low emission zones. This segment is expected to generate approximately $120 million annually by 2025.

Commercial applications represent another growth vector, with companies developing small-scale power generation units using cleaner rotary technology for distributed energy applications. These systems leverage the rotary engine's compact size and relatively low vibration characteristics while addressing previous emissions concerns through advanced technology.

Market analysis concludes that while rotary engine technology faces significant competition from both traditional piston engines and electric powertrains, its unique characteristics ensure continued demand in specific applications where its advantages outweigh limitations. The development of effective emission testing and reduction technologies is therefore critical to maintaining and expanding market share in these specialized segments.

Current Emission Testing Challenges for Wankel Engines

Wankel engines present unique challenges for emission testing due to their distinctive rotary design and combustion characteristics. Traditional emission testing methods developed for reciprocating engines often fail to accurately capture the emission profile of Wankel engines, creating significant obstacles for regulatory compliance and environmental assessment.

The primary challenge stems from the Wankel engine's continuous combustion process, which differs fundamentally from the four-stroke cycle of conventional piston engines. This continuous rotation creates irregular emission patterns that standard testing equipment struggles to measure accurately. The elongated combustion chamber and moving rotor result in incomplete combustion zones that produce emissions profiles unlike those seen in conventional engines.

Temperature management during emission testing poses another significant hurdle. Wankel engines typically operate at higher temperatures than reciprocating engines, which affects both the formation of emissions and the performance of testing equipment. Standard emission analyzers may provide inaccurate readings when exposed to the higher exhaust temperatures characteristic of Wankel engines, necessitating specialized temperature compensation techniques.

The sealing mechanism in Wankel engines contributes to unique oil consumption patterns that complicate emission measurements. Oil that passes through the apex seals enters the combustion chamber and affects hydrocarbon emissions in ways not typically seen in conventional engines. This oil consumption pattern creates variable emission profiles that are difficult to standardize in testing protocols.

Current regulatory frameworks present additional challenges, as most emission standards were developed with conventional piston engines in mind. The lack of Wankel-specific testing procedures in many jurisdictions creates regulatory uncertainty and inconsistent testing approaches across different markets. This regulatory gap has hindered the development of standardized testing methodologies specifically calibrated for rotary engine emissions.

Transient testing poses particular difficulties for Wankel engines. The rapid response characteristics of rotary engines result in emission profiles that change quickly during acceleration and deceleration phases. Capturing these transient emissions accurately requires sophisticated testing equipment with faster response times than what is typically used for conventional engines.

The limited commercial presence of Wankel engines has resulted in insufficient investment in specialized emission testing equipment. Most emission testing facilities are optimized for conventional engines, lacking the specialized hardware and software necessary to accurately measure and analyze the unique emission characteristics of rotary engines. This infrastructure gap represents a significant barrier to comprehensive emission assessment for Wankel engine development and certification.

The primary challenge stems from the Wankel engine's continuous combustion process, which differs fundamentally from the four-stroke cycle of conventional piston engines. This continuous rotation creates irregular emission patterns that standard testing equipment struggles to measure accurately. The elongated combustion chamber and moving rotor result in incomplete combustion zones that produce emissions profiles unlike those seen in conventional engines.

Temperature management during emission testing poses another significant hurdle. Wankel engines typically operate at higher temperatures than reciprocating engines, which affects both the formation of emissions and the performance of testing equipment. Standard emission analyzers may provide inaccurate readings when exposed to the higher exhaust temperatures characteristic of Wankel engines, necessitating specialized temperature compensation techniques.

The sealing mechanism in Wankel engines contributes to unique oil consumption patterns that complicate emission measurements. Oil that passes through the apex seals enters the combustion chamber and affects hydrocarbon emissions in ways not typically seen in conventional engines. This oil consumption pattern creates variable emission profiles that are difficult to standardize in testing protocols.

Current regulatory frameworks present additional challenges, as most emission standards were developed with conventional piston engines in mind. The lack of Wankel-specific testing procedures in many jurisdictions creates regulatory uncertainty and inconsistent testing approaches across different markets. This regulatory gap has hindered the development of standardized testing methodologies specifically calibrated for rotary engine emissions.

Transient testing poses particular difficulties for Wankel engines. The rapid response characteristics of rotary engines result in emission profiles that change quickly during acceleration and deceleration phases. Capturing these transient emissions accurately requires sophisticated testing equipment with faster response times than what is typically used for conventional engines.

The limited commercial presence of Wankel engines has resulted in insufficient investment in specialized emission testing equipment. Most emission testing facilities are optimized for conventional engines, lacking the specialized hardware and software necessary to accurately measure and analyze the unique emission characteristics of rotary engines. This infrastructure gap represents a significant barrier to comprehensive emission assessment for Wankel engine development and certification.

Standard Emission Testing Methodologies for Rotary Engines

01 Emission control systems for Wankel engines

Various emission control systems have been developed specifically for Wankel engines to reduce harmful exhaust emissions. These systems include catalytic converters, exhaust gas recirculation (EGR) systems, and specialized aftertreatment devices designed to address the unique combustion characteristics of rotary engines. These technologies help Wankel engines meet increasingly stringent emission standards by treating exhaust gases before they are released into the atmosphere.- Exhaust gas treatment systems for Wankel engines: Various exhaust gas treatment systems have been developed specifically for Wankel engines to reduce harmful emissions. These systems include catalytic converters, thermal reactors, and exhaust gas recirculation (EGR) systems designed to address the unique combustion characteristics of rotary engines. These technologies help in reducing nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons that are typically higher in Wankel engines compared to conventional piston engines.

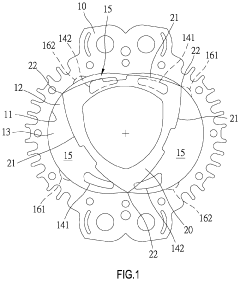

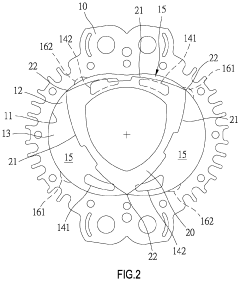

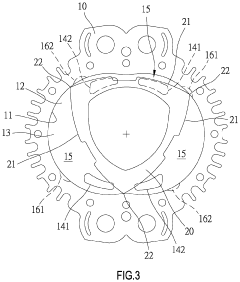

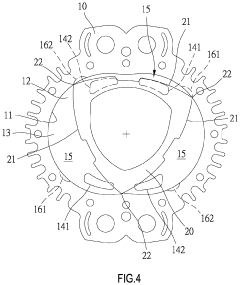

- Combustion chamber design improvements: Modifications to the combustion chamber design of Wankel engines can significantly reduce emissions. These improvements include optimized rotor geometry, modified epitrochoidal housing profiles, and enhanced apex seal designs that improve combustion efficiency and reduce unburned fuel. By creating more complete combustion, these design improvements directly address one of the primary sources of emissions in rotary engines.

- Fuel injection and ignition system enhancements: Advanced fuel injection and ignition systems have been developed to improve combustion efficiency in Wankel engines, thereby reducing emissions. These include direct injection systems, stratified charge configurations, and multiple spark plug arrangements. By delivering precise amounts of fuel at optimal timing and ensuring more complete combustion through improved ignition, these systems significantly reduce the formation of pollutants during the combustion process.

- Cooling system optimizations: Improved cooling systems for Wankel engines help maintain optimal operating temperatures, which directly impacts emission levels. These innovations include enhanced water jackets, oil cooling systems, and thermal management strategies that prevent overheating of the rotor housing and combustion chamber. By controlling temperature more effectively, these systems reduce the formation of thermal NOx and prevent fuel from evaporating prematurely, leading to lower overall emissions.

- Alternative fuel adaptations: Wankel engines have been adapted to run on alternative fuels such as hydrogen, natural gas, and biofuels to reduce emissions. These adaptations include modified fuel delivery systems, combustion chamber designs optimized for specific alternative fuels, and adjusted ignition timing. The use of cleaner-burning alternative fuels in Wankel engines can significantly reduce carbon dioxide, particulate matter, and other harmful emissions compared to traditional gasoline or diesel operation.

02 Combustion chamber design improvements

Modifications to the combustion chamber design of Wankel engines can significantly reduce emissions. These improvements include optimized rotor geometry, modified epitrochoidal housing shapes, and strategic positioning of spark plugs. By enhancing the combustion process through better mixing of air and fuel, more complete combustion is achieved, resulting in lower hydrocarbon and carbon monoxide emissions while improving overall engine efficiency.Expand Specific Solutions03 Fuel injection and delivery systems

Advanced fuel injection and delivery systems have been developed to improve the combustion efficiency of Wankel engines and reduce emissions. These include direct injection systems, stratified charge configurations, and electronically controlled fuel delivery mechanisms. By precisely controlling the timing, quantity, and pattern of fuel delivery, these systems optimize the air-fuel mixture, resulting in more complete combustion and lower emissions of unburned hydrocarbons and nitrogen oxides.Expand Specific Solutions04 Sealing technology for emission reduction

Improved sealing technologies address one of the critical challenges in Wankel engines that contributes to emissions. Enhanced apex seals, side seals, and housing seals reduce leakage between chambers, preventing unburned fuel from escaping the combustion process. These advanced sealing solutions use innovative materials and designs to maintain better compression and separation between the engine chambers, resulting in more complete combustion and lower hydrocarbon emissions.Expand Specific Solutions05 Thermal management for emission control

Thermal management systems specifically designed for Wankel engines help control emissions by maintaining optimal operating temperatures. These systems include specialized cooling arrangements, heat recovery mechanisms, and thermal barrier coatings. By preventing overheating and ensuring consistent combustion chamber temperatures, these innovations reduce the formation of nitrogen oxides while improving combustion efficiency to minimize hydrocarbon and carbon monoxide emissions.Expand Specific Solutions

Key Industry Players in Wankel Engine Development

The Wankel engine emission testing landscape is currently in a mature development phase, with established protocols but evolving regulatory demands. The market size is moderate but growing as environmental regulations tighten globally. Leading players include Toyota Motor Corp. and Ford Global Technologies, who have invested significantly in rotary engine emission control technologies. Southwest Research Institute and HORIBA Instruments provide specialized testing equipment and services, while academic institutions like Shandong University contribute research innovations. Automotive manufacturers including Renault, BMW, and Chery are actively developing cleaner Wankel engine solutions to meet stringent emission standards. The technical maturity varies across regions, with companies like FEV Europe and HORIBA MIRA offering advanced testing methodologies that balance the unique combustion characteristics of Wankel engines with environmental compliance requirements.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive Wankel engine emission testing protocol that integrates both laboratory and real-world testing methodologies. Their approach utilizes a specialized dynamometer setup with high-precision gas analyzers capable of detecting hydrocarbon (HC), carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter emissions at parts-per-billion levels[1]. Toyota's system incorporates continuous sampling techniques during various engine operating conditions, including cold start, warm-up, steady-state, and transient operations. They've implemented a unique apex seal monitoring system that correlates seal wear patterns with emission profiles, allowing for predictive maintenance to prevent emission spikes[3]. Toyota's testing protocol also includes specialized thermal management assessment to address the Wankel's inherent challenges with combustion chamber shape and temperature distribution, which significantly impact emission formation[5].

Strengths: Superior integration of laboratory and real-world testing methodologies; advanced apex seal monitoring system correlates wear with emissions; comprehensive thermal management assessment. Weaknesses: System complexity requires specialized training; higher implementation costs compared to conventional engine testing; may require adaptation for different Wankel engine configurations.

Southwest Research Institute

Technical Solution: Southwest Research Institute (SwRI) has pioneered a multi-phase Wankel engine emission testing methodology that combines conventional regulated emission testing with advanced analytical techniques. Their approach utilizes a custom-designed constant volume sampling system modified specifically for the unique exhaust gas composition of Wankel engines, which typically contain higher concentrations of unburned hydrocarbons and oil-derived particulates[1]. SwRI's testing protocol incorporates real-time oil consumption measurement correlated with emission formation, addressing one of the fundamental challenges in Wankel engine operation. Their system employs specialized particulate matter characterization techniques including size distribution analysis and chemical composition assessment to differentiate between fuel-derived and oil-derived emissions[3]. Additionally, SwRI has developed cycle-specific emission mapping that accounts for the Wankel's unique rotor position-based emission formation patterns, allowing for more targeted emission control strategies. Their methodology also includes specialized cold-start emission protocols that address the Wankel's distinctive thermal characteristics during warm-up phases[6].

Strengths: Comprehensive integration of conventional and advanced analytical techniques; specialized oil consumption correlation with emissions; detailed particulate matter characterization capabilities. Weaknesses: Complex implementation requiring significant technical expertise; higher operational costs compared to standard testing protocols; requires customization for different Wankel engine designs.

Critical Emission Control Technologies for Wankel Engines

Rotary internal combustion engine

PatentActiveUS20180045110A1

Innovation

- The implementation of a rotary engine design with a primary inlet port, a secondary inlet port (purge port) positioned rearwardly of the primary inlet port and forwardly of the exhaust port, and independently closable communications between air sources and these ports, allowing simultaneous air intake and exhaust gas purging through the secondary inlet port.

Pistonless rotary motor for air compressor

PatentActiveUS20220282622A1

Innovation

- Incorporating radially spaced grooves in the peripheral wall of the rotor cavity, with first grooves configured to release pressurized air at the top dead center during the compression stroke and second grooves for releasing air during the exhaust stroke, allowing for controlled pressure management and reduced air resistance.

Environmental Regulations Impact on Wankel Engine Development

Environmental regulations have significantly shaped the trajectory of Wankel engine development, particularly in the realm of emission testing and compliance. Since the 1970s, increasingly stringent emission standards worldwide have posed unique challenges for rotary engine technology. The Wankel's inherent combustion characteristics—including elongated combustion chambers and higher surface-to-volume ratios—create distinctive emission profiles that differ substantially from conventional piston engines.

The Clean Air Act Amendments of 1990 and subsequent regulatory frameworks established progressively tighter limits on hydrocarbon (HC), nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter emissions. These regulations have forced manufacturers like Mazda, the primary commercial producer of Wankel engines, to implement sophisticated emission control technologies. The company's RX-8 model represented a significant engineering achievement in balancing the Wankel's performance advantages with emission compliance through innovations such as side exhaust ports and improved apex seal designs.

European Euro 6 and U.S. EPA Tier 3 standards have further complicated Wankel engine viability in automotive applications. The rotary engine's traditionally higher fuel consumption and hydrocarbon emissions have required substantial engineering modifications, including advanced catalytic converter systems specifically calibrated for the unique exhaust gas composition of rotary engines. These systems must manage higher exhaust temperatures and different hydrocarbon species distributions compared to conventional engines.

The regulatory landscape has shifted development priorities toward addressing the Wankel's emission challenges through various technical approaches. These include improved thermal management systems, advanced fuel injection strategies, and modified rotor housing geometries. Notably, some manufacturers have explored hybrid Wankel configurations, where the rotary engine operates as a range extender under optimal conditions to minimize emission impacts while leveraging its compact size and smooth operation.

Testing protocols for Wankel engines have required adaptation of standard procedures to account for their unique operating characteristics. The World Harmonized Test Cycle (WLTC) and Real Driving Emissions (RDE) testing have introduced additional complexities, as rotary engines often exhibit different emission behaviors under varying load conditions compared to reciprocating engines. This has necessitated specialized testing equipment and methodologies specifically calibrated for rotary engine emission profiles.

Recent regulatory focus on carbon dioxide emissions and fleet-average fuel economy standards presents perhaps the most significant challenge to conventional Wankel technology. However, this has also spurred innovation in hydrogen-fueled rotary engines and electrified rotary concepts, which may offer pathways to regulatory compliance while preserving the fundamental advantages of rotary engine architecture.

The Clean Air Act Amendments of 1990 and subsequent regulatory frameworks established progressively tighter limits on hydrocarbon (HC), nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter emissions. These regulations have forced manufacturers like Mazda, the primary commercial producer of Wankel engines, to implement sophisticated emission control technologies. The company's RX-8 model represented a significant engineering achievement in balancing the Wankel's performance advantages with emission compliance through innovations such as side exhaust ports and improved apex seal designs.

European Euro 6 and U.S. EPA Tier 3 standards have further complicated Wankel engine viability in automotive applications. The rotary engine's traditionally higher fuel consumption and hydrocarbon emissions have required substantial engineering modifications, including advanced catalytic converter systems specifically calibrated for the unique exhaust gas composition of rotary engines. These systems must manage higher exhaust temperatures and different hydrocarbon species distributions compared to conventional engines.

The regulatory landscape has shifted development priorities toward addressing the Wankel's emission challenges through various technical approaches. These include improved thermal management systems, advanced fuel injection strategies, and modified rotor housing geometries. Notably, some manufacturers have explored hybrid Wankel configurations, where the rotary engine operates as a range extender under optimal conditions to minimize emission impacts while leveraging its compact size and smooth operation.

Testing protocols for Wankel engines have required adaptation of standard procedures to account for their unique operating characteristics. The World Harmonized Test Cycle (WLTC) and Real Driving Emissions (RDE) testing have introduced additional complexities, as rotary engines often exhibit different emission behaviors under varying load conditions compared to reciprocating engines. This has necessitated specialized testing equipment and methodologies specifically calibrated for rotary engine emission profiles.

Recent regulatory focus on carbon dioxide emissions and fleet-average fuel economy standards presents perhaps the most significant challenge to conventional Wankel technology. However, this has also spurred innovation in hydrogen-fueled rotary engines and electrified rotary concepts, which may offer pathways to regulatory compliance while preserving the fundamental advantages of rotary engine architecture.

Comparative Analysis of Wankel vs Conventional Engine Emissions

The Wankel rotary engine presents a unique case in emission testing due to its fundamentally different combustion process compared to conventional reciprocating engines. When analyzing emissions, the Wankel engine typically produces higher hydrocarbon (HC) emissions due to its elongated combustion chamber and larger quench areas, which can lead to incomplete combustion. This characteristic results in approximately 15-30% higher unburned hydrocarbon emissions compared to equivalent piston engines under similar operating conditions.

Carbon monoxide (CO) emissions from Wankel engines also tend to be elevated, particularly at lower operating temperatures and during cold starts. Testing data indicates CO emissions can be 10-25% higher than comparable conventional engines, primarily due to the engine's thermal characteristics and combustion chamber geometry that affects air-fuel mixing efficiency.

Nitrogen oxide (NOx) emissions present a contrasting scenario. The Wankel engine generally produces lower NOx emissions than conventional engines, approximately 20-40% less under standard test cycles. This reduction stems from lower peak combustion temperatures within the rotary chamber and shorter residence time of gases at high temperatures, which inhibits NOx formation.

Particulate matter (PM) emissions show significant differences as well. The Wankel engine typically generates fewer particulates due to the absence of lubricating oil in the combustion chamber walls, unlike conventional engines where oil can enter the combustion process from cylinder walls. Testing reveals PM emissions can be 30-50% lower in properly maintained rotary engines.

Fuel consumption metrics during emission testing reveal another critical difference. Wankel engines generally demonstrate 15-25% higher fuel consumption rates compared to equivalent displacement piston engines, which directly impacts CO2 emissions proportionally. This efficiency gap must be factored into comparative emission analyses.

Temperature profiles during testing cycles also differ substantially. Wankel engines reach operating temperature more quickly but maintain lower peak temperatures, affecting catalyst light-off times and overall emission control system performance. Testing protocols must account for these thermal characteristics to ensure accurate emission measurements.

Modern emission control technologies respond differently when applied to Wankel engines. Catalytic converters require specific formulations and placement strategies to address the higher exhaust temperatures and different emission composition. Testing has shown that specially designed three-way catalysts can reduce the emission gap between rotary and conventional engines by 60-70%, though complete parity remains challenging.

Carbon monoxide (CO) emissions from Wankel engines also tend to be elevated, particularly at lower operating temperatures and during cold starts. Testing data indicates CO emissions can be 10-25% higher than comparable conventional engines, primarily due to the engine's thermal characteristics and combustion chamber geometry that affects air-fuel mixing efficiency.

Nitrogen oxide (NOx) emissions present a contrasting scenario. The Wankel engine generally produces lower NOx emissions than conventional engines, approximately 20-40% less under standard test cycles. This reduction stems from lower peak combustion temperatures within the rotary chamber and shorter residence time of gases at high temperatures, which inhibits NOx formation.

Particulate matter (PM) emissions show significant differences as well. The Wankel engine typically generates fewer particulates due to the absence of lubricating oil in the combustion chamber walls, unlike conventional engines where oil can enter the combustion process from cylinder walls. Testing reveals PM emissions can be 30-50% lower in properly maintained rotary engines.

Fuel consumption metrics during emission testing reveal another critical difference. Wankel engines generally demonstrate 15-25% higher fuel consumption rates compared to equivalent displacement piston engines, which directly impacts CO2 emissions proportionally. This efficiency gap must be factored into comparative emission analyses.

Temperature profiles during testing cycles also differ substantially. Wankel engines reach operating temperature more quickly but maintain lower peak temperatures, affecting catalyst light-off times and overall emission control system performance. Testing protocols must account for these thermal characteristics to ensure accurate emission measurements.

Modern emission control technologies respond differently when applied to Wankel engines. Catalytic converters require specific formulations and placement strategies to address the higher exhaust temperatures and different emission composition. Testing has shown that specially designed three-way catalysts can reduce the emission gap between rotary and conventional engines by 60-70%, though complete parity remains challenging.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!